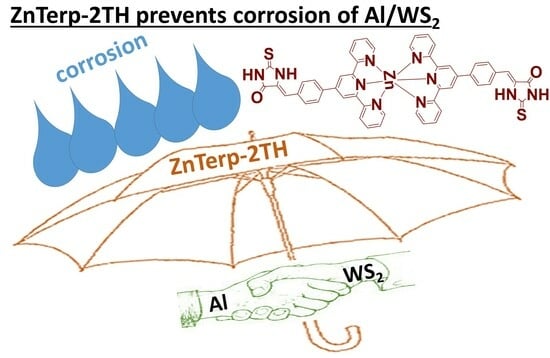

Significance of Zn Complex Concentration on Microstructure Evolution and Corrosion Behavior of Al/WS2

Abstract

:1. Introduction

2. Results and Discussion

2.1. NMR and Mass Analysis of ZnTerp-2TH

2.2. Thermal Analysis

2.3. Study of X-ray Diffraction (XRD)

2.4. Fourier Transform Infrared (FTIR) Analysis

2.5. Investigation of Morphology and Energy-Dispersive X-ray (EDX) Analysis

2.6. Corrosion Behavior

3. Experimental

3.1. Synthesis of ZnTerp-2TH

3.2. Synthesis of Al/WS2 and Al/WS2/ZnTerp-2TH Composites

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Bharthasaradhi, R.; Nehru, L.C. Structural and Phase Transition of α-Al2O3 Powders Obtained by Co-Precipitation Method. Phase Transit. 2015, 89, 77–83. [Google Scholar] [CrossRef]

- Wang, Q.; Lei, L.; Wang, L.; Cao, Y.; Wen, Y.; Lu, Z.; Shang, W. Study of Functional Perylene Diimides for Corrosion Protection on Aluminum Alloy Surfaces. J. Taiwan Inst. Chem. Eng. 2023, 147, 104933. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, D.L. Contribution of Orowan Strengthening Effect in Particulate-Reinforced Metal Matrix Nanocomposites. Mater. Sci. Eng. A 2008, 483–484, 148–152. [Google Scholar] [CrossRef]

- Sun, D.; Lin, X.; Xu, J.; Lu, Z.; Huang, J.; Li, S.; Campos, L.C. Efficient Degradation of Triclosan by Aluminium Acetylacetonate Doped Polymeric Carbon Nitride Photocatalyst under Visible Light. J. Environ. Chem. Eng. 2023, 11, 109186. [Google Scholar] [CrossRef]

- Bhuvanasundari, S.; Venkatachalam, G.; Doble, M.; Thomas, T. Magnetically Recoverable, Non-Toxic, Leach Resistant Aluminum Ferrite (AlFeO3) Photocatalyst for Wastewater Remediation. Ceram. Int. 2022, 48, 32326–32337. [Google Scholar] [CrossRef]

- Li, N.; Feng, L.P.; Su, J.; Zeng, W.; Liu, Z.T. Optical and Electrical Properties of Al:WS2 Films Prepared by Atomic Layer Deposition and Vulcanization. RSC Adv. 2016, 6, 64879–64884. [Google Scholar] [CrossRef]

- Zhang, Y.; Ye, J.; Matsuhashi, Y.; Iwasa, Y. Ambipolar MoS2 Thin Flake Transistors [Supporting Information]. Nano Lett. 2012, 12, 1136–1140. [Google Scholar] [CrossRef] [PubMed]

- Levi, R.; Bitton, O.; Leitus, G.; Tenne, R.; Joselevich, E. Field-Effect Transistors Based on WS2 Nanotubes with High Current-Carrying Capacity. Nano Lett. 2013, 13, 3736–3741. [Google Scholar] [CrossRef]

- Niste, V.B.; Ratoi, M.; Tanaka, H.; Xu, F.; Zhu, Y.; Sugimura, J. Self-Lubricating Al-WS2 Composites for Efficient and Greener Tribological Parts. Sci. Rep. 2017, 7, 14665. [Google Scholar] [CrossRef]

- Huang, S.-J.; Peng, W.-Y.; Visic, B.; Zak, A. Al Alloy Metal Matrix Composites Reinforced by WS2 Inorganic Nanomaterials. Mater. Sci. Eng. A 2018, 709, 290–300. [Google Scholar] [CrossRef]

- Li, N.; Feng, L.-P.; Li, D.-P.; Su, J.; Liu, Z.-T. Optical and Electrical Properties of Al–WS2 Films via H2S Sulfurization of Al–WOx. Mater. Des. 2016, 92, 129–134. [Google Scholar] [CrossRef]

- Sakthivel, S.; Neppolian, B.; Shankar, M.V.; Arabindoo, B.; Palanichamy, M.; Murugesan, V. Solar Photocatalytic Degradation of Azo Dye: Comparison of Photocatalytic Efficiency of ZnO and TiO2. Sol. Energy Mater. Sol. Cells 2003, 77, 65–82. [Google Scholar] [CrossRef]

- Tehfe, M.A.; Dumur, F.; Telitel, S.; Gigmes, D.; Contal, E.; Bertin, D.; Morlet-Savary, F.; Graff, B.; Fouassier, J.P.; Lalevée, J. Zinc-Based Metal Complexes as New Photocatalysts in Polymerization Initiating Systems. Eur. Polym. J. 2013, 49, 1040–1049. [Google Scholar] [CrossRef]

- Lee, J.C.; Park, S.; Park, H.-J.; Lee, J.-H.; Kim, H.-S.; Chung, Y.-J. Photocatalytic Degradation of TOC from Aqueous Phenol Solution Using Solution Combusted ZnO Nanopowders. J. Electroceram. 2009, 22, 110–113. [Google Scholar] [CrossRef]

- Yu, J.; Yu, X. Hydrothermal Synthesis and Photocatalytic Activity of Zinc Oxide Hollow Spheres. Environ. Sci. Technol. 2008, 42, 4902–4907. [Google Scholar] [CrossRef] [PubMed]

- Shi, Y.; Zhao, J.; Chen, L.; Li, H.; Zhang, S.; Gao, F. Double Open Mouse-like Terpyridine Parts Based Amphiphilic Ionic Molecules Displaying Strengthened Chemical Adsorption for Anticorrosion of Copper in Sulfuric Acid Solution. Chin. J. Chem. Eng. 2023, 57, 233–246. [Google Scholar] [CrossRef]

- Tao, Z.H.; Zhang, S.T.; Li, W.H.; Hou, B.R. Adsorption and Corrosion Inhibition Behavior of Mild Steel by One Derivative of Triazole-Phenylamide in Acid Solution. Ind. Eng. Chem. Res. 2010, 49, 2593–2599. [Google Scholar] [CrossRef]

- John, S.; Joseph, B.; Balakrishnan, K.V.; Aravindakshan, K.K.; Joseph, A. Electrochemical and Quantum Chemical Study of 4-[(E)-[(2,4-Dihydroxy Phenyl) Methylidine] Amino]-6-Methyl-3-Sulphanylidine-2,3,4,5-Tetra Hydro-1,2,4-Triazin-5-One [DMSTT]. Mater. Chem. Phys. 2010, 123, 218–224. [Google Scholar] [CrossRef]

- Li, X.; Mu, G. Tween-40 as Corrosion Inhibitor for Cold Rolled Steel in Sulphuric Acid: Weight Loss Study, Electrochemical Characterization, and AFM. Appl. Surf. Sci. 2005, 252, 1254–1265. [Google Scholar] [CrossRef]

- Fiala, A.; Chibani, A.; Darchen, A.; Boulkamh, A.; Djebbar, K. Investigations of the Inhibition of Copper Corrosion in Nitric Acid Solutions by Ketene Dithioacetal Derivatives. Appl. Surf. Sci. 2007, 253, 9347–9356. [Google Scholar] [CrossRef]

- Thanusu, J.; Kanagarajan, V.; Gopalakrishnan, M. Spectral Characterization of Novel Bis Heterocycles Comprising Both Piperidine and Thiohydantoin Nuclei. Res. Chem. Intermed. 2010, 36, 1073–1084. [Google Scholar] [CrossRef]

- Yüce, A.O.; Kardaş, G. Adsorption and Inhibition Effect of 2-Thiohydantoin on Mild Steel Corrosion in 0.1 M HCl. Corros. Sci. 2012, 58, 86–94. [Google Scholar] [CrossRef]

- Liu, L.; Hu, Z.; Wu, C.; Chen, X.; Luo, X.; Li, J. Zn(II)-Containing Metallo-Supramolecular Polymers: Synthesis, Photophysical and Electrochemical Properties. J. Macromol. Sci. Part A 2019, 56, 918–925. [Google Scholar] [CrossRef]

- Manzhelii, E.A.; Beloglazkina, E.K.; Majouga, A.G.; Zyk, N.V. Novel Ditopic Organic Ligands Containing the Terpyridine and 2-Thiohydantoin Fragments. Russ. Chem. Bull. 2013, 62, 2631–2633. [Google Scholar] [CrossRef]

