Propionic Anhydride Modification of Cellulosic Kenaf Fibre Enhancement with Bionanocarbon in Nanobiocomposites

Abstract

:1. Introduction

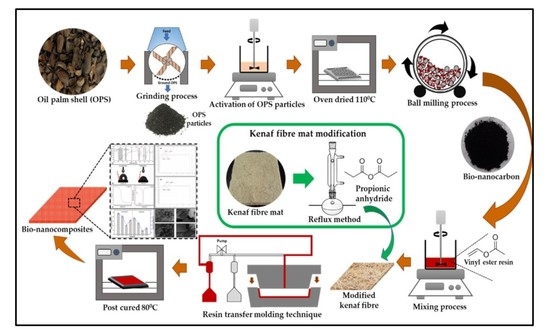

2. Materials and Method

2.1. Materials

2.2. Chemical Modification of Nonwoven Kenaf Fibre

2.3. Preparation of Bionanocarbon

2.4. Characterisation of Bio Nanocarbon and Kenaf Fibre

2.5. Preparation of Nanocomposites

2.6. Characterisation of Bio-Nanocomposites

3. Results and Discussion

3.1. Characterisation of Nonwoven Kenaf Fibre

3.1.1. Weight Percent Gain Properties

3.1.2. Morphological Analysis

3.1.3. Structural, Wettability, and Thermal Properties

3.2. Characterisation of Bio Nanocarbon

3.3. Characterisation of Nanocomposites

3.3.1. Physical Properties

3.3.2. Mechanical Properties

3.3.3. Morphological Analysis

3.3.4. Chemical Structural Analysis

3.3.5. Thermal Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Edeerozey, A.M.; Akil, H.M.; Azhar, A.; Ariffin, M.Z. Chemical modification of kenaf fibers. Mater. Lett. 2007, 61, 2023–2025. [Google Scholar] [CrossRef]

- Oyekanmi, A.; Saharudin, N.; Hazwan, C.M.; Abdul Khalil, H.P.S.; Olaiya, N.; Abdullah, C.; Alfatah, T.; Gopakumar, D.; Pasquini, D. Improved Hydrophobicity of Macroalgae Biopolymer Film Incorporated with Kenaf Derived CNF Using Silane Coupling Agent. Molecules 2021, 26, 2254. [Google Scholar] [CrossRef]

- Razak, N.I.A.; Ibrahim, N.A.; Zainuddin, N.; Rayung, M.; Saad, W.Z. The influence of chemical surface modification of kenaf fiber using hydrogen peroxide on the mechanical properties of biodegradable kenaf fiber/poly (lactic acid) composites. Molecules 2014, 19, 2957–2968. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Radzuan, N.; Tholibon, D.; Sulong, A.; Muhamad, N.; Haron, C.C. Effects of High-Temperature Exposure on the Mechanical Properties of Kenaf Composites. Polymers 2020, 12, 1643. [Google Scholar] [CrossRef]

- Kim, J.; Cho, D. Effects of Waste Expanded Polypropylene as Recycled Matrix on the Flexural, Impact, and Heat Deflection Temperature Properties of Kenaf Fiber/Polypropylene Composites. Polymers 2020, 12, 2578. [Google Scholar] [CrossRef]

- Ariawan, D.; Salim, M.S.; Taib, R.M.; Thirmizir, M.A.; Ishak, Z.M. Interfacial characterisation and mechanical properties of heat treated non-woven kenaf fibre and its reinforced composites. Compos. Interfaces 2018, 25, 187–203. [Google Scholar] [CrossRef]

- Azwa, Z.; Yousif, B.; Azwa, Z.; Yousif, B. Characteristics of kenaf fibre/epoxy composites subjected to thermal degradation. Polym. Degrad. Stab. 2013, 98, 2752–2759. [Google Scholar] [CrossRef]

