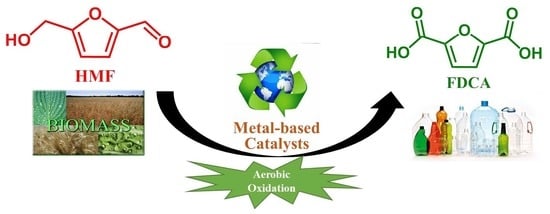

Recent Developments in Metal-Based Catalysts for the Catalytic Aerobic Oxidation of 5-Hydroxymethyl-Furfural to 2,5-Furandicarboxylic Acid

Abstract

:1. Introduction

2. Noble Metal Catalysts for FDCA Production

2.1. Au-Based Catalysts

2.2. Pt-Based Catalysts

2.3. Pd-Based Catalysts

2.4. Other Noble Metal Catalysts

3. Non-Noble Metal Catalysts for FDCA Production

4. Conclusions and Perspectives

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bozell, J.J. Connecting Biomass and Petroleum Processing with a Chemical Bridge. Science 2010, 329, 522–523. [Google Scholar] [CrossRef] [PubMed]

- Corma, A.; Iborra, S.; Velty, A. Chemical routes for the transformation of biomass into chemicals. Chem. Rev. 2007, 107, 2411–2502. [Google Scholar] [CrossRef] [PubMed]

- Gallezot, P. Conversion of biomass to selected chemical products. Chem. Soc. Rev. 2012, 41, 1538–1558. [Google Scholar] [CrossRef] [PubMed]

- H. Clark, J.; EI Deswarte, F.; J. Farmer, T. The integration of green chemistry into future biorefineries. Biofuels Bioprod. Biorefin. 2009, 3, 72–90. [Google Scholar] [CrossRef]

- Roy Goswami, S.; Dumont, M.-J.; Raghavan, V. Starch to value added biochemicals. Starch Stärke 2016, 68, 274–286. [Google Scholar] [CrossRef]

- Morais, A.R.; da Costa Lopes, A.M.; Bogel-Łukasik, R. Carbon dioxide in biomass processing: Contributions to the green biorefinery concept. Chem. Rev. 2014, 115, 3–27. [Google Scholar] [CrossRef] [Green Version]

- Van Putten, R.-J.; van der Waal, J.C.; de Jong, E.; Rasrendra, C.B.; Heeres, H.J.; de Vries, J.G. Hydroxymethylfurfural, A Versatile Platform Chemical Made from Renewable Resources. Chem. Rev. 2013, 113, 1499–1597. [Google Scholar] [CrossRef]

- Fukuoka, A.; Dhepe, P.L. Catalytic Conversion of Cellulose into Sugar Alcohols. Angew. Chem. Int. Ed. 2006, 45, 5161–5163. [Google Scholar] [CrossRef]

- Deng, W.; Zhang, Q.; Wang, Y. Polyoxometalates as efficient catalysts for transformations of cellulose into platform chemicals. Dalton Trans. 2012, 41, 9817–9831. [Google Scholar] [CrossRef]

- Rinaldi, R.; Schüth, F. Acid Hydrolysis of Cellulose as the Entry Point into Biorefinery Schemes. ChemSusChem 2009, 2, 1096–1107. [Google Scholar] [CrossRef]

- Pal, P.; Saravanamurugan, S. Recent Advances in the Development of 5-Hydroxymethylfurfural Oxidation with Base (Nonprecious)-Metal-Containing Catalysts. ChemSusChem 2019, 12, 145–163. [Google Scholar] [CrossRef]

- Werpy, T.; Petersen, G. Top Value Added Chemicals from Biomass: Volume I—Results of Screening for Potential Candidates from Sugars and Synthesis Gas; National Renewable Energy Lab.: Golden, CO, USA, 2004.

- Haworth, W.N.; Jones, W.G.M.; Wiggins, L.F. 1. The conversion of sucrose into furan compounds. Part II. Some 2: 5-disubstituted tetrahydrofurans and their products of ring scission. J. Chem. Soc. 1945, 10, 1–4. [Google Scholar] [CrossRef]

- Chen, M.Y.; Ike, M.; Fujita, M. Acute toxicity, mutagenicity, and estrogenicity of bisphenol-A and other bisphenols. Environ. Toxicol. Int. J. 2002, 17, 80–86. [Google Scholar] [CrossRef] [PubMed]

- Swan, S.H. Environmental phthalate exposure in relation to reproductive outcomes and other health endpoints in humans. Environ. Res. 2008, 108, 177–184. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ravindranath, K.; Mashelkar, R.A. Polyethylene terephthalate-I. Chemistry, thermodynamics and transport properties. Chem. Eng. Sci. 1986, 41, 2197–2214. [Google Scholar] [CrossRef]

- Chen, G.; van Straalen, N.M.; Roelofs, D. The ecotoxicogenomic assessment of soil toxicity associated with the production chain of 2,5-furandicarboxylic acid (FDCA), a candidate bio-based green chemical building block. Green Chem. 2016, 18, 4420–4431. [Google Scholar] [CrossRef]

- Lancefield, C.S.; Teunissen, L.W.; Weckhuysen, B.M.; Bruijnincx, P.C. Iridium-catalysed primary alcohol oxidation and hydrogen shuttling for the depolymerisation of lignin. Green Chem. 2018, 20, 3214–3221. [Google Scholar] [CrossRef]

- De Jong, E.; Dam, M.; Sipos, L.; Gruter, G.-J. Furandicarboxylic acid (FDCA), a versatile building block for a very interesting class of polyesters. In Biobased Monomers, Polymers, and Materials; ACS Symposium Series; American Chemical Society: Washington, DC, USA, 2012; pp. 1–13. [Google Scholar]

- Pan, T.; Deng, J.; Xu, Q.; Zuo, Y.; Guo, Q.X.; Fu, Y. Catalytic Conversion of Furfural into a 2,5-Furandicarboxylic Acid-Based Polyester with Total Carbon Utilization. ChemSusChem 2013, 6, 47–50. [Google Scholar] [CrossRef]

