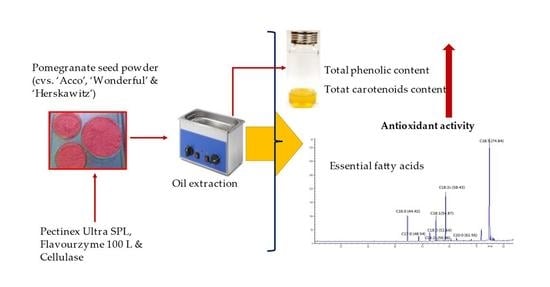

Effects of Enzymatic Pretreatment of Seeds on the Physicochemical Properties, Bioactive Compounds, and Antioxidant Activity of Pomegranate Seed Oil

Abstract

:1. Introduction

2. Results and Discussion

2.1. Oil Yield and Seed Microstructure Changes

2.2. Refractive and Yellowness Index

2.3. Peroxide Value, Conjugated Dienes, ρ-Anisidine Value, and Total Oxidation Value

2.4. Total Carotenoid Content, Total Phenolic Content, and Antioxidant Capacity

2.5. Phytosterols Composition

2.6. Fatty Acids Composition

2.7. Principal Component Analysis

3. Materials and Methods

3.1. Materials

3.2. Enzyme Pretreatment

3.3. Oil Extraction

3.4. Pomegranate Seeds Microstructure Analysis

3.5. Determination of PSO Quality Indices

3.5.1. Yellowness and Refractive Index

3.5.2. Peroxide Value, Conjugated Dienes, ρ-Anisidine Value, and Total Oxidation Value

3.6. Bioactive Compounds and Antioxidant Activity Determination

3.6.1. Total Carotenoids and Total Phenolic Content

3.6.2. Phytosterol Composition

3.7. Antioxidant Activity

3.7.1. Radical Scavenging Capacity

3.7.2. Ferric Reducing Antioxidant Power

3.8. Analysis of Fatty Acid Composition

3.9. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Khoddami, A.; Bin, Y.; Man, C.; Roberts, T.H. Physicochemical properties, and fatty acid profile of seed oil from pomegranate (Punica granatum L.) extracted by cold pressing. Eur. J. Lipid Sci. Tech. 2014, 116, 553–562. [Google Scholar] [CrossRef]

- Çavdar, H.K.; Yanik, D.K.; Gok, U.; Gogus, F. Optimisation of microwave-assisted extraction of pomegranate (Punica granatum L.) seed oil and evaluation of its physicochemical and bioactive properties. Food Technol. Biotechnol. 2017, 55, 86–94. [Google Scholar]

- Aruna, P.; Venkataramanamma, D.; Singh, A.K.; Singh, R.P. Health benefits of punicic acid: A review. Compr. Rev. Food Sci. Food Saf. 2016, 15, 16–27. [Google Scholar] [CrossRef]

- Aruna, P.; Manohar, B.; Singh, R.P. Processing of pomegranate seed waste and mass transfer studies of extraction of pomegranate seed oil. J. Food Process. Preserv. 2018, 42, 1–11. [Google Scholar] [CrossRef]

- Lansky, E.P.; Newman, R.A. Punica granatum (pomegranate) and its potential for prevention and treatment of inflammation and cancer. J. Ethnopharmacol. 2007, 109, 177–206. [Google Scholar] [CrossRef]

- Fawole, O.A.; Opara, U.L. Developmental changes in maturity indices of pomegranate fruit: A descriptive review. Sci. Hort. 2013, 159, 152–161. [Google Scholar] [CrossRef]

- Tian, Y.; Xu, Z.; Zheng, B.; Lo, Y.M. Ultrasonics Sonochemistry Optimization of ultrasonic-assisted extraction of pomegranate (Punica granatum L.) seed oil. Ultrason. Sonochem. 2013, 20, 202–208. [Google Scholar] [CrossRef]

- Fetzer, D.L.; Cruz, P.N.; Hamerski, F.; Corazza, M.L. Extraction of baru (Dipteryx alata vogel) seed oil using compressed solvents technology. Supercrit. Fluids 2018, 137, 23–33. [Google Scholar] [CrossRef]

- Al-Hamamre, Z.; Foerster, S.; Hartmann, F.; Kröger, M.; Kaltschmitt, M. Oil extracted from spent coffee grounds as a renewable source for fatty acid methyl ester manufacturing. Fuel. 2012, 96, 70–76. [Google Scholar] [CrossRef]