- Bernard, M.; Khalina, A.; Ali, A.; Janius, R.; Faizal, M.; Hasnah, K.; Sanuddin, A. The effect of processing parameters on the mechanical properties of kenaf fibre plastic composite. Mater. Des. 2011, 32, 1039–1043. [Google Scholar] [CrossRef]

- Melelli, A.; Arnould, O.; Beaugrand, J.; Bourmaud, A. The Middle Lamella of Plant Fibers Used as Composite Reinforcement: Investigation by Atomic Force Microscopy. Molecules 2020, 25, 632. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Valadez-Gonzalez, A.; Cervantes-Uc, J.; Olayo, R.; Herrera-Franco, P. Effect of fiber surface treatment on the fiber–matrix bond strength of natural fiber reinforced composites. Compos. Part B Eng. 1999, 30, 309–320. [Google Scholar] [CrossRef]

- Khalil, H.A.; Suraya, N.L. Anhydride modification of cultivated kenaf bast fibers: Morphological, spectroscopic and thermal studies. BioResources 2011, 6, 1122–1135. [Google Scholar]

- Paturel, A.; Dhakal, H.N. Influence of Water Absorption on the Low Velocity Falling Weight Impact Damage Behaviour of Flax/Glass Reinforced Vinyl Ester Hybrid Composites. Molecules 2020, 25, 278. [Google Scholar] [CrossRef] [Green Version]

- Jiang, H.; Ma, C.; Li, M.; Cao, Z. Femtosecond Laser Drilling of Cylindrical Holes for Carbon Fiber-Reinforced Polymer (CFRP) Composites. Molecules 2021, 26, 2953. [Google Scholar] [CrossRef]

- Li, X.; Lei, B.; Lin, Z.; Huang, L.; Tan, S.; Cai, X. The utilization of bamboo charcoal enhances wood plastic composites with excellent mechanical and thermal properties. Mater. Des. 2014, 53, 419–424. [Google Scholar] [CrossRef]

- Abdullah, C.K.; Ismail, I.; Fazita, M.R.N.; Olaiya, N.G.; Nasution, H.; Oyekanmi, A.A.; Nuryawan, A.; Abdul Khalil, H.P.S. Properties and Interfacial Bonding Enhancement of Oil Palm Bio-Ash Nanoparticles Biocomposites. Polymers 2021, 13, 1615. [Google Scholar] [CrossRef] [PubMed]

- Swaminathan, P.D.; Uddin, N.; Wooley, P.; Asmatulu, R. Fabrication and Biological Analysis of Highly Porous PEEK Bionanocomposites Incorporated with Carbon and Hydroxyapatite Nanoparticles for Biological Applications. Molecules 2020, 25, 3572. [Google Scholar] [CrossRef] [PubMed]

- Ramos-Galicia, L.; López-Barroso, J.; Rodríguez-González, J.A.; Velasco-Santos, C.; Rubio-González, C.; Martínez-Hernández, A.L. Processing of Epoxy Composites Based on Carbon Nanomaterials. In Epoxy Composites: Fabrication, Characterization and Applications; Wiley: Toronto, ON, Canada, 2021; pp. 125–175. [Google Scholar]

- Zhou, Y.; Pervin, F.; Jeelani, S.; Mallick, P.K. Improvement in mechanical properties of carbon fabric–epoxy composite using carbon nanofibers. J. Mater. Process. Technol. 2008, 198, 445–453. [Google Scholar] [CrossRef]

- Çavdar, A.D.; Mengeloglu, F.; Karakus, K.; Tomak, E.D. Effect of chemical modification with maleic, propionic, and succinic anhydrides on some properties of wood flour filled HDPE composites. BioResources 2014, 9, 6490–6503. [Google Scholar] [CrossRef] [Green Version]

- Leszczyńska, A.; Radzik, P.; Szefer, E.; Mičušík, M.; Omastová, M.; Pielichowski, K. Surface modification of cellulose nanocrystals with succinic anhydride. Polymers 2019, 11, 866. [Google Scholar] [CrossRef] [Green Version]

