Progress in Liquid Atomization and Spray Systems

(Closed)

Share This Topical Collection

Editors

Dr. Miguel R. Oliveira Panão

Dr. Miguel R. Oliveira Panão

Dr. Miguel R. Oliveira Panão

Dr. Miguel R. Oliveira Panão

E-Mail

Website

Guest Editor

Department of Mechanical Engineering, Rua Luis Reis Santos, University of Coimbra, 3030-788 Coimbra, Portugal

Interests: thermal engineering systems; renewable energy technologies; thermal design and optimization; thermal management; thermal storage; energy capture technology; thermal engineering economics; laser diagnostics; heat and fluid multiphase flows; constructal theory; information theory in data analysis

Special Issues, Collections and Topics in MDPI journals

Dr. Ana Moita

Dr. Ana Moita

Dr. Ana Moita

Dr. Ana Moita

E-Mail

Website

Guest Editor

1. CINAMIL—Centro de Investigação Desenvolvimento e Inovação da Academia Militar, Academia Militar, Instituto Universitário Militar, Rua Gomes Freire, 1169-203 Lisboa, Portugal

2. IN+—Center for Innovation, Technology and Policy Research, Instituto Superior Técnico, Universidade de Lisboa, Avenida Rovisco Pais, 1049-001 Lisboa, Portugal

Interests: energy; solar pannels; cooling; nanofluids; microfluidics; biofluids

Special Issues, Collections and Topics in MDPI journals

Topical Collection Information

Dear Colleagues,

The science of liquid atomization depends on the fundamental knowledge of the hydrodynamic mechanisms underlying the generations of droplets and particles and their transport in the environment. These atomization strategies, applied to spray systems, are an essential element in several engineering applications.

The scope of this Topic Collection highlights the progress in liquid atomization and spray systems from the fundamental and applied points of view. The progress of new scientific insights in the formation mechanisms of the liquid breakup, and transport of liquid droplets and particles, allows advancing the knowledge of drop or particle dispersion and the design and optimization of spray systems.

There are numerous challenges that we face in this century where the knowledge of liquid atomization and spray systems plays an important role, such as:

- Aerosol dispersion (e.g., related to contaminated environments);

- Application of spray systems to sustainable energy technology and storage;

- Thermal management technologies;

- Agriculture;

- Medicine;

- Pharmaceutical applications;

- Painting and coating industries;

- And many others.

This Topic Collection will consider submissions on the following topics:

New developments

- In physical models of liquid atomization;

- And atomization strategies;

Advances

- In multiphase flow transport of droplets and particles;

- In statistical approaches to experimental spray characterization;

Innovative

- Experimental techniques in droplet and spray characterization;

- Applications in spray technology;

- Insights and applications of drop/spray–wall interactions;

- Research in the dynamic thermofluid behavior of sprays under extreme environments.

Prof. Dr. Miguel R. Oliveira Panão

Dr. Ana Sofia Moita

Collection Editors

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the collection website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Applied Sciences is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript.

The Article Processing Charge (APC) for publication in this open access journal is 2400 CHF (Swiss Francs).

Submitted papers should be well formatted and use good English. Authors may use MDPI's

English editing service prior to publication or during author revisions.

Published Papers (5 papers)

Open AccessArticle

Error Correction and Reanalysis of the Vibration Analysis of a Piezoelectric Ultrasonic Atomizer to Control Atomization Rate

by

Fan Zhang, Bo-Chuan Chen, Zhen-Zhen Gui, Jian-Hui Zhang, Xi Huang, Jia-Li Liang, Yao-Hua Zeng, Tian Tan, Tang Xie, Yu-Xin Wen and Jia-Long Wang

Cited by 1 | Viewed by 1044

Abstract

Dynamic mesh atomizers have been widely used in various fields because of their compact structure, low energy consumption, and low production costs. The finite element method is an important technique to analyze the factors affecting the atomization performance of dynamic mesh atomizers. However,

[...] Read more.

Dynamic mesh atomizers have been widely used in various fields because of their compact structure, low energy consumption, and low production costs. The finite element method is an important technique to analyze the factors affecting the atomization performance of dynamic mesh atomizers. However, at present, there is a lack of decisive solutions to the basic problems of boundary setting in terms of the simulation and vibration displacement characteristics of atomizers under different vibration modes. In this paper, two errors were found in the

