The Missing Limb: Including Impacts of Biomass Extraction on Forest Carbon Stocks in Greenhouse Gas Balances of Wood Use

Abstract

:1. Introduction

2. Materials and Methods

2.1. Total GHG Balance

2.2. GHG Emissions along the Production Chain (PCWP)

2.3. Carbon Storage Capacity of Wood Products (CSWP)

2.4. Carbon Storage Balance in Forests (CSBF)

2.5. Substitution Effects

3. Results

4. Discussion

4.1. Integration of the CSBF into the GHG Balance of Wood Products

4.2. Comparison to Other Indicators and Influencing Factors

4.3. Relevance of the CSBF for Climate Policy and Forest-Based Mitigation

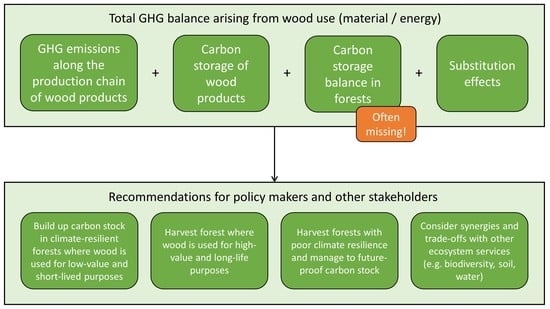

5. Conclusions

- In climate-resilient forest stands with high ecological integrity (e.g., mainly deciduous and mixed forests in Germany) where mainly low-quality and short-lived wood products are expected, harvesting should be reduced to build up forest carbon stock.

- In forest stands with poor climate resilience and low ecological integrity (e.g., spruce forests in unsuitable locations in Germany), harvesting should continue with the long-term goal of conversion into climate-resilient forests.

- In forests where wood output is primarily used for high-value and long-lived products, carbon stock accumulation through reduced harvesting is likely to not reduce overall GHG emissions.

- Synergies and trade-offs with other ecosystem services such as biodiversity, soil and water should be factored into decision-making.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- United Nations. Paris Agreement; United Nations: San Francisco, CA, USA, 2021; pp. 1–27. Available online: http://unfccc.int/files/essential_background/convention/application/pdf/english_paris_agreement.pdf (accessed on 28 December 2021).

- Rogelj, J.; Shindell, D.; Jiang, K.; Fifita, S.; Forster, P.; Ginzburg, V.; Handa, C.; Kheshgi, H.; Kobayashi, S.; Kriegler, E.; et al. Mitigation Pathways Compatible with 1.5 °C in the Context of Sustainable Development. In Global Warming of 1.5 °C. An IPCC Special Report on the Impacts of Global Warming of 1.5 °C above Pre-Industrial Levels and Related Global Greenhouse Gas Emission Pathways, in the Context of Strengthening the Global Response to the Threat of Climate Change, Sustainable Development, and Efforts to Eradicate Poverty; Intergovernmental Panel on Climate Change (IPCC): Geneva, Switzerland, 2018; pp. 1–174. Available online: https://www.ipcc.ch/site/assets/uploads/sites/2/2019/05/SR15_Chapter2_Low_Res.pdf (accessed on 28 December 2021).

- United Nations Environment Programme. Emissions Gap Report 2021: The Heat Is On—A World of Climate Promises Not Yet Delivered; United Nations Environment Programme: Nairobi, Kenia, 2021; pp. 1–79. Available online: https://www.unep.org/emissions-gap-report-2021 (accessed on 28 December 2021).

- European Commission. Proposal for a Regulation of the European Parliament and of the Council Amending Regulations (EU) 2018/841 as Regards the Scope, Simplifying the Compliance Rules, Setting out the Targets of the Member States for 2030 and Committing to the Collective Achievement of Climate Neutrality by 2035 in the Land Use, Forestry and Agriculture Sector, and (EU) 2018/1999 as Regards Improvement in Monitoring, Reporting, Tracking of Progress and Review. Brussels, 14.7.2021. COM(2021) 554 Final ANNEX. Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:ea67fbc9-e4ec-11eb-a1a5-01aa75ed71a1.0001.02/DOC_2&format=PDF (accessed on 27 December 2021).