- Perrier, A.; Delsart, C.; Boussetta, N.; Grimi, N.; Citeau, M.; Vorobiev, E. Effect of ultrasound and green solvents addition on the oil extraction efficiency from rapeseed flakes. Ultrason. Sonochem. 2017, 39, 58–65. [Google Scholar] [CrossRef] [PubMed]

- Saxena, B.D.K.; Sharma, S.K.; Sambi, S.S. Kinetics and thermodynamics of cottonseed oil extraction. Grasas Aceites. 2011, 62, 198–205. [Google Scholar] [CrossRef]

- Citeau, M.; Slabi, S.A.; Joffre, F.; Carré, P. Improved rapeseed oil extraction yield and quality via cold separation of ethanol miscella. OCL 2018, 25, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.-J.; Gasmalla, M.A.A.; Li, P.; Yang, R. Enzyme-assisted extraction processing from oilseeds: Principle, processing, and application. Innov. Food Sci. Emerg. Technol. 2016, 35, 184–193. [Google Scholar] [CrossRef]

- Oberoi, H.S.; Babbar, N.; Dhaliwal, S.S.; Kaur, S.; Vadlani, P.V.; Bhargav, V.K.; Patil, R.T. Enhanced oil recovery by pre-treatment of mustard seeds using crude enzyme extract obtained from mixed-culture solid-state fermentation of kinnow (Citrus reticulata) waste and wheat bran. Food Bioprocess. Technol. 2012, 5, 759–767. [Google Scholar] [CrossRef]

- Passos, C.P.; Yilmaz, S.; Silva, C.M.; Coimbra, M.A. Enhancement of grape seed oil extraction using a cell wall degrading enzyme cocktail. Food Chem. 2009, 115, 48–53. [Google Scholar] [CrossRef]

- Latif, S.; Anwar, F. Physicochemical studies of hemp (Cannabis sativa) seed oil using enzyme-assisted cold-pressing. Eur. J. Lipid Sci. Tech. 2009, 111, 1042–1048. [Google Scholar] [CrossRef]

- Grasso, F.V.; Montoya, P.A.; Camusso, C.C.; Maroto, B.G. Enzymatic pretreatment. Int. J. Agron. 2012, 2012, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Perez, E.E.; Fernández, M.B.; Nolasco, S.H.; Crapistea, G.H. Effect of pectinase on the oil solvent extraction from different genotypes of sunflflower (Helianthus annuus L.). J. Food Eng. 2013, 117, 393–398. [Google Scholar] [CrossRef]

- Nikiforidis, C.V. Structure and function of oleosomes (oil bodies). Adv. Colloid Interface Sci. 2019, 274, 1–6. [Google Scholar] [CrossRef]

- Soto, C.; Chamy, R.; Zúñiga, M.E. Enzymatic hydrolysis and pressing conditions effect on borage oil extraction by cold pressing. Food Chem. 2008, 102, 834–840. [Google Scholar] [CrossRef]

- Sarkhosh, A.; Zamani, Z.; Fatahi, R.; Ranjbar, H. Evaluation of genetic diversity among Iranian soft-seed pomegranate accessions by fruit characteristics and RAPD markers. Sci. Hort. 2009, 12, 313–319. [Google Scholar] [CrossRef]

- Li, F.; Yang, L.; Zhao, T.; Zhao, J.; Zou, Y.; Zou, Y.; Wu, X. Optimization of enzymatic pretreatment for n-hexane extraction of oil from Silybum marianum seeds using response surface methodology. Food Bioproduct Process. 2012, 90, 87–94. [Google Scholar] [CrossRef]

- Szydłowska-Czerniaka, A.; Trokowskia, A.; Karlovitsb, G.; Szłyka, E. Effect of refifining processes on antioxidant capacity, total contents of phenolics and carotenoids in palm oils. Food Chem. 2011, 129, 1187–1192. [Google Scholar] [CrossRef]

- Costa, A.M.M.; Silva, L.O.; Torres, A.G. Chemical composition of commercial cold-pressed pomegranate (Punica granatum) seed oil from Turkey and Israel, and the use of bioactive compounds for samples’ origin preliminary discrimination. J. Food Compos. Anal. 2019, 75, 8–16. [Google Scholar] [CrossRef]

- Baydar, G.N.; Özkan, G.; Çetin, E.S. Characterization of grape seed and pomace oil extracts. Fats Oils. 2007, 58, 29–33. [Google Scholar]