- Chee, S.S.; Jawaid, M.; Sultan, M.; Alothman, O.Y.; Abdullah, L.C. Thermomechanical and dynamic mechanical properties of bamboo/woven kenaf mat reinforced epoxy hybrid composites. Compos. Part B Eng. 2019, 163, 165–174. [Google Scholar] [CrossRef]

- Aprilia, N.A.S.; Abdul Khalil, H.P.S.; Bhat, A.H.; Dungani, R.; Hossain, S. Exploring material properties of vinyl ester biocomposites filled carbonized jatropha seed shell. BioResources 2014, 9, 4888–4898. [Google Scholar] [CrossRef] [Green Version]

- Chandramohan, D.; Murali, B.; Vasantha-Srinivasan, P.; Kumar, S.D. Mechanical, moisture absorption, and abrasion resistance properties of bamboo–jute–glass fiber composites. J. Bio Tribo Corros. 2019, 5, 1–8. [Google Scholar] [CrossRef]

- King, J.A.; Klimek, D.R.; Miskioglu, I.; Odegard, G.M. Mechanical properties of graphene nanoplatelet/epoxy composites. J. Appl. Polym. Sci. 2013, 128, 4217–4223. [Google Scholar] [CrossRef]

- Singh, S.; Deepak, D.; Aggarwal, L.; Gupta, V. Tensile and flexural behavior of hemp fiber reinforced virgin-recycled HDPE matrix composites. Procedia Mater. Sci. 2014, 6, 1696–1702. [Google Scholar] [CrossRef] [Green Version]

- Ratanawilai, T.; Taneerat, K. Alternative polymeric matrices for wood-plastic composites: Effects on mechanical properties and resistance to natural weathering. Constr. Build. Mater. 2018, 172, 349–357. [Google Scholar] [CrossRef]

- Hill, C.A.S.; Abdul Khalil, H.P.S.; MHale, D. A study of the potential of acetylation to improve the properties of plant fibres. Ind. Crop. Prod. 1998, 8, 53–63. [Google Scholar] [CrossRef]

- Babatunde, O.E.; Yatim, J.M.; Ishak, M.Y.; Masoud, R.; Meisam, R. Potentials of kenaf fibre in bio-composite production: A review. J. Teknol. 2015, 77. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Zhang, L.-P.; Peng, F.; Bian, J.; Yuan, T.-Q.; Xu, F.; Sun, R.-C. Microwave-Assisted Solvent-Free Acetylation of Cellulose with Acetic Anhydride in the Presence of Iodine as a Catalyst. Molecules 2009, 14, 3551–3566. [Google Scholar] [CrossRef]

- Salim, M.; Ariawan, D.; Rasyid, M.A.; Thirmizir, M.A.; Taib, R.M.; Ishak, Z.M. Effect of fibre surface treatment on interfacial and mechanical properties of non-woven kenaf fibre reinforced acrylic based polyester composites. Polym. Compos. 2019, 40, E214–E226. [Google Scholar] [CrossRef]

- Atiqah, A.; Jawaid, M.; Ishak, M.R.; Sapuan, S.M. Effect of Alkali and Silane Treatments on Mechanical and Interfacial Bonding Strength of Sugar Palm Fibers with Thermoplastic Polyurethane. J. Nat. Fibers 2018, 15, 251–261. [Google Scholar] [CrossRef]

- Datta, J.; Kopczyńska, P. Effect of kenaf fibre modification on morphology and mechanical properties of thermoplastic polyurethane materials. Ind. Crop. Prod. 2015, 74, 566–576. [Google Scholar] [CrossRef]

- Sreekala, M.S.; Kumaran, M.G.; Joseph, S.; Jacob, M.; Thomas, S. Oil Palm Fibre Reinforced Phenol Formaldehyde Composites: Influence of Fibre Surface Modifications on the Mechanical Performance. Appl. Compos. Mater. 2000, 7, 295–329. [Google Scholar] [CrossRef]

