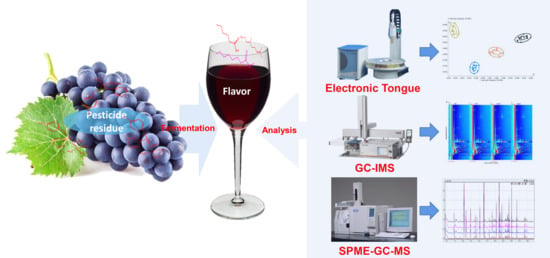

Influence of Triazole Pesticides on Wine Flavor and Quality Based on Multidimensional Analysis Technology

Abstract

:1. Introduction

2. Results and Discussion

2.1. Electronic Sensory Evaluation

2.1.1. Electronic Nose Analysis

2.1.2. Electronic Tongue Analysis

2.2. GC-IMS Analysis

2.2.1. Effects of the Different Triazole Pesticide Treatments on the VOCs in Wine

2.2.2. Comparison of the VOC Fingerprints in the Triazole-Pesticide-Treated and Control Wine Samples

2.3. Head-Space SPME-GC-MS Analysis

2.3.1. GC-MS Qualitative Analysis

2.3.2. GC-MS Quantitative Analysis

Alcohols

Esters

Diverse Volatile Compounds

2.4. Combined Sensory, GC-IMS, and SPME-GC-MS Analysis

3. Material and Methods

3.1. Materials and Reagents

3.2. Red Wine Processing

3.3. Electronic Nose Detection

3.4. Electronic Tongue Detection

3.5. GC-IMS Analysis of the Volatile Compounds

3.6. Head-Space SPME-GC-MS Analysis of the Volatile Compounds

3.7. Data Statistics

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Mortensen, E.L.; Jensen, H.H.; Sanders, S.A.; Reinisch, J.M. Better Psychological Functioning and Higher Social Status May Largely Explain the Apparent Health Benefits of Wine. Arch. Intern. Med. 2001, 161, 1844–1848. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- OIV. OIV FOCUS 2017 Distribution of the World’s Grapevine Varieties; International Organisation of Vine and Wine: Paris, France, 2017; p. 54. ISBN 979-10-91799-89-8. [Google Scholar]

- Flamini, R. Mass spectrometry in grape and wine chemistry. Part I: Polyphenols. Mass Spectrom. Rev. 2003, 22, 218–250. [Google Scholar] [CrossRef] [PubMed]

- Cabras, P.; Angioni, A. Pesticide Residues in Grapes, Wine, and Their Processing Products. J. Agric. Food Chem. 2000, 48, 967–973. [Google Scholar] [PubMed]

- Zhang, A.; Xie, X.; Liu, W. Enantioselective separation and phytotoxicity on Rice Seedlings of paclobutrazol. J. Agric. Food Chem. 2011, 59, 4300–4305. [Google Scholar] [CrossRef] [PubMed]

- Singh, N. Mobility of four triazole fungicides in two Indian soils. Pest Manag. Sci. 2005, 61, 191–196. [Google Scholar] [CrossRef] [PubMed]

- Lerat, S.; Simao-Beaunoir, A.-M.; Beaulieu, C. Genetic and physiological determinants of Streptomyces scabies pathogenicity. Mol. Plant Pathol. 2009, 10, 579–585. [Google Scholar] [CrossRef]

- Corrales, M.; Fernández, A.; Pinto, M.G.V.; Butz, P.; Franz, C.M.; Schuele, E.; Tauscher, B. Characterization of phenolic content, in vitro biological activity, and pesticide loads of extracts from white grape skins from organic and conventional cultivars. Food Chem. Toxicol. 2010, 48, 3471–3476. [Google Scholar] [CrossRef]

- FAO. FAO Plant Production and Protection. Paper, 502(574), 1 from the Report of the Joint Meeting of the FAO Panel of Experts on Pesticide Residues in Food and the Environment and the WHO Core Assessment Group on Pesticide Residues; Food and Agriculture Organization of the United Nations: Geneva, Switzerland, 2009. [Google Scholar]

- Lv, X.; Pan, L.; Wang, J.; Lu, L.; Yan, W.; Zhu, Y.; Xu, Y.; Guo, M.; Zhuang, S. Effects of triazole fungicides on androgenic disruption and CYP3A4 enzyme activity. Environ. Pollut. 2017, 222, 504–512. [Google Scholar] [CrossRef]

