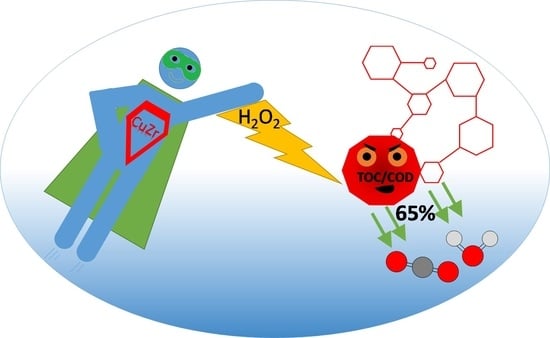

Removal of Organics from Landfill Leachate by Heterogeneous Fenton-like Oxidation over Copper-Based Catalyst

Abstract

:1. Introduction

2. Results and Discussion

2.1. Effect of Reaction Variables

2.2. Two-Step Fenton-like Oxidation

2.3. Catalytic Activity after Recycling

3. Materials and Methods

3.1. Materials

3.2. Catalytic Activity Measurements

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kulikowska, D.; Klimiuk, E. The effect of landfill age on municipal leachate composition. Bioresour. Technol. 2008, 99, 5981–5985. [Google Scholar] [CrossRef]

- Li, L.; Fu, X.; Ai, J.; Zhou, H.; Zhang, W.; Wang, D.; Liu, Z. Process parameters study and organic evolution of old landfill leachate treatment using photo-Fenton-like systems: Cu2+ vs Fe2+ as catalysts. Sep. Purif. Technol. 2019, 211, 972–982. [Google Scholar] [CrossRef]

- Li, W.; Zhou, Q.; Hua, T. Removal of Organic Matter from Landfill Leachate by Advanced Oxidation Processes: A Review. Int. J. Chem. Eng. 2010, 2010, 270532. [Google Scholar] [CrossRef] [Green Version]

- Koshy, L.; Paris, E.; Ling, S.; Jones, T.; Bérubé, K. Bioreactivity of leachate from municipal solid waste landfills—Assessment of toxicity. Sci. Total Environ. 2007, 384, 171–181. [Google Scholar] [CrossRef] [PubMed]

- Sruthi, T.; Gandhimathi, R.; Ramesh, S.; Nidheesh, P. Stabilized landfill leachate treatment using heterogeneous Fenton and electro-Fenton processes. Chemosphere 2018, 210, 38–43. [Google Scholar] [CrossRef] [PubMed]

- Alvarez-Vazquez, H.; Jefferson, B.; Judd, S.J. Membrane bioreactors vs conventional biological treatment of landfill leachate: A brief review. J. Chem. Technol. Biotechnol. 2004, 79, 1043–1049. [Google Scholar] [CrossRef]

- Deng, Y. Physical and oxidative removal of organics during Fenton treatment of mature municipal landfill leachate. J. Hazard. Mater. 2007, 146, 334–340. [Google Scholar] [CrossRef]

- Primo, O.; Rueda, A.; Rivero, M.J.; Ortiz, I. An Integrated Process, Fenton Reaction−Ultrafiltration, for the Treatment of Landfill Leachate: Pilot Plant Operation and Analysis. Ind. Eng. Chem. Res. 2008, 47, 946–952. [Google Scholar] [CrossRef]

- Abbas, A.A.; Jingsong, G.; Ping, L.Z.; Ya, P.Y.; Al-Rekabi, W.S. Review on Landfill Leachate Treatments. Am. J. Appl. Sci. 2009, 6, 672–684. [Google Scholar] [CrossRef]

- Wu, J.J.; Wu, C.-C.; Ma, H.-W.; Chang, C.-C. Treatment of landfill leachate by ozone-based advanced oxidation processes. Chemosphere 2004, 54, 997–1003. [Google Scholar] [CrossRef]

- Zang, C.; Hu, S.; Jin, S.; Chen, F. Catalytic Process Optimization of Birnessite-based Fenton-like Reaction with Surface Cu2+ Modification. ChemCatChem 2018, 10, 3576–3582. [Google Scholar] [CrossRef]

- Wang, J.L.; Xu, L.J. Advanced Oxidation Processes for Wastewater Treatment: Formation of Hydroxyl Radical and Application. Crit. Rev. Environ. Sci. Technol. 2012, 42, 251–325. [Google Scholar] [CrossRef]

- Aneggi, E.; Cabbai, V.; Trovarelli, A.; Goi, D. Potential of Ceria-Based Catalysts for the Oxidation of Landfill Leachate by Heterogeneous Fenton Process. Int. J. Photoenergy 2012, 2012, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Tarr, M.A. Fenton and Modified Fenton Methods for Pollutant Degradation. In Chemical Degradation Methods for Wastes and Pollutants; CRC Press: Boca Raton, FL, USA, 2003; pp. 159–190. [Google Scholar]

