Highly Transparent Red Organic Light-Emitting Diodes with AZO/Ag/AZO Multilayer Electrode

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

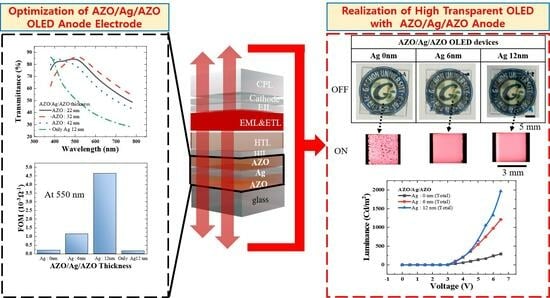

3.1. Optimization of the Electro-Optical Properties of the AZO/Ag/AZO Transparent Electrodes

3.2. Design of a Transparent OLED Structure Based on the AZO–Ag–AZO

3.3. Optimization and Analysis of the AZO–Ag–AZO-Based Transparent OLED

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yang, S.; M. R., A.R.; Kaminski, J.; Pepin, H. Opportunities for Industry 4.0 to Support Remanufacturing. Appl. Sci. 2018, 8, 1177. [Google Scholar] [CrossRef]

- Dash, B.; Ansari, M.F.; Swayamsiddha, S. Fusion of Artificial Intelligence and 5G in Defining Future UAV Technologies—A Review. In Proceedings of the 2023 International Conference on Device Intelligence, Computing and Communication Technologies, (DICCT), Dehradun, India, 17–18 March 2023; pp. 312–316. [Google Scholar]

- Farshid, M.; Paschen, J.; Eriksson, T.; Kietzmann, J. Go boldly!: Explore augmented reality (AR), virtual reality (VR), and mixed reality (MR) for business. Bus. Horiz. 2018, 61, 657–663. [Google Scholar] [CrossRef]

- Min, J.; Tu, J.; Xu, C.; Lukas, H.; Shin, S.; Yang, Y.; Solomon, S.A.; Mukasa, D.; Gao, W. Skin-Interfaced Wearable Sweat Sensors for Precision Medicine. Chem. Rev. 2023, 123, 5049–5138. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Lu, K.; Xu, Z.; Lin, Z.; Ning, H.; Qiu, T.; Yang, Z.; Zheng, H.; Yao, R.; Peng, J. Recent Developments in Flexible Transparent Electrode. Crystals 2021, 11, 511. [Google Scholar] [CrossRef]

- Jeon, Y.; Choi, H.-R.; Kwon, J.H.; Choi, S.; Nam, K.M.; Park, K.-C.; Choi, K.C. Sandwich-structure transferable free-form OLEDs for wearable and disposable skin wound photomedicine. Light Sci. Appl. 2019, 8, 114. [Google Scholar] [CrossRef] [PubMed]

- Jeon, Y.; Choi, H.-R.; Lim, M.; Choi, S.; Kim, H.; Kwon, J.H.; Park, K.-C.; Choi, K.C. A Wearable Photobiomodulation Patch Using a Flexible Red-Wavelength OLED and Its In Vitro Differential Cell Proliferation Effects. Adv. Mater. Technol. 2018, 3, 1700391. [Google Scholar] [CrossRef]

- Choi, S.; Jeon, Y.; Kwon, J.H.; Ihm, C.; Kim, S.Y.; Choi, K.C. Wearable Photomedicine for Neonatal Jaundice Treatment Using Blue Organic Light-Emitting Diodes (OLEDs): Toward Textile-Based Wearable Phototherapeutics. Adv. Sci. 2022, 9, 2204622. [Google Scholar] [CrossRef]

- Ku, M.; Hwang, J.C.; Oh, B.; Park, J.-U. Smart Sensing Systems Using Wearable Optoelectronics. Adv. Intell. Syst. 2020, 2, 1900144. [Google Scholar] [CrossRef]

- Hu, Y.; Diao, X.; Wang, C.; Hao, W.; Wang, T. Effects of heat treatment on properties of ITO films prepared by rf magnetron sputtering. Vacuum 2004, 75, 183–188. [Google Scholar] [CrossRef]