- Ball, G.L.; McLellan, C.J.; Bhat, V.S. Toxicological review and oral risk assessment of terephthalic acid (TPA) and its esters: A category approach. Crit. Rev. Toxicol. 2012, 42, 28–67. [Google Scholar] [CrossRef]

- Eerhart, A.J.J.E.; Faaij, A.P.C.; Patel, M.K. Replacing fossil based PET with biobased PEF; process analysis, energy and GHG balance. Energy Environ. Sci. 2012, 5, 6407–6422. [Google Scholar] [CrossRef]

- Fittig, R.; Heinzelmann, H. Production of 2,5-furandicarboxylic acid by the reaction of fuming hydrobromic acid with mucic acid under pressure. Chem. Ber. 1876, 9, 1198. [Google Scholar]

- Rose, M.; Weber, D.; Lotsch, B.V.; Kremer, R.K.; Goddard, R.; Palkovits, R. Biogenic metal–organic frameworks: 2,5-Furandicarboxylic acid as versatile building block. Microporous Mesoporous Mater. 2013, 181, 217–221. [Google Scholar] [CrossRef] [Green Version]

- Chadderdon, D.J.; Xin, L.; Qi, J.; Qiu, Y.; Krishna, P.; More, K.L.; Li, W. Electrocatalytic oxidation of 5-hydroxymethylfurfural to 2,5-furandicarboxylic acid on supported Au and Pd bimetallic nanoparticles. Green Chem. 2014, 16, 3778–3786. [Google Scholar] [CrossRef]

- Wang, K.F.; Liu, C.L.; Sui, K.Y.; Guo, C.; Liu, C.Z. Efficient Catalytic Oxidation of 5-Hydroxymethylfurfural to 2,5-Furandicarboxylic Acid by Magnetic Laccase Catalyst. ChemBioChem 2018, 19, 654–659. [Google Scholar] [CrossRef] [PubMed]

- Ban, H.; Pan, T.; Cheng, Y.; Wang, L.; Li, X. Solubilities of 2,5-Furandicarboxylic Acid in Binary Acetic Acid + Water, Methanol + Water, and Ethanol + Water Solvent Mixtures. J. Chem. Eng. Data 2018, 63, 1987–1993. [Google Scholar] [CrossRef]

- Sajid, M.; Zhao, X.; Liu, D. Production of 2, 5-furandicarboxylic acid (FDCA) from 5-hydroxymethylfurfural (HMF): Recent progress focusing on the chemical-catalytic routes. Green Chem. 2018, 20, 5427–5453. [Google Scholar] [CrossRef]

- Xuan, Y.; He, R.; Han, B.; Wu, T.; Wu, Y. Catalytic Conversion of Cellulose into 5-Hydroxymethylfurfural Using [PSMIM] HSO4 and ZnSO4·7H2O Co-catalyst in Biphasic System. Waste Biomass Valoriz. 2018, 9, 401–408. [Google Scholar] [CrossRef]

- Dijkman, W.P.; Groothuis, D.E.; Fraaije, M.W. Enzyme-Catalyzed Oxidation of 5-Hydroxymethylfurfural to Furan-2,5-dicarboxylic Acid. Angew. Chem. Int. Ed. 2014, 53, 6515–6518. [Google Scholar] [CrossRef]

- Chen, C.T.; Nguyen, C.V.; Wang, Z.Y.; Bando, Y.; Yamauchi, Y.; Bazziz, M.T.S.; Fatehmulla, A.; Farooq, W.A.; Yoshikawa, T.; Masuda, T. Hydrogen Peroxide Assisted Selective Oxidation of 5-Hydroxymethylfurfural in Water under Mild Conditions. ChemCatChem 2018, 10, 361–365. [Google Scholar] [CrossRef]

- Nam, D.-H.; Taitt, B.J.; Choi, K.-S. Copper-Based Catalytic Anodes To Produce 2,5-Furandicarboxylic Acid, a Biomass-Derived Alternative to Terephthalic Acid. ACS Catal. 2018, 8, 1197–1206. [Google Scholar] [CrossRef]

- Xu, S.; Zhou, P.; Zhang, Z.; Yang, C.; Zhang, B.; Deng, K.; Bottle, S.; Zhu, H. Selective Oxidation of 5-Hydroxymethylfurfural to 2,5-Furandicarboxylic Acid Using O2 and a Photocatalyst of Co-thioporphyrazine Bonded to g-C3N4. J. Am. Chem. Soc. 2017, 139, 14775–14782. [Google Scholar] [CrossRef] [PubMed]

- Hutchings, G.J. Vapor phase hydrochlorination of acetylene: Correlation of catalytic activity of supported metal chloride catalysts. J. Catal. 1985, 96, 292–295. [Google Scholar] [CrossRef]

- Masatake, H.; Tetsuhiko, K.; Hiroshi, S.; Nobumasa, Y. Novel Gold Catalysts for the Oxidation of Carbon Monoxide at a Temperature far Below 0 °C. Chem. Lett. 1987, 16, 405–408. [Google Scholar]

- Casanova, O.; Iborra, S.; Corma, A. Biomass into Chemicals: Aerobic Oxidation of 5-Hydroxymethyl-2-furfural into 2,5-Furandicarboxylic Acid with Gold Nanoparticle Catalysts. ChemSusChem 2009, 2, 1138–1144. [Google Scholar] [CrossRef] [PubMed]

- Lolli, A.; Amadori, R.; Lucarelli, C.; Cutrufello, M.G.; Rombi, E.; Cavani, F.; Albonetti, S. Hard-template preparation of Au/CeO2 mesostructured catalysts and their activity for the selective oxidation of 5-hydroxymethylfurfural to 2,5-furandicarboxylic acid. Microporous Mesoporous Mater. 2016, 226, 466–475. [Google Scholar] [CrossRef]

