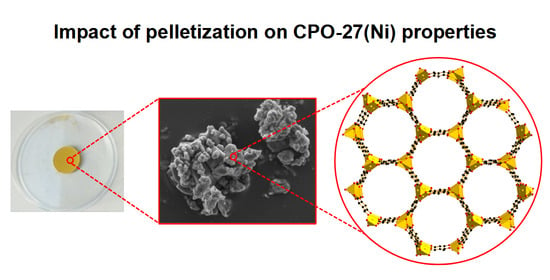

Impact of Compression on the Textural and Structural Properties of CPO-27(Ni)

Abstract

:1. Introduction

2. Results and Discussions

2.1. Starting Material Characterization

2.2. Pelletization

2.3. Nitrogen Sorption Analyses

2.4. Thermogravimetric Analyses

2.5. Powder X-ray Diffraction Analyses

2.6. Scanning Electron Microscopy

3. Materials and Methods

3.1. Materials

3.1.1. Raw Materials

3.1.2. Synthesis of CPO-27(Ni) Powder

3.1.3. Pelletization

3.2. Characterization Techniques

3.2.1. Nitrogen Sorption Measurements at −196.15 °C

3.2.2. Powder X-ray Diffraction (PXRD)

3.2.3. Thermogravimetric Analyses

3.2.4. Scanning Electron Microscopy

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Wang, Q.; Astruc, D. State of the Art and Prospects in Metal-Organic Framework (MOF)-Based and MOF-Derived Nanocatalysis. Chem. Rev. 2020, 120, 1438–1511. [Google Scholar] [CrossRef] [PubMed]

- Chaplais, G.; Fraux, G.; Paillaud, J.-L.; Marichal, C.; Nouali, H.; Fuchs, A.H.; Coudert, F.-X.; Patarin, J. Impacts of the Imidazolate Linker Substitution (CH3, Cl, or Br) on the Structural and Adsorptive Properties of ZIF-8. J. Phys. Chem. C 2018, 122, 26945–26955. [Google Scholar] [CrossRef]

- Stock, N.; Biswas, S. Synthesis of Metal-Organic Frameworks (MOFs): Routes to Various MOF Topologies, Morphologies, and Composites. Chem. Rev. 2012, 112, 933–969. [Google Scholar] [CrossRef] [PubMed]

- Dietzel, P.D.C.; Panella, B.; Hirscher, M.; Blom, R.; Fjellvag, H. Hydrogen adsorption in a nickel based coordination polymer with open metal sites in the cylindrical cavities of the desolvated framework. Chem. Commun. 2006, 9, 959–961. [Google Scholar] [CrossRef]

- Dietzel, P.D.C.; Morita, Y.; Blom, R.; Fjellvag, H. An in situ high-temperature single-crystal investigation of a dehydrated metal-organic framework compound and field-induced magnetization of one-dimensional metaloxygen chains. Angew. Chem. Int. Ed. 2005, 44, 6354–6358. [Google Scholar] [CrossRef]

- Rosi, N.L.; Kim, J.; Eddaoudi, M.; Chen, B.L.; O’Keeffe, M.; Yaghi, O.M. Rod packings and metal-organic frameworks constructed from rod-shaped secondary building units. J. Am. Chem. Soc. 2005, 127, 1504–1518. [Google Scholar] [CrossRef]

- Dietzel, P.D.C.; Blom, R.; Fjellvåg, H. Base-Induced Formation of Two Magnesium Metal-Organic Framework Compounds with a Bifunctional Tetratopic Ligand. Eur. J. Inorg. Chem. 2008, 2008, 3624–3632. [Google Scholar] [CrossRef]

- Das, A.K.; Vemuri, R.S.; Kutnyakov, I.; McGrail, B.P.; Motkuri, R.K. An Efficient Synthesis Strategy for Metal-Organic Frameworks: Dry-Gel Synthesis of MOF-74 Framework with High Yield and Improved Performance. Sci. Rep. 2016, 6, 28050. [Google Scholar] [CrossRef]

- Kim, S.-J.; Kwon, Y.; Kim, D.; Park, H.; Cho, Y.H.; Nam, S.-E.; Park, Y.-I. A Review on Polymer Precursors of Carbon Molecular Sieve Membranes for Olefin/Paraffin Separation. Membranes 2021, 11, 482. [Google Scholar] [CrossRef]

- Mohamed, M.H.; Yang, Y.; Li, L.; Zhang, S.; Ruffley, J.P.; Jarvi, A.G.; Saxena, S.; Veser, G.; Johnson, J.K.; Rosi, N.L. Designing Open Metal Sites in Metal-Organic Frameworks for Paraffin/Olefin Separations. J. Am. Chem. Soc. 2019, 141, 13003–13007. [Google Scholar] [CrossRef]

- Lamia, N.; Jorge, M.; Granato, M.A.; Almeida Paz, F.A.; Chevreau, H.; Rodrigues, A.E. Adsorption of propane, propylene and isobutane on a metal-organic framework: Molecular simulation and experiment. Chem. Eng. Sci. 2009, 64, 3246–3259. [Google Scholar] [CrossRef]

- Dietzel, P.D.C.; Georgiev, P.A.; Eckert, J.; Blom, R.; Straessle, T.; Unruh, T. Interaction of hydrogen with accessible metal sites in the metal-organic frameworks M2(dhtp) (CPO-27-M; M = Ni, Co, Mg). Chem. Commun. 2010, 46, 4962–4964. [Google Scholar] [CrossRef] [PubMed]

- Pato-Doldán, B.; Rosnes, M.H.; Dietzel, P.D.C. An In-Depth Structural Study of the Carbon Dioxide Adsorption Process in the Porous Metal-Organic Frameworks CPO-27-M. ChemSusChem 2017, 10, 1710–1719. [Google Scholar] [CrossRef] [PubMed]

- Pato-Doldán, B.; Rosnes, M.H.; Chernyshov, D.; Dietzel, P.D.C. Carbon dioxide induced structural phase transition in metal-organic frameworks CPO-27. CrystEngComm 2020, 22, 4353–4358. [Google Scholar] [CrossRef]

- Chen, C.; Feng, X.; Zhu, Q.; Dong, R.; Yang, R.; Cheng, Y.; He, C. Microwave-Assisted Rapid Synthesis of Well-Shaped MOF-74 (Ni) for CO2 Efficient Capture. Inorg. Chem. 2019, 58, 2717–2728. [Google Scholar] [CrossRef] [PubMed]

- Tagliabue, M.; Rizzo, C.; Millini, R.; Dietzel, P.D.C.; Blom, R.; Zanardi, S. Methane storage on CPO-27-Ni pellets. J. Porous Mater. 2011, 18, 289–296. [Google Scholar] [CrossRef]

- Hindocha, S.; Poulston, S. Study of the scale-up, formulation, ageing and ammonia adsorption capacity of MIL-100(Fe), Cu-BTC and CPO-27(Ni) for use in respiratory protection filters. Faraday Discuss. 2017, 201, 113–125. [Google Scholar] [CrossRef]

- Peralta, D.; Barthelet, K.; Pérez-Pellitero, J.; Chizallet, C.; Chaplais, G.; Simon-Masseron, A.; Pirngruber, G.D. Adsorption and Separation of Xylene Isomers: CPO-27-Ni vs HKUST-1 vs NaY. J. Phys. Chem. C 2012, 116, 21844–21855. [Google Scholar] [CrossRef]

- Dietzel, P.D.C.; Besikiotis, V.; Blom, R. Application of metal-organic frameworks with coordinatively unsaturated metal sites in storage and separation of methane and carbon dioxide. J. Mater. Chem. 2009, 19, 7362–7370. [Google Scholar] [CrossRef]

- Chen, S.; Li, X.; Duan, J.; Fu, Y.; Wang, Z.; Zhu, M.; Li, N. Investigation of highly efficient adsorbent based on Ni-MOF-74 in the separation of CO2 from natural gas. Chem. Eng. J. 2021, 419, 129653. [Google Scholar] [CrossRef]

- Liu, J.; Tian, J.; Thallapally, P.K.; McGrail, B.P. Selective CO2 Capture from Flue Gas Using Metal-Organic Frameworks—A Fixed Bed Study. J. Phys. Chem. C 2012, 116, 9575–9581. [Google Scholar] [CrossRef]