- Hennenberg, K.; Boettcher, H.; Reise, J.; Herold, A.; Bohn, F.; Gutsch, M.; Reyer, C. Interpretation des Klimaschutzgesetzes für die Waldbewirtschaftung verlangt adäquate Datenbasis—Reaktion auf die Stellungnahme des Wissenschaftlichen Beirats für Waldpolitik beim BMEL (vom 22.06.2021); Öko-Institut Working Paper 3/2021; Öko-Institut: Freiburg, Germany, 2021; pp. 1–28. Available online: https://www.oeko.de/fileadmin/oekodoc/03-WP-Klimaschutzgesetz-Waldbewirtschaftung.pdf (accessed on 27 December 2021).

- Strogies, M.; Gniffke, P. Submission under the United Nations Framework Convention on Climate Change and the Kyoto Protocol 2021. National Inventory Report for the German Greenhouse Gas Inventory 1990–2019; UBA Climate Change 44/2021; Umweltbundesamt: Dessau-Roßlau, Germany, 2021; pp. 1–994. Available online: https://www.umweltbundesamt.de/sites/default/files/medien/5750/publikationen/2021-05-19_cc_44-2021_nir_2021_0.pdf (accessed on 27 December 2021).

- BMEL. Ergebnisse der Waldzustandserhebung 2020; Bundesministerium für Ernährung und Landwirtschaft (BMEL): Bonn, Germany, 2021; pp. 1–72. Available online: https://www.bmel.de/SharedDocs/Downloads/DE/Broschueren/ergebnisse-waldzustandserhebung-2020.pdf?__blob=publicationFile&v=8 (accessed on 27 December 2021).

- Ibisch, P.; Gohr, C.; Mann, D.; Blumröder, J. Der Wald in Deutschland auf dem Weg in die Heißzeit. Vitalität, Schädigung und Erwärmung in den Extremsommern 2018–2020; Hochschule für nachhaltige Entwicklung Eberswalde: Eberswalde, Germany, 2021; pp. 1–96. Available online: https://www.researchgate.net/publication/356443090_Der_Wald_in_Deutschland_auf_dem_Weg_in_die_Heisszeit_Vitalitat_Schadigung_und_Erwarmung_in_den_Extremsommern_2018-2020 (accessed on 27 December 2021).

- DESTATIS 41261-0003; Schadholzeinschlag: Deutschland, Jahre, Einschlagsursache, Holzartengruppen, Waldeigentumsarten. 2011–2020. Statistisches Bundesamt (Destatis): Wiesbaden, Germany, 2021. Available online: https://www-genesis.destatis.de/genesis//online?operation=table&code=41261-0003&bypass=true&levelindex=1&levelid=1640635855139#abreadcrumb (accessed on 27 December 2021).

- Jochem, D.; Weimar, H.; Dieter, M. Holzeinschlag kalamitätsbedingt weiter angestiegen. Holz-Zent. 2021, 147, 563–564. Available online: https://literatur.thuenen.de/digbib_extern/dn063967.pdf (accessed on 27 December 2021).

- Eionet Central Data Repository: GHG Inventory EU 15-01-2022, Germany. Available online: https://cdr.eionet.europa.eu/de/eu/mmr/art07_inventory/ghg_inventory/envyefchw (accessed on 28 December 2021).

- Röhling, S.; Dunger, K.; Kändler, G.; Klatt, S.; Riedel, T.; Stümer, W.; Brötz, J. Comparison of Calculation Methods for Estimating Annual Carbon Stock Change in German Forests under Forest Management in the German Greenhouse Gas Inventory. Carbon Balance Manag. 2016, 11, 12. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Krause, A.; Knoke, T.; Rammig, A. A regional assessment of land-based carbon mitigation potentials: Bioenergy, BECCS, reforestation, and forest management. Global Change Biol. Bioenergy 2020, 12, 346–360. [Google Scholar] [CrossRef]

- Bösch, M.; Elsasser, P.; Rock, J.; Weimar, H.; Dieter, M. Extent and costs of forest-based climate change mitigation in Germany: Accounting for substitution. Carbon Manag. 2019, 10, 127–134. [Google Scholar] [CrossRef]

- Böttcher, H.; Hennenberg, K.; Winger, C. Forest Vision Germany. Waldvision Deutschland. Description of Methodology, Assumptions and Results.; Oeko-Institute: Freiburg/Berlin/Darmstadt, Germany, 2018; pp. 1–77. Available online: https://www.oeko.de/fileadmin/oekodoc/Forest-Vision-Methods-and-Results.pdf (accessed on 27 December 2021).