- Kim, M.; Su, Y.; Fukuoka, A.; Hensen, E.J.M.; Nakajima, K. Aerobic Oxidation of 5-(Hydroxymethyl)furfural Cyclic Acetal Enables Selective Furan-2,5-dicarboxylic Acid Formation with CeO2-Supported Gold Catalyst. Angew. Chem. Int. Ed. 2018, 57, 8235–8239. [Google Scholar] [CrossRef]

- Gorbanev, Y.Y.; Klitgaard, S.K.; Woodley, J.M.; Christensen, C.H.; Riisager, A. Gold-Catalyzed Aerobic Oxidation of 5-Hydroxymethylfurfural in Water at Ambient Temperature. ChemSusChem 2009, 2, 672–675. [Google Scholar] [CrossRef]

- Cai, J.; Ma, H.; Zhang, J.; Song, Q.; Du, Z.; Huang, Y.; Xu, J. Gold Nanoclusters Confined in a Supercage of Y Zeolite for Aerobic Oxidation of HMF under Mild Conditions. Chem. Eur. J. 2013, 19, 14215–14223. [Google Scholar] [CrossRef]

- Pasini, T.; Piccinini, M.; Blosi, M.; Bonelli, R.; Albonetti, S.; Dimitratos, N.; Lopez-Sanchez, J.A.; Sankar, M.; He, Q.; Kiely, C.J.; et al. Selective oxidation of 5-hydroxymethyl-2-furfural using supported gold–copper nanoparticles. Green Chem. 2011, 13, 2091–2099. [Google Scholar] [CrossRef]

- Villa, A.; Schiavoni, M.; Campisi, S.; Veith, G.M.; Prati, L. Pd-modified Au on Carbon as an Effective and Durable Catalyst for the Direct Oxidation of HMF to 2,5-Furandicarboxylic Acid. ChemSusChem 2013, 6, 609–612. [Google Scholar] [CrossRef]

- Gupta, N.K.; Nishimura, S.; Takagaki, A.; Ebitani, K. Hydrotalcite-supported gold-nanoparticle-catalyzed highly efficient base-free aqueous oxidation of 5-hydroxymethylfurfural into 2,5-furandicarboxylic acid under atmospheric oxygen pressure. Green Chem. 2011, 13, 824–827. [Google Scholar] [CrossRef]

- Gao, T.; Gao, T.; Fang, W.; Cao, Q. Base-free aerobic oxidation of 5-hydroxymethylfurfural to 2,5-furandicarboxylic acid in water by hydrotalcite-activated carbon composite supported gold catalyst. Mol. Catal. 2017, 439, 171–179. [Google Scholar] [CrossRef]

- Wan, X.; Zhou, C.; Chen, J.; Deng, W.; Zhang, Q.; Yang, Y.; Wang, Y. Base-Free Aerobic Oxidation of 5-Hydroxymethyl-furfural to 2,5-Furandicarboxylic Acid in Water Catalyzed by Functionalized Carbon Nanotube-Supported Au–Pd Alloy Nanoparticles. ACS Catal. 2014, 4, 2175–2185. [Google Scholar] [CrossRef]

- Bonincontro, D.; Lolli, A.; Villa, A.; Prati, L.; Dimitratos, N.; Veith, G.M.; Chinchilla, L.E.; Botton, G.A.; Cavani, F.; Albonetti, S. AuPd-nNiO as an effective catalyst for the base-free oxidation of HMF under mild reaction conditions. Green Chem. 2019, 21, 4090–4099. [Google Scholar] [CrossRef]

- Gao, Z.; Xie, R.; Fan, G.; Yang, L.; Li, F. Highly Efficient and Stable Bimetallic AuPd over La-Doped Ca–Mg–Al Layered Double Hydroxide for Base-Free Aerobic Oxidation of 5-Hydroxymethylfurfural in Water. ACS Sustain. Chem. Eng. 2017, 5, 5852–5861. [Google Scholar] [CrossRef]

- Davis, S.E.; Zope, B.N.; Davis, R.J. On the mechanism of selective oxidation of 5-hydroxymethylfurfural to 2,5-furandicarboxylic acid over supported Pt and Au catalysts. Green Chem. 2012, 14, 143–147. [Google Scholar] [CrossRef]

- Davis, S.E.; Benavidez, A.D.; Gosselink, R.W.; Bitter, J.H.; de Jong, K.P.; Datye, A.K.; Davis, R.J. Kinetics and mechanism of 5-hydroxymethylfurfural oxidation and their implications for catalyst development. J. Mol. Catal. A 2014, 388, 123–132. [Google Scholar] [CrossRef]

- Zope, B.N.; Hibbitts, D.D.; Neurock, M.; Davis, R.J. Reactivity of the gold/water interface during selective oxidation catalysis. Science 2010, 330, 74–78. [Google Scholar] [CrossRef] [Green Version]

- Zope, B.N.; Davis, S.E.; Davis, R.J. Influence of reaction conditions on diacid formation during Au-catalyzed oxidation of glycerol and hydroxymethylfurfural. Top. Catal. 2012, 55, 24–32. [Google Scholar] [CrossRef]

- Verdeguer, P.; Merat, N.; Gaset, A. Oxydation catalytique du HMF en acide 2,5-furane dicarboxylique. J. Mol. Catal. 1993, 85, 327–344. [Google Scholar] [CrossRef]

- Rass, H.A.; Essayem, N.; Besson, M. Selective aqueous phase oxidation of 5-hydroxymethylfurfural to 2,5-furandicarboxylic acid over Pt/C catalysts: Influence of the base and effect of bismuth promotion. Green Chem. 2013, 15, 2240–2251. [Google Scholar] [CrossRef]

- Ait Rass, H.; Essayem, N.; Besson, M. Selective Aerobic Oxidation of 5-HMF into 2,5-Furandicarboxylic Acid with Pt Catalysts Supported on TiO2- and ZrO2-Based Supports. ChemSusChem 2015, 8, 1206–1217. [Google Scholar] [CrossRef] [PubMed]