- Walia, S.; Saha, S.; Tripathi, V.; Sharma, K.K. Phytochemical biopesticides: Some recent developments. Phytochem. Rev. 2017, 16, 989–1007. [Google Scholar] [CrossRef]

- Bakırcı, G.T.; Acay, D.B.Y.; Bakırcı, F.; Otles, S. Pesticide residues in fruits and vegetables from the Aegean region, Turkey. Food Chem. 2014, 160, 379–392. [Google Scholar] [CrossRef]

- GB 2763-2019. National food safety standard-maximum residue limits for pesticides in food. In Standardization administration of the People’s Republic of China; Agriculture Press: Beijing, China, 2019. (In Chinese) [Google Scholar]

- Caboni, P.; Cabras, P. Chapter 2—Pesticides’ Influence on Wine Fermentation. In Advances in Food and Nutrition Research; Elsevier: Amsterdam, The Netherlands, 2010; Volume 59, pp. 43–62. [Google Scholar]

- Vitalini, S.; Ruggiero, A.; Rapparini, F.; Neri, L.; Tonni, M.; Iriti, M. The application of chitosan and benzothiadiazole in vineyard (Vitis vinifera L. cv Groppello Gentile) changes the aromatic profile and sensory attributes of wine. Food Chem. 2014, 162, 192–205. [Google Scholar] [CrossRef] [PubMed]

- González-Álvarez, M.; González-Barreiro, C.; Cancho-Grande, B.; Simal-Gándara, J. Impact of phytosanitary treatments with fungicides (cyazofamid, famoxadone, mandipropamid and valifenalate) on aroma compounds of Godello white wines. Food Chem. 2012, 131, 826–836. [Google Scholar] [CrossRef]

- Ruediger, G.A.; Pardon, K.H.; Sas, A.N.; Godden, P.W.; Pollnitz, A.P. Fate of Pesticides during the Winemaking Process in Relation to Malolactic Fermentation. J. Agric. Food Chem. 2005, 53, 3023–3026. [Google Scholar] [CrossRef] [PubMed]

- Parker, M.; Capone, D.L.; Francis, I.L.; Herderich, M. Aroma Precursors in Grapes and Wine: Flavor Release during Wine Production and Consumption. J. Agric. Food Chem. 2017, 66, 2281–2286. [Google Scholar] [CrossRef] [PubMed]

- Escuder-Gilabert, L.; Peris, M. Review: Highlights in recent applications of electronic tongues in food analysis. Anal. Chim. Acta 2010, 665, 15–25. [Google Scholar] [CrossRef] [PubMed]

- Valente, N.I.P.; Rudnitskaya, A.; Oliveira, J.; Gaspar, E.M.; Gomes, M.T.S. Cheeses Made from Raw and Pasteurized Cow’s Milk Analysed by an Electronic Nose and an Electronic Tongue. Sensors 2018, 18, 2415. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Botelho, G.; Mendes-Faia, A.; Clímaco, M.C. Differences in Odor-Active Compounds of Trincadeira Wines Obtained from Five Different Clones. J. Agric. Food Chem. 2008, 56, 7393–7398. [Google Scholar] [CrossRef]

- Li, H.; Jiang, D.; Liu, W.; Yang, Y.; Zhang, Y.; Jin, C.; Sun, S.Y. Comparison of fermentation behaviors and properties of raspberry wines by spontaneous and controlled alcoholic fermentations. Food Res. Int. 2020, 128, 108801. [Google Scholar] [CrossRef]

- Yin, Y.; Zhao, Y. A feature selection strategy of E-nose data based on PCA coupled with Wilks Λ-statistic for discrimination of vinegar samples. J. Food Meas. Charact. 2019, 13, 2406–2416. [Google Scholar] [CrossRef]

- Briz-Cid, N.; Castro-Sobrino, L.; Rial-Otero, R.; Cancho-Grande, B.; Simal-Gándara, J. Fungicide residues affect the sensory properties and flavonoid composition of red wine. J. Food Compos. Anal. 2018, 66, 185–192. [Google Scholar] [CrossRef]