- Gutsch, M.; Lasch-Born, P.; Kollas, C.; Suckow, F.; Reyer, C.P.O. Balancing Trade-Offs between Ecosystem Services in Germany’s Forests under Climate Change. Environ. Res. Lett. 2018, 13, 045012. [Google Scholar] [CrossRef]

- Oehmichen, K.; Klatt, S.; Gerber, K.; Polley, H.; Röhling, S.; Dunger, K. Die alternativen WEHAM-Szenarien: Holzpräferenz, Naturschutzpräferenz und Trendfortschreibung—Szenarienentwicklung, Ergebnisse und Analyse; Thünen Report 59; Johann Heinrich von Thünen-Institut: Braunschweig, Germany, 2018; pp. 1–91. Available online: https://literatur.thuenen.de/digbib_extern/dn059875.pdf (accessed on 27 December 2021).

- Knauf, M.; Köhl, M.; Mues, V.; Olschofsky, K.; Frühwald, A. Modeling the CO2-effects of forest management and wood usage on a regional basis. Carbon Balance Manag. 2015, 10, 13. [Google Scholar] [CrossRef] [Green Version]

- IPCC. 2006 IPCC Guidelines for National Greenhouse Gas Inventories. Prepared by the National Greenhouse Gas Inventories Programme; Eggleston, H.S., Buendia, L., Miwa, K., Ngara, T., Tanabe, K., Eds.; Intergovernmental Panel on Climate Change: Hayama, Japan, 2006; Volume 1, ISBN 4-88788-032-4.

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organisation for Standardization: Geneva, Switzerland, 2006; pp. 1–20.

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organisation for Standardization: Geneva, Switzerland, 2006; pp. 1–46.

- IPCC. Climate Change and Land: An IPCC Special Report on Climate Change, Desertification, Land Degradation, Sustainable Land Management, Food Security, and Greenhouse Gas Fluxes in Terrestrial Ecosystems; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2019. Available online: https://www.ipcc.ch/site/assets/uploads/2019/11/SRCCL-Full-Report-Compiled-191128.pdf (accessed on 27 December 2021).

- Fehrenbach, H.; Köppen, S.; Kauertz, B.; Wellenreuther, F.; Baur, F.; Wern, B.; Breitmayer, E. Biomassekaskaden—Mehr Ressourceneffizienz Durch Stoffliche Kaskadennutzung von Biomasse—von der Theorie zur Praxis—Gesamtökologische Betrachtung ausgewählter Biomassekaskaden; UBA Texte 53/2017; Umweltbundesamt: Dessau-Roßlau, Germany, 2017; pp. 1–112. Available online: https://www.umweltbundesamt.de/sites/default/files/medien/1410/publikationen/2017-06-13_texte_53-2017_biokaskaden_anlage.pdf (accessed on 27 December 2021).

- Höglmeier, K.; Steubing, B.; Weber-Blaschke, G.; Richter, K. LCA-Based Optimization of Wood Utilization under Special Consideration of a Cascading Use of Wood. J. Environ. Manag. 2015, 152, 158–170. [Google Scholar] [CrossRef]

- Sathre, R.; González-García, S. Life Cycle Assessment (LCA) of Wood-Based Building Materials. In Eco-efficient Construction and Building Materials; Woodhead Publishing Limited: Cambridge, UK, 2014; pp. 311–337. Available online: https://0-linkinghub-elsevier-com.brum.beds.ac.uk/retrieve/pii/B9780857097675500145 (accessed on 27 December 2021)ISBN 978-0-85709-767-5.

- Helin, T.; Holma, A.; Soimakallio, S. Is Land Use Impact Assessment in LCA Applicable for Forest Biomass Value Chains? Findings from Comparison of Use of Scandinavian Wood, Agro-Biomass and Peat for Energy. Int. J. Life Cycle Assess. 2014, 19, 770–785. [Google Scholar] [CrossRef]

- European Commission. Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources. Available online: https://eur-lex.europa.eu/eli/dir/2018/2001/oj (accessed on 23 December 2021).