- Lin, H.K.; Chung, B.F. Effects of thermal treatment on optoelectrical properties of AZO/Ag-Mg-Al thin films. Appl. Surf. Sci. 2019, 467–468, 249–254. [Google Scholar] [CrossRef]

- Liu, S.; Liu, W.; Yu, J.; Zhang, W.; Zhang, L.; Wen, X.; Yin, Y.; Xie, W. Silver/germanium/silver: An effective transparent electrode for flexible organic light-emitting devices. J. Mater. Chem. C 2014, 2, 835–840. [Google Scholar] [CrossRef]

- Zhang, Q.; Xu, M.; Zhou, L.; Liu, S.; Wang, W.; Zhang, L.; Xie, W.; Yu, C. A flexible organic mechanoluminophore device. Nat. Commun. 2023, 14, 1257. [Google Scholar] [CrossRef] [PubMed]

- Pan, T.; Liu, S.; Zhang, L.; Xie, W.; Yu, C. A flexible, multifunctional, optoelectronic anticounterfeiting device from high-performance organic light-emitting paper. Light Sci. Appl. 2022, 11, 59. [Google Scholar] [CrossRef] [PubMed]

- Han, H.; Theodore, N.D.; Alford, T.L. Improved conductivity and mechanism of carrier transport in zinc oxide with embedded silver layer. J. Appl. Phys. 2008, 103, 013708. [Google Scholar] [CrossRef]

- Chae, H.; Park, Y.; Jo, Y.; Jeon, Y.; Lee, H.J.; Yoo, S.; Choi, K.C. Blue Transparent OLEDs with High Stability and Transmittance for Modulating Sleep Disorders. Adv. Mater. Interfaces 2023, 10, 2202443. [Google Scholar] [CrossRef]

- Yu, S.; Santoro, G.; Yao, Y.; Babonneau, D.; Schwartzkopf, M.; Zhang, P.; Vayalil, S.K.; Wessels, P.; Döhrmann, R.; Drescher, M.; et al. Following the Island Growth in Real Time: Ag Nanocluster Layer on Alq3 Thin Film. J. Phys. Chem. C 2015, 119, 4406–4413. [Google Scholar] [CrossRef]

- Han, Y.C.; Lim, M.S.; Park, J.H.; Choi, K.C. Optical Effect of Surface Morphology of Ag on Multilayer Electrode Applications for OLEDs. IEEE Electron Device Lett. 2014, 35, 238–240. [Google Scholar] [CrossRef]

- Palik, E.D. Handbook of Optical Constants of Solids; Academic Press: Cambridge, MA, USA, 1998; Volume 3. [Google Scholar]

- Haacke, G. New figure of merit for transparent conductors. J. Appl. Phys. 1976, 47, 4086–4089. [Google Scholar] [CrossRef]

- Zhang, C.; Ji, C.; Park, Y.-B.; Guo, L.J. Thin-Metal-Film Based Transparent Conductors: Material Preparation, Optical Design, and Device Applications. Adv. Opt. Mater. 2021, 9, 2001298. [Google Scholar] [CrossRef]

- Aonuma, M.; Oyamada, T.; Sasabe, H.; Miki, T.; Adachi, C. Material design of hole transport materials capable of thick-film formation in organic light emitting diodes. Appl. Phys. Lett. 2007, 90, 183503. [Google Scholar] [CrossRef]

- Chen, T.L.; Betancur, R.; Ghosh, D.S.; Martorell, J.; Pruneri, V. Efficient polymer solar cell employing an oxidized Ni capped Al:ZnO anode without the need of additional hole-transporting-layer. Appl. Phys. Lett. 2012, 100, 013310. [Google Scholar] [CrossRef]

- Choo, D.C.; Im, H.C.; Lee, D.U.; Kim, T.W.; Han, J.W.; Choi, E.H. Effective barrier height and work function of Mg:Ag thin films with a low Mg concentration acting as cathodes in high-efficiency organic light emitting devices. Solid State Commun. 2005, 136, 365–368. [Google Scholar] [CrossRef]