- Galvao, M.; Narain, N.; Nigam, N. Influence of different cultivars on oil quality and chemical characteristics of avocado fruit. Food Sci. Technol. 2014, 34, 539–546. [Google Scholar] [CrossRef] [Green Version]

- Pathare, P.B.; Opara, U.L.; Al-said, F.A. Colour measurement and analysis in fresh and processed foods: A review. Food Bioprocess. Technol. 2013, 6, 36–60. [Google Scholar] [CrossRef]

- Charoenprasert, S.; Mitchell, A. Factors inflfluencing phenolic compounds in table olives (Olea europaea). J. Agric. Food Chem. 2012, 60, 7081–7095. [Google Scholar] [CrossRef] [PubMed]

- Kha, T.C.; Nguyen, M.H.; Roach, P.D.; Stathopoulous, C.E. Effect of galic aril microwave processing conditions on oil extraction efficiency and β-carotene and lycopene content. J. Food Eng. 2013, 117, 486–491. [Google Scholar] [CrossRef]

- Codex Alimentarius. Standard for Named Vegetable Oils- Codex Stan 210-1999; Codex Alimentarius: Rome, Italy, 1999. [Google Scholar]

- Basiri, S. Evaluation of antioxidant and antiradical properties of pomegranate (Punica granatum L.) seed and defatted seed extracts. J. Food Sci. Technol. 2015, 52, 1117–1123. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Choe, E.; Min, D.B. Mechanisms and factors for edible oil oxidation. Compr. Rev. Food Sci. Food Saf. 2006, 5, 169–186. [Google Scholar] [CrossRef]

- Fathi-Achachlouei, B.; Azadmard-damirchi, S.; Zahedi, Y.; Shaddel, R. Microwave pretreatment as a promising strategy for increment of nutraceutical content and extraction yield of oil from milk thistle seed. Ind. Crop. Prod. 2019, 128, 527–533. [Google Scholar] [CrossRef]

- Koroleva, O.; Torkova, A.; Nikolaev, I.; Khrameeva, E.; Fedorova, T.; Tsentalovich, M.; Amarowicz, R. Evaluation of the antiradical properties of phenolic acids. Int. J. Mol. Sci. 2014, 15, 16351–16380. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nimse, S.B.; Pal, D. Free radicals, natural antioxidants, and theirreaction mechanisms. Rsc Adv. 2015, 5, 7986–28006. [Google Scholar] [CrossRef] [Green Version]

- Young, A.J.; Lowe, G.M. Antioxidant and prooxidant properties of carotenoids. Arch. Biochem. Biophys. 2001, 385, 20–27. [Google Scholar] [CrossRef] [PubMed]

- Szabo, K.; Dulf, F.V.; Teleky, B.-E.; Eleni, P.; Boukouvalas, C.; Krokida, M.; Kapsalis, N.; Rusu, A.V.; Socol, C.T.; Vodnar, D.C. Evaluation of the bioactive compounds found in tomato seed oil and tomato peels influenced by industrial heat treatments. Foods 2021, 10, 110. [Google Scholar] [CrossRef] [PubMed]

- Gornas, P.; Rudzinska, M.; Raczyk, M.; Mišina, I.; Soliven, A.; Segliņa, D. Composition of bioactive compounds in kernel oils recovered from sour cherry (Prunus cerasus L.) by-products: Impact of the cultivar on potential applications. Ind. Crop. Prod. 2015, 82, 44–50. [Google Scholar] [CrossRef]

- De Santana, F.C.; Shinagawa, F.B.; da Silva Araujo, E.; Costa, A.M.; Mancini-Filho, J. Chemical composition and antioxidant capacity of brazilian passiflora seed oil. J. Food Sci. 2015, 80, C2647–C2654. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; He, C.; Zhu, R.; Shen, R.; Yu, Y.; Peng, Q.; Gao, J.; Li, Y.; Wang, M. Seed oil of five black tartary buckwheat cultivars with biochemical characterization and antioxidant properties. J. Am. Oil Chem. Soc. 2016, 93, 1127–1136. [Google Scholar] [CrossRef]

- Lin, D.; Xiao, M.; Zhao, J.; Li, Z.; Xing, B.; Li, X.; Kong, M.; Li, L.; Zhang, Q.; Liu, Y. An overview of plant phenolic compounds and their importance in human nutrition and management of type 2 diabetes. Molecules 2016, 21, 1374. [Google Scholar] [CrossRef]

- Kumar, N.; Goel, N. Phenolic acids: Natural versatile molecules with promising therapeutic applications. Biotechnol. Rep. 2019, 24, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Jing, P.; Ye, T.; Shi, H.; Sheng, Y.; Slavin, M.; Gao, B.; Liu, L.; Lucy, L. Antioxidant properties and phytochemical composition of China-grown pomegranate seed. Food Chem. 2012, 132, 1457–1464. [Google Scholar] [CrossRef]

- Xi, W.; Lu, J.; Qun, J.; Jiao, B. Characterization of phenolic profile and antioxidant capacity of different fruit part from lemon (Citrus limon Burm.) cultivars. J. Food Sci. Technol. 2017, 54, 1108–1118. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Abbasi, H.; Rezaei, K.; Rashidi, L. Extraction of essential oils from the seeds of pomegranate using organic solvents and supercritical CO2. J. Am. Oil Chem. Soc. 2008, 85, 83–89. [Google Scholar] [CrossRef]

- Ramadan, M.F.; Sitohy, M.Z.; Moersel, J. Solvent and enzyme-aided aqueous extraction of goldenberry (Physalis peruviana L.) pomace oil: Impact of processing on composition and quality of oil and meal. Eur. Food Res. Technol. 2008, 226, 1445–1458. [Google Scholar] [CrossRef]

- Pande, G.; Akoh, C.C. Antioxidant capacity and lipid characterization of six Georgia-grown pomegranate cultivars. J. Agric. Food Chem. 2009, 57, 9427–9436. [Google Scholar] [CrossRef]

- Wen, X.; Zhu, M.; Hu, R.; Zhao, J.; Chen, Z.; Li, J.; Ni, Y. Characterisation of seed oil from different grape cultivars grown in China. J. Food Sci. Technol. 2016, 53, 3129–3136. [Google Scholar] [CrossRef] [PubMed]

- Caligiani, A.; Bonzanini, F.; Palla, G.; Cirlini, M.; Bruni, R. Characterization of a potential nutraceutical ingredient: Pomegranate (Punica granatum L.) seed oil unsaponifiable fraction. Plant Foods Hum. Nutr. 2010, 65, 277–283. [Google Scholar] [CrossRef]

- Verardo, V.; Garcia-salas, P.; Baldi, E.; Segura-carretero, A.; Fernandez-gutierrez, A.; Fiorenza, M. Pomegranate seed as a source of nutraceutical oil naturally rich in bioactive lipids. Food Res. Int. 2014, 65, 445–452. [Google Scholar] [CrossRef]

- Fernandes, L.; Pereira, J.A.; Lopez-Cortes, I.; Salazar, D.M.; Ramalhosa, E.; Casal, S. Lipid composition of seed oil of different pomegranate (Punica granatum L.) cultivars from Spain. J. Food Compos. Anal. 2015, 39, 13–22. [Google Scholar] [CrossRef]

- He, W.S.; Zhu, H.; Chen, Z.H. Plant Sterols: Chemical and enzymatic structural modifications and effects on their cholesterol-lowering activity. J. Agric. Food Chem. 2018, 66, 3047–3062. [Google Scholar] [CrossRef]

- Teng, H.; Chen, L.; Huang, Q.; Wang, J.; Lin, Q.; Liu, M.; Lee, W.Y.; Song, H. Ultrasonic-assisted extraction of raspberry seed oil and evaluation of its physicochemical properties, fatty acid compositions and antioxidant activities. PLOS ONE 2016, 11, e0153457. [Google Scholar] [CrossRef] [PubMed]

- Concha, J.; Soto, C.; Chamy, R.; Zúñiga, E. Enzymatic pretreatment on rose-hip oil extraction: Hydrolysis and pressing conditions. J. Am. Oil Chem. Soc. 2004, 81, 549–552. [Google Scholar] [CrossRef]

- Wang, X.; Liang, X.; Zhao, L.; Huang, B.B. Cultivar characterization of tea seed oil by their active components and antioxidant capacity. J. Am. Oil Chem. Soc. 2014, 91, 629–639. [Google Scholar] [CrossRef]

- Wang, H.; Hu, Z.; Wang, Y.; Chen, H.; Huang, X. Phenolic compounds, and the antioxidant activities in litchi pericarp: Difference among cultivars. Sci. Hort. 2011, 129, 784–789. [Google Scholar] [CrossRef]

- Gornas, P.; Rudzinska, M.; Segliņa, D. Lipophilic composition of eleven apple seed oil: A promising source of unconventional oil from industry by-products. Ind. Crop. Prod. 2014, 60, 86–91. [Google Scholar] [CrossRef]

- Goula, A.M.; Papatheodorou, A.; Karasavva, S.; Kaderides, K. Ultrasound-assisted aqueous enzymatic extraction of oil frompomegranate seed. Waste Biomass Valorization 2018, 9, 1–11. [Google Scholar] [CrossRef]

- Kaseke, T.; Opara, U.L.; Fawole, O.A. Effect of blanching pomegranate seed on physicochemical attributes, bioactive compounds, and antioxidant activity of extracted oil. Molecules 2020, 25, 2554. [Google Scholar] [CrossRef] [PubMed]

- Cruz, R.M.S.; Khmelinski, I.; Vieira, M.C. Methods in Food Analysis, 1st ed.; Taylor and Francis Group: New York, NY, USA, 2016. [Google Scholar]

- ISO. Animal and Vegetable Fats and Oils. In ISO 3656 Determination of Ultraviolet Absorbance Expressed as Specific UV Extinction; International Organisation for Standardisation, 2011; pp. 1–8. Available online: https://www.iso.org/standard/51008 (accessed on 27 May 2020).

- AOCS. Official Methods and Recommended Practices of the American Oil Chemists’ Society; Firestone, D., Ed.; AOCS Press: Champaign, IL, USA, 2003. [Google Scholar]

- Ranjith, A.; Kumar, K.S.; Venugopalan, V.V.; Arumughan, C.; Sawhney, R.C.; Singh, V. Fatty acids, tocols, and carotenoids in pulp oil of three sea buckthorn species (Hippophae rhamnoides, H. salicifolia, and H. tibetana) grown in the Indian Himalayas. J. Am. Oil Chem. Soc. 2006, 83, 359–364. [Google Scholar] [CrossRef]

- Siano, F.; Straccia, M.C.; Paolucci, M.; Fasulo, G.; Boscaino, F.; Volpe, M.G. Physico-chemical properties and fatty acid composition of pomegranate, cherry, and pumpkin seed oil. J. Sci. Food Agric. 2015, 96, 1730–1735. [Google Scholar] [CrossRef]

- Benzie, I.F.F.; Strain, J.J. The ferric reducing ability of plasma (FRAP) as a measure of antioxidant power: The FRAP Assay. Anal. Biochem. 1996, 239, 70–76. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mphahlele, R.R.; Fawole, O.A.; Makunga, N.P.; Linus Opara, U.L. Functional properties of pomegranate fruit parts: Influence of packaging systems and storage time. J. Food Meas. Charact. 2017, 11, 2233–2246. [Google Scholar] [CrossRef]

| Cultivar/Treatment | ||||||

|---|---|---|---|---|---|---|

| Parameter | Wonderful | Herskawitz | Acco | |||

| Un-Pretreated | Enzyme Pretreated | Un-Pretreated | Enzyme Pretreated | Un-Pretreated | Enzyme Pretreated | |

| RI | 1.5177 ± 0.0000 a | 1.5177 ± 0.0001 a | 1.5177 ± 0.0000 a | 1.5175 ± 0.0000 a | 1.5176 ± 0.0000 a | 1.5177 ± 0.0001 a |

| K232 | 0.29 ± 0.02 b | 0.28 ± 0.03 b | 0.24 ± 0.02 ab | 0.20 ± 0.02 a | 0.22 ± 0.01 ab | 0.17 ± 0.04 a |

| PV | 0.04 ± 0.01 e | 0.08 ± 0.02 d | 0.09 ± 0.01 d | 0.12 ± 0.01 cd | 0.22 ± 0.02 b | 0.33 ± 0.04 a |

| AV | 1.6 ± 0.2 a | 1.1 ± 0.0 cb | 1.4 ± 0.2 ac | 0.9 ± 0.0 c | 1.3 ± 0.1 ac | 1.0 ± 0.12 bc |

| TOTOX | 1.7 ± 0.2 a | 1.2 ± 0.1 ac | 1.5 ± 0.2 ac | 1.1 ± 0.0 bc | 1.8 ± 0.1 a | 1.7 ± 0.2 ab |

| Cultivar/Treatment | ||||||

|---|---|---|---|---|---|---|

| Phytosterol | Wonderful | Herskawitz | Acco | |||

| Untreated | Enzyme Treated | Untreated | Enzyme Treated | Untreated | Enzyme Treated | |