- Cynkar, W.; Dambergs, R.; Smith, P.; Cozzolino, D. Classification of Tempranillo wines according to geographic origin: Combination of mass spectrometry based electronic nose and chemometrics. Anal. Chim. Acta 2010, 660, 227–231. [Google Scholar] [CrossRef] [PubMed]

- Peris, D.; Pérez-Torrado, R.; Hittinger, C.T.; Barrio, E.; Querol, A. On the origins and industrial applications of Saccharomyces cerevisiae × Saccharomyces kudriavzevii hybrids. Yeast 2018, 35, 51–69. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Langdon, Q.K.; Peris, D.; Baker, E.P.; Opulente, D.A.; Nguyen, H.-V.; Bond, U.; Gonçalves, P.; Sampaio, J.P.; Libkind, D.; Hittinger, C.T. Fermentation innovation through complex hybridization of wild and domesticated yeasts. Nat. Ecol. Evol. 2019, 3, 1576–1586. [Google Scholar] [CrossRef]

- Li, Y.; Jiang, J.H.; Chen, Z.P.; Xu, C.J.; Yu, R.Q. Robust linear discriminant analysis for chemical pattern recognition. J. Chemom. 1999, 13, 3–13. [Google Scholar] [CrossRef]

- Bhattacherjee, A.K.; Singh, V.K. Uptake of soil applied paclobutrazol in mango cv. Dashehari and its persistence in soil, leaves and fruits. Indian J. Plant Physiol. 2015, 20, 39–43. [Google Scholar] [CrossRef]

- Ahmed, W.; Tahir, F.M.; Rajwana, I.A.; Raza, S.A.; Asad, H.U. Comparative Evaluation of Plant Growth Regulators for Preventing Premature Fruit Drop and Improving Fruit Quality Parameters in ‘Dusehri’ Mango. Int. J. Fruit Sci. 2012, 12, 372–389. [Google Scholar] [CrossRef]

- Ferreira, V.; Ortín, N.; Escudero, A.; López, R.; Cacho, J. Chemical Characterization of the Aroma of Grenache Rosé Wines: Aroma Extract Dilution Analysis, Quantitative Determination, and Sensory Reconstitution Studies. J. Agric. Food Chem. 2002, 50, 4048–4054. [Google Scholar] [CrossRef]

- Torrens, J.; Urpí, P.; Riu-Aumatell, M.; Vichi, S.; López-Tamames, E.; Buxaderas, S. Different commercial yeast strains affecting the volatile and sensory profile of cava base wine. Int. J. Food Microbiol. 2008, 124, 48–57. [Google Scholar] [CrossRef]

- Ferreira, V.; Lopez, R. The Actual and Potential Aroma of Winemaking Grapes. Biomolecules 2019, 9, 818. [Google Scholar] [CrossRef] [Green Version]

- Lytra, G.; Tempère, S.; Marchand, S.; De Revel, G.; Barbe, J.-C. How do esters and dimethyl sulphide concentrations affect fruity aroma perception of red wine? Demonstration by dynamic sensory profile evaluation. Food Chem. 2016, 194, 196–200. [Google Scholar] [CrossRef]

- Segurel, M.A.; Razungles, A.J.; Riou, C.; Salles, M.; Baumes, R.L. Contribution of Dimethyl Sulfide to the Aroma of Syrah and Grenache Noir Wines and Estimation of Its Potential in Grapes of These Varieties. J. Agric. Food Chem. 2004, 52, 7084–7093. [Google Scholar] [CrossRef] [PubMed]

- Burdock, G.A. Fenaroli’s Handbook of Flavor Ingredients, 6th ed.; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Available online: http://www.flavornet.org/flavornet.html (accessed on 3 October 2020).

- Lesschaeve, I.; Langlois, D.; Etiévant, P. Volatile Compounds in Strawberry Jam: Influence of Cooking on Volatiles. J. Food Sci. 1991, 56, 1393–1398. [Google Scholar] [CrossRef]

- van Gemert, L.J. Odour Thresholds: Compilations of Odour Threshold Values in Air, Water and Other Media, 2nd ed.; Oliemans Punter & Co.: Zeist, The Netherlands, 2011. [Google Scholar]

- Rapp, A.; Mandery, H. Wine aroma. Cell. Mol. Life Sci. 1986, 42, 873–884. [Google Scholar] [CrossRef]