- Vogelpohl, A.; Kim, S.M. Advanced oxidation processes (AOPs) in wastewater treatment. J. Ind. Eng. Chem. 2004, 10, 33–40. [Google Scholar]

- Capodaglio, A.G. Critical Perspective on Advanced Treatment Processes for Water and Wastewater: AOPs, ARPs, and AORPs. Appl. Sci. 2020, 10, 4549. [Google Scholar] [CrossRef]

- Ma, D.; Yi, H.; Lai, C.; Liu, X.; Huo, X.; An, Z.; Li, L.; Fu, Y.; Li, B.; Zhang, M.; et al. Critical review of advanced oxidation processes in organic wastewater treatment. Chemosphere 2021, 275, 130104. [Google Scholar] [CrossRef]

- Torkashvand, J.; Kalantary, R.R.; Heidari, N.; Kazemi, Z.; Kazemi, Z.; Farzadkia, M.; Amoohadi, V.; Oshidari, Y. Application of ultrasound irradiation in landfill leachate treatment. Environ. Sci. Pollut. Res. 2021, 28, 47741–47751. [Google Scholar] [CrossRef]

- Liao, Z.; Dai, S.; Long, S.; Yu, Y.; Ali, J.; Wang, H.; Chen, Z.; Chen, Z. Pd based in situ AOPs with heterogeneous catalyst of FeMgAl layered double hydrotalcite for the degradation of bisphenol A and landfill leachate through multiple pathways. Environ. Sci. Pollut. Res. 2018, 25, 35623–35636. [Google Scholar] [CrossRef]

- Liu, Z.; Pan, L.; Hu, F.; Hu, Y. Advanced landfill leachate biochemical effluent treatment using Fe-Mn/AC activates O3/Na2S2O8 process: Process optimization, wastewater quality analysis, and activator characterization. Environ. Sci. Pollut. Res. 2020, 27, 15337–15349. [Google Scholar] [CrossRef]

- Adityosulindro, S.; Julcour, C.; Riboul, D.; Barthe, L. Degradation of ibuprofen by photo-based advanced oxidation processes: Exploring methods of activation and related reaction routes. Int. J. Environ. Sci. Technol. 2021, 1–14. [Google Scholar] [CrossRef]

- Labrada, K.G.; Cuello, D.R.A.; Sánchez, I.S.; Batle, M.G.; Manero, M.-H.; Barthe, L.; Jáuregui-Haza, U.J. Optimization of ciprofloxacin degradation in wastewater by homogeneous sono-Fenton process at high frequency. J. Environ. Sci. Heal. Part A 2018, 53, 1139–1148. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Adityosulindro, S.; Barthe, L.; González-Labrada, K.; Haza, U.J.J.; Delmas, H.; Julcour, C. Sonolysis and sono-Fenton oxidation for removal of ibuprofen in (waste)water. Ultrason. Sonochem. 2017, 39, 889–896. [Google Scholar] [CrossRef] [Green Version]

- Pouran, S.R.; Raman, A.A.A.; Daud, W.M.A.W. Review on the application of modified iron oxides as heterogeneous catalysts in Fenton reactions. J. Clean. Prod. 2014, 64, 24–35. [Google Scholar] [CrossRef] [Green Version]

- Garrido-Ramírez, E.; Theng, B.; Mora, M. Clays and oxide minerals as catalysts and nanocatalysts in Fenton-like reactions—A review. Appl. Clay Sci. 2010, 47, 182–192. [Google Scholar] [CrossRef]

- Pliego, G.; Zazo, J.A.; Garcia, M.M.; Munoz, M.; Casas, J.A.; Rodriguez, J.J. Trends in the Intensification of the Fenton Process for Wastewater Treatment: An Overview. Crit. Rev. Environ. Sci. Technol. 2015, 45, 2611–2692. [Google Scholar] [CrossRef]

- Sillanpää, M.; Ncibi, M.C.; Matilainen, A. Advanced oxidation processes for the removal of natural organic matter from drinking water sources: A comprehensive review. J. Environ. Manag. 2018, 208, 56–76. [Google Scholar] [CrossRef]

- Bokare, A.D.; Choi, W. Review of iron-free Fenton-like systems for activating H2O2 in advanced oxidation processes. J. Hazard. Mater. 2014, 275, 121–135. [Google Scholar] [CrossRef] [PubMed]

- González-Burciaga, L.A.; Núñez-Núñez, C.M.; Proal-Nájera, J.B. Challenges of TiO2 heterogeneous photocatalysis on cytostatic compounds degradation: State of the art. Environ. Sci. Pollut. Res. 2021, 1–24. [Google Scholar] [CrossRef]