- Sahu, R.; Dhepe, P.L. Synthesis of 2,5-furandicarboxylic acid by the aerobic oxidation of 5-hydroxymethyl furfural over supported metal catalysts. React. Kinet. Mech. Catal. 2014, 112, 173–187. [Google Scholar] [CrossRef]

- Miao, Z.; Wu, T.; Li, J.; Yi, T.; Zhang, Y.; Yang, X. Aerobic oxidation of 5-hydroxymethylfurfural (HMF) effectively catalyzed by a Ce0.8Bi0.2O2−δ supported Pt catalyst at room temperature. RSC Adv. 2015, 5, 19823–19829. [Google Scholar] [CrossRef]

- Niu, W.; Wang, D.; Yang, G.; Sun, J.; Wu, M.; Yoneyama, Y.; Tsubaki, N. Pt Nanoparticles Loaded on Reduced Graphene Oxide as an Effective Catalyst for the Direct Oxidation of 5-Hydroxymethylfurfural (HMF) to Produce 2,5-Furandicarboxylic Acid (FDCA) under Mild Conditions. Bull. Chem. Soc. Jpn. 2014, 87, 1124–1129. [Google Scholar] [CrossRef]

- Zhang, Y.; Xue, Z.; Wang, J.; Zhao, X.; Deng, Y.; Zhao, W.; Mu, T. Controlled deposition of Pt nanoparticles on Fe3O4@carbon microspheres for efficient oxidation of 5-hydroxymethylfurfural. RSC Adv. 2016, 6, 51229–51237. [Google Scholar] [CrossRef]

- Vinke, P.; van Dam, H.E.; van Bekkum, H. Platinum Catalyzed Oxidation of 5-Hydroxymethylfurfural. In Studies in Surface Science and Catalysis; Centi, G., Trifiro, F., Eds.; Elsevier: Amsterdam, The Netherlands, 1990; Volume 55, pp. 147–158. [Google Scholar]

- Chen, H.; Shen, J.; Chen, K.; Qin, Y.; Lu, X.; Ouyang, P.; Fu, J. Atomic layer deposition of Pt nanoparticles on low surface area zirconium oxide for the efficient base-free oxidation of 5-hydroxymethylfurfural to 2,5-furandicarboxylic acid. Appl. Catal. A Gen. 2018, 555, 98–107. [Google Scholar] [CrossRef]

- Han, X.; Geng, L.; Guo, Y.; Jia, R.; Liu, X.; Zhang, Y.; Wang, Y. Base-free aerobic oxidation of 5-hydroxymethylfurfural to 2,5-furandicarboxylic acid over a Pt/C–O–Mg catalyst. Green Chem. 2016, 18, 1597–1604. [Google Scholar] [CrossRef]

- Han, X.; Li, C.; Guo, Y.; Liu, X.; Zhang, Y.; Wang, Y. N-doped carbon supported Pt catalyst for base-free oxidation of 5-hydroxymethylfurfural to 2,5-furandicarboxylic acid. Appl. Catal. A Gen. 2016, 526, 1–8. [Google Scholar] [CrossRef]

- Shen, J.; Chen, H.; Chen, K.; Qin, Y.; Lu, X.; Ouyang, P.; Fu, J. Atomic Layer Deposition of a Pt-Skin Catalyst for Base-Free Aerobic Oxidation of 5-Hydroxymethylfurfural to 2,5-Furandicarboxylic Acid. Ind. Eng. Chem. Res. 2018, 57, 2811–2818. [Google Scholar] [CrossRef] [Green Version]

- Siankevich, S.; Savoglidis, G.; Fei, Z.; Laurenczy, G.; Alexander, D.T.; Yan, N.; Dyson, P.J. A novel platinum nanocatalyst for the oxidation of 5-Hydroxymethylfurfural into 2,5-Furandicarboxylic acid under mild conditions. J. Catal. 2014, 315, 67–74. [Google Scholar] [CrossRef]

- Siankevich, S.; Mozzettini, S.; Bobbink, F.; Ding, S.; Fei, Z.; Yan, N.; Dyson, P.J. Influence of the Anion on the Oxidation of 5-Hydroxymethylfurfural by Using Ionic-Polymer-Supported Platinum Nanoparticle Catalysts. ChemPlusChem 2018, 83, 19–23. [Google Scholar] [CrossRef]

- Davis, S.E.; Houk, L.R.; Tamargo, E.C.; Datye, A.K.; Davis, R.J. Oxidation of 5-hydroxymethylfurfural over supported Pt, Pd and Au catalysts. Catal. Today 2011, 160, 55–60. [Google Scholar] [CrossRef]

- Siyo, B.; Schneider, M.; Radnik, J.; Pohl, M.-M.; Langer, P.; Steinfeldt, N. Influence of support on the aerobic oxidation of HMF into FDCA over preformed Pd nanoparticle based materials. Appl. Catal. A Gen. 2014, 478, 107–116. [Google Scholar] [CrossRef]

- Siyo, B.; Schneider, M.; Pohl, M.-M.; Langer, P.; Steinfeldt, N. Synthesis, characterization, and application of PVP-Pd NP in the aerobic oxidation of 5-hydroxymethylfurfural (hmf). Catal. Lett. 2014, 144, 498–506. [Google Scholar] [CrossRef]

- Rathod, P.V.; Jadhav, V.H. Efficient Method for Synthesis of 2,5-Furandicarboxylic Acid from 5-Hydroxymethylfurfural and Fructose Using Pd/CC Catalyst under Aqueous Conditions. ACS Sustain. Chem. Eng. 2018, 6, 5766–5771. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhen, J.; Liu, B.; Lv, K.; Deng, K. Selective aerobic oxidation of the biomass-derived precursor 5-hydroxymethylfurfural to 2,5-furandicarboxylic acid under mild conditions over a magnetic palladium nanocatalyst. Green Chem. 2015, 17, 1308–1317. [Google Scholar] [CrossRef]

