Porous Silica-Based Organic-Inorganic Hybrid Catalysts: A Review

Abstract

:1. Introduction to Hybrid Organic-Inorganic Materials

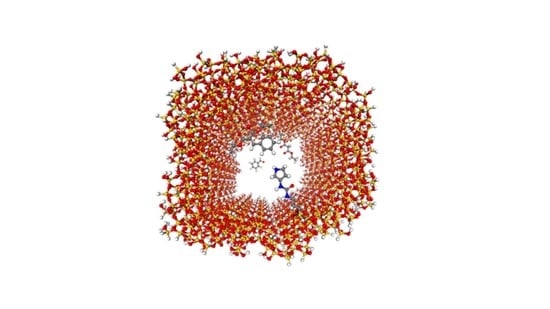

2. Mesoporous Silica-Based Hybrid Materials

2.1. Post-Synthetic Modification (Grafting)

2.2. Co-Condensation Method (“One-Pot”)

2.3. Periodic Mesoporous Organosilicas (PMOs)

3. Sol-Gel Chemistry and Hybrid Materials

3.1. Hydrolysis Reactions

3.2. Condensation Reactions

3.3. Particle Growth and Si-O-Si Hydrolysis

3.4. Fluoride-Catalyzed Hydrolysis and Condensation

3.5. Surfactant-Mediated Sol-Gel Synthesis

3.6. Silyl-Derivatives Precursors

4. Silica-Based Hybrids in Heterogeneous Catalysis

4.1. Acid Catalysts

Sulfonated Periodic Mesoporous Organosilicas (PMOs)

4.2. Base Catalysts

Base–H-Bond Donor Cooperative Catalysis

4.3. Organometallic Catalysts

5. Silica-Based Multi-Functional Hybrid Catalysts

6. Conclusions and Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chorkendorff, I.; Niemantsverdriet, J.W. Concepts of Modern Catalysis and Kinetics, 2nd ed.; Wiley-VCH: Hoboken, NJ, USA, 2007. [Google Scholar]

- Gallego, E.M.; Paris, C.; Cantín, Á.; Moliner, M.; Corma, A. Conceptual Similarities between Zeolites and Artificial Enzymes. Chem. Sci. 2019, 10, 8009–8015. [Google Scholar]

- Gallego, E.M.; Portilla, M.T.; Paris, C.; León-Escamilla, A.; Boronat, M.; Moliner, M.; Corma, A. “Ab Initio” Synthesis of Zeolites for Preestablished Catalytic Reactions. Science 2017, 355, 1051–1054. [Google Scholar]

- Wohlfahrt, G.; Witt, S.; Hendle, J.; Schomburg, D.; Kalisz, H.M.; Hecht, H.J. 1.8 and 1.9 Å Resolution Structures of the Penicillium Amagasakiense and Aspergillus Niger Glucose Oxidases as a Basis for Modelling Substrate Complexes. Acta Crystallogr. Sect. D Biol. Crystallogr. 1999, 55, 969–977. [Google Scholar]

- Donoeva, B.; De Jong, K.P. Torn between Two Sites. Nat. Mater. 2020, 19, 5–6. [Google Scholar]

- Kamat, P.V. Photophysical, Photochemical and Photocatalytic Aspects of Metal Nanoparticles. J. Phys. Chem. B 2002, 106, 7729–7744. [Google Scholar]

- Jain, P.K.; Huang, X.; El-Sayed, I.H.; El-Sayed, M.A. Review of Some Interesting Surface Plasmon Resonance-Enhanced Properties of Noble Metal Nanoparticles and Their Applications to Biosystems. Plasmonics 2007, 2, 107–118. [Google Scholar]

- Liu, L.; Corma, A. Metal Catalysts for Heterogeneous Catalysis: From Single Atoms to Nanoclusters and Nanoparticles. Chem. Rev. 2018, 118, 4981–5079. [Google Scholar]

- Qiao, B.; Wang, A.; Yang, X.; Allard, L.F.; Jiang, Z.; Cui, Y.; Liu, J.; Li, J.; Zhang, T. Single-Atom Catalysis of CO Oxidation Using Pt/FeOx. Nat. Chem. 2011, 3, 634–641. [Google Scholar] [PubMed]

- Wang, A.; Li, J.; Zhang, T. Heterogeneous Single-Atom Catalysis. Nat. Rev. Chem. 2018, 2, 65–81. [Google Scholar]

- Sanchez, C.; Julián, B.; Belleville, P.; Popall, M. Applications of Hybrid Organic-Inorganic Nanocomposites. J. Mater. Chem. 2005, 15, 3559–3592. [Google Scholar]

- Martins Estevão, B.; Miletto, I.; Marchese, L.; Gianotti, E. Optimized Rhodamine B Labeled Mesoporous Silica Nanoparticles as Fluorescent Scaffolds for the Immobilization of Photosensitizers: A Theranostic Platform for Optical Imaging and Photodynamic Therapy. Phys. Chem. Chem. Phys. 2016, 18, 9042–9052. [Google Scholar] [PubMed]

- Parejo, P.G.; Alvarez-Herrero, A.; Zayat, M.; Levy, D. Thermo-Optic Properties of Hybrid Sol–Gel Thin Films Doped with Rhodamine 6G at High Vacuum Conditions. J. Mater. Sci. 2015, 50, 6677–6687. [Google Scholar]

- Catauro, M.; Barrino, F.; Poggetto, G.D.; Crescente, G.; Piccolella, S.; Pacifico, S. New SiO2/Caffeic Acid Hybrid Materials: Synthesis and Characterization. Materials 2020, 13, 394. [Google Scholar]