Vibration Analysis of a Piezoelectric Ultrasonic Atomizer to Control Atomization Rate paper written by Esteban Guerra-Bravo et al. in 2021. First, in the finite element analysis, the boundary condition of the atomizing sheet was set to be fixed, which is inconsistent with the actual support situation and seriously affects the vibration of the atomizing sheet. Second, in the simulation result, from the first mode to the third mode, the growth rate of the maximum displacement at the center of the atomizing sheet was as high as 77.12%, even up to 221.05%, which is inconsistent with the existing vibration theory. In view of these errors, in this paper, the working principle of dynamic mesh atomizers is analyzed and the vibration equation of the atomizing sheet under peripheral simple support is derived. Through comparison with the literature, it was proven that the boundary setting and vibration displacement of the atomizing sheet in the original paper are unreasonable. By measuring the atomizing rate of the atomizing sheet under different boundary conditions, it was proven that the peripheral freedom of the atomizing sheet should be greater than or equal to 1, namely, peripheral freedom or peripheral simply supported. The vibration displacement theory was used for the simulation, and the relationship between the vibration displacement and resonant frequency of the atomizing sheet under peripheral simple support was measured. It was found that with the increase in the resonance frequency, the maximum displacement of vibration modes with only nodal circles was larger than that of the other vibration modes, and the maximum displacement increased slightly with the increase in the number of nodal circles by about 0.98%.

Full article

►▼

Show Figures

Open AccessArticle

Improvement of Mesh Atomizer Performance by Electrolytic Polishing

by

Jia-Li Liang, Fan Zhang, Jian-Hui Zhang, Wei-Qing Huang, Yu-Xin Wen and Bo-Chuan Chen

Cited by 1 | Viewed by 1449

Abstract

Piezoelectric atomization, which breaks liquid into tiny droplets, is widely used in aerospace, medicine, and health. Most research in piezoelectric atomizers has increased the atomization amount by improving mechanical structure and optimizing the vibration characteristics. However, as the core component of the atomizer

[...] Read more.

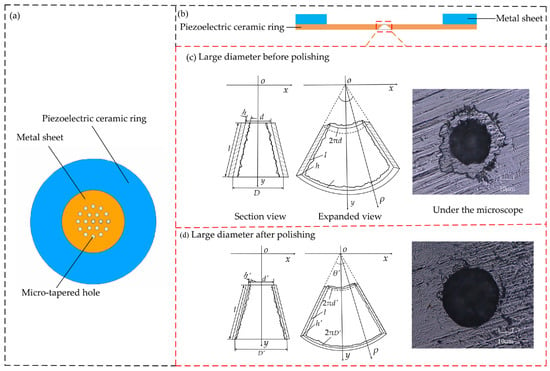

Piezoelectric atomization, which breaks liquid into tiny droplets, is widely used in aerospace, medicine, and health. Most research in piezoelectric atomizers has increased the atomization amount by improving mechanical structure and optimizing the vibration characteristics. However, as the core component of the atomizer is to realize atomization using the dynamic conical angle effect, the micro-tapered hole on the atomizing sheet has not been deeply studied. To eliminate the negative influence of the uneven burr caused by the hole machining process on the atomizing sheet, electrolytic polishing processing is proposed in this study to improve the quality of the micro-tapered holes. First, a theoretical model of the atomization amount and the conical angle is established. Second, the hole diameter and burr height are measured using a microscope, and the effectiveness of polishing on the burr removal of holes is verified. Lastly, the relationship between the conical angle and atomization amount is determined through an atomization amount experiment, which guides the revision of the theoretical model. The experimental results show that when the conical angle is 48,267° (the polishing time is 5 min), the atomization amount reaches a maximum of 5.202 mL/min, which is 3.93 times larger than that of the untreated one. This study demonstrates that polishing can effectively remove burr in the process of hole machining, which provides theoretical guidance for improving the quality of atomization sheets, and will further improve the atomization number of atomizers.

Full article

►▼

Show Figures

Open AccessArticle

Searching for a Numerical Model for Prediction of Pressure-Swirl Atomizer Internal Flow

by

Milan Maly, Jaroslav Slama, Ondrej Cejpek and Jan Jedelsky

Cited by 1 | Viewed by 1956

Abstract

Numerical prediction of discharge parameters allows design of a pressure-swirl atomizer in a fast and cheap manner, yet it must provide reliable results for a wide range of geometries and operating regimes. Many authors have used different numerical setups for similar cases and

[...] Read more.

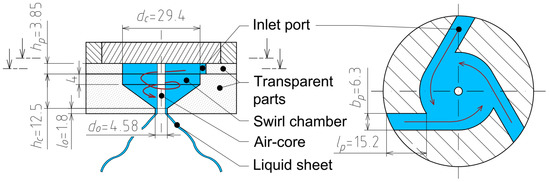

Numerical prediction of discharge parameters allows design of a pressure-swirl atomizer in a fast and cheap manner, yet it must provide reliable results for a wide range of geometries and operating regimes. Many authors have used different numerical setups for similar cases and often concluded opposite suggestions on numerical setup. This paper compares 2D (two-dimensional) axisymmetric, 3D (three-dimensional) periodic and full 3D numerical models used for estimation of the internal flow characteristics of a pressure-swirl atomizer. The computed results are compared with experimental data in terms of spray cone angle, discharge coefficient (