- Agostini, A.; Giuntoli, J.; Boulamanti, A.; Marelli, L. Carbon Accounting of Forest Bioenergy. Conclusions and Recommendations from a Critical Literature Review; European Commission, Joint Research Centre, Institute for Energy and Transport: Luxembourg, 2014; pp. 1–88. [Google Scholar] [CrossRef]

- ISO 14067:2018; Greenhouse Gases—Carbon Footprint of Products—Requirements and Guidelines for Quantification. International Organisation for Standardization: Geneva, Switzerland, 2018; pp. 1–46.

- IPCC. Chapter 12: Harvested Wood Products. In Guidelines for National Greenhouse Gas Inventories, Volume 4: Agriculture, Forestry and Other Land Use; Eggleston, H.S., Buendia, L., Miwa, K., Ngara, T., Tanabe, K., Eds.; Intergovernmental Panel on Climate Change, pepared by the National Greenhouse Gas Inventories Programme; Institute for Global Environmental Strategies (IGES): Hayama, Japan, 2006. [Google Scholar]

- Rüter, S.; Werner, F.; Forsell, N.; Prins, C.; Vial, E.; Levet, A. ClimWood2030, Climate Benefits of Material Substitution by Forest Biomass and Harvested Wood Products: Perspective 2030—Final Report; Thünen Report 42; Johann Heinrich von Thünen-Institut: Braunschweig, Germany, 2016; Available online: https://literatur.thuenen.de/digbib_extern/dn056927.pdf (accessed on 27 December 2021)ISBN 978-3-86576-160-6.

- Leskinen, P.; Cardellini, G.; González-García, S.; Hurmekoski, E.; Sathre, R.; Seppälä, J.; Smyth, C.; Stern, T.; Verkerk, P.J. Substitution Effects of Wood-Based Products in Climate Change Mitigation; From Science to Policy; European Forest Institute: Joensuu, Finland, 2018; Volume 7, Available online: https://efi.int/sites/default/files/files/publication-bank/2019/efi_fstp_7_2018.pdf (accessed on 27 December 2021)ISBN 978-952-5980-70-7. [CrossRef]

- Sahoo, K.; Bergman, R.; Alanya-Rosenbaum, S.; Gu, H.; Liang, S. Life Cycle Assessment of Forest-Based Products: A Review. Sustainability 2019, 11, 4722. [Google Scholar] [CrossRef] [Green Version]

- R Core Team. R: A Language and Environment for Statistical Computing. R Version 4.0.2 (22.06.2020); R Foundation for Statistical Computing: Vienna, Austria, 2021; Available online: https://www.R-project.org/ (accessed on 28 December 2021).

- Hennenberg, K.; Boettcher, H.; Wiegmann, K.; Reise, J.; Fehrenbach, H. Kohlenstoffspeicherung in Wald Und Holzprodukten. AFZ-Der Wald 2019, 17, 36–39. Available online: https://co2-speichersaldo.de/media/Hennenberg_Oekobilanz_sl.pdf (accessed on 27 December 2021).

- Öko-Institut CO2-Speichersaldo. Available online: https://co2-speichersaldo.de/ (accessed on 27 December 2021).

- Fachagentur Nachwachsende Rohstoffe (FNR). Basisdaten Bioenergie Deutschland 2021; FNR: Gülzow-Prüzen, Germany, 2020; pp. 1–52. Available online: https://www.fnr.de/fileadmin/Projekte/2020/Mediathek/broschuere_basisdaten_bioenergie_2020_web.pdf (accessed on 28 December 2021).

- Pingoud, K.; Pohjola, J.; Valsta, L. Assessing the Integrated Climatic Impacts of Forestry and Wood Products. Silva Fenn. 2010, 44, 155–175. [Google Scholar] [CrossRef] [Green Version]

- Geng, A.; Yang, H.; Chen, J.; Hong, Y. Review of Carbon Storage Function of Harvested Wood Products and the Potential of Wood Substitution in Greenhouse Gas Mitigation. For. Policy Econ. 2017, 85, 192–200. [Google Scholar] [CrossRef]

- Hafner, A.; Rüter, S.; Ebert, S.; Schäfer, S.; König, H.; Cristofaro, L.; Diederichs, S.; Kleinhenz, M.; Krechel, M. Treibhausgasbilanzierung von Holzgebäuden—Umsetzung neuer Anforderungen an Ökobilanzen und Ermittlung empirischer Substitutionsfaktoren (THG-Holzbau); BMEL/BMUB: Bochum, Germany, 2017; Available online: https://literatur.thuenen.de/digbib_extern/dn058600.pdf (accessed on 28 December 2021)ISBN 978-3-00-055101-7.

