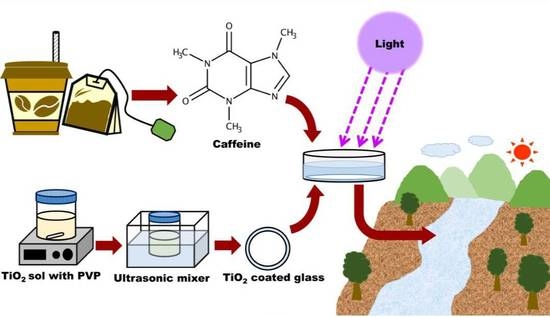

Enhanced Photocatalytic Degradation of Caffeine Using Titanium Dioxide Photocatalyst Immobilized on Circular Glass Sheets under Ultraviolet C Irradiation

Abstract

:1. Introduction

2. Results

2.1. Characterizations of TiO2 Film Immobilized on Glass Sheets

2.1.1. Morphology of TiO2 Film

2.1.2. Crystalline Structure of TiO2 Film

2.2. Degradation of Caffeine by Photocatalytic Process

2.2.1. Effects of Irradiation Time and Photocatalyst Coated

2.2.2. Effects of Initial Concentration

2.2.3. Reusability of Photocatalyst

3. Discussion

4. Materials and Methods

4.1. Materials

4.2. Preparation of TiO2 Immobilized Glass Sheets

4.3. Characterizations

4.4. Photocatalytic Reactor

4.5. Photocatalytic Experiment

4.6. Analysis of Caffeine Concentration

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Cardenas, M.A.R.; Ali, I.; Lai, F.Y.; Dawes, L.; Thier, R.; Rajapakse, J. Removal of micropollutants through a biological wastewater treatment plant in a subtropical climate, Queensland-Australia. J. Environ. Health Sci. Eng. 2016, 14, 14–23. [Google Scholar] [CrossRef] [Green Version]

- Turner, R.D.; Warne, M.S.J.; Dawes, L.A.; Thompson, K.; Will, G.D. Greywater irrigation as a source of organic micro-pollutants to shallow groundwater and nearby surface water. Sci. Total Environ. 2019, 669, 570–578. [Google Scholar] [CrossRef]

- Indermuhle, C.; De Vidales, M.J.M.; Sáez, C.; Robles, J.; Cañizares, P.; García-Reyes, J.F.; Molina-Díaz, A.; Comninellis, C.; Rodrigo, M.A. Degradation of caffeine by conductive diamond electrochemical oxidation. Chemosphere 2013, 93, 1720–1725. [Google Scholar] [CrossRef]

- Marques, R.R.; Sampaio, M.J.; Carrapiço, P.M.; Silva, C.G.; Morales-Torres, S.; Dražić, G.; Faria, J.L.; Silva, A.M. Photocatalytic degradation of caffeine: Developing solutions for emerging pollutants. Catal. Today 2013, 209, 108–115. [Google Scholar] [CrossRef]

- Ghosh, M.; Manoli, K.; Shen, X.; Wang, J.H.; Ray, A.K. Solar photocatalytic degradation of caffeine with titanium dioxide and zinc oxide nanoparticles. J. Photochem. Photobiol. A 2019, 377, 1–7. [Google Scholar] [CrossRef]

- Arnaud, M. The Pharmacology of Caffeine. In Progress in Drug Research/Fortschritte Der Arzneimittelforschung/Progrès Des Recherches Pharmaceutiques; Birkhäuser: Basel, Switzerland, 1987; pp. 273–313. [Google Scholar]

- Edwards, Q.A.; Kulikov, S.M.; Garner-O’Neale, L.D. Caffeine in surface and wastewaters in Barbados, West Indies. SpringerPlus 2015, 4, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Elhalil, A.; Elmoubarki, R.; Farnane, M.; Machrouhi, A.; Sadiq, M.; Mahjoubi, F.; Qourzal, S.; Barka, N. Photocatalytic degradation of caffeine as a model pharmaceutical pollutant on Mg doped ZnO-Al2O3 heterostructure. Environ. Nanotechnol. Monit. Manag. 2018, 10, 63–72. [Google Scholar] [CrossRef]

- Chuang, L.C.; Luo, C.H.; Huang, S.W.; Wu, Y.C.; Huang, Y.C. Photocatalytic Degradation Mechanism and Kinetics of Caffeine in Aqueous Suspension of Nano-TiO2. In Advanced Materials Research; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2011; Volume 214, pp. 97–102. [Google Scholar]