- Mei, N.; Liu, B.; Zheng, J.; Lv, K.; Tang, D.; Zhang, Z. A novel magnetic palladium catalyst for the mild aerobic oxidation of 5-hydroxymethylfurfural into 2,5-furandicarboxylic acid in water. Catal. Sci. Technol. 2015, 5, 3194–3202. [Google Scholar] [CrossRef]

- Liu, B.; Ren, Y.; Zhang, Z. Aerobic oxidation of 5-hydroxymethylfurfural into 2,5-furandicarboxylic acid in water under mild conditions. Green Chem. 2015, 17, 1610–1617. [Google Scholar] [CrossRef]

- Lolli, A.; Albonetti, S.; Utili, L.; Amadori, R.; Ospitali, F.; Lucarelli, C.; Cavani, F. Insights into the reaction mechanism for 5-hydroxymethylfurfural oxidation to FDCA on bimetallic Pd–Au nanoparticles. Appl. Catal. A Gen. 2015, 504, 408–419. [Google Scholar] [CrossRef]

- Xia, H.; An, J.; Hong, M.; Xu, S.; Zhang, L.; Zuo, S. Aerobic oxidation of 5-hydroxymethylfurfural to 2,5-difurancarboxylic acid over Pd-Au nanoparticles supported on Mg-Al hydrotalcite. Catal. Today 2019, 319, 113–120. [Google Scholar] [CrossRef]

- Gupta, K.; Rai, R.K.; Singh, S.K. Catalytic aerial oxidation of 5-hydroxymethyl-2-furfural to furan-2,5-dicarboxylic acid over Ni–Pd nanoparticles supported on Mg(OH)2 nanoflakes for the synthesis of furan diesters. Inorg. Chem. Front. 2017, 4, 871–880. [Google Scholar] [CrossRef]

- Wang, Y.; Yu, K.; Lei, D.; Si, W.; Feng, Y.; Lou, L.-L.; Liu, S. Basicity-Tuned Hydrotalcite-Supported Pd Catalysts for Aerobic Oxidation of 5-Hydroxymethyl-2-furfural under Mild Conditions. ACS Sustain. Chem. Eng. 2016, 4, 4752–4761. [Google Scholar] [CrossRef]

- Zakrzewska, M.E.; Bogel-Łukasik, E.; Bogel-Łukasik, R. Ionic Liquid-Mediated Formation of 5-Hydroxymethylfurfural—A Promising Biomass-Derived Building Block. Chem. Rev. 2011, 111, 397–417. [Google Scholar] [CrossRef]

- Yi, G.; Teong, S.P.; Zhang, Y. Base-free conversion of 5-hydroxymethylfurfural to 2,5-furandicarboxylic acid over a Ru/C catalyst. Green Chem. 2016, 18, 979–983. [Google Scholar] [CrossRef]

- Kerdi, F.; Ait Rass, H.; Pinel, C.; Besson, M.; Peru, G.; Leger, B.; Rio, S.; Monflier, E.; Ponchel, A. Evaluation of surface properties and pore structure of carbon on the activity of supported Ru catalysts in the aqueous-phase aerobic oxidation of HMF to FDCA. Appl. Catal. A Gen. 2015, 506, 206–219. [Google Scholar] [CrossRef]

- Ståhlberg, T.; Eyjólfsdóttir, E.; Gorbanev, Y.Y.; Sádaba, I.; Riisager, A. Aerobic oxidation of 5-(hydroxymethyl) furfural in ionic liquids with solid ruthenium hydroxide catalysts. Catal. Lett. 2012, 142, 1089–1097. [Google Scholar] [CrossRef]

- Mishra, D.K.; Lee, H.J.; Kim, J.; Lee, H.-S.; Cho, J.K.; Suh, Y.-W.; Yi, Y.; Kim, Y.J. MnCo2O4 spinel supported ruthenium catalyst for air-oxidation of HMF to FDCA under aqueous phase and base-free conditions. Green Chem. 2017, 19, 1619–1623. [Google Scholar] [CrossRef]

- Gao, T.; Yin, Y.; Fang, W.; Cao, Q. Highly dispersed ruthenium nanoparticles on hydroxyapatite as selective and reusable catalyst for aerobic oxidation of 5-hydroxymethylfurfural to 2,5-furandicarboxylic acid under base-free conditions. Mol. Catal. 2018, 450, 55–64. [Google Scholar] [CrossRef]

- Pichler, C.M.; Al-Shaal, M.G.; Gu, D.; Joshi, H.; Ciptonugroho, W.; Schüth, F. Ruthenium Supported on High-Surface-Area Zirconia as an Efficient Catalyst for the Base-Free Oxidation of 5-Hydroxymethylfurfural to 2,5-Furandicarboxylic Acid. ChemSusChem 2018, 11, 2083–2090. [Google Scholar] [CrossRef]

- Nie, J.; Xie, J.; Liu, H. Activated carbon-supported ruthenium as an efficient catalyst for selective aerobic oxidation of 5-hydroxymethylfurfural to 2,5-diformylfuran. Chin. J. Catal. 2013, 34, 871–875. [Google Scholar] [CrossRef]

- Artz, J.; Mallmann, S.; Palkovits, R. Selective Aerobic Oxidation of HMF to 2,5-Diformylfuran on Covalent Triazine Frameworks-Supported Ru Catalysts. ChemSusChem 2015, 8, 672–679. [Google Scholar] [CrossRef] [PubMed]

- Vuyyuru, K.R.; Strasser, P. Oxidation of biomass derived 5-hydroxymethylfurfural using heterogeneous and electrochemical catalysis. Catal. Today 2012, 195, 144–154. [Google Scholar] [CrossRef]

- Schade, O.R.; Kalz, K.F.; Neukum, D.; Kleist, W.; Grunwaldt, J.-D. Supported gold- and silver-based catalysts for the selective aerobic oxidation of 5-(hydroxymethyl)furfural to 2,5-furandicarboxylic acid and 5-hydroxymethyl-2-furancarboxylic acid. Green Chem. 2018, 20, 3530–3541. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.; Deng, K. Recent advances in the catalytic synthesis of 2,5-furandicarboxylic acid and its derivatives. ACS Catal. 2015, 5, 6529–6544. [Google Scholar] [CrossRef]