- Oliva, J.; Zalacain, A.; Payá, P.; Salinas, M.R.; Barba, A. Effect of the use of recent commercial fungicides [under good and critical agricultural practices] on the aroma composition of Monastrell red wines. Anal. Chim. Acta 2008, 617, 107–118. [Google Scholar] [CrossRef]

- Oliva, J.; Navarro, S.; Barba, A.; Navarro, G.; Salinas, M.R. Effect of pesticide residues on the aromatic composition of red wines. J. Agric. Food Chem. 1999, 47, 2830–2836. [Google Scholar] [CrossRef] [PubMed]

- Noguerol-Pato, R.; González-Rodríguez, R.; González-Barreiro, C.; Cancho-Grande, B.; Simal-Gándara, J. Influence of tebuconazole residues on the aroma composition of Mencía red wines. Food Chem. 2011, 124, 1525–1532. [Google Scholar] [CrossRef]

- Oliva, J.; Martínez-Gil, A.M.; Lorenzo, C.; Cámara, M.; Salinas, M.R.; Barba, A.; Garde-Cerdán, T. Influence of the use of fungicides on the volatile composition of Monastrell red wines obtained from inoculated fermentation. Food Chem. 2015, 170, 401–406. [Google Scholar] [CrossRef] [PubMed]

- Malcorps, P.; Cheval, J.M.; Jamil, S.; Dufour, J.P. A New Model for the Regulation of Ester Synthesis by Alcohol Acetyltransferase in Saccharomyces cerevisiae during Fermentation. J. Am. Soc. Brew. Chem. 1991, 49, 47–53. [Google Scholar] [CrossRef]

- Garcia, M.A.; Oliva, J.; Barba, A.; Cámara, M.Á.; Pardo, F.; Díaz-Plaza, E.M. Effect of Fungicide Residues on the Aromatic Composition of White Wine Inoculated with Three Saccharomyces cerevisiae Strains. J. Agric. Food Chem. 2004, 52, 1241–1247. [Google Scholar] [CrossRef] [PubMed]

- Perestrelo, R.M.D.S.; Fernandes, A.; Albuquerque, F.F.; Marques, J.C.; Câmara, J.S. Analytical characterization of the aroma of Tinta Negra Mole red wine: Identification of the main odorants compounds. Anal. Chim. Acta 2006, 563, 154–164. [Google Scholar] [CrossRef] [Green Version]

- Kong, Z.; Li, M.; An, J.; Chen, J.; Bao, Y.; Francis, F.; Dai, X. The fungicide triadimefon affects beer flavor and composition by influencing Saccharomyces cerevisiae metabolism. Sci. Rep. 2016, 6, 33552. [Google Scholar] [CrossRef] [PubMed]

- Munayyer, H.K.; Mann, P.A.; Chau, A.S.; Yarosh-Tomaine, T.; Greene, J.R.; Hare, R.S.; Heimark, L.; Palermo, R.E.; Loebenberg, D.; McNicholas, P.M. Posaconazole Is a Potent Inhibitor of Sterol 14α-Demethylation in Yeasts and Molds. Antimicrob. Agents Chemother. 2004, 48, 3690–3696. [Google Scholar] [CrossRef] [PubMed] [Green Version]

Sample Availability: Samples of the compound cyclohexanone are available from the authors. |

| Elution Order | Compound | Retention Index | Descriptor | Concentration (mg/L) | Odor Threshold (mg/L) | |||

|---|---|---|---|---|---|---|---|---|

| CK | SZT | WZC | DXZ | |||||

| 1 | Ethanol | 463 | Pungent, wine a | 33.13 | 27.66 | 22.2 | 27.59 | 100 d |

| 2 | Isobutanol | 597 | Disagreeable, wine a | 5.27 | 2.08 | -- | 4.17 | 40 d |

| 3 | Pentane | 518 | Alkane b | 2.48 | 2.41 | 7.09 | 2.33 | 4.1 d |

| 4 | Isoamyl acetate | 820 | Banana a | 6.05 | 3.39 | 2.39 | 1.22 | 0.2 d |

| 5 | Isoamyl alcohol | 697 | Fusel oil, pungent a | 72.82 | 80.02 | 73.73 | 60.65 | 30 d |