- Dahal, E.; Allemeier, D.; Isenhart, B.; Cianciulli, K.; White, M.S. Characterization of higher harmonic modes in Fabry–Pérot microcavity organic light emitting diodes. Sci. Rep. 2021, 11, 8456. [Google Scholar] [CrossRef] [PubMed]

- Lee, D.; Cho, E.-S.; Jeon, Y.; Kwon, S.J. Characterization of the material and electrical properties depending on the Mg:Ag ratio as a cathode for TEOLED. Mater. Chem. Phys. 2023, 303, 127742. [Google Scholar] [CrossRef]

- Huseynova, G.; Lee, J.H.; Kim, Y.H.; Lee, J. Transparent Organic Light-Emitting Diodes: Advances, Prospects, and Challenges. Adv. Opt. Mater. 2021, 9, 2002040. [Google Scholar] [CrossRef]

- Ciobotaru, I.C.; Enculescu, M.; Polosan, S.; Enculescu, I.; Ciobotaru, C.C. Organic Light-Emitting Diodes with Electrospun Electrodes for Double-Side Emissions. Micromachines 2023, 14, 543. [Google Scholar] [CrossRef]

- Lim, S.F.; Ke, L.; Wang, W.; Chua, S.J. Correlation between dark spot growth and pinhole size in organic light-emitting diodes. Appl. Phys. Lett. 2001, 78, 2116–2118. [Google Scholar] [CrossRef]

- Bingel, A.; Stenzel, O.; Naujok, P.; Müller, R.; Shestaeva, S.; Steglich, M.; Schulz, U.; Kaiser, N.; Tünnermann, A. AZO/Ag/AZO transparent conductive films: Correlation between the structural, electrical, and optical properties and development of an optical model. Opt. Mater. Express 2016, 6, 3217. [Google Scholar] [CrossRef]

- Silva, H.D.O.X.; Faraco, T.A.; Maciel, I.O.; Quirino, W.G.; Fragneaud, B.; Pereira, P.G.; Legnani, C. High optoelectronic quality of AZO films grown by RF-magnetron sputtering for organic electronics applications. Semicond. Sci. Technol. 2023, 38, 065004. [Google Scholar] [CrossRef]

- Liu, H.; Liu, Y.-F.; Xiong, P.-P.; Chen, P.; Li, H.-Y.; Hou, J.-W.; Kang, B.-N.; Duan, Y. Aluminum-Doped Zinc Oxide Transparent Electrode Prepared by Atomic Layer Deposition for Organic Light Emitting Devices. IEEE Trans. Nanotechnol. 2017, 16, 634–638. [Google Scholar] [CrossRef]

- Dugrenil, B.; Séguy, I.; Lee, H.-Y.; Camps, T.; Lin, Y.-C.; Doucet, J.B.; Chiu, Y.-S.; Salvagnac, L.; Bedel-Pereira, E.; Ternisien, M. AZO electrodes deposited by atomic layer deposition for OLED fabrication. In Proceedings of the Organic Photonics VI, Brussels, Belgium, 13–17 April 2014; pp. 127–132. [Google Scholar]

- Choi, Y.-J.; Gong, S.C.; Park, C.-S.; Lee, H.-S.; Jang, J.G.; Chang, H.J.; Yeom, G.Y.; Park, H.-H. Improved Performance of Organic Light-Emitting Diodes Fabricated on Al-Doped ZnO Anodes Incorporating a Homogeneous Al-Doped ZnO Buffer Layer Grown by Atomic Layer Deposition. ACS Appl. Mater. Interfaces 2013, 5, 3650–3655. [Google Scholar] [CrossRef] [PubMed]

- Jiang, X.; Wong, F.L.; Fung, M.K.; Lee, S.T. Aluminum-doped zinc oxide films as transparent conductive electrode for organic light-emitting devices. Appl. Phys. Lett. 2003, 83, 1875–1877. [Google Scholar] [CrossRef]

- Zhao, J.; Xie, S.; Han, S.; Yang, Z.; Ye, L.; Yang, T. Organic light-emitting diodes with AZO films as electrodes. Synth. Met. 2000, 114, 251–254. [Google Scholar] [CrossRef]