- Saha, B.; Gupta, D.; Abu-Omar, M.M.; Modak, A.; Bhaumik, A. Porphyrin-based porous organic polymer-supported iron (III) catalyst for efficient aerobic oxidation of 5-hydroxymethyl-furfural into 2,5-furandicarboxylic acid. J. Catal. 2013, 299, 316–320. [Google Scholar] [CrossRef]

- Gao, L.; Deng, K.; Zheng, J.; Liu, B.; Zhang, Z. Efficient oxidation of biomass derived 5-hydroxymethylfurfural into 2,5-furandicarboxylic acid catalyzed by Merrifield resin supported cobalt porphyrin. Chem. Eng. J. 2015, 270, 444–449. [Google Scholar] [CrossRef]

- Jain, A.; Jonnalagadda, S.C.; Ramanujachary, K.V.; Mugweru, A. Selective oxidation of 5-hydroxymethyl-2-furfural to furan-2,5-dicarboxylic acid over spinel mixed metal oxide catalyst. Catal. Commun. 2015, 58, 179–182. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, Z.; Liu, B. Catalytic Conversion of Fructose and 5-Hydroxymethylfurfural into 2,5-Furandicarboxylic Acid over a Recyclable Fe3O4–CoOx Magnetite Nanocatalyst. ACS Sustain. Chem. Eng. 2015, 3, 406–412. [Google Scholar] [CrossRef]

- Yan, D.; Xin, J.; Shi, C.; Lu, X.; Ni, L.; Wang, G.; Zhang, S. Base-free conversion of 5-hydroxymethylfurfural to 2,5-furandicarboxylic acid in ionic liquids. Chem. Eng. J. 2017, 323, 473–482. [Google Scholar] [CrossRef]

- Yan, D.; Xin, J.; Zhao, Q.; Gao, K.; Lu, X.; Wang, G.; Zhang, S. Fe–Zr–O catalyzed base-free aerobic oxidation of 5-HMF to 2,5-FDCA as a bio-based polyester monomer. Catal. Sci. Technol. 2018, 8, 164–175. [Google Scholar] [CrossRef]

- Hayashi, E.; Komanoya, T.; Kamata, K.; Hara, M. Heterogeneously-Catalyzed Aerobic Oxidation of 5-Hydroxymethylfurfural to 2,5-Furandicarboxylic Acid with MnO2. ChemSusChem 2017, 10, 654–658. [Google Scholar] [CrossRef] [PubMed]

- Bao, L.; Sun, F.-Z.; Zhang, G.-Y.; Hu, T.-L. Aerobic Oxidation of 5-Hydroxymethylfurfural to 2,5-Furandicarboxylic Acid over Holey 2 D Mn2O3 Nanoflakes from a Mn-based MOF. ChemSusChem 2019. [Google Scholar] [CrossRef] [PubMed]

- Han, X.; Li, C.; Liu, X.; Xia, Q.; Wang, Y. Selective oxidation of 5-hydroxymethylfurfural to 2,5-furandicarboxylic acid over MnOx–CeO2 composite catalysts. Green Chem. 2017, 19, 996–1004. [Google Scholar] [CrossRef]

- Zhang, S.; Sun, X.; Zheng, Z.; Zhang, L. Nanoscale center-hollowed hexagon MnCo2O4 spinel catalyzed aerobic oxidation of 5-hydroxymethylfurfural to 2,5-furandicarboxylic acid. Catal. Commun. 2018, 113, 19–22. [Google Scholar] [CrossRef]

- Gao, T.; Yin, Y.; Zhu, G.; Cao, Q.; Fang, W. Co3O4 NPs decorated Mn-Co-O solid solution as highly selective catalyst for aerobic base-free oxidation of 5-HMF to 2,5-FDCA in water. Catal. Today 2019. [Google Scholar] [CrossRef]

- Neațu, F.; Marin, R.S.; Florea, M.; Petrea, N.; Pavel, O.D.; Pârvulescu, V.I. Selective oxidation of 5-hydroxymethyl furfural over non-precious metal heterogeneous catalysts. Appl. Catal. B Environ. 2016, 180, 751–757. [Google Scholar] [CrossRef]

- Hayashi, E.; Yamaguchi, Y.; Kamata, K.; Tsunoda, N.; Kumagai, Y.; Oba, F.; Hara, M. Effect of MnO2 Crystal Structure on Aerobic Oxidation of 5-Hydroxymethylfurfural to 2,5-Furandicarboxylic Acid. J. Am. Chem. Soc. 2019, 141, 890–900. [Google Scholar] [CrossRef]

- Weckhuysen, B.M. Preface: Recent advances in the in-situ characterization of heterogeneous catalysts. Chem. Soc. Rev. 2010, 39, 4557–4559. [Google Scholar] [CrossRef]

| Catalysts | Base | Reaction Conditions | HMF Conv. (%) | FDCA Yield (%) | Ref. | ||

