Electromagnetic Processing of Metals

A special issue of Metals (ISSN 2075-4701).

Deadline for manuscript submissions: closed (31 January 2022) | Viewed by 8314

Special Issue Editor

Special Issue Information

Dear Colleagues,

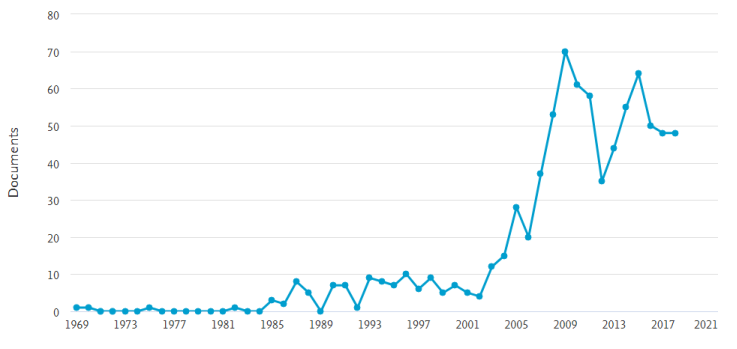

Electromagnetic Processing of Materials (EPM) is a relatively new branch of materials science and engineering, with more than 40 years of history, originally meant to exploit specific phenomena occurring when applying electric and magnetic fields to materials. Phenomenological approaches to EPM date back to the eraly 1920’s and 30’s, with the invention of electromagnetic levitation and electromagnetic mixing. EPM involves resistance heating, dielectric heating, induction heating, UV or IR heating and electric arc heating, but more recently also field assisted sintering techniques ( FAST), like Spark Plasma Sintering, or the use of energy beams have entered the scope of EPM. When it comes to metals, EPM is usually exploited making use of the Lorentz Force for shape controlling, fluid driving but also making use of the direct conversion of the enrgy associated with the elcrcomagnetic field into heat. Some specific fields, like microwave processing of metals and metal-containing ores are nowadays experiencing a renewed interesest, as shown in the following figure.

Source: Scopus, serach with keywords Microwaves AND Metallurgy, but results can be much larger

This Special Issue will cover fundamental studies of electric and magnetic field - metals interaction, as well as applications of EPM to metallurgy (extractive metallurgy, preliminary operations, melting, sintering, metal powders production, thermochemical treatments,...) and emerging fields, like processing of intermetallics, high entropy alloys, metallic glasses and metal nanoparticles. Papers addressing dedicated equipment for electroheat applied to metallurgy, safety and environmetnal aspects of electromagnetic processing of metals are welcome as well. This special issue will be an update on the latest developments of the field and emerging applications.

Assoc. Prof. Dr. Paolo Veronesi

Guest Editor

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the special issue website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Metals is an international peer-reviewed open access monthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2600 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- Electromagnetic processing

- Induction

- Microwave

- FAST

- Magnetic levitation

- Arc melting

- Laser processing

- Electron beam processing

- Resistance heating

- Metallurgy

- Ores

- Powder metallurgy

- Sintering

- Melting

- Synthesis

- Nanoparticles

- High entropy alloys

- Intermetallics

- Metallic glasses

- Heat treatment