- Zarrelli, A.; DellaGreca, M.; Iesce, M.R.; Lavorgna, M.; Temussi, F.; Schiavone, L.; Criscuolo, E.; Parrella, A.; Previtera, L.; Isidori, M. Ecotoxicological evaluation of caffeine and its derivatives from a simulated chlorination step. Sci. Total Environ. 2014, 470, 453–458. [Google Scholar] [CrossRef] [Green Version]

- Arfanis, M.K.; Adamou, P.; Moustakas, N.G.; Triantis, T.M.; Kontos, A.G.; Falaras, P. Photocatalytic degradation of salicylic acid and caffeine emerging contaminants using titania nanotubes. Chem. Eng. J. 2017, 310, 525–536. [Google Scholar] [CrossRef]

- Buerge, I.J.; Poiger, T.; Müller, M.D.; Buser, H.R. Caffeine, an anthropogenic marker for wastewater contamination of surface waters. Environ. Sci. Technol. 2003, 37, 691–700. [Google Scholar] [CrossRef]

- Luna, R.; Solis, C.; Ortiz, N.; Galicia, A.; Sandoval, F.; Zermeño, B.; Moctezuma, E. Photocatalytic Degradation of Caffeine in a Solar Reactor System. Int. J. Chem. React. Eng. 2018, 16, 1–10. [Google Scholar] [CrossRef]

- Moore, M.; Greenway, S.; Farris, J.; Guerra, B. Assessing caffeine as an emerging environmental concern using conventional approaches. Arch. Environ. Contam. Toxicol. 2008, 54, 31–35. [Google Scholar] [CrossRef]

- Pires, A.; Almeida, Â.; Calisto, V.; Schneider, R.J.; Esteves, V.I.; Wrona, F.J.; Soares, A.M.; Figueira, E.; Freitas, R. Long-term exposure of polychaetes to caffeine: Biochemical alterations induced in Diopatra neapolitana and Arenicola marina. Environ. Pollut. 2016, 214, 456–463. [Google Scholar] [CrossRef]

- Fernandes, A.; Mello, F.; Thode Filho, S.; Carpes, R.; Honório, J.; Marques, M.; Felzenszwalb, I.; Ferraz, E. Impacts of discarded coffee waste on human and environmental health. Ecotoxicol. Environ. Saf. 2017, 141, 30–36. [Google Scholar] [CrossRef]

- Rosal, R.; Rodríguez, A.; Perdigón-Melón, J.A.; Petre, A.; García-Calvo, E.; Gómez, M.J.; Agüera, A.; Fernández-Alba, A.R. Degradation of caffeine and identification of the transformation products generated by ozonation. Chemosphere 2009, 74, 825–831. [Google Scholar] [CrossRef]

- Souza, F.S.; Féris, L.A. Degradation of caffeine by advanced oxidative processes: O3 and O3/UV. Ozone Sci. Eng. 2015, 37, 379–384. [Google Scholar] [CrossRef]

- Klamerth, N.; Malato, S.; Maldonado, M.; Aguera, A.; Fernández-Alba, A. Application of photo-Fenton as a tertiary treatment of emerging contaminants in municipal wastewater. Environ. Sci. Technol. 2010, 44, 1792–1798. [Google Scholar] [CrossRef]

- Trovó, A.G.; Silva, T.F.; Gomes, O., Jr.; Machado, A.E.; Neto, W.B.; Muller, P.S., Jr.; Daniel, D. Degradation of caffeine by photo-Fenton process: Optimization of treatment conditions using experimental design. Chemosphere 2013, 90, 170–175. [Google Scholar]

- Gould, J.; Richards, J. The kinetics and products of the chlorination of caffeine in aqueous solution. Water Res. 1984, 18, 1001–1009. [Google Scholar] [CrossRef]

- Shu, Z.; Bolton, J.R.; Belosevic, M.; El Din, M.G. Photodegradation of emerging micropollutants using the medium-pressure UV/H2O2 advanced oxidation process. Water Res. 2013, 47, 2881–2889. [Google Scholar] [CrossRef]

- Muangmora, R.; Kemacheevakul, P.; Chuangchote, S. Titanium dioxide and its modified forms as photocatalysts for air treatment. Curr. Anal. Chem. 2020, 16, in press. [Google Scholar] [CrossRef]

- Srisasiwimon, N.; Chuangchote, S.; Laosiripojana, N.; Sagawa, T. TiO2/lignin-based carbon composited photocatalysts for enhanced photocatalytic conversion of lignin to high value chemicals. ACS Sustain. Chem. Eng. 2018, 6, 13968–13976. [Google Scholar] [CrossRef]

- Sudha, D.; Sivakumar, P. Review on the photocatalytic activity of various composite catalysts. Chem. Eng. Process 2015, 97, 112–133. [Google Scholar] [CrossRef]

- Ahmad, R.; Ahmad, Z.; Khan, A.U.; Mastoi, N.R.; Aslam, M.; Kim, J. Photocatalytic systems as an advanced environmental remediation: Recent developments, limitations and new avenues for applications. J. Environ. Chem. Eng. 2016, 4, 4143–4164. [Google Scholar] [CrossRef]

- Awfa, D.; Ateia, M.; Fujii, M.; Johnson, M.S.; Yoshimura, C. Photodegradation of pharmaceuticals and personal care products in water treatment using carbonaceous-TiO2 composites: A critical review of recent literature. Water Res. 2018, 142, 26–45. [Google Scholar]

- Pathakoti, K.; Manubolu, M.; Hwang, H.M. Nanotechnology Applications for Environmental Industry. In Handbook of Nanomaterials for Industrial Applications; Hussain, C.M., Ed.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 894–907. [Google Scholar]

- Bouarioua, A.; Zerdaoui, M. Photocatalytic activities of TiO2 layers immobilized on glass substrates by dip-coating technique toward the decolorization of methyl orange as a model organic pollutant. J. Environ. Chem. Eng. 2017, 5, 1565–1574. [Google Scholar] [CrossRef]

- Laamari, M.; Ben Youssef, A.; Bousselmi, L. Electrophoretic deposition of titanium dioxide films on copper in aqueous media. Water Sci. Technol. 2016, 74, 424–430. [Google Scholar] [CrossRef]

- Sirirerkratana, K.; Kemacheevakul, P.; Chuangchote, S. Color removal from wastewater by photocatalytic process using titanium dioxide-coated glass, ceramic tile, and stainless steel sheets. J. Clean Prod. 2019, 215, 123–130. [Google Scholar] [CrossRef]

- Hasan, A.; Waibhaw, G.; Tiwari, S.; Dharmalingam, K.; Shukla, I.; Pandey, L.M. Fabrication and characterization of chitosan, polyvinylpyrrolidone, and cellulose nanowhiskers nanocomposite films for wound healing drug delivery application. J. Biomed. Mater. Res. A 2017, 105, 2391–2404. [Google Scholar] [CrossRef]

- Xie, H.; Liu, B.; Zhao, X. Facile process to greatly improve the photocatalytic activity of the TiO2 thin film on window glass for the photodegradation of acetone and benzene. Chem. Eng. J. 2016, 284, 1156–1164. [Google Scholar] [CrossRef]

- Albano, G.; Evangelisti, C.; Aronica, L.A. Hydrogenolysis of Benzyl Protected Phenols and Aniline Promoted by Supported Palladium Nanoparticles. ChemistrySelect 2017, 2, 384–388. [Google Scholar] [CrossRef]

- Albano, G.; Interlandi, S.; Evangelisti, C.; Aronica, L.A. Polyvinylpyridine-Supported Palladium Nanoparticles: A Valuable Catalyst for the Synthesis of Alkynyl Ketones via Acyl Sonogashira Reactions. Catal. Lett. 2020, 150, 652–659. [Google Scholar] [CrossRef]

- Chaudhuri, B.; Mondal, B.; Ray, S.; Sarkar, S. A novel biocompatible conducting polyvinyl alcohol (PVA)-polyvinylpyrrolidone (PVP)-hydroxyapatite (HAP) composite scaffolds for probable biological application. Coll. Surf. B Biointerfaces 2016, 143, 71–80. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Feng, G. A one-step-assembled three-dimensional network of silver/polyvinylpyrro lidone (PVP) nanowires and its application in energy storage. Nanoscale 2020, 12, 10573–10583. [Google Scholar] [CrossRef] [PubMed]

- Yao, J.; Takahashi, M.; Yoko, T. Controlled preparation of macroporous TiO2 films by photo polymerization-induced phase separation method and their photocatalytic performance. Thin Solid Films 2009, 517, 6479–6485. [Google Scholar] [CrossRef]

- Jiang, H.; Dai, H.; Meng, X.; Zhang, L.; Deng, J.; Liu, Y.; Au, C.T. Hydrothermal fabrication and visible-light-driven photocatalytic properties of bismuth vanadate with multiple morphologies and/or porous structures for Methyl Orange degradation. J. Environ. Sci. 2012, 24, 449–457. [Google Scholar] [CrossRef]

- Ohno, T.; Sarukawa, K.; Tokieda, K.; Matsumura, M. Morphology of a TiO2 photocatalyst (Degussa, P-25) consisting of anatase and rutile crystalline phases. J. Catal. 2001, 203, 82–86. [Google Scholar] [CrossRef]

- Neppolian, B.; Wang, Q.; Jung, H.; Choi, H. Ultrasonic-assisted sol-gel method of preparation of TiO2 nano-particles: Characterization, properties and 4-chlorophenol removal application. Ultrason. Sonochem. 2007, 15, 649–658. [Google Scholar] [CrossRef]

- Moghaddam, H.M.; Nasirian, S. Ultrasonic wave effects on the diameter of TiO2 nanoparticles. S. Afr. J. Sci. 2011, 107, 01–05. [Google Scholar]

- Nosaka, Y.; Nakamura, M.; Hirakawa, T. Behavior of superoxide radicals formed on TiO2 powder photocatalysts studied by a chemiluminescent probe method. Phys. Chem. Chem. Phys. 2002, 4, 1088–1092. [Google Scholar] [CrossRef]

- Li, M.; Yin, J.J.; Wamer, W.G.; Lo, Y.M. Mechanistic characterization of titanium dioxide nanoparticle-induced toxicity using electron spin resonance. J. Food Drug Anal. 2014, 22, 76–85. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Abdellah, M.H.; Nosier, S.A.; El-Shazly, A.H.; Mubarak, A.A. Photocatalytic decolorization of methylene blue using TiO2/UV system enhanced by air sparging. Alex. Eng. J. 2018, 57, 3727–3735. [Google Scholar] [CrossRef]

- Ge, J.; Zhang, Y.; Heo, Y.J.; Park, S.J. Advanced Design and Synthesis of Composite Photocatalysts for the Remediation of Wastewater: A Review. Catalysts 2019, 9, 122. [Google Scholar] [CrossRef] [Green Version]

- Krivec, M.; Žagar, K.; Suhadolnik, L.; Čeh, M.; Dražić, G. Highly efficient TiO2-based microreactor for photocatalytic applications. ACS Appl. Mater. Interfaces 2013, 5, 9088–9094. [Google Scholar] [CrossRef] [PubMed]

- Sacco, O.; Sannino, D.; Matarangolo, M.; Viano, V. Room Temperature Synthesis of V-Doped TiO2 and Its Photocatalytic Activity in the Removal of Caffeine under UV Irradiation. Materials 2019, 12, 911. [Google Scholar] [CrossRef] [Green Version]

- Simonsen, M.E.; Jensen, H.; Li, Z.; Søgaard, E.G. Surface properties and photocatalytic activity of nanocrystalline titania films. J. Photochem. Photobiol. A 2008, 200, 192–200. [Google Scholar] [CrossRef] [Green Version]

| Photocatalyst | The Initial Concentration of Caffeine (mg/L) | Light Source | Irradiation Time (h) | Removal Efficiency | Reference |

|---|---|---|---|---|---|

| Commercial TiO2 Evonik-Degussa P25 (powder) | 20 | Natural Sunlight | 3 | ~100% | [13] |

| Commercial TiO2 Sigma-Aldrich (powder) | 30 | Solar simulator | 8 | ~100% | [5] |

| TiO2 synthesized by sol–gel method (powder) | 25 | UVA-LED strip | 6 | 80% | [48] |

| Commercial TiO2 Evonik-Degussa P25 coated on microscopy glass | 15 | UVA lamp | 4 | ~65% | [11] |

| TiO2 nanotube synthesized by electrochemical anodization | 15 | UVA lamp | 4 | ~50% | [11] |

| TiO2 film synthesized by sol–gel method coated on the circular glass sheet | 20 | UVC lamp | 3 | ~100% | This study |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muangmora, R.; Kemacheevakul, P.; Punyapalakul, P.; Chuangchote, S. Enhanced Photocatalytic Degradation of Caffeine Using Titanium Dioxide Photocatalyst Immobilized on Circular Glass Sheets under Ultraviolet C Irradiation. Catalysts 2020, 10, 964. https://0-doi-org.brum.beds.ac.uk/10.3390/catal10090964

Muangmora R, Kemacheevakul P, Punyapalakul P, Chuangchote S. Enhanced Photocatalytic Degradation of Caffeine Using Titanium Dioxide Photocatalyst Immobilized on Circular Glass Sheets under Ultraviolet C Irradiation. Catalysts. 2020; 10(9):964. https://0-doi-org.brum.beds.ac.uk/10.3390/catal10090964

Chicago/Turabian StyleMuangmora, Rattana, Patiya Kemacheevakul, Patiparn Punyapalakul, and Surawut Chuangchote. 2020. "Enhanced Photocatalytic Degradation of Caffeine Using Titanium Dioxide Photocatalyst Immobilized on Circular Glass Sheets under Ultraviolet C Irradiation" Catalysts 10, no. 9: 964. https://0-doi-org.brum.beds.ac.uk/10.3390/catal10090964