| 6 | Ethyl caproate | 984 | Fruit a | 20.46 | 20.24 | 20.55 | 26.95 | 0.08 d |

| 7 | Cyclohexanone * | 891 | Peppermint a | 20.0 | 20.0 | 20.0 | 20.0 | 20 |

| 8 | Ethyl heptanoate | 1083 | Pineapple b | -- | -- | 0.27 | 0.39 | 0.3 d |

| 9 | Ethyl lactate | 848 | Wine, cream a | -- | -- | 0.11 | 1.92 | 8 d |

| 10 | Hexyl formate | 981 | Apple, unripe plum b | 1.28 | 1.22 | 2.39 | 1.1 | 6.4 d |

| 11 | 1-Hexanol | 860 | Sweet, green fruity b | 2.77 | 2.89 | 1.23 | 2.34 | 8 d |

| 12 | Methyl octanoate | 1083 | Oranges, grapes a | 13.33 | 14.8 | 16.33 | 18.78 | 0.2 d |

| 13 | 1,3-Di-tert-butylbenzene | 1334 | Unknown | 0.33 | 0.27 | -- | -- | Unknown e |

| 14 | Ethyl caprylate | 1183 | Orange, oily a | 85.87 | 92.28 | 88.98 | 78.35 | 0.51 c |

| 15 | Acetic acid | 576 | Pungent, vinegar a | 2.7 | 1.99 | 2.53 | 0.56 | 22 d |

| 16 | Isopentyl hexanoate | 1218 | Banana, pineapple b | 0.82 | 0.94 | 1.43 | 0.96 | 0.9 d |

| 17 | Methyl nonanoate | 1183 | Wine, coconut a | 0.24 | 0.37 | -- | 0.18 | 0.04 d |

| 18 | Propyl caprylate | 1282 | Spice a | 0.47 | -- | 0.85 | 0.35 | Unknown e |

| 19 | Ethyl nonanoate | 1282 | Grape, rose, wine b | 5.24 | 8.29 | 2.31 | 2.84 | 0.377 d |

| 20 | (R,R)-2,3-Butanediol | 743 | Unknown | 1.3 | 1.36 | -- | 1.25 | Unknown e |

| 21 | Linalool | 1082 | Lily, citrus a | -- | -- | 0.46 | -- | 5 d |

| 22 | Isobutyl caprylate | 1317 | Unknown | 0.78 | 0.76 | 0.86 | 0.78 | Unknown e |

| 23 | 1-Octanol | 1059 | Orange, rose a | 1.36 | 1.91 | 1.8 | 1.33 | 0.13 d |

| 24 | 2,3-Butanediol | 743 | Spices b | 1.97 | 1.52 | 1.6 | 1.29 | 20 d |

| 25 | Methyl n-caprate | 1282 | Unknown | 10.83 | 9.7 | 11.13 | 8.44 | Unknown e |

| 26 | Ethyl caprate | 1381 | Coconut a | 55.15 | 53.01 | 49.81 | 39.4 | 2.4 c |

| 27 | Methyl cis-4-decenoate | 1290 | Unknown | 0.57 | -- | -- | 0.4 | Unknown e |

| 28 | Isoamyl caprylate | 1417 | Fruity b | 2.11 | -- | -- | 4.77 | 0.125 d |

| 29 | 3-Methylbutyl octanoate | 1417 | Fruity, brandy a | 6.73 | 7.6 | 7.7 | 6.3 | 0.125 d |

| 30 | 2-Methyl butyric acid | 811 | Cheese, fruit a | -- | -- | -- | 0.31 | 5.9 d |

| 31 | Diethyl succinate | 1151 | Faint, pleasant a | 0.37 | 0.28 | 3.09 | 0.44 | 200 d |

| 32 | 3-Methylthiopropanol | 912 | Onion, meat a | 0.33 | 0.28 | 0.37 | 0.26 | 4 d |

| 33 | Ethyl undecanoate | 1481 | Coconut a | 0.41 | 0.27 | -- | 0.08 | Unknown e |

| 34 | 2-Undecenal | 1311 | Fresh aldehyde a | 0.15 | -- | -- | -- | 0.001 d |

| 35 | 1-Decanol | 1258 | Flower, fatty a | 1.69 | 2 | 2.1 | 1.3 | 2.8 d |

| 36 | Citronellol | 1179 | Rose b | 1.26 | 1.8 | 1.43 | 0.7 | 0.1 d |

| 37 | Methyl salicylate | 1281 | Ilex leaf a | 0.96 | 1.59 | 1.12 | 1.45 | 0.071 d |

| 38 | Ethyl phenylacetate | 1259 | Rose a | -- | 1.03 | 1.16 | 0.96 | 0.65 c |

| 39 | Methyl laurate | 1481 | Fatty, floral a | 2.93 | 2.36 | 2.73 | 2.11 | Unknown e |

| 40 | Ethyl salicylate | 1380 | Wintergreen b | 0.54 | 0.6 | 0.52 | 0.47 | 0.115 d |

| 41 | Phenethyl acetate | 1259 | Sweet a | 4.17 | 3.25 | 1.41 | 0.87 | 1.8 d |

| 42 | Hexanoic acid | 974 | Stink, unpleasant a | -- | -- | -- | 2.28 | 0.42 d |

| 43 | Ethyl laurate | 1580 | Apricot a | 14.43 | 12.47 | 12.93 | 9.13 | 0.5 d |

| 44 | Isoamyl decanoate | 1615 | Unknown | 1.26 | 1.47 | 1.68 | 0.98 | 5 d |

| 45 | Phenylethyl alcohol | 1136 | Rose b | 14.7 | 13.98 | 16.36 | 17.31 | 7.5 c |

| 46 | 1-Dodecanol | 1457 | Fatty, waxy a | -- | -- | -- | 0.04 | 0.073 d |

| 47 | Methyl tetradecanoate | 1680 | Onion, honey, orris a | 0.16 | 0.12 | 0.26 | 0.3 | 0.5 d |

| 48 | Strawberry furanone | 1022 | Fruit, caramel a | 0.12 | 0.12 | 0.08 | -- | Unknown e |

| 49 | Ethyl myristate | 1779 | Essence b | 1.27 | 1.22 | 1.29 | 1.86 | 0.5 d |

| 50 | Octanoic acid | 1173 | Mildly unpleasant a | 11.39 | 11.82 | 12.25 | 12.62 | 10 d |

| 51 | Ethyl pentadecanoate | 1878 | Unknown | -- | -- | -- | 0.07 | Unknown e |

| 52 | Nonanoic acid | 1272 | Light fat, coconut a | -- | -- | -- | 0.08 | 3.0 d |

| 53 | Myristyl alcohol | 1656 | Essence a | -- | -- | 0.18 | -- | 5 d |

| 54 | Methyl hexadecanoate | 1878 | Unknown | 0.3 | 0.29 | 0.27 | 0.46 | 2 d |

| 55 | Methyl palmitoleate | 1886 | Unknown | 0.11 | -- | 0.19 | 0.06 | Unknown e |

| 56 | Ethyl palmitate | 1978 | Mild, sweet a | 1.5 | 1.94 | 2.04 | 2.16 | 2 d |

| 57 | n-Decanoic acid | 1372 | Unpleasant a | 2.88 | 2.63 | 3.45 | 2.5 | 1 d |

| 58 | Ethyl 9-hexadecenoate | 1986 | Unknown | 1.23 | 1.64 | 1.73 | 1.25 | Unknown e |

| 59 | 2,4-Di-tert-butylphenol | 1555 | Burning, sweet a | 1.45 | 2.45 | 1.82 | 1.37 | Unknown e |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, O.; Li, M.; Chen, J.; Li, R.; Quan, R.; Zhang, Z.; Kong, Z.; Dai, X. Influence of Triazole Pesticides on Wine Flavor and Quality Based on Multidimensional Analysis Technology. Molecules 2020, 25, 5596. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules25235596

Xiao O, Li M, Chen J, Li R, Quan R, Zhang Z, Kong Z, Dai X. Influence of Triazole Pesticides on Wine Flavor and Quality Based on Multidimensional Analysis Technology. Molecules. 2020; 25(23):5596. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules25235596

Chicago/Turabian StyleXiao, Ouli, Minmin Li, Jieyin Chen, Ruixing Li, Rui Quan, Zezhou Zhang, Zhiqiang Kong, and Xiaofeng Dai. 2020. "Influence of Triazole Pesticides on Wine Flavor and Quality Based on Multidimensional Analysis Technology" Molecules 25, no. 23: 5596. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules25235596