- Leturcq, P. GHG Displacement Factors of Harvested Wood Products: The Myth of Substitution. Sci Rep. 2020, 10, 20752. [Google Scholar] [CrossRef] [PubMed]

- Pingoud, K.; Ekholm, T.; Soimakallio, S.; Helin, T. Carbon Balance Indicator for Forest Bioenergy Scenarios. GCB Bioenergy 2016, 8, 171–182. [Google Scholar] [CrossRef] [Green Version]

- Valade, A.; Luyssaert, S.; Vallet, P.; Njakou Djomo, S.; Jesus Van Der Kellen, I.; Bellassen, V. Carbon Costs and Benefits of France’s Biomass Energy Production Targets. Carbon Balance Manag. 2018, 13, 26. [Google Scholar] [CrossRef]

- Seppälä, J.; Heinonen, T.; Pukkala, T.; Kilpeläinen, A.; Mattila, T.; Myllyviita, T.; Asikainen, A.; Peltola, H. Effect of Increased Wood Harvesting and Utilization on Required Greenhouse Gas Displacement Factors of Wood-Based Products and Fuels. J. Environ. Manag. 2019, 247, 580–587. [Google Scholar] [CrossRef]

- Bentsen, N. Carbon Debt and Payback Time—Lost in the Forest? Renew. Sustain. Energy Rev. 2017, 73, 1211–1217. [Google Scholar] [CrossRef]

- Searchinger, T.D.; Beringer, T.; Holtsmark, B.; Kammen, D.M.; Lambin, E.F.; Lucht, W.; Raven, P.; van Ypersele, J.-P. Europe’s Renewable Energy Directive Poised to Harm Global Forests. Nat. Commun. 2018, 9, 3741. [Google Scholar] [CrossRef] [Green Version]

- Hurmekoski, E.; Smyth, C.E.; Stern, T.; Verkerk, P.J.; Asada, R. Substitution Impacts of Wood Use at the Market Level: A Systematic Review. Environ. Res. Lett. 2021, 16, 123004. [Google Scholar] [CrossRef]

- Myllyviita, T.; Soimakallio, S.; Judl, J.; Seppälä, J. Wood Substitution Potential in Greenhouse Gas Emission Reduction–Review on Current State and Application of Displacement Factors. For. Ecosyst. 2021, 8, 42. [Google Scholar] [CrossRef]

- IEA Bioenergy The Use of Forest Biomass for Climate Change Mitigation: Response to Statements of EASAC 2019. Available online: https://www.ieabioenergy.com/wp-content/uploads/2019/12/WoodyBiomass-Climate_EASACresponse_Nov2019.pdf (accessed on 28 December 2021).

- Norton, M.; Baldi, A.; Buda, V.; Carli, B.; Cudlin, P.; Jones, M.B.; Korhola, A.; Michalski, R.; Novo, F.; Oszlányi, J.; et al. Serious Mismatches Continue between Science and Policy in Forest Bioenergy. GCB Bioenergy 2019, 11, 1256–1263. [Google Scholar] [CrossRef] [Green Version]

- Camia, A.; Giuntoli, J.; Jonsson, K.; Robert, N.; Cazzaniga, N.; Jasinevičius, G.; Avitabile, V.; Grassi, G.; Barredo Cano, J.I.; Mubareka, S. The Use of Woody Biomass for Energy Production in the EU.EUR 30548 EN.; Publications Office of the European Union: Luxembourg, 2020; Available online: https://publications.jrc.ec.europa.eu/repository/handle/JRC122719 (accessed on 28 December 2021)ISBN 978-92-76-27866-5.

- Bolte, A.; Ammer, C.; Annighöfer, P.; Bauhus, J.; Eisenhauer, D.-R.; Geisler, C.; Leder, B.; Petercord, R.; Rock, J.; Seifert, T.; et al. Fakten Zum Thema: Wälder Und Klimaschutz. AFZ-Der Wald 2021, 11, 12–15. Available online: https://literatur.thuenen.de/digbib_extern/dn063660.pdf (accessed on 28 December 2021).