|---|---|---|---|---|---|---|---|

| T (°C) | Oxidant P (bar) | Time (h) | |||||

| Au/CeO2 | NaOH | 130 | Air, 10 | 8 | 100 | >99 | [36] |

| Au/TiO2 | NaOH | 130 | Air, 10 | 8 | 100 | >99 | [36] |

| Au/Fe2O3 | NaOH | 130 | Air, 10 | 8 | 100 | 15 | [36] |

| Au/C | NaOH | 130 | Air, 10 | 8 | 100 | 44 | [36] |

| Au/m-CeO2 | NaOH | 70 | O2, 10 | 4 | 100 | 92 | [37] |

| Au/CeO2 | Na2CO3 | 140 | O2, 5.0 | 15 | >99 | 91 | [38] |

| Au/TiO2 | NaOH | 30 | O2, 20 | 18 | 100 | 71 | [39] |

| Au/HY | NaOH | 60 | O2, 0.3 | 6 | >99 | >99 | [40] |

| Au/TiO2 | NaOH | 60 | O2, 0.3 | 6 | >99 | 85 | [40] |

| Au/Mg(OH)2 | NaOH | 60 | O2, 0.3 | 6 | >99 | 76 | [40] |

| Au/CeO2 | NaOH | 60 | O2, 0.3 | 6 | >99 | 73 | [40] |

| Au/H-MOR | NaOH | 60 | O2, 0.3 | 6 | 96 | 15 | [40] |

| Au/Na-ZSM5-25 | NaOH | 60 | O2, 0.3 | 6 | 92 | 1 | [40] |

| Au-Cu/TiO2 | NaOH | 95 | O2, 10 | 4 | 100 | 99 | [41] |

| Au8-Pd2/C | NaOH | 60 | O2, 30 | 4 | >99 | >99 | [42] |

| Au/HT | Base free | 95 | O2, 1 | 7 | >99 | >99 | [43] |

| Au/HT-AC | Base free | 100 | O2, 5 | 12 | 100 | >99 | [44] |

| Au-Pd/CNT | Base free | 100 | O2, 5 | 12 | 100 | 94 | [45] |

| Au-Pd/CNT | Base free | 100 | Air, 10 | 12 | 100 | 96 | [45] |

| Au-Pd/CNT | Base free | 100 | O2, 5 | 18 | 100 | 91 | [45] |

| AuPd-nNiO a | Base free | 90 | O2, 10 | 6 | 95 | 70 | [46] |

| AuPd-La-CaMgAl-LDH b | Base free | 100 | O2, 5 | 6 | 96.1 | 89.4 | [47] |

| Catalysts | Base | Reaction Conditions | HMF Conv. (%) | FDCA Yield (%) | Ref. | ||

|---|---|---|---|---|---|---|---|

| T (°C) | Oxidant P (bar) | Time (h) | |||||

| Pt/C | NaOH | 25 | O2, 1 | 2 | 100 | 81 | [52] |

| Pt-Pb/C | NaOH | 25 | O2, 1 | 2 | 100 | 99 | [52] |

| Pt/C | Na2CO3 | 100 | Air, 40 | 6 | 99 | 69 | [53] |

| Pt-Bi/C | Na2CO3 | 100 | Air, 40 | 6 | 100 | >99 | [53] |

| Pt/TiO2 | Na2CO3 | 100 | Air, 40 | 6 | 90 | 84 | [54] |

| Pt-Bi/TiO2 | Na2CO3 | 100 | Air, 40 | 6 | >99 | 99 | [54] |

| Pt/Al2O3 | Na2CO3 | 75 | O2, 1 | 12 | 96 | 96 | [55] |

| Pt/ZrO2 | Na2CO3 | 75 | O2, 1 | 12 | 100 | 94 | [55] |

| Pt/C | Na2CO3 | 75 | O2, 1 | 12 | 100 | 89 | [55] |

| Pt/CeO2 | Na2CO3 | 75 | O2, 1 | 12 | 100 | 8 | [55] |

| Pt/TiO2 | Na2CO3 | 75 | O2, 1 | 12 | 96 | 2 | [55] |

| Pt/Ce0.8Bi0.2O2-δ | NaOH | 23 | O2, 10 | 0.5 | 100 | 98 | [56] |

| Pt/CeO2 | NaOH | 23 | O2, 10 | 0.5 | 100 | 20 | [56] |

| Pt/RGO a | NaOH | 25 | O2, 1 | 24 | 100 | 84 | [57] |

| Fe3O4@C@Pt | Na2CO3 | 90 | O2, 1 | 4 | 100 | 100 | [58] |

| Pt/Al2O3 | pH = 9 | 60 | O2, 0.2 | 6 | 100 | 99 | [59] |

| Pt/ZrO2 | Base free | 100 | O2, 4 | 12 | 100 | 97.3 | [60] |

| Pt/C-O-Mg | Base free | 110 | O2, 10 | 12 | >99 | 97 | [61] |

| Pt/C-EDA-x b | Base free | 110 | O2, 10 | 12 | 100 | 96 | [62] |

| Pt-Ni/AC | Base free | 100 | O2, 4 | 15 | 100 | 97.5 | [63] |

| Pt-PVP-GLY c | Base free | 80 | O2, 1 | 24 | 100 | 94 | [64] |

| Pt-PVP-NaBH4 | Base free | 80 | O2, 1 | 24 | 100 | 80 | [64] |

| Pt-PVP-EtOH | Base free | 80 | O2, 1 | 24 | 100 | 75 | [64] |

| Pt-PVP-H2 | Base free | 80 | O2, 1 | 24 | 100 | 19 | [64] |

| Pt-NP-Cl d | Base free | 80 | O2, 1 | 6 | 100 | 65 | [65] |

| Pt-NP5 e | Base free | 80 | O2, 1 | 6 | 100 | 60 | [65] |

| Catalysts | Base | Reaction Conditions | HMF Conv. (%) | FDCA Yield (%) | Ref. | ||