- Böhme, U.; Barth, B.; Paula, C.; Kuhnt, A.; Schwieger, W.; Mundstock, A.; Caro, J.; Hartmann, M. Ethene/ethane and propene/propane separation via the olefin and paraffin selective metal-organic framework adsorbents CPO-27 and ZIF-8. Langmuir 2013, 29, 8592–8600. [Google Scholar] [CrossRef]

- Abedini, H.; Shariati, A.; Khosravi-Nikou, M.R. Adsorption of propane and propylene on M-MOF-74 (M = Cu, Co): Equilibrium and kinetic study. Chem. Eng. Res. Des. 2020, 153, 96–106. [Google Scholar] [CrossRef]

- Lv, Y.; Xu, P.; Yu, H.; Xu, J.; Li, X. Ni-MOF-74 as sensing material for resonant-gravimetric detection of ppb-level CO. Sens. Actuators B 2018, 262, 562–569. [Google Scholar] [CrossRef]

- Xiao, T.; Liu, D. The most advanced synthesis and a wide range of applications of MOF-74 and its derivatives. Microporous Mesoporous Mater. 2019, 283, 88–103. [Google Scholar] [CrossRef]

- Yao, H.-F.; Yang, Y.; Liu, H.; Xi, F.-G.; Gao, E.-Q. CPO-27-M as heterogeneous catalysts for aldehyde cyanosilylation and styrene oxidation. J. Mol. Catal. A Chem. 2014, 394, 57–65. [Google Scholar] [CrossRef]

- Shah, J.; Wu, T.; Lucero, J.; Carreon, M.A.; Carreon, M.L. Nonthermal Plasma Synthesis of Ammonia over Ni-MOF-74. ACS Sustain. Chem. Eng. 2019, 7, 377–383. [Google Scholar] [CrossRef]

- Salama, R.S.; Mannaa, M.A.; Altass, H.M.; Ibrahim, A.A.; Khder, A.E.-R.S. Palladium supported on mixed-metal-organic framework (Co-Mn-MOF-74) for efficient catalytic oxidation of CO. RSC Adv. 2021, 11, 4318–4326. [Google Scholar] [CrossRef]

- Vornholt, S.M.; Duncan, M.J.; Warrender, S.J.; Semino, R.; Ramsahye, N.A.; Maurin, G.; Smith, M.W.; Tan, J.-C.; Miller, D.N.; Morris, R.E. Multifaceted Study of the Interactions between CPO-27-Ni and Polyurethane and Their Impact on Nitric Oxide Release Performance. ACS Appl. Mater. Interfaces 2020, 12, 58263–58276. [Google Scholar] [CrossRef]

- Yeskendir, B.; Dacquin, J.-P.; Lorgouilloux, Y.; Courtois, C.; Royer, S.; Dhainaut, J. From metal-organic framework powders to shaped solids: Recent developments and challenges. Mater. Adv. 2021, 2, 7139–7186. [Google Scholar] [CrossRef]

- Perego, C.; Villa, P. Catalyst preparation methods. Catal. Today 1997, 34, 281–305. [Google Scholar] [CrossRef]

- Bazer-Bachi, D.; Assie, L.; Lecocq, V.; Harbuzaru, B.; Falk, V. Towards industrial use of metal-organic framework: Impact of shaping on the MOF properties. Powder Technol. 2014, 255, 52–59. [Google Scholar] [CrossRef]

- Wong-Ng, W.; Kaduk, J.A.; Wu, H.; Suchomel, M. Synchrotron X-ray studies of metal-organic framework M2(2,5-dihydroxyterephthalate), M = (Mn, Co, Ni, Zn) (MOF-74). Powder Diffr. 2012, 27, 256–262. [Google Scholar] [CrossRef]

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.P.; Rodriguez-Reinoso, F.; Rouquerol, J.; Sing, K.S.W. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar] [CrossRef]

- Rosnes, M.H.; Pato-Doldan, B.; Johnsen, R.E.; Mundstock, A.; Caro, J.; Dietzel, P.D.C. Role of the metal cation in the dehydration of the microporous metal-organic frameworks CPO-27-M. Microporous Mesoporous Mater. 2020, 309, 110503. [Google Scholar] [CrossRef]