- Wissenschaftlicher Beirat für Waldpolitik. Geplante Änderung des Klimaschutzgesetzes Riskiert Reduktion der Potenziellen Klimaschutzbeiträge von Wald und Holz. Stellungnahme; Wissenschaftlicher Beirat Waldpolitik beim BMEL (Hrsg.): Berlin, Germany, 2021; Available online: https://www.bmel.de/SharedDocs/Downloads/DE/_Ministerium/Beiraete/waldpolitik/klimaschutzgesetz.pdf?__blob=publicationFile&v=5 (accessed on 28 December 2021).

- Wissenschaftlicher Beirat für Waldpolitik. Die Anpassung von Wäldern und Waldwirtschaft an den Klimawandel; Wissenschaftlicher Beirat für Waldpolitik: Berlin, Germany, 2021; Available online: https://www.bmel.de/SharedDocs/Downloads/DE/_Ministerium/Beiraete/waldpolitik/gutachten-wbw-anpassung-klimawandel.pdf?__blob=publicationFile&v=2 (accessed on 28 December 2021)ISBN 978-3-00-070408-6.

- Höltermann, A.; Reise, J.; Finck, P.; Riecken, U. Forstlich ungenutzte Wälder in Deutschland. Nat. Und Landsch. 2020, 95, 80–87. [Google Scholar] [CrossRef]

- Hennenberg, K.J.; Winter, S.; Reise, J. Die dritte Bundeswaldinventur aus Sicht des Naturschutzes. Nat. Und Landsch. 2017, 92, 201–208. [Google Scholar] [CrossRef]

- Luick, R.; Hennenberg, K.; Leuschner, C.; Grossmann, M.; Jedicke, E.; Schoof, N.; Waldenspuhl, T. Primeval, Natural and Commercial Forests in the Context Biodiversity and Climate Protection. Part 1: Functions for Biodiversity and as Carbon Sinks and Reservoirs. Nat. Und Landsch. 2021, 53, 12–25. Available online: https://www.nul-online.de/Primeval-Forests-Natural-Forests-and-Managed-Forests-in-the-Context-of-the-Biodiversity-Debate-and-Climate-Protection,QUlEPTcwMDQ4OTYmTUlEPTExMTE.html?UID=578458F2200F98A04A40433ACE61AC7F9EAED1984F18FB (accessed on 27 December 2021). [CrossRef]

- Devi, A.S. Influence of Trees and Associated Variables on Soil Organic Carbon: A Review. J. Ecol. Environ. 2021, 45, 5. [Google Scholar] [CrossRef]

- Müller, J. Die forsthydrologische Forschung im Nordostdeutschen Tiefland: Veranlassung, Methoden, Ergebnisse und Perspektiven; University of Rostock: Rostock, Germany, 2019; Available online: https://www.openagrar.de/receive/openagrar_mods_00055651 (accessed on 28 December 2021).

| Use | Product | Wood Input from Forests * | Proportion of Wood in the Product | GHG Emissions along the Production Chain (PCWP) |

|---|---|---|---|---|

| (kg Woodair-dry kg Product−1) | (kg CO2-eq. kg Product−1) | |||

| Material | Construction wood | 1.04 | 1.00 | 0.18 |

| Chipboard | 1.09 | 0.95 | 0.40 | |

| MDF ** | 0.64 | 0.56 | 2.68 | |

| Energy | Wood chips | 1.00 | 1.00 | 0.04 |

| Pellets | 1.00 | 1.00 | 0.19 | |

| Firewood | 1.00 | 1.00 | 0.07 |

| Product | Carbon Content of Wood [30] | Carbon Storage Capacity of Products * | CO2 Storage Capacity of Products (CSWP) ** |

