Recent Advances in the Application of Metal–Organic Frameworks for Polymerization and Oligomerization Reactions

Abstract

:1. Introduction

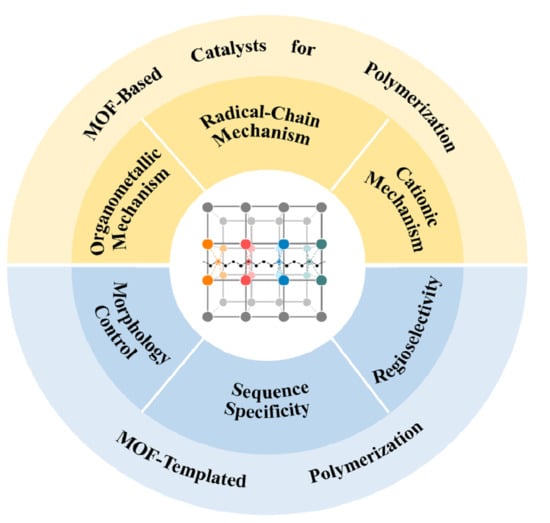

2. MOF-Based Catalysts for Polymerization and Oligomerization Reactions

2.1. MOF-Catalyzed Polymerization through Organometallic Mechanism

2.1.1. Zirconium-Based MOF Catalysts

2.1.2. Nickel-Based MOF Catalysts

2.1.3. Cobalt-Based MOF Catalysts

2.1.4. Vanadium-Based MOF Catalysts

2.1.5. Chromium-Based MOF Catalysts

2.1.6. Lanthanide-Based MOF Catalysts

2.2. MOF-Catalyzed Polymerization through Radical-Chain Mechanism

2.2.1. Titanium-Based MOFs as Photocatalysts

2.2.2. Copper-Based MOF Catalysts

2.2.3. MOFs as Photo-Initiators for Radical Polymerization

2.3. Cationic Polymerization with Acidic MOFs

3. MOF-Templated Polymerization

3.1. MOF-Templated Polymerization with Morphology Control

3.1.1. MOF-Templated Electrochemical Polymerization

3.1.2. MOF-Templated Polymerizations through Redox Mechanism

3.1.3. MOF-Templated Radical Polymerization and Click Polymerization

3.1.4. MOF-Templated Polycondensation

3.2. MOF-Templated Sequence-Specific and Crosslinking-Specific Polymerization

3.3. MOF-Templated Regioselective and Branching-Selective Polymerization

4. Overview and Outlook

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| 1D | one-dimensional |

| 2D | two-dimensional |

| 2,6-ndc | 2,6-naphthalenedicarboxylate |

| 3D | three-dimensional |

| ATRP | atom transfer radical polymerization |

| bdc | para-terephthalate, or 1,4-benzene dicarboxylate |

| BTB | 1,3,5-benzentrisbenzoate |

| Brbdc | 2-(2-bromo-2-methylpropanamido)-1,4-benzenedicarboxylate |

| CFA-1 | Zn5(OAc)4(bibtz)3 |

| dabco | 1,4-diazabi-cyclo[2.2.2]octane |

| DOT | dioxythiophene |

| DNA | deoxyribonucleic acid |

| form | formate |

| H2BTDD | bis(1H-1,2,3-triazolo[4,5-b],[4′,5′-i])dibenzo[1,4]dioxin) |

| MOF | Metal–organic framework |

| MMAO-12 | methylaluminoxane-12 |

| MFU-4l | Zn5Cl4(BTDD)3 |

| MMA | methyl methacrylate |

| mRNA | messenger RNA |

| NMR | Nuclear Magnetic Resonance |

| Ni2(dobdc) | dobdc = 2,5-dioxodo-1,4-benzenedicarboxylate; Ni-MOF-74 |

| Ni2(dobpdc) | dobpdc = 4,4′-dioxodo-[1,1′-biphenyl]-3,3′-dicarboxylate |

| ox | oxalate |

| PPy | polypyrrole |

| PEDOT | poly 3,4-ethylenedioxythiophene |

| PMMA | poly(methylmethacrylate |

| PDI | polydispersity |

| pzdc | pyrazine-2,3-dicarboxylate |

| PGlc | polyglucose |

| RAFT | reversible addition–fragmentation chain transfer |

| SBUs | secondary building units |

| TpMes | HB(3-mesitylpyrazolyl)3 |

| ted | triethylenediamine |

| tRNA | transfer RNA |

| TTCs | trithiocarbonates |

| UV | ultraviolet |

| XRD | X-ray diffraction |

| Zn2(bdc)2(dabco) | Zn2(benzene-1,4-dicarboxylate)2(1,4-diazabicyclo[2.2.2]-octane) |

| ZrMe-BTC | Zr6(μ3-O)4(μ3-OLi)4Me6-benzene tricarboxylates |

References

- Zhou, H.C.; Long, J.R.; Yaghi, O.M. Introduction to metal-organic frameworks. Chem. Rev. 2012, 112, 673–674. [Google Scholar] [CrossRef] [PubMed]

- Furukawa, H.; Cordova, K.E.; O’Keeffe, M.; Yaghi, O.M. The chemistry and applications of metal-organic frameworks. Science 2013, 341, 1230444. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cook, T.R.; Zheng, Y.R.; Stang, P.J. Metal-organic frameworks and self-assembled supramolecular coordination complexes: Comparing and contrasting the design, synthesis, and functionality of metal-organic materials. Chem. Rev. 2013, 113, 734–777. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cohen, S.M. Postsynthetic methods for the functionalization of metal-organic frameworks. Chem. Rev. 2012, 112, 970–1000. [Google Scholar] [CrossRef] [PubMed]