- Toki, M.; Chow, T.Y.; Ohnaka, T.; Samura, H.; Saegusa, T. Structure of Poly(Vinylpyrrolidone)-Silica Hybrid. Polym. Bull. 1992, 29, 653–660. [Google Scholar]

- Saegusa, T.; Chujo, Y. Organic polymer hybrids with silica gel formed by means of the sol-gel method. Polym. Prep. 1989, 1, 39. [Google Scholar]

- Sanchez, C.; Ribot, F. Design of Hybrid Organic-Inorganic Materials Synthesized via Sol-Gel Chemistry. New J. Chem. 1994, 18, 1007–1047. [Google Scholar]

- Díaz, U.; Brunel, D.; Corma, A. Catalysis Using Multifunctional Organosiliceous Hybrid Materials. Chem. Soc. Rev. 2013, 42, 4083–4097. [Google Scholar]

- Ghiaci, M.; Abbaspur, A.; Kia, R.; Seyedeyn-Azad, F. Equilibrium Isotherm Studies for the Sorption of Benzene, Toluene, and Phenol onto Organo-Zeolites and as-Synthesized MCM-41. Sep. Purif. Technol. 2004, 40, 217–229. [Google Scholar]

- Yang, K.; Chen, B.; Zhu, L. Graphene-Coated Materials Using Silica Particles as a Framework for Highly Efficient Removal of Aromatic Pollutants in Water. Sci. Rep. 2015, 5, 11641. [Google Scholar]

- Gaona, A.; Moreno, J.M.; Velty, A.; Díaz, U.; Corma, A. One-Pot Synthesis of Hierarchical Porous Layered Hybrid Materials Based on Aluminosilicate Sheets and Organic Functional Pillars. J. Mater. Chem. A 2014, 2, 19360–19375. [Google Scholar]

- Hoffmann, F.; Cornelius, M.; Morell, J.; Fröba, M. Silica-Based Mesoporous Organic-Inorganic Hybrid Materials. Angew. Chemie Int. Ed. 2006, 45, 3216–3251. [Google Scholar] [CrossRef] [PubMed]

- Asefa, T.; MacLachlan, M.J.; Coombs, N.; Ozin, G.A. Periodic Mesoporous Organosilicas with Organic Groups inside the Channel Walls. Nature 1999, 402, 867–871. [Google Scholar] [CrossRef]

- Inagaki, S.; Guan, S.; Fukushima, Y.; Ohsuna, T.; Terasaki, O. Novel Mesoporous Materials with a Uniform Distribution of Organic Groups and Inorganic Oxide in Their Frameworks. J. Am. Chem. Soc. 1999, 121, 9611–9614. [Google Scholar] [CrossRef]

- Fujita, S.; Inagaki, S. Self-Organization of Organosilica Solids with Molecular-Scale and Mesoscale Periodicities. Chem. Mater. 2008, 20, 891–908. [Google Scholar] [CrossRef]

- Melde, B.J.; Holland, B.T.; Blanford, C.F.; Stein, A. Mesoporous Sieves with Unified Hybrid Inorganic/Organic Frameworks. Chem. Mater. 1999, 11, 3302–3308. [Google Scholar] [CrossRef]

- Inagaki, S.; Guan, S.; Ohsuna, T.; Terasaki, O. An Ordered Mesoporous Organosilica Hybrid Material with a Crystal-like Wall Structure. Nature 2002, 416, 304–307. [Google Scholar] [CrossRef] [PubMed]

- Mizoshita, N.; Tani, T.; Inagaki, S. Syntheses, Properties and Applications of Periodic Mesoporous Organosilicas Prepared from Bridged Organosilane Precursors. Chem. Soc. Rev. 2011, 40, 789–800. [Google Scholar] [CrossRef] [PubMed]

- Osterholtz, F.D.; Pohl, E.R. Kinetics of the Hydrolysis and Condensation of Organofunctional Alkoxysilanes: A Review. J. Adhes. Sci. Technol. 1992, 6, 127–149. [Google Scholar] [CrossRef]

- Schmidt, H.; Scholze, H.; Kaiser, A. Principles of Hydrolysis and Condensation Reaction of Alkoxysilanes. J. Non. Cryst. Solids 1984, 63, 1–11. [Google Scholar] [CrossRef]

- Iler, R.K. Polymerization of Silica. In The Chemistry of Silica: Solubility, Polymerization, Colloid and Surface Properties and Biochemistry of Silica; Wiley: Hoboken, NJ, USA, 1979; pp. 172–311. [Google Scholar]

- Jeffrey Brinker, C. Sol-Gel Processing of Silica. In Colloidal Silica: Fundamentals and Applications; CRC Press: Boca Raton, FL, USA, 2005; pp. 615–635. [Google Scholar]

- Winter, R.; Chan, J.B.; Frattini, R.; Jonas, J. The Effect of Fluoride on the Sol-Gel Process. J. Non. Cryst. Solids 1988, 105, 214–222. [Google Scholar] [CrossRef]

- Pope, E.J.A.; Mackenzie, J.D. Sol-Gel Processing of Silica. II. The Role of the Catalyst. J. Non. Cryst. Solids 1986, 87, 185–198. [Google Scholar] [CrossRef]

- Reale, E.; Leyva, A.; Corma, A.; Martínez, C.; García, H.; Rey, F. A Fluoride-Catalyzed Sol-Gel Route to Catalytically Active Non-Ordered Mesoporous Silica Materials in the Absence of Surfactants. J. Mater. Chem. 2005, 15, 1742–1754. [Google Scholar] [CrossRef]

- Bernards, T.N.M.; Van Bommel, M.J.; Boonstra, A.H. Hydrolysis-Condensation Processes of the Tetra-Alkoxysilanes TPOS, TEOS and TMOS in Some Alcoholic Solvents. J. Non. Cryst. Solids 1991, 134, 1–13. [Google Scholar] [CrossRef]

- Yilmaz, B.; Müller, U. Catalytic Applications of Zeolites in Chemical Industry. Top. Catal. 2009, 52, 888–895. [Google Scholar] [CrossRef] [Green Version]

- Aoyama, T.; Takido, T.; Kodomari, M. Silica Gel-Supported Polyphosphoric Acid (PPA/SiO2) as an Efficient and Reusable Catalyst for Conversion of Carbonyl Compounds into Oxathioacetals and Dithioacetals. Synlett 2004, 2, 2307–2310. [Google Scholar] [CrossRef]

- Khatik, G.L.; Sharma, G.; Kumar, R.; Chakraborti, A.K. Scope and Limitations of HClO4-SiO2 as an Extremely Efficient, Inexpensive, and Reusable Catalyst for Chemoselective Carbon-Sulfur Bond Formation. Tetrahedron 2007, 63, 1200–1210. [Google Scholar] [CrossRef]

- Bandgar, B.P.; Patil, A.V.; Chavan, O.S. Silica Supported Fluoroboric Acid as a Novel, Efficient and Reusable Catalyst for the Synthesis of 1,5-Benzodiazepines under Solvent-Free Conditions. J. Mol. Catal. A Chem. 2006, 256, 99–105. [Google Scholar] [CrossRef]

- Rajput, V.K.; Roy, B.; Mukhopadhyay, B. Sulfuric Acid Immobilized on Silica: An Efficient Reusable Catalyst for Selective Hydrolysis of the Terminal O-Isopropylidene Group of Sugar Derivatives. Tetrahedron Lett. 2006, 47, 6987–6991. [Google Scholar] [CrossRef]

- Kaur, M.; Sharma, S.; Bedi, P.M.S. Silica Supported Brönsted Acids as Catalyst in Organic Transformations: A Comprehensive Review. Cuihua Xuebao Chin. J. Catal. 2015, 36, 520–549. [Google Scholar] [CrossRef]

- Kourasi, M.; Wills, R.G.A.; Shah, A.A.; Walsh, F.C. Heteropolyacids for Fuel Cell Applications. Electrochim. Acta 2014, 127, 454–466. [Google Scholar] [CrossRef]

- Rafiee, E.; Rashidzadeh, S.; Azad, A. Silica-Supported Heteropoly Acids: Highly Efficient Catalysts for Synthesis of α-Aminonitriles, Using Trimethylsilyl Cyanide or Potassium Cyanide. J. Mol. Catal. A Chem. 2007, 261, 49–52. [Google Scholar] [CrossRef]

- Xiong, J.; Zhu, W.; Ding, W.; Yang, L.; Zhang, M.; Jiang, W.; Zhao, Z.; Li, H. Hydrophobic Mesoporous Silica-Supported Heteropolyacid Induced by Ionic Liquid as a High Efficiency Catalyst for the Oxidative Desulfurization of Fuel. RSC Adv. 2015, 5, 16847–16855. [Google Scholar] [CrossRef]

- Kozhevnikov, I.V. Friedel-Crafts Acylation and Related Reactions Catalysed by Heteropoly Acids. Appl. Catal. A Gen. 2003, 256, 3–18. [Google Scholar] [CrossRef]

- Li, J.; Yang, Z.; Li, S.; Jin, Q.; Zhao, J. Review on Oxidative Desulfurization of Fuel by Supported Heteropolyacid Catalysts. J. Ind. Eng. Chem. 2020, 82, 1–16. [Google Scholar] [CrossRef]

- Ren, Y.; Yue, B.; Gu, M.; He, H. Progress of the Application of Mesoporous Silica-Supported Heteropolyacids in Heterogeneous Catalysis and Preparation of Nanostructured Metal Oxides. Materials 2010, 3, 764–785. [Google Scholar] [CrossRef] [Green Version]

- Tsukuda, E.; Sato, S.; Takahashi, R.; Sodesawa, T. Production of Acrolein from Glycerol over Silica-Supported Heteropoly Acids. Catal. Commun. 2007, 8, 1349–1353. [Google Scholar] [CrossRef]

- Vázquez, P.; Pizzio, L.; Cáceres, C.; Blanco, M.; Thomas, H.; Alesso, E.; Finkielsztein, L.; Lantaño, B.; Moltrasio, G.; Aguirre, J. Silica-Supported Heteropolyacids as Catalysts in Alcohol Dehydration Reactions. J. Mol. Catal. A Chem. 2000, 161, 223–232. [Google Scholar] [CrossRef]

- Arias, M.; Laurenti, D.; Geantet, C.; Vrinat, M.; Hideyuki, I.; Yoshimura, Y. Gasoline Desulfurization by Catalytic Alkylation over Silica-Supported Heteropolyacids: From Model Reaction to Real Feed Conversion. Catal. Today 2008, 130, 190–194. [Google Scholar] [CrossRef]

- Doustkhah, E.; Luque, R.; Kim, J.; Lin, J.; Ide, Y.; Yamauchi, Y.; Rostamnia, S.; Wu, K.C.-W.; Len, C.; Luo, X.; et al. Development of Sulfonic-Acid-Functionalized Mesoporous Materials: Synthesis and Catalytic Applications. Chem. A Eur. J. 2018, 25, 1614–1635. [Google Scholar] [CrossRef]

- Van Rhijn, W.M.; De Vos, D.E.; Sels, B.F.; Bossaert, W.D.; Jacobs, P.A. Sulfonic Acid Functionalised Ordered Mesoporous Materials as Catalysts for Condensation and Esterification Reactions. Chem. Commun. 1998, 3, 317–318. [Google Scholar] [CrossRef]

- Lim, M.H.; Blanford, C.F.; Stein, A. Synthesis of Ordered Microporous Silicates with Organosulfur Surface Groups and Their Applications as Solid Acid Catalysts. Chem. Mater. 1998, 10, 467–470. [Google Scholar] [CrossRef]

- Boveri, M.; Aguilar-Pliego, J.; Pérez-Pariente, J.; Sastre, E. Optimization of the Preparation Method of HSO3-Functionalized MCM-41 Solid Catalysts. Catal. Today 2005, 107, 868–873. [Google Scholar] [CrossRef]

- Dacquin, J.P.; Cross, H.E.; Brown, D.R.; Düren, T.; Williams, J.J.; Lee, A.F.; Wilson, K. Interdependent Lateral Interactions, Hydrophobicity and Acid Strength and Their Influence on the Catalytic Activity of Nanoporous Sulfonic Acid Silicas. Green Chem. 2010, 12, 1383–1391. [Google Scholar] [CrossRef]

- Pérez-Pariente, J.; Díaz, I.; Mohino, F.; Sastre, E. Selective Synthesis of Fatty Monoglycerides by Using Functionalised Mesoporous Catalysts. Appl. Catal. A Gen. 2003, 254, 173–188. [Google Scholar] [CrossRef]

- Bossaert, W.D.; De Vos, D.E.; Van Rhijn, W.M.; Bullen, J.; Grobet, P.J.; Jacobs, P.A. Mesoporous Sulfonic Acids as Selective Heterogeneous Catalysts for the Synthesis of Monoglycerides. J. Catal. 1999, 182, 156–164. [Google Scholar] [CrossRef]

- Van Grieken, R.; Melero, J.A.; Morales, G. Fries Rearrangement of Phenyl Acetate over Sulfonic Modified Mesostructured SBA-15 Materials. Appl. Catal. A Gen. 2005, 289, 143–152. [Google Scholar] [CrossRef]

- Zhao, W.; Salame, P.; Launay, F.; Gédéon, A.; Hao, Z. Sulfonic Acid Functionalised SBA-15 as Catalysts for Beckmann Rearrangement and Esterification Reaction. J. Porous. Mater. 2008, 15, 139–143. [Google Scholar] [CrossRef] [Green Version]

- Rostamnia, S.; Pourhassan, F. The SBA-15/SO3H Nanoreactor as a Highly Efficient and Reusable Catalyst for Diketene-Based, Four-Component Synthesis of Polyhydroquinolines and Dihydropyridines under Neat Conditions. Chin. Chem. Lett. 2013, 24, 401–403. [Google Scholar] [CrossRef]

- Srinivas, D.; Saikia, L. Functionalized SBA-15 and Its Catalytic Applications in Selective Organic Transformations. Catal. Surv. Asia. 2008, 12, 114–130. [Google Scholar] [CrossRef]

- Gianotti, E.; Diaz, U.; Velty, A.; Corma, A. Designing Bifunctional Acid-Base Mesoporous Hybrid Catalysts for Cascade Reactions. Catal. Sci. Technol. 2013, 3, 2677–2688. [Google Scholar] [CrossRef]

- Zeidan, R.K.; Hwang, S.J.; Davis, M.E. Multifunctional Heterogeneous Catalysts: SBA-15-Containing Primary Amines and Sulfonic Acids. Angew. Chemie Int. Ed. 2006, 45, 6332–6335. [Google Scholar] [CrossRef] [PubMed]

- Zuo, D.; Lane, J.; Culy, D.; Schultz, M.; Pullar, A.; Waxman, M. Applied Catalysis B: Environmental Sulfonic Acid Functionalized Mesoporous SBA-15 Catalysts for Biodiesel Production. Appl. Catal. B Environ. 2013, 129, 342–350. [Google Scholar] [CrossRef]

- Parambadath, S.; Chidambaram, M.; Singh, A.P. Synthesis, Characterization and Catalytic Properties of Benzyl Sulphonic Acid Functionalized Zr-TMS Catalysts. Catal. Today 2004, 97, 233–240. [Google Scholar] [CrossRef]

- Requies, J.; Güemez, M.B.; Arias, P.L. Applied Catalysis B: Environmental Dehydration of d-Xylose to Furfural Using Selective and Hydrothermally Stable Arenesulfonic SBA-15 Catalysts. Appl. Catal. B Environ. 2014, 145, 34–42. [Google Scholar]

- Wang, X.; Cheng, S.; Chan, J.C.C.; Chao, J.C.H. Template-Free Synthesis of Mesoporous Phenylsulfonic Acid Functionalized Silica. Micropor. Mesopor. Mat. 2006, 96, 321–330. [Google Scholar] [CrossRef]

- Krawiec, P.; Kockrick, E.; Borchardt, L.; Geiger, D.; Corma, A.; Kaskel, S. Ordered Mesoporous Carbide Derived Carbons: Novel Materials for Catalysis and Adsorption. J. Phys. Chem. C 2009, 113, 7755–7761. [Google Scholar] [CrossRef]

- Habib, S.; Salam, P.; Launay, F.; Semmer-herledan, V.; Marie, O.; Zhao, W.; Antoine, G. Investigation of the Catalytic Activity of Extracted and Smoothly Calcined Arenesulfonic Modified SBA-15 Materials. J. Mol. Catal. A 2007, 271, 117–125. [Google Scholar] [CrossRef]

- Harmer, M.A.; Sun, Q.; Michalczyk, M.J.; Yang, Z. Unique Silane Modified Perfluorosulfonic Acids as Versatile Reagents for New Solid Acid Catalysts. Chem. Comm. 1997, 18, 1803–1804. [Google Scholar] [CrossRef]

- Alvaro, M.; Corma, A.; Das, D.; Fornés, V.; García, H. “ Nafion ” -Functionalized Mesoporous MCM-41 Silica Shows High Activity and Selectivity for Carboxylic Acid Esterification and Friedel–Crafts Acylation Reactions. J. Catal. 2005, 231, 48–55. [Google Scholar] [CrossRef]

- Macquarrie, D.J.; Tavener, S.J.; Harmer, M.A. Novel Mesoporous Silica-Perfluorosulfonic Acid Hybrids as Strong Heterogeneous Brønsted Catalysts. Chem. Commun. 2005, 18, 2363–2365. [Google Scholar] [CrossRef]

- Erigoni, A.; Paul, G.; Meazza, M.; Hernández-Soto, M.C.; Miletto, I.; Rios, R.; Segarra, C.; Marchese, L.; Raja, R.; Rey, F.; et al. Acid Properties of Organosiliceous Hybrid Materials Based on Pendant (Fluoro)Aryl-Sulfonic Groups through a Spectroscopic Study with Probe Molecules. Catal. Sci. Technol. 2019, 9, 6308–6317. [Google Scholar] [CrossRef]

- Rostami, A.; Tahmasbi, B.; Gholami, H.; Taymorian, H. Supported N-Propylsulfamic Acid on Magnetic Nanoparticles Used as Recoverable and Recyclable Catalyst for the Synthesis of 2,3-Dihydroquinazolin- 4(1H)-Ones in Water. Chin. Chem. Lett. 2013, 24, 211–214. [Google Scholar] [CrossRef]

- Hajjami, M.; Ghorbani, F.; Bakhti, F. MCM-41-N-Propylsulfamic Acid: An Efficient Catalyst for One-Pot Synthesis of 1-Amidoalkyl-2-Naphtols. Appl. Catal. A Gen. 2014, 470, 303–310. [Google Scholar] [CrossRef]

- Clapp, L.B. Sulfamic Acid and Its Uses. J. Chem. Educ. 1943, 20, 189–191. [Google Scholar] [CrossRef]

- Pirez, C.; Lee, A.F.; Jones, C.; Wilson, K. Can Surface Energy Measurements Predict the Impact of Catalyst Hydrophobicity upon Fatty Acid Esterification over Sulfonic Acid Functionalised Periodic Mesoporous Organosilicas? Catal. Today 2014, 234, 167–173. [Google Scholar] [CrossRef]

- Mbaraka, I.K.; Shanks, B.H. Design of Multifunctionalized Mesoporous Silicas for Esterification of Fatty Acid. J. Catal. 2005, 229, 365–373. [Google Scholar] [CrossRef]

- Karimi, B.; Zareyee, D. Design of a Highly Efficient and Water-Tolerant Sulfonic Acid Nanoreactor Based on Tunable Ordered Porous Silica for the von Pechmann Reaction. Org. Lett. 2008, 10, 3989–3992. [Google Scholar] [CrossRef]

- Yang, Q.; Kapoor, M.P.; Inagaki, S. Sulfuric Acid-Functionalized Mesoporous Benzene-Silica with a Molecular-Scale Periodicity in the Walls. J. Am. Chem. Soc. 2002, 124, 9694–9695. [Google Scholar] [CrossRef]

- Karaki, M.; Karout, A.; Toufaily, J.; Rataboul, F.; Essayem, N.; Lebeau, B. Synthesis and Characterization of Acidic Ordered Mesoporous Organosilica SBA-15: Application to the Hydrolysis of Cellobiose and Insight into the Stability of the Acidic Functions. J. Catal. 2013, 305, 204–216. [Google Scholar] [CrossRef]

- Karam, A.; Alonso, J.C.; Gerganova, T.I.; Ferreira, P.; Bion, N.; Barrault, J.; Jérôme, F. Sulfonic Acid Functionalized Crystal-like Mesoporous Benzene-Silica as a Remarkable Water-Tolerant Catalyst. Chem. Commun. 2009, 45, 7000–7002. [Google Scholar] [CrossRef] [Green Version]

- Kapoor, M.P.; Yanagi, M.; Kasama, Y.; Yokoyama, T.; Inagaki, S.; Shimada, T.; Nanbu, H.; Juneja, L.R. Self-Assembly of Cubic Phenylene Bridged Mesoporous Hybrids from Allylorganosilane Precursors. J. Mater. Chem. 2006, 16, 3305–3311. [Google Scholar] [CrossRef]

- Shylesh, S.; Wagener, A.; Seifert, A.; Ernst, S.; Thiel, W.R. Mesoporous Organosilicas with Acidic Frameworks and Basic Sites in the Pores: An Approach to Cooperative Catalytic Reactions. Angew. Chem. Int. Ed. 2010, 49, 184–187. [Google Scholar] [CrossRef] [PubMed]

- Alauzun, J.; Mehdi, A.; Reyé, C.; Corriu, R.J.P. Mesoporous Materials with an Acidic Framework and Basic Pores. A Successful Cohabitation. J. Am. Chem. Soc. 2006, 128, 8718–8719. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Shantz, D.F. Nitroaldol Reactions Catalyzed by Amine-MCM-41 Hybrids. J. Catal. 2010, 271, 170–177. [Google Scholar] [CrossRef]

- Shimizu, K.; Suzuki, H.; Hayashi, E.; Kodama, T.; Tsuchiya, Y. Catalytic Direct 1, 4-Conjugate Addition of Aldehydes to Vinylketones on Secondary-Amines Immobilised in FSM-16 Silica Lated FSM-16 Mesoporous Silica, Which Can Be Regarded as a Novel Heterogeneous Catalysis for a Practical C–C Bond. Chem. Commun. 2002, 2, 16–17. [Google Scholar]

- Bass, J.D.; Solovyov, A.; Pascall, A.J.; Katz, A. Acid-Base Bifunctional and Dielectric Outer-Sphere Effects in Heterogeneous Catalysis: A Comparative Investigation of Model Primary Amine Catalysts. J. Am. Chem. Soc. 2006, 128, 3737–3747. [Google Scholar] [CrossRef]

- Konuray, A.O.; Fernández-Francos, X.; Ramis, X. Analysis of the Reaction Mechanism of the Thiol-Epoxy Addition Initiated by Nucleophilic Tertiary Amines. Polym. Chem. 2017, 8, 5934–5947. [Google Scholar] [CrossRef] [Green Version]

- Borch Jacobsen, C.; Meldal, M.; Diness, F. Mechanism and Scope of Base-Controlled Catalyst-Free N-Arylation of Amines with Unactivated Fluorobenzenes. Chem. A Eur. J. 2017, 23, 846–851. [Google Scholar] [CrossRef]

- Khoi, V.N.; Morrill, L.C.; Smith, A.D.; Romo, D. Catalytic Generation of Ammonium Enolates and Related Tertiary Amine-Derived Intermediates: Applications, Mechanism, and Stereochemical Models (n → p*). Lewis Base Catal. Org. Synth. 2016, 2, 527–653. [Google Scholar]

- Balbino, J.M.; De Menezes, E.W.; Benvenutti, E.V.; Cataluña, R.; Ebeling, G.; Dupont, J. Silica-Supported Guanidine Catalyst for Continuous Flow Biodiesel Production. Green Chem. 2011, 13, 3111–3116. [Google Scholar] [CrossRef]

- Barbarini, A.; Maggi, R.; Mazzacani, A.; Mori, G.; Sartori, G.; Sartorio, R. Cycloaddition of CO2 to Epoxides over Both Homogeneous and Silica-Supported Guanidine Catalysts. Tetrahedron Lett. 2003, 44, 2931–2934. [Google Scholar] [CrossRef]

- Motos-Pérez, B.; Roeser, J.; Thomas, A.; Hesemann, P. Imidazolium-Functionalized SBA-15 Type Silica: Efficient Organocatalysts for Henry and Cycloaddition Reactions. Appl. Organomet. Chem. 2013, 27, 290–299. [Google Scholar] [CrossRef]

- Gianotti, E.; Diaz, U.; Colucci, S.; Corma, A. Hybrid Organicinorganic Catalytic Mesoporous Materials with Proton Sponges as Building Blocks. Phys. Chem. Chem. Phys. 2011, 13, 11702–11709. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Wang, L.; Zhang, Y.; Wang, G. Silica Gel Supported Pyrrolidine-Based Chiral Ionic Liquid as Recyclable Organocatalyst for Asymmetric Michael Addition to Nitrostyrenes. Tetrahedron 2008, 64, 7633–7638. [Google Scholar] [CrossRef]

- Llopis, S.; García, T.; Cantín, Á.; Velty, A.; Díaz, U.; Corma, A. Chiral Hybrid Materials Based on Pyrrolidine Building Units to Perform Asymmetric Michael Additions with High Stereocontrol. Catal. Sci. Technol. 2018, 8, 5835–5847. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Brunelli, N.A.; Didas, S.A.; Venkatasubbaiah, K.; Jones, C.W. Tuning Cooperativity by Controlling the Linker Length of Silica-Supported Amines in Catalysis and CO2 Capture. J. Am. Chem. Soc. 2012, 134, 13950–13953. [Google Scholar] [CrossRef]

- Lauwaert, J.; Moschetta, E.G.; Van Der Voort, P.; Thybaut, J.W.; Jones, C.W.; Marin, G.B. Spatial Arrangement and Acid Strength Effects on Acid-Base Cooperatively Catalyzed Aldol Condensation on Aminosilica Materials. J. Catal. 2015, 325, 19–25. [Google Scholar] [CrossRef] [Green Version]

- Brunelli, N.A.; Venkatasubbaiah, K.; Jones, C.W. Cooperative Catalysis with Acid-Base Bifunctional Mesoporous Silica: Impact of Grafting and Co-Condensation Synthesis Methods on Material Structure and Catalytic Properties. Chem. Mater. 2012, 24, 2433–2442. [Google Scholar] [CrossRef]

- Brunelli, N.A.; Jones, C.W. Tuning Acid-Base Cooperativity to Create next Generation Silica-Supported Organocatalysts. J. Catal. 2013, 308, 60–72. [Google Scholar] [CrossRef]

- Lauwaert, J.; De Canck, E.; Esquivel, D.; Van Der Voort, P.; Thybaut, J.W.; Marin, G.B. Effects of Amine Structure and Base Strength on Acid-Base Cooperative Aldol Condensation. Catal. Today 2015, 246, 35–45. [Google Scholar] [CrossRef]

- Erigoni, A.; Hernández-Soto, M.C.; Rey, F.; Segarra, C.; Díaz, U. Highly Active Hybrid Mesoporous Silica-Supported Base Organocatalysts for C–C Bond Formation. Catal. Today 2020, 345, 227–236. [Google Scholar] [CrossRef]

- Kandel, K.; Althaus, S.M.; Peeraphatdit, C.; Kobayashi, T.; Trewyn, B.G.; Pruski, M.; Slowing, I.I. Substrate Inhibition in the Heterogeneous Catalyzed Aldol Condensation: A Mechanistic Study of Supported Organocatalysts. J. Catal. 2012, 291, 63–68. [Google Scholar] [CrossRef]

- Jezequel, M.; Jose, M.; Carrillo-hermosilla, F.; Neugebauer, U.; Niccolai, G.P.; Corker, J.; Fiddy, S.; Evans, J.; Broyer, J.; Malinge, J.; et al. Supported Metallocene Catalysts by Surface Organometallic Chemistry. Synthesis, Characterization, and Reactivity in Ethylene Polymerization of Oxide-Supported Mono- and Biscyclopentadienyl Zirconium Alkyl Complexes: Establishment of Structure / Reactivity Relationship. J. Am. Chem. Soc. 2001, 123, 3520–3540. [Google Scholar]

- Sommer, W.J.; Weck, M. Supported N-Heterocyclic Carbene Complexes in Catalysis. Coord. Chem. Rev. 2007, 251, 860–873. [Google Scholar] [CrossRef]

- Habeche, F.; Hachemaoui, M.; Mokhtar, A.; Chikh, K.; Benali, F.; Mekki, A.; Zaoui, F.; Cherifi, Z.; Boukoussa, B. Recent Advances on the Preparation and Catalytic Applications of Metal Complexes Supported-Mesoporous Silica MCM-41 (Review). J. Inorg. Organomet. Polym. Mater. 2020, 30, 4245–4268. [Google Scholar] [CrossRef]

- Conley, M.P.; Copéret, C.; Thieuleux, C. Mesostructured Hybrid Organic-Silica Materials: Ideal Supports for Well-Defined Heterogeneous Organometallic Catalysts. ACS Catal. 2014, 4, 1458–1469. [Google Scholar] [CrossRef]

- Zamboulis, A.; Moitra, N.; Moreau, J.J.E.; Cattoën, X.; Wong Chi Man, M. Hybrid Materials: Versatile Matrices for Supporting Homogeneous Catalysts. J. Mater. Chem. 2010, 20, 9322–9338. [Google Scholar] [CrossRef]

- Zhang, Q.; Su, H.; Luo, J.; Wei, Y. Recyclable Palladium(II) Imino-Pyridine Complex Immobilized on Mesoporous Silica as a Highly Active and Recoverable Catalyst for Suzuki-Miyaura Coupling Reactions in Aqueous Medium. Tetrahedron 2013, 69, 447–454. [Google Scholar] [CrossRef]

- Polshettiwar, V.; Varma, R.S. Pd-N-Heterocyclic Carbene (NHC) Organic Silica: Synthesis and Application in Carbon-Carbon Coupling Reactions. Tetrahedron 2008, 64, 4637–4643. [Google Scholar] [CrossRef]

- Del Pozo, C.; Corma, A.; Iglesias, M.; Sánchez, F. Recyclable Mesoporous Silica-Supported Chiral Ruthenium-(NHC)NN-Pincer Catalysts for Asymmetric Reactions. Green Chem. 2011, 13, 2471–2481. [Google Scholar] [CrossRef]

- Baleizão, C.; Gigante, B.; Das, D.; Alvaro, M.; Garcia, H.; Corma, A. Synthesis and Catalytic Activity of a Chiral Periodic Mesoporous Organosilica (ChiMO). Chem. Commun. 2003, 3, 1860–1861. [Google Scholar] [CrossRef] [PubMed]

- Baleizão, C.; Gigante, B.; Das, D.; Álvaro, M.; Garcia, H.; Corma, A. Periodic Mesoporous Organosilica Incorporating a Catalytically Active Vanadyl Schiff Base Complex in the Framework. J. Catal. 2004, 223, 106–113. [Google Scholar] [CrossRef]

- Jiang, Y.; Gao, Q. Heterogeneous Hydrogenation Catalyses over Recyclable Pd(0) Nanoparticle Catalysts Stabilized by PAMAM-SBA-15 Organic-Inorganic Hybrid Composites. J. Am. Chem. Soc. 2006, 128, 716–717. [Google Scholar] [CrossRef] [PubMed]

- Budroni, G.; Corma, A.; García, H.; Primo, A. Pd Nanoparticles Embedded in Sponge-like Porous Silica as a Suzuki-Miyaura Catalyst: Similarities and Differences with Homogeneous Catalysts. J. Catal. 2007, 251, 345–353. [Google Scholar] [CrossRef]

- Budroni, G.; Corma, A. Gold-Organic-Inorganic High-Surface-Area Materials as Precursors of Highly Active Catalysts. Angew. Chem. Int. Ed. 2006, 45, 3328–3331. [Google Scholar] [CrossRef]

- Barau, A.; Budarin, V.; Caragheorgheopol, A.; Luque, R.; MacQuarrie, D.J.; Prelle, A.; Teodorescu, V.S.; Zaharescu, M. A Simple and Efficient Route to Active and Dispersed Silica Supported Palladium Nanoparticles. Catal. Lett. 2008, 124, 204–214. [Google Scholar] [CrossRef]

- Schmidt-Winkel, P.; Lukens, W.W.; Yang, P.; Margolese, D.I.; Lettow, J.S.; Ying, J.Y.; Stucky, G.D. Microemulsion Templating of Siliceous Mesostructured Cellular Foams with Well-Defined Ultralarge Mesopores. Chem. Mater. 2000, 12, 686–696. [Google Scholar] [CrossRef]

- Johnston, E.V.; Verho, O.; Kärkäs, M.D.; Shakeri, M.; Tai, C.W.; Palmgren, P.; Eriksson, K.; Oscarsson, S.; Bäckvall, J.E. Highly Dispersed Palladium Nanoparticles on Mesocellular Foam: An Efficient and Recyclable Heterogeneous Catalyst for Alcohol Oxidation. Chem. A Eur. J. 2012, 18, 12202–12206. [Google Scholar] [CrossRef]

- Kim, T.W.; Ryoo, R.; Kruk, M.; Gierszal, K.P.; Jaroniec, M.; Kamiya, S.; Terasaki, O. Tailoring the Pore Structure of SBA-16 Silica Molecular Sieve through the Use of Copolymer Blends and Control of Synthesis Temperature and Time. J. Phys. Chem. B 2004, 108, 11480–11489. [Google Scholar] [CrossRef]

- Yang, H.; Han, X.; Li, G.; Wang, Y. N-Heterocyclic Carbene Palladium Complex Supported on Ionic Liquid-Modified SBA-16: An Efficient and Highly Recyclable Catalyst for the Suzuki and Heck Reactions. Green Chem. 2009, 11, 1184–1193. [Google Scholar] [CrossRef]

- Ma, Z.; Yang, H.; Qin, Y.; Hao, Y.; Li, G. Palladium Nanoparticles Confined in the Nanocages of SBA-16: Enhanced Recyclability for the Aerobic Oxidation of Alcohols in Water. J. Mol. Catal. A Chem. 2010, 331, 78–85. [Google Scholar] [CrossRef]

- Sharma, K.K.; Biradar, A.V.; Das, S.; Asefa, T. Bifunctional Mesoporous Silica Catalyst for C-C Bond Forming Tandem Reactions. Eur. J. Inorg. Chem. 2011, 21, 3174–3182. [Google Scholar] [CrossRef]

- Corma, A.; Díaz, U.; García, T.; Sastre, G.; Velty, A. Multifunctional Hybrid Organic-Inorganic Catalytic Materials with a Hierarchical System of Well-Defined Micro- and Mesopores. J. Am. Chem. Soc. 2010, 132, 15011–15021. [Google Scholar] [CrossRef] [PubMed]

- Gaona, A.; Díaz, U.; Corma, A. Functional Acid and Base Hybrid Catalysts Organized by Associated (Organo)Aluminosilicate Layers for C-C Bond Forming Reactions and Tandem Processes. Chem. Mater. 2017, 29, 1599–1612. [Google Scholar] [CrossRef] [Green Version]

- Li, P.; Liu, H.; Yu, Y.; Cao, C.Y.; Song, W.G. One-Pot Multistep Cascade Reactions over Multifunctional Nanocomposites with Pd Nanoparticles Supported on Amine-Modified Mesoporous Silica. Chem. An Asian J. 2013, 8, 2459–2465. [Google Scholar] [CrossRef]

- Huh, S.; Chen, H.T.; Wiench, J.W.; Pruski, M.; Lin, V.S.Y. Cooperative Catalysis by General Acid and Base Bifunctionalized Mesoporous Silica Nanospheres. Angew. Chem. Int. Ed. 2005, 44, 1826–1830. [Google Scholar] [CrossRef]

- Patankar, S.C.; Dodiya, S.K.; Yadav, G.D. Cascade Engineered Synthesis of Ethyl Benzyl Acetoacetate and Methyl Isobutyl Ketone (MIBK) on Novel Multifunctional Catalyst. J. Mol. Catal. A Chem. 2015, 409, 171–182. [Google Scholar] [CrossRef]

- Huang, Y.; Trewyn, B.G.; Chen, H.T.; Lin, V.S.Y. One-Pot Reaction Cascades Catalyzed by Base- and Acid-Functionalized Mesoporous Silica Nanoparticles. New J. Chem. 2008, 32, 1311–1313. [Google Scholar] [CrossRef]

- Fernandes, A.E.; Jonas, A.M. Design and Engineering of Multifunctional Silica-Supported Cooperative Catalysts. Catal. Today 2019, 334, 173–186. [Google Scholar] [CrossRef]

- Li, P.; Cao, C.Y.; Liu, H.; Yu, Y.; Song, W.G. Synthesis of a Core-Shell-Shell Structured Acid-Base Bifunctional Mesoporous Silica Nanoreactor (MS-SO3H@MS@MS-NH2) and Its Application in Tandem Catalysis. J. Mater. Chem. A 2013, 1, 12804–12810. [Google Scholar] [CrossRef]

- Schwizer, F.; Okamoto, Y.; Heinisch, T.; Gu, Y.; Pellizzoni, M.M.; Lebrun, V.; Reuter, R.; Köhler, V.; Lewis, J.C.; Ward, T.R. Artificial Metalloenzymes: Reaction Scope and Optimization Strategies. Chem. Rev. 2018, 118, 142–231. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Carceller, J.M.; Mifsud, M.; Climent, M.J.; Iborra, S.; Corma, A. Production of Chiral Alcohols from Racemic Mixtures by Integrated Heterogeneous Chemoenzymatic Catalysis in Fixed Bed Continuous Operation. Green Chem. 2020, 22, 2767–2777. [Google Scholar] [CrossRef]

| Catalyst | Active Site |

|---|---|

| Heteropolyacids (HPAs) | Acid |

| Sulfonic acids | Acid |

| Amines | Base |

| N-cycles | Base |

| Organometallic complexes | Redox |

| Metal nanoparticles | Redox |

| Multi-functional catalysts | Multiple |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Erigoni, A.; Diaz, U. Porous Silica-Based Organic-Inorganic Hybrid Catalysts: A Review. Catalysts 2021, 11, 79. https://0-doi-org.brum.beds.ac.uk/10.3390/catal11010079

Erigoni A, Diaz U. Porous Silica-Based Organic-Inorganic Hybrid Catalysts: A Review. Catalysts. 2021; 11(1):79. https://0-doi-org.brum.beds.ac.uk/10.3390/catal11010079

Chicago/Turabian StyleErigoni, Andrea, and Urbano Diaz. 2021. "Porous Silica-Based Organic-Inorganic Hybrid Catalysts: A Review" Catalysts 11, no. 1: 79. https://0-doi-org.brum.beds.ac.uk/10.3390/catal11010079