- Yang, A.; Wu, R.; Zhu, P. Thermal Analysis and Miscibility of Chitin/Polycaprolactone Blends. J. Appl. Polym. Sci. 2001, 81, 3117–3123. [Google Scholar] [CrossRef]

- Ramish, S.M.; Ghorbani-Choghamarani, A.; Mohammadi, M. Microporous Hierarchically Zn-MOF as an Efficient Catalyst for the Hantzsch Synthesis of Polyhydroquinolines. Sci. Rep. 2022, 12, 1479. [Google Scholar] [CrossRef] [PubMed]

- Lai, Z.; He, Q.; Tran, T.H.; Repaka, D.V.M.; Zhou, D.D.; Sun, Y.; Xi, S.; Li, Y.; Chaturvedi, A.; Tan, C.; et al. Metastable 1T′-Phase Group VIB Transition Metal Dichalcogenide Crystals. Nat. Mater. 2021, 20, 1113–1120. [Google Scholar] [CrossRef] [PubMed]

- Sarker, M.S.R.; Alam, M.Z.; Qadir, M.R.; Gafur, M.A.; Moniruzzaman, M. Extraction and Characterization of Alumina Nanopowders from Aluminum Dross by Acid Dissolution Process. Int. J. Miner. Metall. Mater. 2015, 22, 429–436. [Google Scholar] [CrossRef]

- Khaghani-Dehaghani, M.A.; Ebrahimi-Kahrizsangi, R.; Setoudeh, N.; Nasiri-Tabrizi, B. Mechanochemical Synthesis of Al2O3–TiB2 Nanocomposite Powder from Al–TiO2–H3BO3 Mixture. Int. J. Refract. Met. Hard Mater. 2011, 29, 244–249. [Google Scholar] [CrossRef]

- Xu, F.; Yan, C.; Shyng, Y.T.; Chang, H.; Xia, Y.; Zhu, Y. Ultra-Toughened Nylon 12 Nanocomposites Reinforced with IF-WS2. Nanotechnology 2014, 25, 325701. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, K.; Elgallad, E.; Breton, F.; Chen, X.G. Differential Scanning Calorimetry Fingerprints of Various Heat-Treatment Tempers of Different Aluminum Alloys. Metals 2020, 10, 763. [Google Scholar] [CrossRef]

- Xu, X.; Liu, Z.; Zhang, B.; Chen, H.; Zhang, J.; Wang, T.; Zhang, K.; Zhang, J.; Huang, P. Effect of Mn Content on Microstructure and Properties of 6000 Series Aluminum Alloy. Appl. Phys. A Mater. Sci. Process. 2019, 125, 490. [Google Scholar] [CrossRef]

- Rashad, M.; Pan, F.; Tang, A.; Asif, M. Effect of Graphene Nanoplatelets Addition on Mechanical Properties of Pure Aluminum Using a Semi-Powder Method. Prog. Nat. Sci. Mater. Int. 2014, 24, 101–108. [Google Scholar] [CrossRef]

- Wang, S.; Li, S.; Chervy, T.; Shalabney, A.; Azzini, S.; Orgiu, E.; Hutchison, J.A.; Genet, C.; Samorì, P.; Ebbesen, T.W. Coherent Coupling of WS2 Monolayers with Metallic Photonic Nanostructures at Room Temperature. Nano Lett. 2016, 16, 4368–4374. [Google Scholar] [CrossRef]

- Salehi Vaziri, H.; Shokuhfar, A.; Salman Seyyed Afghahi, S. Investigation of Mechanical and Tribological Properties of Aluminum Reinforced with Tungsten Disulfide (WS2) Nanoparticles. Mater. Res. Express 2019, 6, 045018. [Google Scholar] [CrossRef]

- Nasiri, S.; Dashti, A.; Hosseinnezhad, M.; Rabiei, M.; Palevicius, A.; Doustmohammadi, A.; Janusas, G. Mechanochromic and Thermally Activated Delayed Fluorescence Dyes Obtained from D–A–D′ Type, Consisted of Xanthen and Carbazole Derivatives as an Emitter Layer in Organic Light Emitting Diodes. Chem. Eng. J. 2022, 430, 131877. [Google Scholar] [CrossRef]

- Rabiei, M.; Palevicius, A.; Monshi, A.; Nasiri, S.; Vilkauskas, A.; Janusas, G. Comparing Methods for Calculating Nano Crystal Size of Natural Hydroxyapatite Using X-Ray Diffraction. Nanomaterials 2020, 10, 1627. [Google Scholar] [CrossRef]

- Nemati, N.; Khosroshahi, R.; Emamy, M.; Zolriasatein, A. Investigation of Microstructure, Hardness and Wear Properties of Al–4.5 Wt.% Cu–TiC Nanocomposites Produced by Mechanical Milling. Mater. Des. 2011, 32, 3718–3729. [Google Scholar] [CrossRef]

- Matos, R.A.G.; Mendes, J.; Kuffner, B.H.B.; de Lourdes Noronha Motta Melo, M.; Silva, G. Recrystallization Study of the Al4.5 wt.%Cu Alloy Conventionally and Unidirectionally Solidified, Deformed and Heat Treated. Mater. Res. 2021, 23, e20200283. [Google Scholar] [CrossRef]

- Liu, L.N.; Dai, J.G.; Zhao, T.J.; Guo, S.Y.; Hou, D.S.; Zhang, P.; Shang, J.; Wang, S.; Han, S. A Novel Zn(II) Dithiocarbamate/ZnS Nanocomposite for Highly Efficient Cr6+ Removal from Aqueous Solutions. RSC Adv. 2017, 7, 35075–35085. [Google Scholar] [CrossRef]

- Liu, L.; Cui, Z.; Ma, Q.; Cui, W.; Zhang, X. One-Step Synthesis of Magnetic Iron–Aluminum Oxide/Graphene Oxide Nanoparticles as a Selective Adsorbent for Fluoride Removal from Aqueous Solution. RSC Adv. 2016, 6, 10783–10791. [Google Scholar] [CrossRef]

- Alowasheeir, A.; Tominaka, S.; Ide, Y.; Yamauchi, Y.; Matsushita, Y. Two-Dimensional Cyano-Bridged Coordination Polymer of Mn(H2O)2[Ni(CN)4]: Structural Analysis and Proton Conductivity Measurements upon Dehydration and Rehydration. CrystEngComm 2018, 20, 6713–6720. [Google Scholar] [CrossRef]

- Mahvelati-Shamsabadi, T.; Goharshadi, E.K. Photostability and Visible-Light-Driven Photoactivity Enhancement of Hierarchical ZnS Nanoparticles: The Role of Embedment of Stable Defect Sites on the Catalyst Surface with the Assistant of Ultrasonic Waves. Ultrason. Sonochem. 2017, 34, 78–89. [Google Scholar] [CrossRef] [PubMed]

- Kolar, T.; Mušič, B.; Korošec, R.C.; Kokol, V. Addition of Al(OH)3 versus AlO(OH) Nanoparticles on the Optical, Thermo-Mechanical and Heat/Oxygen Transmission Properties of Microfibrillated Cellulose Films. Cellulose 2021, 28, 9441–9460. [Google Scholar] [CrossRef]

- He, H.; Zhang, C.G.; Xia, J.L.; Peng, A.A.; Yang, Y.; Jiang, H.C.; Zheng, L.; Ma, C.Y.; Zhao, Y.D.; Nie, Z.Y.; et al. Investigation of Elemental Sulfur Speciation Transformation Mediated by Acidithiobacillus Ferrooxidans. Curr. Microbiol. 2009, 58, 300–307. [Google Scholar] [CrossRef] [PubMed]

- Kargarnejad, S.; Abbasi-Chianeh, V. Failure Analysis of a Burner Ring Made of 20Cr32Ni1Nb Alloy in Gas Turbine Combustion Chamber. Case Stud. Eng. Fail. Anal. 2014, 2, 138–143. [Google Scholar] [CrossRef]

- Castorena-González, J.H.; Martin, U.; Gaona-Tiburcio, C.; Núñez-Jáquez, R.E.; Almeraya-Calderón, F.M.; Bastidas, J.M.; Bastidas, D.M. Modeling Steel Corrosion Failure in Reinforced Concrete by Cover Crack Width 3D FEM Analysis. Front. Mater. 2020, 7, 41. [Google Scholar] [CrossRef]

- Boughriet, A.; Allahdin, O.; Poumaye, N.; Tricot, G.; Revel, B.; Lesven, L.; Wartel, M. Micro-Analytical Study of a Zeolites/Geo-Polymers/Quartz Composite, Dielectric Behaviour and Contribution to Brønsted Sites Affinity. Ceramics 2022, 5, 908–927. [Google Scholar] [CrossRef]

- Nasiri, S.; Rahimirad, Z.; Dehaghi, M.Y.; Rabiei, M.; Ebrahimi-Kahrizsangi, R.; Palevicius, A.; Janusas, G. Facile Synthesis and Study of Photocatalytic Properties of TiO2-Ag-Ce Nanocomposites. Mater. Lett. 2022, 322, 132489. [Google Scholar] [CrossRef]

- Chen, F.; Ho, P.; Ran, R.; Chen, W.; Si, Z.; Wu, X.; Weng, D.; Huang, Z.; Lee, C. Synergistic Effect of CeO2 Modified TiO2 Photocatalyst on the Enhancement of Visible Light Photocatalytic Performance. J. Alloys Compd. 2017, 714, 560–566. [Google Scholar] [CrossRef]

- Srinivasan, A.; Rajendran, N. Surface Characteristics, Corrosion Resistance and MG63 Osteoblast-like Cells Attachment Behaviour of Nano SiO2–ZrO2 Coated 316L Stainless Steel. RSC Adv. 2015, 5, 26007–26016. [Google Scholar] [CrossRef]

- Cui, X.-J.; Lin, X.-Z.; Liu, C.-H.; Yang, R.-S.; Zheng, X.-W.; Gong, M. Fabrication and Corrosion Resistance of a Hydrophobic Micro-Arc Oxidation Coating on AZ31 Mg Alloy. Corros. Sci. 2015, 90, 402–412. [Google Scholar] [CrossRef]

- Khalajabadi, S.Z.; Abdul Kadir, M.R.; Izman, S.; Ebrahimi-Kahrizsangi, R. Fabrication, Bio-Corrosion Behavior and Mechanical Properties of a Mg/HA/MgO Nanocomposite for Biomedical Applications. Mater. Des. 2015, 88, 1223–1233. [Google Scholar] [CrossRef]

- Flitt, H.J.; Schweinsberg, D.P. Evaluation of Corrosion Rate from Polarisation Curves Not Exhibiting a Tafel Region. Corros. Sci. 2005, 47, 3034–3052. [Google Scholar] [CrossRef]

| Al/WS2 | Al/WS2/5 wt.% ZnTerp-2TH | Al/WS2/10 wt.% ZnTerp-2TH | |||

|---|---|---|---|---|---|

| Element | Weight, % | Element | Weight % | Element | Weight % |

| O | 27.99 | O | 31.08 | O | 29.15 |

| C | 32.29 | C | 34.98 | C | 34.16 |

| Cl | 0.86 | Cl | 0.37 | Cl | 0.24 |

| W | 9.76 | W | 5.11 | W | 7.09 |

| S | 3.73 | S | 5.09 | S | 6.17 |

| Al | 24.04 | Al | 18.02 | Al | 16.14 |

| Cu | 1.33 | Zn | 3.77 | Zn | 5.81 |

| Cu | 1.58 | Cu | 1.24 | ||

| Samples | Ecorr, (mV/Decade) vs. SCE | βa, (mV/Decade) vs. SCE | βc, (mV/Decade) vs. SCE | Icorr, µAcm−2 |

|---|---|---|---|---|

| Al/WS2 | −905 | 765 | −585 | 29 |

| Al/WS2/5 wt.% ZnTerp-2TH | −773 | 352 | −466 | 14 |

| Al/WS2/10 wt.% ZnTerp-2TH | −724 | 661 | −326 | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gawas, P.P.; Pandurangan, P.; Rabiei, M.; Palevicius, A.; Vilkauskas, A.; Janusas, G.; Hosseinnezhad, M.; Ebrahimi-Kahrizsangi, R.; Nasiri, S.; Nunzi, J.M.; et al. Significance of Zn Complex Concentration on Microstructure Evolution and Corrosion Behavior of Al/WS2. Molecules 2023, 28, 7290. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules28217290

Gawas PP, Pandurangan P, Rabiei M, Palevicius A, Vilkauskas A, Janusas G, Hosseinnezhad M, Ebrahimi-Kahrizsangi R, Nasiri S, Nunzi JM, et al. Significance of Zn Complex Concentration on Microstructure Evolution and Corrosion Behavior of Al/WS2. Molecules. 2023; 28(21):7290. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules28217290

Chicago/Turabian StyleGawas, Pratiksha P., Praveenkumar Pandurangan, Marzieh Rabiei, Arvydas Palevicius, Andrius Vilkauskas, Giedrius Janusas, Mozhgan Hosseinnezhad, Reza Ebrahimi-Kahrizsangi, Sohrab Nasiri, Jean Michel Nunzi, and et al. 2023. "Significance of Zn Complex Concentration on Microstructure Evolution and Corrosion Behavior of Al/WS2" Molecules 28, no. 21: 7290. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules28217290