- Sgriccia, N.; Hawley, M.C.; Misra, M. Characterization of natural fiber surfaces and natural fiber composites. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1632–1637. [Google Scholar] [CrossRef]

- Liu, W.; Mohanty, A.K.; Drzal, L.T.; Askel, P.; Misra, M. Effects of alkali treatment on the structure, morphology and thermal properties of native grass fibers as reinforcements for polymer matrix composites. J. Mater. Sci. 2004, 39, 1051–1054. [Google Scholar] [CrossRef]

- Ariawan, D.; Mohd Ishak, Z.A.; Salim, M.S.; Mat Taib, R.; Ahmad Thirmizir, M.Z. Wettability and interfacial characterization of alkaline treated kenaf fiber-unsaturated polyester composites fabricated by resin transfer molding. Polym. Compos. 2017, 38, 507–515. [Google Scholar] [CrossRef]

- Asim, M.; Jawaid, M.; Abdan, K.; Ishak, M.R. Effect of alkali and silane treatments on mechanical and fibre-matrix bond strength of kenaf and pineapple leaf fibres. J. Bionic Eng. 2016, 13, 426–435. [Google Scholar] [CrossRef]

- Faulstich de Paiva, J.M.; Frollini, E. Unmodified and Modified Surface Sisal Fibers as Reinforcement of Phenolic and Lignophenolic Matrices Composites: Thermal Analyses of Fibers and Composites. Macromol. Mater. Eng. 2006, 291, 405–417. [Google Scholar] [CrossRef]

- Abdul Khalil, H.P.S.; Suraya, N.L.; Atiqah, N.; Jawaid, M.; Hassan, A. Mechanical and thermal properties of chemical treated kenaf fibres reinforced polyester composites. J. Compos. Mater. 2012, 47, 3343–3350. [Google Scholar] [CrossRef]

- Saba, N.; Alothman, O.Y.; Almutairi, Z.; Jawaid, M. Magnesium hydroxide reinforced kenaf fibers/epoxy hybrid composites: Mechanical and thermomechanical properties. Constr. Build. Mater. 2019, 201, 138–148. [Google Scholar] [CrossRef]

- Araujo, J.; Waldman, W.; De Paoli, M.-A. Thermal properties of high density polyethylene composites with natural fibres: Coupling agent effect. Polym. Degrad. Stab. 2008, 93, 1770–1775. [Google Scholar] [CrossRef]

- Bandyopadhyay-Ghosh, S.; Ghosh, S.; Sain, M. The use of biobased nanofibres in composites. In Biofiber Reinforcements in Composite Materials; Elsevier: Amsterdam, The Netherlands, 2015; pp. 571–647. [Google Scholar]

- Khan, A.; Sherazi, T.A.; Khan, Y.; Li, S.; Naqvi, S.A.; Cui, Z. Fabrication and characterization of polysulfone/modified nanocarbon black composite antifouling ultrafiltration membranes. J. Membr. Sci. 2018, 554, 71–82. [Google Scholar] [CrossRef]

- Li, N.; Ma, X.; Zha, Q.; Kim, K.; Chen, Y.; Song, C. Maximizing the number of oxygen-containing functional groups on activated carbon by using ammonium persulfate and improving the temperature-programmed desorption characterization of carbon surface chemistry. Carbon 2011, 49, 5002–5013. [Google Scholar] [CrossRef]

- Ayyaru, S.; Ahn, Y.-H. Application of sulfonic acid group functionalized graphene oxide to improve hydrophilicity, permeability, and antifouling of PVDF nanocomposite ultrafiltration membranes. J. Membr. Sci. 2017, 525, 210–219. [Google Scholar] [CrossRef]