- Rocha, J.; Carlos, L.D.; Paz, F.A.; Ananias, D. Luminescent multifunctional lanthanides-based metal-organic frameworks. Chem. Soc. Rev. 2011, 40, 926–940. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, Y.; Li, D.S.; Bu, X.; Feng, P. Metal-Organic Frameworks for Separation. Adv. Mater. 2018, 30, 1705189. [Google Scholar] [CrossRef]

- Li, J.R.; Sculley, J.; Zhou, H.C. Metal-organic frameworks for separations. Chem. Rev. 2012, 112, 869–932. [Google Scholar] [CrossRef]

- Li, J.-R.; Ma, Y.; McCarthy, M.C.; Sculley, J.; Yu, J.; Jeong, H.-K.; Balbuena, P.B.; Zhou, H.-C. Carbon dioxide capture-related gas adsorption and separation in metal-organic frameworks. Coord. Chem. Rev. 2011, 255, 1791–1823. [Google Scholar] [CrossRef]

- Zhang, Y.; Yuan, S.; Day, G.; Wang, X.; Yang, X.; Zhou, H.-C. Luminescent sensors based on metal-organic frameworks. Coord. Chem. Rev. 2018, 354, 28–45. [Google Scholar] [CrossRef]

- Kreno, L.E.; Leong, K.; Farha, O.K.; Allendorf, M.; Van Duyne, R.P.; Hupp, J.T. Metal-organic framework materials as chemical sensors. Chem. Rev. 2012, 112, 1105–1125. [Google Scholar] [CrossRef]

- Hu, Z.; Deibert, B.J.; Li, J. Luminescent metal-organic frameworks for chemical sensing and explosive detection. Chem. Soc. Rev. 2014, 43, 5815–5840. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Burtch, N.C.; Heinen, J.; Bennett, T.D.; Dubbeldam, D.; Allendorf, M.D. Mechanical Properties in Metal-Organic Frameworks: Emerging Opportunities and Challenges for Device Functionality and Technological Applications. Adv. Mater. 2018, 30, 1704124. [Google Scholar] [CrossRef] [PubMed]

- Horcajada, P.; Gref, R.; Baati, T.; Allan, P.K.; Maurin, G.; Couvreur, P.; Ferey, G.; Morris, R.E.; Serre, C. Metal-organic frameworks in biomedicine. Chem. Rev. 2012, 112, 1232–1268. [Google Scholar] [CrossRef] [PubMed]

- Horcajada, P.; Chalati, T.; Serre, C.; Gillet, B.; Sebrie, C.; Baati, T.; Eubank, J.F.; Heurtaux, D.; Clayette, P.; Kreuz, C.; et al. Porous metal-organic-framework nanoscale carriers as a potential platform for drug delivery and imaging. Nat. Mater. 2010, 9, 172–178. [Google Scholar] [CrossRef]

- Sumida, K.; Rogow, D.L.; Mason, J.A.; McDonald, T.M.; Bloch, E.D.; Herm, Z.R.; Bae, T.H.; Long, J.R. Carbon dioxide capture in metal-organic frameworks. Chem. Rev. 2012, 112, 724–781. [Google Scholar] [CrossRef]

- Suh, M.P.; Park, H.J.; Prasad, T.K.; Lim, D.W. Hydrogen storage in metal-organic frameworks. Chem. Rev. 2012, 112, 782–835. [Google Scholar] [CrossRef]

- D’Alessandro, D.M.; Smit, B.; Long, J.R. Carbon dioxide capture: Prospects for new materials. Angew. Chem. Int. Ed. Engl. 2010, 49, 6058–6082. [Google Scholar] [CrossRef] [Green Version]

- Jiao, L.; Wang, Y.; Jiang, H.L.; Xu, Q. Metal-Organic Frameworks as Platforms for Catalytic Applications. Adv. Mater. 2018, 30, 1703663. [Google Scholar] [CrossRef]

- Lee, J.; Farha, O.K.; Roberts, J.; Scheidt, K.A.; Nguyen, S.T.; Hupp, J.T. Metal-organic framework materials as catalysts. Chem. Soc. Rev. 2009, 38, 1450–1459. [Google Scholar] [CrossRef]

- Ma, L.; Abney, C.; Lin, W. Enantioselective catalysis with homochiral metal-organic frameworks. Chem. Soc. Rev. 2009, 38, 1248–1256. [Google Scholar] [CrossRef]

- Kitagawa, S.; Kitaura, R.; Noro, S. Functional porous coordination polymers. Angew. Chem. Int. Ed. Engl. 2004, 43, 2334–2375. [Google Scholar] [CrossRef] [PubMed]

- Cavka, J.H.; Jakobsen, S.; Olsbye, U.; Guillou, N.; Lamberti, C.; Bordiga, S.; Lillerud, K.P. A New Zirconium Inorganic Building Brick Forming Metal Organic. J. Am. Chem. Soc. 2008, 130, 13850–13851. [Google Scholar] [CrossRef] [PubMed]