- Jeong, J.-A.; Shin, H.-S.; Choi, K.-H.; Kim, H.-K. Flexible Al-doped ZnO films grown on PET substrates using linear facing target sputtering for flexible OLEDs. J. Phys. D Appl. Phys. 2010, 43, 465403. [Google Scholar] [CrossRef]

- Jha, J.K.; Sun, W.; Du, J.; Shepherd, N.D. Mechanisms of AZO workfunction tuning for anode use in OLEDs: Surface dipole manipulation with plasma treatments versus nanoscale WOx and VOx interfacial layers. J. Appl. Phys. 2017, 121, 185304. [Google Scholar] [CrossRef]

- Chauhan, R.N.; Singh, C.; Anand, R.S.; Kumar, J. Thickness-Dependent Structural, Optical, and Electrical Characteristics of ZnO:Al Thin Films and Application in OLEDs. IEEE Trans. Electron Devices 2014, 61, 3775–3782. [Google Scholar] [CrossRef]

- Liu, X.-N.; Gao, J.; Gong, J.-H.; Wang, W.-X.; Chen, S.-C.; Dai, M.-J.; Lin, S.-S.; Shi, Q.; Sun, H. Optoelectronic properties of an AZO/Ag multilayer employed as a flexible electrode. Ceram. Int. 2021, 47, 5671–5676. [Google Scholar] [CrossRef]

- Torrisi, G.; Crupi, I.; Mirabella, S.; Terrasi, A. Robustness and electrical reliability of AZO/Ag/AZO thin film after bending stress. Sol. Energy Mater. Sol. Cells 2017, 165, 88–93. [Google Scholar] [CrossRef]

- Lei, P.-H.; Hsu, C.-M.; Fan, Y.-S. Flexible organic light-emitting diodes on a polyestersulfone (PES) substrate using Al-doped ZnO anode grown by dual-plasma-enhanced metalorganic deposition system. Org. Electron. 2013, 14, 236–249. [Google Scholar] [CrossRef]

| AZO/Ag/AZO 0 nm Ag | AZO/Ag/AZO 6 nm Ag | AZO/Ag/AZO 12 nm Ag | |

|---|---|---|---|

| w/o CPL (simulation) | 40.36 | 43.01 | 40.52 |

| CPL 35 nm (simulation) | 56.05 | 58.63 | 53.18 |

| CPL 45 nm (simulation) | 58.30 | 60.86 | 54.66 |

| CPL 55 nm (simulation) | 57.98 | 60.75 | 54.28 |

| CPL 45 nm (Measured) | 56.19 | 50.23 | 54.51 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, D.; Song, M.S.; Seo, Y.H.; Lee, W.W.; Kim, Y.W.; Park, M.; Shin, Y.J.; Kwon, S.J.; Jeon, Y.; Cho, E.-S. Highly Transparent Red Organic Light-Emitting Diodes with AZO/Ag/AZO Multilayer Electrode. Micromachines 2024, 15, 146. https://0-doi-org.brum.beds.ac.uk/10.3390/mi15010146

Lee D, Song MS, Seo YH, Lee WW, Kim YW, Park M, Shin YJ, Kwon SJ, Jeon Y, Cho E-S. Highly Transparent Red Organic Light-Emitting Diodes with AZO/Ag/AZO Multilayer Electrode. Micromachines. 2024; 15(1):146. https://0-doi-org.brum.beds.ac.uk/10.3390/mi15010146

Chicago/Turabian StyleLee, Dongwoon, Min Seok Song, Yong Hyeok Seo, Won Woo Lee, Young Woo Kim, Minseong Park, Ye Ji Shin, Sang Jik Kwon, Yongmin Jeon, and Eou-Sik Cho. 2024. "Highly Transparent Red Organic Light-Emitting Diodes with AZO/Ag/AZO Multilayer Electrode" Micromachines 15, no. 1: 146. https://0-doi-org.brum.beds.ac.uk/10.3390/mi15010146