- Tian, H.; Yao, Y.; Liu, D.; Li, Y.; Jv, R.; Xiang, G.; Xiang, A. Enhanced Interfacial Adhesion and Properties of Polypropylene/Carbon Fiber Composites by Fiber Surface Oxidation in Presence of a Compatibilizer. Polym. Compos. 2019, 40, E654–E662. [Google Scholar] [CrossRef]

- Alamri, H.; Low, I. Effect of water absorption on the mechanical properties of nano-filler reinforced epoxy nanocomposites. Mater. Des. 2012, 42, 214–222. [Google Scholar] [CrossRef] [Green Version]

- Surya, I.; Chong, E.; Abdul Khalil, H.P.S.; Funmilayo, O.G.; Abdullah, C.; Aprilia, N.S.; Olaiya, N.; Lai, T.; Oyekanmi, A. Augmentation of physico-mechanical, thermal and biodegradability performances of bio-precipitated material reinforced in Eucheuma cottonii biopolymer films. J. Mater. Res. Technol. 2021, 12, 1673–1688. [Google Scholar] [CrossRef]

- Arumugam, C.; Arumugam, S.; Muthusamy, S. Mechanical, thermal and morphological properties of unsaturated polyester/chemically treated woven kenaf fiber/AgNPs@PVA hybrid nanobiocomposites for automotive applications. J. Mater. Res. Technol. 2020, 9, 15298–15312. [Google Scholar] [CrossRef]

- Abdul Majid, R.; Ismail, H.; Mat Taib, R. Processing, Tensile, and Thermal Studies of Poly(Vinyl Chloride)/Epoxidized Natural Rubber/Kenaf Core Powder Composites with Benzoyl Chloride Treatment. Polym. Plast. Technol. Eng. 2018, 57, 1507–1517. [Google Scholar] [CrossRef]

- Rao, J.K.; Raizada, A.; Ganguly, D.; Mankad, M.M.; Satyanarayana, S.V.; Madhu, G.M. Enhanced mechanical properties of polyvinyl alcohol composite films containing copper oxide nanoparticles as filler. Polym. Bull. 2015, 72, 2033–2047. [Google Scholar] [CrossRef]

- El-Shekeil, Y.A.; Sapuan, S.M.; Abdan, K.; Zainudin, E.S. Influence of fiber content on the mechanical and thermal properties of Kenaf fiber reinforced thermoplastic polyurethane composites. Mater. Des. 2012, 40, 299–303. [Google Scholar] [CrossRef]

| Mechanical Properties | VE/UK/NC0 | VE/UK/NC1 | VE/UK/NC3 | VE/UK/NC5 | VE/MK/NC0 | VE/MK/NC1 | VE/MK/NC3 | VE/MK/NC5 |

|---|---|---|---|---|---|---|---|---|

| Tensile strength (MPa) | 47.96 ± 1.08 | 54.79 ± 1.26 | 68.65 ± 0.79 | 62.75 ± 0.74 | 57.50 ± 1.04 | 65.36 ± 0.77 | 78.61 ± 1.02 | 73.09 ± 1.28 |

| Tensile modulus (GPa) | 1.75 ± 0.09 | 2.17 ± 0.08 | 2.65 ± 0.06 | 2.46 ± 0.04 | 2.24 ± 0.12 | 2.56 ± 0.08 | 2.87 ± 0.07 | 2.77 ± 0.06 |

| Elongation at break (%) | 7.23 ± 0.38 | 7.08 ± 0.24 | 5.62 ± 0.32 | 5.93 ± 0.14 | 6.36 ± 0.22 | 5.77 ± 0.13 | 5.38 ± 0.21 | 5.45 ± 0.18 |

| Tensile toughness (MPa) | 80.31 ± 1.95 | 83.75 ± 1.43 | 92.67 ± 0.61 | 88.18 ± 1.03 | 86.28 ± 1.05 | 90.63 ± 0.97 | 95.37 ± 1.59 | 93.72 ± 0.60 |