- Mirzaei, M.; Habibi, M.H.; Sabzyan, H. Synthesis, characterization, and dye degradation photocatalytic activity of the nano-size copper iron binary oxide. Environ. Sci. Pollut. Res. 2021, 29, 9173–9192. [Google Scholar] [CrossRef]

- Aneggi, E.; Trovarelli, A.; Goi, D. Degradation of phenol in wastewaters via heterogeneous Fenton-like Ag/CeO 2 catalyst. J. Environ. Chem. Eng. 2017, 5, 1159–1165. [Google Scholar] [CrossRef]

- Cardoso, I.M.F.; Cardoso, R.M.F.; da Silva, J.C.G.E. Advanced Oxidation Processes Coupled with Nanomaterials for Water Treatment. Nanomaterials 2021, 11, 2045. [Google Scholar] [CrossRef] [PubMed]

- Hussain, S.; Aneggi, E.; Goi, D. Catalytic activity of metals in heterogeneous Fenton-like oxidation of wastewater contaminants: A review. Environ. Chem. Lett. 2021, 19, 2405–2424. [Google Scholar] [CrossRef]

- Kezzim, A.; Boudjemaa, A.; Belhadi, A.; Trari, M. Photo-catalytic degradation of ibuprofen over the new semiconducting catalyst α-(Cu, Fe)2O3 prepared by hydrothermal route. Res. Chem. Intermed. 2017, 43, 3727–3743. [Google Scholar] [CrossRef]

- Huang, Z.; Chen, Z.; Chen, Y.; Hu, Y. Synergistic effects in iron-copper bimetal doped mesoporous γ-Al2O3 for Fenton-like oxidation of 4-chlorophenol: Structure, composition, electrochemical behaviors and catalytic performance. Chemosphere 2018, 203, 442–449. [Google Scholar] [CrossRef] [PubMed]

- Nieto-Juarez, J.I.; Pierzchła, K.; Sienkiewicz, A.; Kohn, T. Inactivation of MS2 coliphage in Fenton and Fenton-like systems: Role of transition metals, hydrogen peroxide and sunlight. Environ. Sci. Technol. 2010, 44, 3351–3356. [Google Scholar] [CrossRef]

- Salazar, R.; Brillas, E.; Sirés, I. Finding the best Fe2+/Cu2+ combination for the solar photoelectro-Fenton treatment of simulated wastewater containing the industrial textile dye Disperse Blue 3. Appl. Catal. B Environ. 2012, 115, 107–116. [Google Scholar] [CrossRef]

- Chen, G.; Wu, G.; Li, N.; Lu, X.; Zhao, J.; He, M.; Yan, B.; Zhang, H.; Duan, X.; Wang, S. Landfill leachate treatment by persulphate related advanced oxidation technologies. J. Hazard. Mater. 2021, 418, 126355. [Google Scholar] [CrossRef]

- Teng, C.; Zhou, K.; Zhang, Z.; Peng, C.; Chen, W. Elucidating the structural variation of membrane concentrated landfill leachate during Fenton oxidation process using spectroscopic analyses. Environ. Pollut. 2020, 256, 113467. [Google Scholar] [CrossRef]

- Zhang, Z.; Teng, C.; Zhou, K.; Peng, C.; Chen, W. Degradation characteristics of dissolved organic matter in nanofiltration concentrated landfill leachate during electrocatalytic oxidation. Chemosphere 2020, 255, 127055. [Google Scholar] [CrossRef]

- Hussain, S.; Aneggi, E.; Briguglio, S.; Mattiussi, M.; Gelao, V.; Cabras, I.; Zorzenon, L.; Trovarelli, A.; Goi, D. Enhanced ibuprofen removal by heterogeneous-Fenton process over Cu/ZrO2 and Fe/ZrO2 catalysts. J. Environ. Chem. Eng. 2020, 8. [Google Scholar] [CrossRef]

- Subbulekshmi, N.; Subramanian, E. Nano CuO immobilized fly ash zeolite Fenton-like catalyst for oxidative degradation of p -nitrophenol and p -nitroaniline. J. Environ. Chem. Eng. 2017, 5, 1360–1371. [Google Scholar] [CrossRef]

- Bradu, C.; Frunza, L.; Mihalche, N.; Avramescu, S.-M.; Neaţă, M.; Udrea, I. Removal of Reactive Black 5 azo dye from aqueous solutions by catalytic oxidation using CuO/Al2O3 and NiO/Al2O. Appl. Catal. B Environ. 2010, 96, 548–556. [Google Scholar] [CrossRef]

- Induja, S.; Raghavan, P. Catalytic efficiency of copper oxide in degradation of phenol using sintered calcium phosphate (SCaP) as catalyst support. Catal. Commun. 2013, 33, 7–10. [Google Scholar] [CrossRef]