|---|---|---|---|

| (kg C kg Woodair-dry−1) | (kg C kg Product−1) | (kg CO2-eq. kg Product−1) | |

| Construction wood | 0.50 | −0.50 | −1.83 |

| Chipboard | 0.50 | −0.48 | −1.74 |

| MDF *** | 0.50 | −0.28 | −1.03 |

| Level | Carbon Storage Balance in Forests (CSBF) | Note | ||

|---|---|---|---|---|

| (t CO2-eq. m−3) | (t CO2-eq. tair-dry−1) * | (g CO2-eq. MJ−1) ** | ||

| no-CSBF | 0.00 | 0.00 | 0.00 | No CSBF: The CSBF is not taken into account. This reflects the assumption that the removal of the wood has no effect on the development of the carbon stock in the forest. |

| low-CSBF | 0.25 | 0.52 | 33.5 | Low CSBF: Lower threshold of the CSBF according to data reported in [6,10], see Figure 1 |

| med-CSBF | 0.62 | 1.28 | 82.6 | Medium CSBF: Upper threshold of the CSBF according to data reported in [6,10], see Figure 1 |

| high-CSBF | 1.15 | 2.37 | 152.9 | High CSBF: Higher threshold of the range of the CSBF according to modelling results (period: 2020–2050) [35,36]) |

| Use | Product | no-CSBF * | low-CSBF * | med-CSBF * | high-CSBF * |

|---|---|---|---|---|---|

| (kg CO2-eq. kg Product−1) | |||||

| Material | Construction wood | 0.00 | 0.54 | 1.33 | 2.46 |

| Chipboard | 0.00 | 0.57 | 1.40 | 2.58 | |

| MDF ** | 0.00 | 0.33 | 0.82 | 1.52 | |

| Energy | Wood chips | 0.00 | 0.52 | 1.28 | 2.37 |

| Pellets | 0.00 | 0.52 | 1.28 | 2.37 | |

| Firewood | 0.00 | 0.52 | 1.28 | 2.37 | |

| Material Use | |||||

|---|---|---|---|---|---|

| Wood Product | Substitute | Proportion [23] | Substitution Factor [23] | GHG Emissions Substitute [23] | Substitution Effect (SP) * |

| (kg Substitute kg Wood Product−1) | (kg CO2-eq. kg Substitute−1) | (kg CO2-eq. kg Wood Product−1) | |||

| Construction wood | Steel | 0.50 | 2.00 | 1.72 | −1.72 |

| Concrete | 0.50 | 4.80 | 0.125 | −0.30 | |

| Weighted total | −2.02 | ||||

| Chipboard | Plasterboard | 0.50 | 0.80 | 0.34 | −0.14 |

| Steel sheets | 0.40 | 1.20 | 1.72 | −0.83 | |

| Lightweight concrete elements | 0.10 | 8.00 | 1.17 | −0.94 | |

| Weighted total | −1.87 | ||||

| MDF *** | Plastic (PVC) | 1.00 | 1.0 | 1.56 ** | −1.56 |

| Energy Use | |||||

| Wood product | Substitute | Proportion [27] | Substitution Factor [27] | GHG Emissions Substitute [27] | Substitution Effect (SP) **** |

| (MJ Substitute MJ Wood Product−1) | (g CO2-eq. MJ Substitute−1) | (kg CO2-eq. kg Wood Product−1) | |||

| Energy wood ***** | Fossil fuel mix | 1.0 | 1.0 | 80.0 | −1.20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fehrenbach, H.; Bischoff, M.; Böttcher, H.; Reise, J.; Hennenberg, K.J. The Missing Limb: Including Impacts of Biomass Extraction on Forest Carbon Stocks in Greenhouse Gas Balances of Wood Use. Forests 2022, 13, 365. https://0-doi-org.brum.beds.ac.uk/10.3390/f13030365

Fehrenbach H, Bischoff M, Böttcher H, Reise J, Hennenberg KJ. The Missing Limb: Including Impacts of Biomass Extraction on Forest Carbon Stocks in Greenhouse Gas Balances of Wood Use. Forests. 2022; 13(3):365. https://0-doi-org.brum.beds.ac.uk/10.3390/f13030365

Chicago/Turabian StyleFehrenbach, Horst, Mascha Bischoff, Hannes Böttcher, Judith Reise, and Klaus Josef Hennenberg. 2022. "The Missing Limb: Including Impacts of Biomass Extraction on Forest Carbon Stocks in Greenhouse Gas Balances of Wood Use" Forests 13, no. 3: 365. https://0-doi-org.brum.beds.ac.uk/10.3390/f13030365