| Flexural strength (MPa) | 64.71 ± 1.12 | 68.04 ± 1.05 | 88.23 ± 1.31 | 81.60 ± 0.94 | 78.52 ± 1.52 | 84.74 ± 1.78 | 96.81 ± 1.27 | 91.10 ± 1.32 |

| Flexural modulus (GPa) | 4.68 ± 0.17 | 5.86 ± 0.09 | 7.53 ± 0.16 | 6.35 ± 0.08 | 6.26 ± 0.04 | 7.32 ± 0.13 | 8.38 ± 0.14 | 8.02 ± 0.16 |

| Flexural toughness (GPa) | 62.41 ± 1.50 | 64.71 ± 1.25 | 78.79 ± 0.81 | 72.05 ± 0.58 | 68.75 ± 1.22 | 74.78 ± 0.78 | 85.68 ± 0.93 | 81.07 ± 1.22 |

| Impact strength (kJ/m2) | 4.36 ± 0.19 | 4.73 ± 0.15 | 5.89 ± 0.08 | 5.46 ± 0.15 | 5.05 ± 0.15 | 5.46 ± 0.12 | 6.75 ± 0.18 | 6.27 ± 0.19 |

| Composites | Decomposition Temperature (°C) | Mass Loss (%) | ||||

|---|---|---|---|---|---|---|

| Tonset | Tmax. | 100 °C | 375 °C | 500 °C | 800 °C | |

| VE/UK/NC0 | 372.64 | 418.36 | 3.09 | 28.39 | 92.28 | 96.40 |

| VE/UK/NC1 | 374.20 | 420.18 | 3.75 | 28.15 | 90.98 | 94.98 |

| VE/UK/NC3 | 380.51 | 421.56 | 0.98 | 25.09 | 86.58 | 91.44 |

| VE/UK/NC5 | 376.78 | 420.74 | 1.81 | 27.56 | 88.25 | 93.09 |

| Average | 376.03 | 420.21 | 2.41 | 27.30 | 89.52 | 93.98 |

| Difference | 22 | 4 | 3 | 3 | ||

| VE/MK/NC0 | 392.95 | 425.94 | 2.45 | 23.99 | 88.38 | 92.85 |

| VE/MK/NC1 | 396.59 | 426.93 | 0.79 | 21.47 | 89.65 | 94.48 |

| VE/MK/NC3 | 408.74 | 428.89 | 0.68 | 20.23 | 81.99 | 86.96 |

| VE/MK/NC5 | 405.36 | 427.75 | 2.16 | 21.30 | 86.64 | 90.15 |

| Average | 400.91 | 427.38 | 1.52 | 21.75 | 86.67 | 91.11 |

| Difference | 38 | 9 | 2 | 2 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rizal, S.; Mistar, E.M.; Oyekanmi, A.A.; H.P.S., A.K.; Alfatah, T.; Olaiya, N.G.; Abdullah, C.K. Propionic Anhydride Modification of Cellulosic Kenaf Fibre Enhancement with Bionanocarbon in Nanobiocomposites. Molecules 2021, 26, 4248. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules26144248

Rizal S, Mistar EM, Oyekanmi AA, H.P.S. AK, Alfatah T, Olaiya NG, Abdullah CK. Propionic Anhydride Modification of Cellulosic Kenaf Fibre Enhancement with Bionanocarbon in Nanobiocomposites. Molecules. 2021; 26(14):4248. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules26144248

Chicago/Turabian StyleRizal, Samsul, E. M. Mistar, A. A. Oyekanmi, Abdul Khalil H.P.S., Tata Alfatah, N. G. Olaiya, and C. K. Abdullah. 2021. "Propionic Anhydride Modification of Cellulosic Kenaf Fibre Enhancement with Bionanocarbon in Nanobiocomposites" Molecules 26, no. 14: 4248. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules26144248