| Stigmasterol | 26.0 ± 0.2 bc | 35.4 ± 4.9 b | 45.8 ± 1.5 a | 52.0 ± 5.4 a | 20.5 ± 3.1 c | 29.8 ± 1.5 bc |

| β-Sitosterol | 679 ± 31 b | 640 ± 168 b | 868 ± 24 a | 994 ± 234 a | 991 ± 64 a | 863 ± 67 a |

| Cultivar/Treatment | ||||||

|---|---|---|---|---|---|---|

| Fatty Acid | Wonderful | Herskawitz | Acco | |||

| Un-Pretreated | Enzyme Pretreated | Un-Pretreated | Enzyme Pretreated | Un-Pretreated | Enzyme Pretreated | |

| Palmitic acid | 5.7 ± 0.3c | 8.9 ± 0.2 a | 7.0 ± 0.2 bc | 7.3 ± 0.5 b | 7.8 ± 0.3 ab | 7.8 ± 0.2 ab |

| Stearic acid | 2.9 ± 0.1c | 2.9 ± 0.2 a | 2.3 ± 0.0 bc | 2.4 ± 0.1 b | 2.9 ± 0.0 ab | 2.8 ± 0.0 ab |

| Oleic acid | 7.9 ± 0.8c | 9.1 ± 0.1 a | 7.6 ± 0.1 bc | 7.7 ± 0.3 b | 9.3 ± 0.1 ab | 9.4 ± 0.1 ab |

| Linoleic acid | 18.3 ± 1.7 c | 20.1 ± 0.2 a | 15.2 ± 0.7 bc | 15.6 ± 1.4 b | 12.8 ± 0.6 ab | 14.3 ± 0.4 ab |

| Punicic acid | 59.1 ± 2.7 c | 57.2 ± 0.4 a | 67.2 ± 1.0 bc | 65.6 ± 2.5 b | 66.3 ± 1.0 ab | 64.9 ± 0.7 ab |

| Linolenic acid | 0.07 ± 0.01 c | 0.08 ± 0.01 a | 0.06 ± 0.00 bc | 0.06 ± 0.01 b | 0.06 ± 0.00 ab | 0.06 ± 0.01 ab |

| Arachidic acid | 0.85 ± 0.04 c | 0.90 ± 0.04 a | 0.68 ± 0.01 bc | 0.70 ± 0.04 b | 0.81 ± 0.03 ab | 0.83 ± 0.02 ab |

| SFA | 9.5 ± 0.4 c | 12.6 ± 0.2 a | 10.0 ± 0.2 bc | 10.5 ± 0.7 b | 11.5 ± 0.3 ab | 11.4 ± 0.3 ab |

| MUFA | 7.9 ± 0.8 c | 9.1 ± 0.1 a | 7.6 ± 0.1 bc | 7.7 ± 0.3 b | 9.3 ± 0.1 ab | 9.4 ± 0.1 ab |

| PUFA | 77.5 ± 1.1 c | 77.3 ± 0.4 a | 82.5 ± 0.4 bc | 81.3 ± 1.2 b | 79.2 ± 0.4 ab | 79.2 ± 0.4 ab |

| UFA:SFA ratio | 9.1 ± 0.4 c | 6.9 ± 0.1 a | 9.0 ± 0.2 b | 8.6 ± 0.5 b | 7.7 ± 0.2 b | 7.8 ± 0.2 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaseke, T.; Opara, U.L.; Fawole, O.A. Effects of Enzymatic Pretreatment of Seeds on the Physicochemical Properties, Bioactive Compounds, and Antioxidant Activity of Pomegranate Seed Oil. Molecules 2021, 26, 4575. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules26154575

Kaseke T, Opara UL, Fawole OA. Effects of Enzymatic Pretreatment of Seeds on the Physicochemical Properties, Bioactive Compounds, and Antioxidant Activity of Pomegranate Seed Oil. Molecules. 2021; 26(15):4575. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules26154575

Chicago/Turabian StyleKaseke, Tafadzwa, Umezuruike Linus Opara, and Olaniyi Amos Fawole. 2021. "Effects of Enzymatic Pretreatment of Seeds on the Physicochemical Properties, Bioactive Compounds, and Antioxidant Activity of Pomegranate Seed Oil" Molecules 26, no. 15: 4575. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules26154575