|---|---|---|---|---|---|---|---|

| T (°C) | Oxidant, P (bar) | Time (h) | |||||

| Pd/C | NaOH | 23 | O2, 6.9 | 6 | 100 | 71 | [66] |

| Pd/ZrO2/La2O3 | NaOH | 90 | O2, 1 | 6 | >99 | 90 | [67] |

| Pd/Al2O3 | NaOH | 90 | O2, 1 | 6 | >99 | 78 | [67] |

| Pd/Ti2O3 | NaOH | 90 | O2, 1 | 6 | >99 | 53 | [67] |

| Pd/PVP a | NaOH | 90 | O2, 1.01 | 6 | >99 | 90 | [68] |

| Pd/CC b | K2CO3 | 100 | O2, 20 mL/min | 30 | 100 | 85 | [69] |

| γ-Fe2O3@HAP-Pd c | K2CO3 | 100 | O2, 1 | 6 | 97 | 92.9 | [70] |

| C-Fe2O3-Pd | K2CO3 | 80 | O2, 1 | 4 | 98.2 | 91.8 | [71] |

| Pd/C@Fe2O3 | K2CO3 | 80 | O2, 1 | 6 | 98.4 | 86.7 | [72] |

| Pd-Au/TiO2 | NaOH | 70 | O2, 10 | 4 | 100 | 85 | [73] |

| Pd/TiO2 | NaOH | 70 | O2, 10 | 4 | 100 | 9 | [73] |

| Pd-Au/HT d | NaOH | 60 | O2, 1 | 6 | 100 | 90 | [74] |

| Pd/HT | NaOH | 60 | O2, 1 | 6 | 85 | 6 | [74] |

| Pd-Ni/Mg(OH)2 | Base free | 100 | Air | 16 | >99 | 89 | [75] |

| Pd/HT | Base free | 100 | O2, 1 | 8 | >99 | >99 | [76] |

| Catalysts | Base | Reaction Conditions | HMF Conv. (%) | FDCA Yield (%) | Ref. | ||

|---|---|---|---|---|---|---|---|

| T (°C) | Oxidant, P (bar) | Time (h) | |||||

| Ru/C | CaCO3 | 120 | O2, 2 | 5 | 100 | 95 | [78] |

| Ru/C | Na2CO3 | 120 | O2, 2 | 5 | 100 | 93 | [78] |

| Ru/C | K2CO3 | 120 | O2, 2 | 5 | 100 | 80 | [78] |

| Ru/C | NaOH | 120 | O2, 2 | 5 | 100 | 69 | [78] |

| Ru/C | HT | 120 | O2, 2 | 5 | 100 | 60 | [78] |

| Ru/C | Base free | 120 | O2, 2 | 10 | 100 | 88 | [78] |

| Ru/C | NaHCO3 | 100 | Air, 40 | 2 | 100 | 75 | [79] |

| Ru/ACNaOCl a | NaHCO3 | 100 | Air, 40 | 4 | 100 | 55 | [79] |

| Ru(OH)x/La2O3 | Base free | 100 | O2, 30 | 5 | 98 | 48 | [80] |

| Ru(OH)x/HT b | Base free | 140 | Air,1 | 24 | 99 | 19 | [80] |

| Ru/MnCo2O4 | Base free | 120 | Air, 24 | 10 | 100 | 99.1 | [81] |

| Ru/CoMn2O4 | Base free | 120 | Air, 24 | 10 | 100 | 82.2 | [81] |

| Ru/MnCo2CO3 | Base free | 120 | Air, 24 | 10 | 100 | 69.9 | [81] |

| Ru/HAP c | Base free | 120 | O2, 10 | 24 | 100 | 99.6 | [82] |

| Ru/HAP c | Base free | 140 | O2, 10 | 24 | 100 | 99.9 | [82] |

| Ru/ZrO2 | Base free | 120 | O2, 10 | 16 | 100 | 97 | [83] |

| Catalysts | Additive | Reaction Conditions | HMF Conv. (%) | FDCA Yield (%) | Ref. | ||

|---|---|---|---|---|---|---|---|

| T (°C) | Oxidant P (bar) | Time (h) | |||||

| Fe-POP a | - | 100 | O2, 10 | 10 | 100 | 85 | [89] |

| MR-Co-Py b | CH3CN | 100 | t-BuOOH | 24 | 95.6 | 90.4 | [90] |

| Li2CoMn3 O8 | CH3COOH | 150 | Air, 55 | 8 | 100 | 80 | [91] |

| Fe3O4-CoOx | - | 80 | t-BuOOH | 12 | 97.2 | 68.6 | [92] |

| Ce0.5Fe0.5O2 | [Bmim]Cl | 140 | O2, 20 | 24 | 98.4 | 13.8 | [93] |

| Ce0.5Zr0.5O2 | [Bmim]Cl | 140 | O2, 20 | 24 | 96.1 | 23.2 | [93] |

| Ce0.5Fe0.15Zr0.35O2 | [Bmim]Cl | 140 | O2, 20 | 24 | 99.9 | 44.2 | [93] |

| Fe0.6Zr0.4O2 | [Bmim]Cl | 160 | O2, 20 | 24 | 99.7 | 60.6 | [94] |

| MnO2 | NaHCO3 | 100 | O2, 10 | 24 | >99 | 91.0 | [95] |

| MOF-Mn2O3 | NaHCO3 | 100 | O2, 14 | 24 | 100 | 99.5 | [96] |

| MnOx-CeO2 | KHCO3 | 110 | O2, 20 | 15 | 98 | 91 | [97] |

| MnCo2O4 | KHCO3 | 100 | O2, 20 | 24 | 99.5 | 70.9 | [98] |

| Co3O4/MnxCo | Base free | 140 | O2, 1 | 24 | 100 | >99 | [99] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hameed, S.; Lin, L.; Wang, A.; Luo, W. Recent Developments in Metal-Based Catalysts for the Catalytic Aerobic Oxidation of 5-Hydroxymethyl-Furfural to 2,5-Furandicarboxylic Acid. Catalysts 2020, 10, 120. https://0-doi-org.brum.beds.ac.uk/10.3390/catal10010120

Hameed S, Lin L, Wang A, Luo W. Recent Developments in Metal-Based Catalysts for the Catalytic Aerobic Oxidation of 5-Hydroxymethyl-Furfural to 2,5-Furandicarboxylic Acid. Catalysts. 2020; 10(1):120. https://0-doi-org.brum.beds.ac.uk/10.3390/catal10010120

Chicago/Turabian StyleHameed, Sohaib, Lu Lin, Aiqin Wang, and Wenhao Luo. 2020. "Recent Developments in Metal-Based Catalysts for the Catalytic Aerobic Oxidation of 5-Hydroxymethyl-Furfural to 2,5-Furandicarboxylic Acid" Catalysts 10, no. 1: 120. https://0-doi-org.brum.beds.ac.uk/10.3390/catal10010120