- Li, J.-R.; Kuppler, R.J.; Zhou, H.-C. Selective gas adsorption and separation in metal-organic frameworks. Chem. Soc. Rev. 2009, 38, 1477–1504. [Google Scholar] [CrossRef] [PubMed]

- Rouquerol, J.; Llewellyn, P.; Rouquerol, F. Is the BET equation applicable to microporous adsorbents? Stud. Surf. Sci. Catal. 2007, 160, 49–56. [Google Scholar] [CrossRef]

- Walton, K.S.; Snurr, R.Q. Applicability of the BET method for determining surface areas of microporous metal-organic frameworks. J. Am. Chem. Soc. 2007, 129, 8552–8556. [Google Scholar] [CrossRef]

| Sample | Pressure [MPa] | SBET [m2/g] | SBET Loss 1 [%] | Vμ [cm3/g] | Vμ Loss 2 [%] |

|---|---|---|---|---|---|

| CPO-27(Ni) | - | 1345 | - | 0.49 | - |

| CPO-27(Ni)-5 | 37.7 | 1266 | 6 | 0.46 | 6 |

| CPO-27(Ni)-8 | 60.3 | 1267 | 6 | 0.46 | 6 |

| CPO-27(Ni)-10 | 75.3 | 1258 | 6 | 0.46 | 6 |

| CPO-27(Ni)-30 | 226.0 | 1182 | 12 | 0.43 | 12 |

| CPO-27(Ni)-50 | 376.7 | 1068 | 21 | 0.39 | 20 |

| CPO-27(Ni)-70 | 527.4 | 937 | 30 | 0.34 | 31 |

| CPO-27(Ni)-90 | 678.1 | 865 | 36 | 0.31 | 37 |

| Sample | Weight Loss by Degassing 1 [%] | Weight Loss by TGA 2 [%] |

|---|---|---|

| CPO-27(Ni) | 30 | 32 3/32 4 |

| CPO-27(Ni)-5 | 34 | 34 |

| CPO-27(Ni)-8 | 34 | 33 |

| CPO-27(Ni)-10 | 35 | 35 |

| CPO-27(Ni)-30 | 35 | 35 |

| CPO-27(Ni)-50 | 35 | 35 |

| CPO-27(Ni)-70 | 34 | 34 |

| CPO-27(Ni)-90 | 34 | 34 |

| Sample | Pressure [MPa] | a = b [Å] | c [Å] | Volume [Å3] |

|---|---|---|---|---|

| CPO-27(Ni) | - | 25.943(2) | 6.694(3) | 3901.6(5) |

| CPO-27(Ni)-5 | 37.7 | 25.817(2) | 6.761(4) | 3883.1(3) |

| CPO-27(Ni)-8 | 60.3 | 25.812(3) | 6.757(5) | 3898.6(8) |

| CPO-27(Ni)-10 | 75.3 | 25.937(3) | 6.702(6) | 3904.5(8) |

| CPO-27(Ni)-30 | 226.0 | 25.930(2) | 6.700(5) | 3901.3(6) |

| CPO-27(Ni)-50 | 376.7 | 25.926(2) | 6.702(4) | 3901.4(5) |

| CPO-27(Ni)-70 | 527.4 | 25.932(2) | 6.706(3) | 3905.5(4) |

| CPO-27(Ni)-90 | 678.1 | 25.928(2) | 6.707(3) | 3904.8(4) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Trierweiler Gonçalves, G.; Michelin, L.; Josien, L.; Paillaud, J.-L.; Chaplais, G. Impact of Compression on the Textural and Structural Properties of CPO-27(Ni). Molecules 2023, 28, 6753. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules28196753

Trierweiler Gonçalves G, Michelin L, Josien L, Paillaud J-L, Chaplais G. Impact of Compression on the Textural and Structural Properties of CPO-27(Ni). Molecules. 2023; 28(19):6753. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules28196753

Chicago/Turabian StyleTrierweiler Gonçalves, Gabriel, Laure Michelin, Ludovic Josien, Jean-Louis Paillaud, and Gérald Chaplais. 2023. "Impact of Compression on the Textural and Structural Properties of CPO-27(Ni)" Molecules 28, no. 19: 6753. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules28196753