CD), internal air-core dimensions, and velocity profiles. The three-component velocity was experimentally measured using a Laser Doppler Anemometry in a scaled transparent model of the atomizer. The internal air-core was visualized by a high-speed camera with backlit illumination. Tested conditions covered a wide range of the Reynolds numbers within the inlet ports,

Re = 1000, 2000, 4000. The flow was treated as both steady and transient flow. The numerical solver used laminar and several turbulence models, represented by

k-ε and

k-ω models, Reynolds Stress model (RSM) and Large Eddy Simulation (LES). The laminar solver was capable of closely predicting the

CD, air-core dimensions and velocity profiles compared with the experimental results in both 2D and 3D simulations. The LES performed similarly to the laminar solver for low

Re and was slightly superior for

Re = 4000. The two-equation models were sensitive to proper solving of the near wall flow and were not accurate for low

Re. Surprisingly, the RSM produced the worst results.

Full article

►▼

Show Figures

Open AccessArticle

Mass Flow Scaling of Gas-Assisted Coaxial Atomizers

by

Simon Wachter, Tobias Jakobs and Thomas Kolb

Cited by 4 | Viewed by 1920

Abstract

This study aims to derive basic principles for liquid mass flow scaling of gas-assisted coaxial nozzles. Four liquid mass flow steps were investigated in the range of

= 20–500 kg·h

, applying four atomizers with similar

[...] Read more.

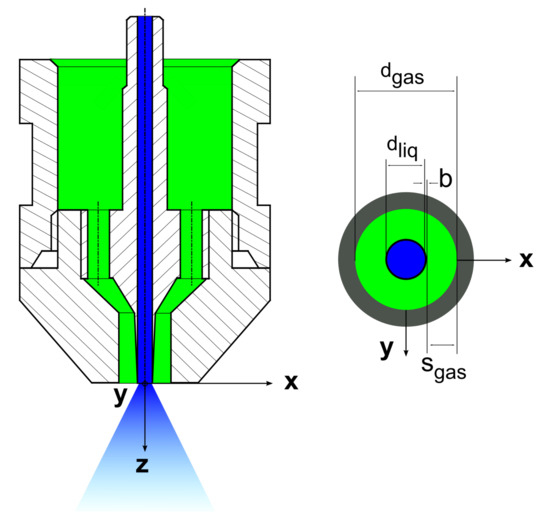

This study aims to derive basic principles for liquid mass flow scaling of gas-assisted coaxial nozzles. Four liquid mass flow steps were investigated in the range of

= 20–500 kg·h

, applying four atomizers with similar geometry designed at

const. High-speed camera and phase Doppler anemometer were utilized to detect the local droplet size distribution. To estimate a reliable measurement plane, a detection method and determination according to the free jet theory was used. The resulting droplet size was analyzed, applying the aerodynamic Weber number, as well as the gas momentum flow. An empirical model was derived out of the measured data, which allows for liquid mass flow scaling when process parameters such as

, liquid mass flow, and required Sauter mean diameter are specified. The model was developed as a first step towards liquid mass flow scaling of gas-assisted coaxial atomizers within the investigated range of operating conditions.

Full article

►▼

Show Figures

Open AccessReview

Advances in Piezoelectric Jet and Atomization Devices

by

Qiufeng Yan, Jiahan You, Wanting Sun, Ying Wang, Hongmei Wang and Lei Zhang

Cited by 8 | Viewed by 4506

Abstract

In recent years, the piezoelectric jet and atomization devices have exhibited tremendous advantages including their simple construction, and the fact that they are discreet and portable as well as low cost. They have been widely used in cell printing, spray cooling, drug delivery,

[...] Read more.

In recent years, the piezoelectric jet and atomization devices have exhibited tremendous advantages including their simple construction, and the fact that they are discreet and portable as well as low cost. They have been widely used in cell printing, spray cooling, drug delivery, and other industry fields. First, in this paper, two different concepts of jet and atomization are defined, respectively. Secondly, based on these two concepts, the piezoelectric jet and atomization devices can be divided into two different categories: piezoelectric micro jet device and piezoelectric atomization device. According to the organizational structure, piezoelectric micro jet devices can be classified into four different models: bend mode, push mode, squeeze mode, and shear mode. In addition, their development history and structural characteristics are summarized, respectively. According to the location of applied energy, there are two kinds of piezoelectric atomization devices, i.e., the static mesh atomization device and the vibration mesh atomization device, and both their advantages and drawbacks are discussed. The research achievements are summarized in three aspects of cell printing, spray cooling, and drug delivery. Finally, the future development trends of piezoelectric jet and atomization devices are prospected and forecasted.

Full article

►▼

Show Figures