- Hyde, S.T.; Chen, B.; O’Keeffe, M. Some equivalent two-dimensional weavings at the molecular scale in 2D and 3D metal–organic frameworks. CrystEngComm 2016, 18, 7607–7613. [Google Scholar] [CrossRef]

- Perez-Ramirez, J.; Christensen, C.H.; Egeblad, K.; Christensen, C.H.; Groen, J.C. Hierarchical zeolites: Enhanced utilisation of microporous crystals in catalysis by advances in materials design. Chem. Soc. Rev. 2008, 37, 2530–4252. [Google Scholar] [CrossRef] [PubMed]

- Bosch, M.; Yuan, S.; Rutledge, W.; Zhou, H.C. Stepwise Synthesis of Metal-Organic Frameworks. Acc. Chem. Res. 2017, 50, 857–865. [Google Scholar] [CrossRef] [PubMed]

- Lu, G.; Li, S.; Guo, Z.; Farha, O.K.; Hauser, B.G.; Qi, X.; Wang, Y.; Wang, X.; Han, S.; Liu, X.; et al. Imparting functionality to a metal-organic framework material by controlled nanoparticle encapsulation. Nat. Chem. 2012, 4, 310–316. [Google Scholar] [CrossRef]

- Farha, O.K.; Eryazici, I.; Jeong, N.C.; Hauser, B.G.; Wilmer, C.E.; Sarjeant, A.A.; Snurr, R.Q.; Nguyen, S.T.; Yazaydin, A.O.; Hupp, J.T. Metal-organic framework materials with ultrahigh surface areas: Is the sky the limit? J. Am. Chem. Soc. 2012, 134, 15016–15021. [Google Scholar] [CrossRef] [Green Version]

- Ploetz, E.; Engelke, H.; Lächelt, U.; Wuttke, S. The Chemistry of Reticular Framework Nanoparticles: MOF, ZIF, and COF Materials. Adv. Funct. Mater. 2020, 30, 1909062. [Google Scholar] [CrossRef]

- Yang, P.; Zhao, W.; Shkurenko, A.; Belmabkhout, Y.; Eddaoudi, M.; Dong, X.; Alshareef, H.N.; Khashab, N.M. Polyoxometalate-Cyclodextrin Metal-Organic Frameworks: From Tunable Structure to Customized Storage Functionality. J. Am. Chem. Soc. 2019, 141, 1847–1851. [Google Scholar] [CrossRef] [Green Version]

- Stuart, M.A.; Huck, W.T.; Genzer, J.; Muller, M.; Ober, C.; Stamm, M.; Sukhorukov, G.B.; Szleifer, I.; Tsukruk, V.V.; Urban, M.; et al. Emerging applications of stimuli-responsive polymer materials. Nat. Mater. 2010, 9, 101–113. [Google Scholar] [CrossRef]

- de Las Heras Alarcon, C.; Pennadam, S.; Alexander, C. Stimuli responsive polymers for biomedical applications. Chem. Soc. Rev. 2005, 34, 276–285. [Google Scholar] [CrossRef] [PubMed]

- Biju, V. Chemical modifications and bioconjugate reactions of nanomaterials for sensing, imaging, drug delivery and therapy. Chem. Soc. Rev. 2014, 43, 744–764. [Google Scholar] [CrossRef] [PubMed]

- Uemura, T.; Kitagawa, K.; Horike, S.; Kawamura, T.; Kitagawa, S.; Mizuno, M.; Endo, K. Radical polymerisation of styrene in porous coordination polymers. Chem. Commun. 2005, 48, 5968–5970. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Uemura, T.; Yanai, N.; Kitagawa, S. Polymerization reactions in porous coordination polymers. Chem. Soc. Rev. 2009, 38, 1228–1236. [Google Scholar] [CrossRef] [Green Version]

- Begum, S.; Hassan, Z.; Brase, S.; Tsotsalas, M. Polymerization in MOF-Confined Nanospaces: Tailored Architectures, Functions, and Applications. Langmuir 2020, 36, 10657–10673. [Google Scholar] [CrossRef]

- Walsh, D.J.; Hyatt, M.G.; Miller, S.A.; Guironnet, D. Recent Trends in Catalytic Polymerizations. ACS Catal. 2019, 9, 11153–11188. [Google Scholar] [CrossRef]

- D’Amore, M.; Thushara, K.S.; Piovano, A.; Causà, M.; Bordiga, S.; Groppo, E. Surface Investigation and Morphological Analysis of Structurally Disordered MgCl2 and MgCl2/TiCl4 Ziegler–Natta Catalysts. ACS Catal. 2016, 6, 5786–5796. [Google Scholar] [CrossRef]

- Credendino, R.; Liguori, D.; Fan, Z.; Morini, G.; Cavallo, L. Toward a Unified Model Explaining Heterogeneous Ziegler–Natta Catalysis. ACS Catal. 2015, 5, 5431–5435. [Google Scholar] [CrossRef] [Green Version]

- Grau, E.; Lesage, A.; Norsic, S.; Copéret, C.; Monteil, V.; Sautet, P. Tetrahydrofuran in TiCl4/THF/MgCl2: A Non-Innocent Ligand for Supported Ziegler–Natta Polymerization Catalysts. ACS Catal. 2012, 3, 52–56. [Google Scholar] [CrossRef] [Green Version]

- Astruc, D.; Lu, F.; Aranzaes, J.R. Nanoparticles as recyclable catalysts: The frontier between homogeneous and heterogeneous catalysis. Angew. Chem. Int. Ed. Engl. 2005, 44, 7852–7872. [Google Scholar] [CrossRef]

- Yoon, M.; Srirambalaji, R.; Kim, K. Homochiral metal-organic frameworks for asymmetric heterogeneous catalysis. Chem. Rev. 2012, 112, 1196–1231. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Wang, X.; Antonietti, M. Polymeric graphitic carbon nitride as a heterogeneous organocatalyst: From photochemistry to multipurpose catalysis to sustainable chemistry. Angew. Chem. Int. Ed. Engl. 2012, 51, 68–89. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.X.; Zou, K.Y.; Zhang, X.; Han, T.; Yang, Y. Hierarchically Flower-like N-Doped Porous Carbon Materials Derived from an Explosive 3-Fold Interpenetrating Diamondoid Copper Metal-Organic Framework for a Supercapacitor. Inorg. Chem. 2016, 55, 6552–6562. [Google Scholar] [CrossRef]

- Thomas, T.; Dixon, M.P.; Kueh, A.J.; Voss, A.K. Mof (MYST1 or KAT8) is essential for progression of embryonic development past the blastocyst stage and required for normal chromatin architecture. Mol. Cell. Biol. 2008, 28, 5093–5105. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fracaroli, A.M.; Siman, P.; Nagib, D.A.; Suzuki, M.; Furukawa, H.; Toste, F.D.; Yaghi, O.M. Seven Post-synthetic Covalent Reactions in Tandem Leading to Enzyme-like Complexity within Metal-Organic Framework Crystals. J. Am. Chem. Soc. 2016, 138, 8352–8355. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Strobel, S.A.; Cochrane, J.C. RNA catalysis: Ribozymes, ribosomes, and riboswitches. Curr. Opin. Chem. Biol. 2007, 11, 636–643. [Google Scholar] [CrossRef] [Green Version]

- Erlacher, M.D.; Polacek, N. Ribosomal catalysis: The evolution of mechanistic concepts for peptide bond formation and peptidyl-tRNA hydrolysis. RNA Biol. 2008, 5, 5–12. [Google Scholar] [CrossRef] [Green Version]

- Pitzer, J.; Steiner, K. Amides in Nature and Biocatalysis. J. Biotechnol. 2016, 235, 32–46. [Google Scholar] [CrossRef]

- Hagner, P.R.; Mazan-Mamczarz, K.; Dai, B.; Balzer, E.M.; Corl, S.; Martin, S.S.; Zhao, X.F.; Gartenhaus, R.B. Ribosomal protein S6 is highly expressed in non-Hodgkin lymphoma and associates with mRNA containing a 5’ terminal oligopyrimidine tract. Oncogene 2011, 30, 1531–1541. [Google Scholar] [CrossRef] [Green Version]

- Schmied, W.H.; Tnimov, Z.; Uttamapinant, C.; Rae, C.D.; Fried, S.D.; Chin, J.W. Controlling orthogonal ribosome subunit interactions enables evolution of new function. Nature 2018, 564, 444–448. [Google Scholar] [CrossRef]

- Woolford, J.L., Jr.; Baserga, S.J. Ribosome biogenesis in the yeast Saccharomyces cerevisiae. Genetics 2013, 195, 643–681. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bakshi, S.; Siryaporn, A.; Goulian, M.; Weisshaar, J.C. Superresolution imaging of ribosomes and RNA polymerase in live Escherichia coli cells. Mol. Microbiol. 2012, 85, 21–38. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Klet, R.C.; Tussupbayev, S.; Borycz, J.; Gallagher, J.R.; Stalzer, M.M.; Miller, J.T.; Gagliardi, L.; Hupp, J.T.; Marks, T.J.; Cramer, C.J.; et al. Single-Site Organozirconium Catalyst Embedded in a Metal-Organic Framework. J. Am. Chem. Soc. 2015, 137, 15680–15683. [Google Scholar] [CrossRef] [PubMed]

- Ji, P.; Solomon, J.B.; Lin, Z.; Johnson, A.; Jordan, R.F.; Lin, W. Transformation of Metal-Organic Framework Secondary Building Units into Hexanuclear Zr-Alkyl Catalysts for Ethylene Polymerization. J. Am. Chem. Soc. 2017, 139, 11325–11328. [Google Scholar] [CrossRef] [PubMed]

- Canivet, J.; Aguado, S.; Schuurman, Y.; Farrusseng, D. MOF-supported selective ethylene dimerization single-site catalysts through one-pot postsynthetic modification. J. Am. Chem. Soc. 2013, 135, 4195–4198. [Google Scholar] [CrossRef]

- Zhang, T.; Song, F.; Lin, W. Blocking bimolecular activation pathways leads to different regioselectivity in metal-organic framework catalysis. Chem. Commun. 2012, 48, 8766–8768. [Google Scholar] [CrossRef]

- Mlinar, A.N.; Shylesh, S.; Ho, O.C.; Bell, A.T. Propene Oligomerization using Alkali Metal- and Nickel-Exchanged Mesoporous Aluminosilicate Catalysts. ACS Catal. 2013, 4, 337–343. [Google Scholar] [CrossRef] [Green Version]

- Mlinar, A.N.; Keitz, B.K.; Gygi, D.; Bloch, E.D.; Long, J.R.; Bell, A.T. Selective Propene Oligomerization with Nickel(II)-Based Metal–Organic Frameworks. ACS Catal. 2014, 4, 717–721. [Google Scholar] [CrossRef]

- Metzger, E.D.; Comito, R.J.; Hendon, C.H.; Dinca, M. Mechanism of Single-Site Molecule-Like Catalytic Ethylene Dimerization in Ni-MFU-4l. J. Am. Chem. Soc. 2017, 139, 757–762. [Google Scholar] [CrossRef]

- Metzger, E.D.; Brozek, C.K.; Comito, R.J.; Dinca, M. Selective Dimerization of Ethylene to 1-Butene with a Porous Catalyst. ACS Cent. Sci. 2016, 2, 148–153. [Google Scholar] [CrossRef] [Green Version]

- Finiels, A.; Fajula, F.; Hulea, V. Nickel-based solid catalysts for ethylene oligomerization—A review. Catal. Sci. Technol. 2014, 4, 2412–2426. [Google Scholar] [CrossRef]

- Metzger, E.D.; Comito, R.J.; Wu, Z.; Zhang, G.; Dubey, R.C.; Xu, W.; Miller, J.T.; Dincă, M. Highly Selective Heterogeneous Ethylene Dimerization with a Scalable and Chemically Robust MOF Catalyst. ACS Sustain. Chem. Eng. 2019, 7, 6654–6661. [Google Scholar] [CrossRef]

- Dubey, R.J.; Comito, R.J.; Wu, Z.; Zhang, G.; Rieth, A.J.; Hendon, C.H.; Miller, J.T.; Dinca, M. Highly Stereoselective Heterogeneous Diene Polymerization by Co-MFU-4l: A Single-Site Catalyst Prepared by Cation Exchange. J. Am. Chem. Soc. 2017, 139, 12664–12669. [Google Scholar] [CrossRef] [PubMed]

- Comito, R.J.; Wu, Z.; Zhang, G.; Lawrence, J.A.; Korzynski, M.D., 3rd; Kehl, J.A.; Miller, J.T.; Dinca, M. Stabilized Vanadium Catalyst for Olefin Polymerization by Site Isolation in a Metal-Organic Framework. Angew. Chem. Int. Ed. Engl. 2018, 57, 8135–8139. [Google Scholar] [CrossRef] [PubMed]

- Park, H.D.; Comito, R.J.; Wu, Z.; Zhang, G.; Ricke, N.; Sun, C.; Van Voorhis, T.; Miller, J.T.; Román-Leshkov, Y.; Dincă, M. Gas-Phase Ethylene Polymerization by Single-Site Cr Centers in a Metal–Organic Framework. ACS Catal. 2020, 10, 3864–3870. [Google Scholar] [CrossRef]

- Vitorino, M.J.; Devic, T.; Tromp, M.; Férey, G.R.; Visseaux, M. Lanthanide Metal-Organic Frameworks as Ziegler-Natta Catalysts for the Selective Polymerization of Isoprene. Macromol. Chem. Phys. 2009, 210, 1923–1932. [Google Scholar] [CrossRef]

- Rodrigues, I.; Mihalcea, I.; Volkringer, C.; Loiseau, T.; Visseaux, M. Water-free neodymium 2,6-naphthalenedicarboxylates coordination complexes and their application as catalysts for isoprene polymerization. Inorg. Chem. 2012, 51, 483–490. [Google Scholar] [CrossRef]

- Russell, S.; Loiseau, T.; Volkringer, C.; Visseaux, M. Luminescent Lanthanide Metal Organic Frameworks for cis-Selective Isoprene Polymerization Catalysis. Inorganics 2015, 3, 467–481. [Google Scholar] [CrossRef] [Green Version]

- Escribano, P.; Julián-López, B.; Planelles-Aragó, J.; Cordoncillo, E.; Viana, B.; Sanchez, C. Photonic and nanobiophotonic properties of luminescent lanthanide-doped hybrid organic–inorganic materials. J. Mater. Chem. 2008, 18, 23–40. [Google Scholar] [CrossRef]

- Nguyen, H.L.; Gandara, F.; Furukawa, H.; Doan, T.L.; Cordova, K.E.; Yaghi, O.M. A Titanium-Organic Framework as an Exemplar of Combining the Chemistry of Metal- and Covalent-Organic Frameworks. J. Am. Chem. Soc. 2016, 138, 4330–4333. [Google Scholar] [CrossRef]

- Nguyen, H.L.; Vu, T.T.; Le, D.; Doan, T.L.H.; Nguyen, V.Q.; Phan, N.T.S. A Titanium–Organic Framework: Engineering of the Band-Gap Energy for Photocatalytic Property Enhancement. ACS Catal. 2016, 7, 338–342. [Google Scholar] [CrossRef]

- Lee, H.-C.; Antonietti, M.; Schmidt, B.V.K.J. A Cu(II) metal–organic framework as a recyclable catalyst for ARGET ATRP. Polym. Chem. 2016, 7, 7199–7203. [Google Scholar] [CrossRef] [Green Version]

- Lee, H.-C.; Fantin, M.; Antonietti, M.; Matyjaszewski, K.; Schmidt, B.V.K.J. Synergic Effect between Nucleophilic Monomers and Cu(II) Metal–Organic Framework for Visible-Light-Triggered Controlled Photopolymerization. Chem. Mater. 2017, 29, 9445–9455. [Google Scholar] [CrossRef]

- Marshall, N.; James, W.; Fulmer, J.; Crittenden, S.; Thompson, A.B.; Ward, P.A.; Rowe, G.T. Polythiophene Doping of the Cu-Based Metal-Organic Framework (MOF) HKUST-1 Using Innate MOF-Initiated Oxidative Polymerization. Inorg. Chem. 2019, 58, 5561–5575. [Google Scholar] [CrossRef] [PubMed]

- Xing, H.; Chen, D.; Li, X.; Liu, Y.; Wang, C.; Su, Z. A visible-light responsive zirconium metal–organic framework for living photopolymerization of methacrylates. RSC Adv. 2016, 6, 66444–66450. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, D.; Li, X.; Yu, Z.; Xia, Q.; Liang, D.; Xing, H. Visible-light-induced controlled radical polymerization of methacrylates mediated by a pillared-layer metal–organic framework. Green Chem. 2016, 18, 1475–1481. [Google Scholar] [CrossRef]

- Zhang, J.; Dumur, F.; Horcajada, P.; Livage, C.; Xiao, P.; Fouassier, J.P.; Gigmes, D.; Lalevée, J. Iron-Based Metal-Organic Frameworks (MOF) as Photocatalysts for Radical and Cationic Polymerizations under Near UV and Visible LEDs (385-405 nm). Macromol. Chem. Phys. 2016, 217, 2534–2540. [Google Scholar] [CrossRef]

- Fu, Q.; Ranji-Burachaloo, H.; Liu, M.; McKenzie, T.G.; Tan, S.; Reyhani, A.; Nothling, M.D.; Dunstan, D.E.; Qiao, G.G. Controlled RAFT polymerization facilitated by a nanostructured enzyme mimic. Polym. Chem. 2018, 9, 4448–4454. [Google Scholar] [CrossRef]

- Reyhani, A.; Ranji-Burachaloo, H.; McKenzie, T.G.; Fu, Q.; Qiao, G.G. Heterogeneously Catalyzed Fenton-Reversible Addition–Fragmentation Chain Transfer Polymerization in the Presence of Air. Macromolecules 2019, 52, 3278–3287. [Google Scholar] [CrossRef]

- Arata, K. Organic syntheses catalyzed by superacidic metal oxides: Sulfated zirconia and related compounds. Green Chem. 2009, 11, 1719–1728. [Google Scholar] [CrossRef]

- Trickett, C.A.; Osborn Popp, T.M.; Su, J.; Yan, C.; Weisberg, J.; Huq, A.; Urban, P.; Jiang, J.; Kalmutzki, M.J.; Liu, Q.; et al. Identification of the strong Bronsted acid site in a metal-organic framework solid acid catalyst. Nat. Chem. 2019, 11, 170–176. [Google Scholar] [CrossRef] [PubMed]

- Liu, P.; Redekop, E.; Gao, X.; Liu, W.C.; Olsbye, U.; Somorjai, G.A. Oligomerization of Light Olefins Catalyzed by Bronsted-Acidic Metal-Organic Framework-808. J. Am. Chem. Soc. 2019, 141, 11557–11564. [Google Scholar] [CrossRef] [PubMed]

- Ben, T.; Shi, K.; Cui, Y.; Pei, C.; Zuo, Y.; Guo, H.; Zhang, D.; Xu, J.; Deng, F.; Tian, Z.; et al. Targeted synthesis of an electroactive organic framework. J. Mater. Chem. 2011, 21, 3451–3479. [Google Scholar] [CrossRef] [Green Version]

- Lu, C.; Ben, T.; Xu, S.; Qiu, S. Electrochemical synthesis of a microporous conductive polymer based on a metal-organic framework thin film. Angew. Chem. Int. Ed. Engl. 2014, 53, 6454–6458. [Google Scholar] [CrossRef] [PubMed]

- Klyatskaya, S.; Kanj, A.B.; Molina-Jiron, C.; Heidrich, S.; Velasco, L.; Natzeck, C.; Gliemann, H.; Heissler, S.; Weidler, P.; Wenzel, W.; et al. Conductive Metal-Organic Framework Thin Film Hybrids by Electropolymerization of Monosubstituted Acetylenes. ACS Appl. Mater. Interfaces 2020, 12, 30972–30979. [Google Scholar] [CrossRef]

- Jadhav, A.; Gupta, K.; Ninawe, P.; Ballav, N. Imparting Multifunctionality by Utilizing Biporosity in a Zirconium-Based Metal-Organic Framework. Angew. Chem. Int. Ed. Engl. 2020, 59, 2215–2219. [Google Scholar] [CrossRef]

- Yanai, N.; Uemura, T.; Ohba, M.; Kadowaki, Y.; Maesato, M.; Takenaka, M.; Nishitsuji, S.; Hasegawa, H.; Kitagawa, S. Fabrication of two-dimensional polymer arrays: Template synthesis of polypyrrole between redox-active coordination nanoslits. Angew. Chem. Int. Ed. Engl. 2008, 47, 9883–9886. [Google Scholar] [CrossRef]

- Le Ouay, B.; Boudot, M.; Kitao, T.; Yanagida, T.; Kitagawa, S.; Uemura, T. Nanostructuration of PEDOT in Porous Coordination Polymers for Tunable Porosity and Conductivity. J. Am. Chem. Soc. 2016, 138, 10088–10091. [Google Scholar] [CrossRef]

- MacLean, M.W.; Kitao, T.; Suga, T.; Mizuno, M.; Seki, S.; Uemura, T.; Kitagawa, S. Unraveling Inter- and Intrachain Electronics in Polythiophene Assemblies Mediated by Coordination Nanospaces. Angew. Chem. Int. Ed. Engl. 2016, 55, 708–713. [Google Scholar] [CrossRef]

- Kitao, T.; MacLean, M.W.A.; Le Ouay, B.; Sasaki, Y.; Tsujimoto, M.; Kitagawa, S.; Uemura, T. Preparation of polythiophene microrods with ordered chain alignment using nanoporous coordination template. Polym. Chem. 2017, 8, 5077–5081. [Google Scholar] [CrossRef]

- Lee, H.-C.; Hwang, J.; Schilde, U.; Antonietti, M.; Matyjaszewski, K.; Schmidt, B.V.K.J. Toward Ultimate Control of Radical Polymerization: Functionalized Metal–Organic Frameworks as a Robust Environment for Metal-Catalyzed Polymerizations. Chem. Mater. 2018, 30, 2983–2994. [Google Scholar] [CrossRef]

- Hwang, J.; Lee, H.-C.; Antonietti, M.; Schmidt, B.V.K.J. Free radical and RAFT polymerization of vinyl esters in metal–organic-frameworks. Polym. Chem. 2017, 8, 6204–6208. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Chen, D.; Guo, Z.; Wei, Z.; Zhang, X.; Xing, H. Visible-light-induced controlled radical polymerization of methacrylates mediated by zirconium-porphryinic metal–organic frameworks. New J. Chem. 2020, 44, 5235–5242. [Google Scholar] [CrossRef]

- Anan, S.; Mochizuki, Y.; Kokado, K.; Sada, K. Step-Growth Copolymerization Between an Immobilized Monomer and a Mobile Monomer in Metal-Organic Frameworks. Angew. Chem. Int. Ed. Engl. 2019, 58, 8018–8023. [Google Scholar] [CrossRef] [PubMed]

- Kobayashi, Y.; Honjo, K.; Kitagawa, S.; Uemura, T. Preparation of Porous Polysaccharides Templated by Coordination Polymer with Three-Dimensional Nanochannels. ACS Appl. Mater. Interfaces 2017, 9, 11373–11379. [Google Scholar] [CrossRef]

- Kitao, T.; Bracco, S.; Comotti, A.; Sozzani, P.; Naito, M.; Seki, S.; Uemura, T.; Kitagawa, S. Confinement of single polysilane chains in coordination nanospaces. J. Am. Chem. Soc. 2015, 137, 5231–5238. [Google Scholar] [CrossRef]

- Distefano, G.; Suzuki, H.; Tsujimoto, M.; Isoda, S.; Bracco, S.; Comotti, A.; Sozzani, P.; Uemura, T.; Kitagawa, S. Highly ordered alignment of a vinyl polymer by host-guest cross-polymerization. Nat. Chem. 2013, 5, 335–341. [Google Scholar] [CrossRef]

- Mochizuki, S.; Ogiwara, N.; Takayanagi, M.; Nagaoka, M.; Kitagawa, S.; Uemura, T. Sequence-regulated copolymerization based on periodic covalent positioning of monomers along one-dimensional nanochannels. Nat. Commun. 2018, 9, 329. [Google Scholar] [CrossRef] [Green Version]

- Uemura, T.; Kitaura, R.; Ohta, Y.; Nagaoka, M.; Kitagawa, S. Nanochannel-promoted polymerization of substituted acetylenes in porous coordination polymers. Angew. Chem. Int. Ed. Engl. 2006, 45, 4112–4116. [Google Scholar] [CrossRef]

- Uemura, T.; Hiramatsu, D.; Kubota, Y.; Takata, M.; Kitagawa, S. Topotactic linear radical polymerization of divinylbenzenes in porous coordination polymers. Angew. Chem. Int. Ed. Engl. 2007, 46, 4987–4990. [Google Scholar] [CrossRef]

- Ling, J.J.J.; Policarpo, R.L.; Rabideau, A.E.; Liao, X.L.; Pentelute, B.L. Protein Thioester Synthesis Enabled by Sortase. J. Am. Chem. Soc. 2012, 134, 10749–10752. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Uemura, T.; Nakanishi, R.; Kaseda, T.; Uchida, N.; Kitagawa, S. Controlled Cyclopolymerization of Difunctional Vinyl Monomers in Coordination Nanochannels. Macromolecules 2014, 47, 7321–7326. [Google Scholar] [CrossRef]

- Kobayashi, Y.; Horie, Y.; Honjo, K.; Uemura, T.; Kitagawa, S. The controlled synthesis of polyglucose in one-dimensional coordination nanochannels. Chem. Commun. 2016, 52, 5156–5159. [Google Scholar] [CrossRef]

- Rivera-Torrente, M.; Pletcher, P.D.; Jongkind, M.K.; Nikolopoulos, N.; Weckhuysen, B.M. Ethylene Polymerization over Metal–Organic Framework Crystallites and the Influence of Linkers on Their Fracturing Process. ACS Catal. 2019, 9, 3059–3069. [Google Scholar] [CrossRef] [Green Version]

- Dong, Z.; Sun, Y.; Chu, J.; Zhang, X.; Deng, H. Multivariate Metal-Organic Frameworks for Dialing-in the Binding and Programming the Release of Drug Molecules. J. Am. Chem. Soc. 2017, 139, 14209–14216. [Google Scholar] [CrossRef]

- Helal1, A.; Yamani1, Z.H.; Cordova1, K.E.; Yaghi1, O.M. Multivariate metal-organic frameworks. Natl. Sci. Rev. 2017, 4, 296–298. [Google Scholar] [CrossRef]

- Ji, Z.; Li, T.; Yaghi, O.M. Sequencing of metals in multivariate metal-organic frameworks. Science 2020, 369, 674–780. [Google Scholar] [CrossRef]

- Feng, L.; Yuan, S.; Li, J.L.; Wang, K.Y.; Day, G.S.; Zhang, P.; Wang, Y.; Zhou, H.C. Uncovering Two Principles of Multivariate Hierarchical Metal-Organic Framework Synthesis via Retrosynthetic Design. ACS Cent. Sci. 2018, 4, 1719–1726. [Google Scholar] [CrossRef] [Green Version]

- Nath, I.; Chakraborty, J.; Verpoort, F. Metal organic frameworks mimicking natural enzymes: A structural and functional analogy. Chem. Soc. Rev. 2016, 45, 4127–4170. [Google Scholar] [CrossRef]

- Wright, A.M.; Wu, Z.; Zhang, G.; Mancuso, J.L.; Comito, R.J.; Day, R.W.; Hendon, C.H.; Miller, J.T.; Dincă, M. A Structural Mimic of Carbonic Anhydrase in a Metal-Organic Framework. Chem 2018, 4, 2894–2901. [Google Scholar] [CrossRef] [Green Version]

- Roberts, J.M.; Fini, B.M.; Sarjeant, A.A.; Farha, O.K.; Hupp, J.T.; Scheidt, K.A. Urea metal-organic frameworks as effective and size-selective hydrogen-bond catalysts. J. Am. Chem. Soc. 2012, 134, 3334–3337. [Google Scholar] [CrossRef] [PubMed]

- McGuirk, C.M.; Katz, M.J.; Stern, C.L.; Sarjeant, A.A.; Hupp, J.T.; Farha, O.K.; Mirkin, C.A. Turning on catalysis: Incorporation of a hydrogen-bond-donating squaramide moiety into a Zr metal-organic framework. J. Am. Chem. Soc. 2015, 137, 919–925. [Google Scholar] [CrossRef] [PubMed]

- Siu, P.W.; Brown, Z.J.; Farha, O.K.; Hupp, J.T.; Scheidt, K.A. A mixed dicarboxylate strut approach to enhancing catalytic activity of a de novo urea derivative of metal-organic framework UiO-67. Chem. Commun. 2013, 49, 10920–10922. [Google Scholar] [CrossRef] [PubMed]

- Dong, X.W.; Liu, T.; Hu, Y.Z.; Liu, X.Y.; Che, C.M. Urea postmodified in a metal-organic framework as a catalytically active hydrogen-bond-donating heterogeneous catalyst. Chem. Commun. 2013, 49, 7681–7683. [Google Scholar] [CrossRef]

- Katz, M.J.; Mondloch, J.E.; Totten, R.K.; Park, J.K.; Nguyen, S.T.; Farha, O.K.; Hupp, J.T. Simple and compelling biomimetic metal-organic framework catalyst for the degradation of nerve agent simulants. Angew. Chem. Int. Ed. Engl. 2014, 53, 497–501. [Google Scholar] [CrossRef]

- Yang, X.L.; Wu, C.D. Metalloporphyrinic framework containing multiple pores for highly efficient and selective epoxidation. Inorg. Chem. 2014, 53, 4797–4799. [Google Scholar] [CrossRef]

- Pullen, S.; Fei, H.; Orthaber, A.; Cohen, S.M.; Ott, S. Enhanced photochemical hydrogen production by a molecular diiron catalyst incorporated into a metal-organic framework. J. Am. Chem. Soc. 2013, 135, 16997–17003. [Google Scholar] [CrossRef]

- Sasan, K.; Lin, Q.; Mao, C.; Feng, P. Incorporation of iron hydrogenase active sites into a highly stable metal-organic framework for photocatalytic hydrogen generation. Chem. Commun. 2014, 50, 10390–10393. [Google Scholar] [CrossRef]

- Feng, Y.; Chen, C.; Liu, Z.; Fei, B.; Lin, P.; Li, Q.; Sun, S.; Du, S. Application of a Ni mercaptopyrimidine MOF as highly efficient catalyst for sunlight-driven hydrogen generation. J. Mater. Chem. A 2015, 3, 7163–7169. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, F.; Ji, P. Recent Advances in the Application of Metal–Organic Frameworks for Polymerization and Oligomerization Reactions. Catalysts 2020, 10, 1441. https://0-doi-org.brum.beds.ac.uk/10.3390/catal10121441

Ren F, Ji P. Recent Advances in the Application of Metal–Organic Frameworks for Polymerization and Oligomerization Reactions. Catalysts. 2020; 10(12):1441. https://0-doi-org.brum.beds.ac.uk/10.3390/catal10121441

Chicago/Turabian StyleRen, Fangyu, and Pengfei Ji. 2020. "Recent Advances in the Application of Metal–Organic Frameworks for Polymerization and Oligomerization Reactions" Catalysts 10, no. 12: 1441. https://0-doi-org.brum.beds.ac.uk/10.3390/catal10121441