- Dong, J.; Tian, T.; Ren, L.; Zhang, Y.; Xu, J.; Cheng, X. CuO nanoparticles incorporated in hierarchical MFI zeolite as highly active electrocatalyst for non-enzymatic glucose sensing. Colloids Surfaces B Biointerfaces 2015, 125, 206–212. [Google Scholar] [CrossRef] [PubMed]

- Liou, R.-M.; Chen, S.-H. CuO impregnated activated carbon for catalytic wet peroxide oxidation of phenol. J. Hazard. Mater. 2009, 172, 498–506. [Google Scholar] [CrossRef] [PubMed]

- Sohrabnezhad, S.; Moghaddam, M.M.; Salavatiyan, T. Synthesis and characterization of CuO–montmorillonite nanocom-posite by thermal decomposition method and antibacterial activity of nanocomposite. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2014, 125, 73–78. [Google Scholar] [CrossRef] [PubMed]

- Huo, C.; Ouyang, J.; Yang, H. CuO nanoparticles encapsulated inside Al-MCM-41 mesoporous materials via direct synthetic route. Sci. Rep. 2014, 4, 3682. [Google Scholar] [CrossRef]

- Lu, Y.; Liu, X.; Qiu, K.; Cheng, J.; Wang, W.; Yan, H.; Tang, C.; Kim, J.-K.; Luo, Y. Facile Synthesis of Graphene-Like Copper Oxide Nanofilms with Enhanced Electrochemical and Photocatalytic Properties in Energy and Environmental Applications. ACS Appl. Mater. Interfaces 2015, 7, 9682–9690. [Google Scholar] [CrossRef]

- Nasrollahzadeh, M.; Sajadi, S.M.; Rostami-Vartooni, A.; Bagherzadeh, M.; Safari, R. Immobilization of copper nanoparticles on perlite: Green synthesis, characterization and catalytic activity on aqueous reduction of 4-nitrophenol. J. Mol. Catal. A Chem. 2015, 400, 22–30. [Google Scholar] [CrossRef]

- Hussain, S.; Aneggi, E.; Trovarelli, A.; Goi, D. Heterogeneous Fenton-like oxidation of ibuprofen over zirconia-supported iron and copper catalysts: Effect of process variables. J. Water Process Eng. 2021, 44, 102343. [Google Scholar] [CrossRef]

- Zhang, H.; Choi, H.J.; Huang, C.-P. Optimization of Fenton process for the treatment of landfill leachate. J. Hazard. Mater. 2005, 125, 166–174. [Google Scholar] [CrossRef]

- Mirzaee, S.A.; Jaafarzadeh, N.; Jorfi, S.; Gomes, H.T.; Ahmadi, M. Enhanced degradation of Bisphenol A from high saline polycarbonate plant wastewater using wet air oxidation. Process Saf. Environ. Prot. 2018, 120, 321–330. [Google Scholar] [CrossRef] [Green Version]

- Arques, A.; Amat, A.M.; García-Ripoll, A.; Vicente, R. Detoxification and/or increase of the biodegradability of aqueous solutions of dimethoate by means of solar photocatalysis. J. Hazard. Mater. 2007, 146, 447–452. [Google Scholar] [CrossRef]

- Rouidi, L.M.; Maurício, R.; Boukhrissa, A.; Ait-Amar, H.; Balamane, O. Characterization and treatment of landfill leachates by electro-Fenton process: A case study in Algeria. Water Environ. Res. 2020, 92, 123–137. [Google Scholar] [CrossRef]

- Laiju, A.R.; Sivasankar, T.; Nidheesh, P.V. Iron-loaded mangosteen as a heterogeneous Fenton catalyst for the treatment of landfill leachate. Environ. Sci. Pollut. Res. 2014, 21, 10900–10907. [Google Scholar] [CrossRef] [PubMed]

- Xavier, S.; Gandhimathi, R.; Nidheesh, P.V.; Ramesh, S.T. Comparison of homogeneous and heterogeneous Fenton processes for the removal of reactive dye Magenta MB from aqueous solution. Desalination Water Treat. 2015, 53, 109–118. [Google Scholar] [CrossRef]

- Choina, J.; Kosslick, H.; Fischer, C.; Flechsig, G.-U.; Frunza, L.; Schulz, A. Photocatalytic decomposition of pharmaceutical ibuprofen pollutions in water over titania catalyst. Appl. Catal. B Environ. 2013, 129, 589–598. [Google Scholar] [CrossRef]

- Xu, H.-Y.; Liu, W.-C.; Qi, S.-Y.; Li, Y.; Zhao, Y.; Li, J.-W. Kinetics and optimization of the decoloration of dyeing wastewater by a schorl-catalyzed Fenton-like reaction. J. