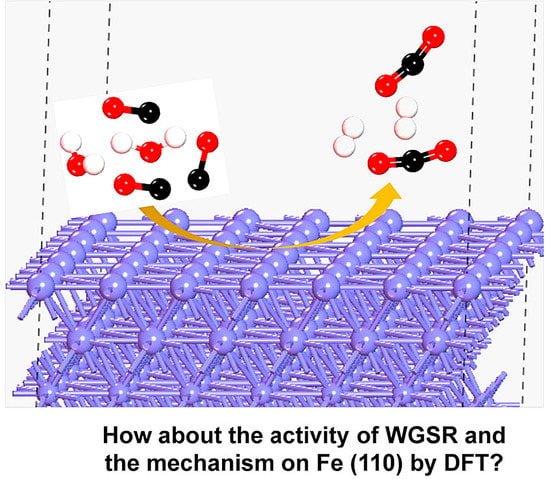

Water Gas Shift Reaction Activity on Fe (110): A DFT Study

Abstract

:1. Introduction

2. Results and Discussion

2.1. The Processes of H2O Dissociation and CO2 Formation

2.2. Migration of H and H2 Formation on Fe (110)

2.3. Electron Property Analysis of Adsorbed H on Fe (110)

3. Calculation Method and Model

3.1. Methods

3.2. Calculation Model

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Newsome, D.S. The water-gas shift reaction. Catal. Rev. 1980, 21, 275–318. [Google Scholar] [CrossRef]

- Pal, D.; Chand, R.; Upadhyay, S.; Mishra, P. Performance of water gas shift reaction catalysts: A review. Renew. Sustain. Energy Rev. 2018, 93, 549–565. [Google Scholar] [CrossRef]

- Gokhale, A.A.; Dumesic, A.J.A.; Mavrikakis, M. On the mechanism of low-temperature water gas shift reaction on copper. J. Am. Chem. Soc. 2008, 130, 1402–1414. [Google Scholar] [CrossRef] [PubMed]

- Reddy, G.K.; Kim, S.J.; Dong, J.; Smirniotis, P.G.; Jasinski, J.B. Long-term WGS stability of Fe/Ce and Fe/Ce/Cr catalysts at high and low steam to CO ratios—XPS and Mössbauer spectroscopic study. Appl. Catal. A Gen. 2012, 415, 101–110. [Google Scholar] [CrossRef]

- Puig-Molina, A.; Cano, F.M.; Janssens, T.V.W. The Cu promoter in an Iron−Chromium−Oxide Based Water−Gas shift catalyst under industrial conditions studied by in-Situ XAFS. J. Phys. Chem. C 2010, 114, 15410–15416. [Google Scholar] [CrossRef]

- Kundu, M.L.; Sengupta, A.C.; Maiti, G.C.; Sen, B.; Ghosh, S.K.; Kuznetsov, V.I.; Kustova, G.N.; Yurchenko, E.N. Characterization of chromia-promoted γ-iron oxide catalysts and their CO conversion efficiency. J. Catal. 1988, 112, 375–383. [Google Scholar] [CrossRef]

- Rhodes, C.; Williams, B.P.; King, F.; Hutchings, G.J. Promotion of Fe3O4/Cr2O3 high temperature water gas shift catalyst. Catal. Commun. 2002, 3, 381–384. [Google Scholar] [CrossRef]

- Lee, D.-W.; Lee, M.S.; Lee, J.Y.; Kim, S.; Eom, H.-J.; Moon, D.J.; Lee, K.-Y. The review of Cr-free Fe-based catalysts for high-temperature water-gas shift reactions. Catal. Today 2013, 210, 2–9. [Google Scholar] [CrossRef]

- Patlolla, A.; Carino, E.V.; Ehrlich, S.N.; Stavitski, E.; Frenkel, A.I. Application of Operando XAS, XRD, and Raman Spectroscopy for Phase Speciation in Water Gas Shift Reaction Catalysts. ACS Catal. 2012, 2, 2216–2223. [Google Scholar] [CrossRef]

- Liu, X.-W.; Zhao, S.; Meng, Y.; Peng, Q.; Dearden, A.K.; Huo, C.-F.; Yang, Y.; Li, Y.-W.; Wen, X.-D. Mössbauer spectroscopy of iron carbides: From prediction to experimental confirmation. Sci. Rep. 2016, 6, 26184. [Google Scholar] [CrossRef] [Green Version]

- Zhu, M.; Wachs, I.E. Iron-Based catalysts for the high-temperature water–gas shift (HT-WGS) reaction: A review. ACS Catal. 2016, 6, 722–732. [Google Scholar] [CrossRef]

- Reddy, G.K.; Boolchand, P.; Smirniotis, P.G. Unexpected behavior of copper in modified ferrites during high temperature WGS reaction aspects of Fe3+↔ Fe2+ Redox chemistry from Mössbauer and XPS studies. J. Phys. Chem. C 2012, 116, 11019–11031. [Google Scholar] [CrossRef]

- Cherkezova-Zheleva, Z.; Mitov, I. In situ Mössbauer investigation of iron oxide catalyst in water gas shift reaction–Impact of oxyreduction potential and temperature. J. Phys. Conf. Ser. 2010, 217, 012044. [Google Scholar] [CrossRef]

- Day, M.; Tachibana, S.; Bell, J.; Lijewski, M.; Beckner, V.; Cheng, R.K. A combined computational and experimental characterization of lean premixed turbulent low swirl laboratory flames: I. Methane flames. Combust. Flame 2012, 159, 275–290. [Google Scholar] [CrossRef]

- Meng, Y.; Liu, X.-W.; Bai, M.; Guo, W.-P.; Cao, D.-B.; Yang, Y.; Li, Y.-W.; Wen, X.-D. Prediction on morphologies and phase equilibrium diagram of iron oxides nanoparticles. Appl. Surf. Sci. 2019, 480, 478–486. [Google Scholar] [CrossRef]

- Bruix, A.; Margraf, J.T.; Andersen, M.; Reuter, K. First-principles-based multiscale modelling of heterogeneous catalysis. Nat. Catal. 2019, 2, 659–670. [Google Scholar] [CrossRef]

- Van der Ven, A.; Thomas, J.; Puchala, B.; Natarajan, A. First-Principles statistical mechanics of multicomponent crystals. Annu. Rev. Mater. Res. 2018, 48, 27–55. [Google Scholar] [CrossRef]

- Oba, F.; Kumagai, Y. Design and exploration of semiconductors from first principles: A review of recent advances. Appl. Phys. Express 2018, 11, 060101. [Google Scholar] [CrossRef]

- Yang, T.; Wen, X.D.; Cao, D.B.; Li, Y.W.; Wang, J.G.; Huo, C.F. Structures and energetics of H2O adsorption on the Fe3O4 (111) surface. J. Fuel Chem. Technol. 2009, 37, 506–512. [Google Scholar] [CrossRef]

- Grillo, M.E.; Finnis, M.W.; Ranke, W. Surface structure and water adsorption on Fe3O4(111): Spin-density functional theory and on-site Coulomb interactions. Phys. Rev. B 2008, 77, 075407. [Google Scholar] [CrossRef] [Green Version]

- Parkinson, G.S.; Novotný, Z.; Jacobson, P.; Schmid, M.; Diebold, U. Room Temperature Water Splitting at the Surface of Magnetite. J. Am. Chem. Soc. 2011, 133, 12650–12655. [Google Scholar] [CrossRef]

- Huang, D.-M.; Cao, D.-B.; Li, Y.-W.; Jiao, H. Density Function Theory Study of CO Adsorption on Fe3O4(111) Surface. J. Phys. Chem. B 2006, 110, 13920–13925. [Google Scholar] [CrossRef]

- Mulakaluri, N.; Pentcheva, R.; Scheffler, M. Coverage-Dependent Adsorption Mode of Water on Fe3O4(001): Insights from First Principles Calculations. J. Phys. Chem. C 2010, 114, 11148–11156. [Google Scholar] [CrossRef]

- Mulakaluri, N.; Pentcheva, R.; Wieland, M.; Moritz, W.; Scheffler, M. Partial Dissociation of Water on Fe3O4(001): Adsorbate Induced Charge and Orbital Order. Phys. Rev. Lett. 2009, 103, 176102. [Google Scholar] [CrossRef] [Green Version]

- Meng, Y.; Liu, X.-Y.; Bai, M.-M.; Chen, J.; Ma, Y.-J.; Wen, X.-D. Adsorption or deoxidation of H2 interacted with Fe3O4 surface under different H coverage: A DFT study. Appl. Surf. Sci. 2020, 502, 144097. [Google Scholar] [CrossRef]

- Stanka, B.; Hebenstreit, W.; Diebold, U.; Chambers, S. Surface reconstruction of Fe3O4(001). Surf. Sci. 2000, 448, 49–63. [Google Scholar] [CrossRef]

- Bliem, R.; McDermott, E.; Ferstl, P.; Setvin, M.; Gamba, O.; Pavelec, J.; Schneider, M.A.; Schmid, M.; Diebold, U.; Blaha, P.; et al. Subsurface cation vacancy stabilization of the magnetite (001) surface. Science 2014, 346, 1215–1218. [Google Scholar] [CrossRef] [Green Version]

- Arndt, B.; Bliem, R.; Gamba, O.; van der Hoeven, J.E.; Noei, H.; Diebold, U.; Parkinson, G.; Stierle, A. Atomic structure and stability of magnetite Fe3O4(001): An X-ray view. Surf. Sci. 2016, 653, 76–81. [Google Scholar] [CrossRef] [Green Version]

- Lemire, C.; Meyer, R.; Henrich, V.; Shaikhutdinov, S.; Freund, H.-J. The surface structure of Fe3O4(111) films as studied by CO adsorption. Surf. Sci. 2004, 572, 103–114. [Google Scholar] [CrossRef]

- Ritter, M.; Weiss, W. Fe3O4(111) surface structure determined by LEED crystallography. Surf. Sci. 1999, 432, 81–94. [Google Scholar] [CrossRef]

- Pentcheva, R.; Wendler, F.; Meyerheim, H.L.; Moritz, W.; Jedrecy, N.; Scheffler, M. Jahn-Teller stabilization of a “polar” metal oxide surface: Fe3O4 (001). Phys. Rev. Lett. 2005, 94, 126101. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, L.; Ni, G.; Han, B.; Zhou, C.G.; Wu, J.P. Mechanism of Water Gas Shift Reaction on Fe3O4 (111) Surface. Ac. Chim. Sin. 2011, 69, 393–398. [Google Scholar]

- Huang, L.; Han, B.; Zhang, Q.; Fan, M.; Cheng, H. Mechanistic study on water gas shift reaction on the Fe3O4 (111) reconstructed surface. J. Phys. Chem. C 2015, 119, 28934–28945. [Google Scholar] [CrossRef]

- Rim, K.T.; Eom, D.; Chan, S.-W.; Flytzani-Stephanopoulos, M.; Flynn, G.W.; Wen, X.-D.; Batista, E.R. Scanning tunneling microscopy and theoretical study of water adsorption on Fe3O4: Implications for catalysis. J. Am. Chem. Soc. 2012, 134, 18979–18985. [Google Scholar] [CrossRef]

- Meng, Y.; Liu, X.Y.; Chen, J.; Ma, Y.J.; Zhao, S. First-principle study on the reaction mechanism of water-gas shift on the Fe3O4 (001)-B surface. J. Fuel Chem. Technol. 2020, 48, 601–609. [Google Scholar]

- Liu, X.; Ma, Z.; Meng, Y.; Ma, Y.-J.; Wen, X.-D. First-principles study on the mechanism of water-gas shift reaction on the Fe3O4 (111)-Fetet1. Mol. Catal. 2021, 516, 111998. [Google Scholar] [CrossRef]

- Kresse, G.; Furthmüller, J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput. Mater. Sci. 1996, 6, 15–50. [Google Scholar] [CrossRef]

- Kresse, G.; Furthmüller, J. Efficient iterative schemes for Ab Initio Total-Energy calculations using a Plane-wave Basis Set. Phys. Rev. B 1996, 54, 11169–11186. [Google Scholar] [CrossRef]

- Blöchl, P.E. Projector Augmented-wave Method. Phys. Rev. B 1994, 50, 17953–17979. [Google Scholar] [CrossRef] [Green Version]

- Kresse, G.; Hafner, J. First-principles study of the adsorption of atomic H on Ni (111), (100) and (110). Surf. Sci. 2000, 459, 287–302. [Google Scholar] [CrossRef]

- Perdew, J.P.; Burke, K.; Ernzerhof, M. Errata: Generalized gradient approximation made simple. Phys. Rev. Lett. 1997, 78, 1396. [Google Scholar] [CrossRef] [Green Version]

- Methfessel, M.; Paxton, A.T. High-precision sampling for Brillouin-zone integration in metals. Phys. Rev. B 1989, 40, 3616. [Google Scholar] [CrossRef] [Green Version]

- Jónsson, H.; Mills, G.; Jacobsen, K.W. Classical and Quantum Dynamics in Condensed Phase Simulations; World Scientific: Singapore, 1998; p. 385. [Google Scholar]

- Henkelmann, G.; Uberuaga, B.P.; Jnsson, H. A climbing image nudged elastic band method for finding saddle points and minimum energy paths. J. Chem. Phys. 2000, 113, 9901–9904. [Google Scholar] [CrossRef] [Green Version]

- Wang, T.; Tian, X.-X.; Li, Y.-W.; Wang, J.; Beller, M.; Jiao, H. Coverage-Dependent CO adsorption and dissociation mechanisms on iron surfaces from dft computations. ACS Catal. 2014, 4, 1991–2005. [Google Scholar] [CrossRef]

| Fe3O4 | Fe-110 | ||||||

|---|---|---|---|---|---|---|---|

| 001 | 111 | ||||||

| Ea | ΔE | Ea | ΔE | Ea | ΔE | ||

| H2O(g) + * → H2O* | - | −0.70 | - | −0.86 | - | −0.34 | |

| H2O* + * → HO* + H* | 0.32 | 0.07 | 0.14 | −0.20 | 0.68 | −1.23 | |

| Red. | HO* + * → H* + O* | 0.95 | 0.42 | 1.21 | 0.96 | 0.90 | −0.55 |

| CO(g) + * → CO* | - | −0.53 | - | 0.74 | - | −1.94 | |

| CO* + O* → CO2** | 0.22 | −2.32 | 0.11 | −1.77 | 1.82 | 1.55 | |

| CO2** → CO2 (g) + 2* | - | 0.06 | - | 0.22 | - | 0.38 | |

| Ass. | HO* + CO* → COOH*+* | 0.10 | −0.47 | 0.46 | −0.47 | 2.08 | 1.33 |

| COOH* + *→ CO2* + H* | 0.06 | −0.86 | 0.14 | −0.61 | 1.03 | −0.13 | |

| CO2** → CO2 (g) + 2* | - | 0.06 | - | 0.22 | - | 0.37 | |

| Reg. | CO + Os* ↔ CO2* | 0.60 | 0.27 | 0.85 | −0.80 | ||

| CO2*→ CO2 (g) + * | - | 0.10 | - | 0.04 | |||

| H2O + Ov* ↔ H2O* | - | −0.66 | - | −0.45 | |||

| H2O + Ov* ↔ OH* + H* | 0.10 | −1.38 | 0.79 | −0.64 | |||

| Path | Fe3O4 | Fe-110 | ||

|---|---|---|---|---|

| (001) | (111) | |||

| 2H ↔ H2* | ΔE (eV) | 0.04 | 0.11 | 1.43 |

| Ea (eV) | 1.98 | 1.97 | 1.47 | |

| Fe3O4 (111) | Fe3O4 (001) | Fe (110) | ||||

|---|---|---|---|---|---|---|

| Δq (e) | H-1 | H-2 | H-1 | H-2 | H-1 | H-2 |

| −0.69 | −0.67 | −0.65 | −0.64 | 0.36 | 0.36 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Ma, Z.; Gao, X.; Bai, M.; Ma, Y.; Meng, Y. Water Gas Shift Reaction Activity on Fe (110): A DFT Study. Catalysts 2022, 12, 27. https://0-doi-org.brum.beds.ac.uk/10.3390/catal12010027

Liu X, Ma Z, Gao X, Bai M, Ma Y, Meng Y. Water Gas Shift Reaction Activity on Fe (110): A DFT Study. Catalysts. 2022; 12(1):27. https://0-doi-org.brum.beds.ac.uk/10.3390/catal12010027

Chicago/Turabian StyleLiu, Xiaoyan, Zeyu Ma, Xinhua Gao, Miaomiao Bai, Yajun Ma, and Yu Meng. 2022. "Water Gas Shift Reaction Activity on Fe (110): A DFT Study" Catalysts 12, no. 1: 27. https://0-doi-org.brum.beds.ac.uk/10.3390/catal12010027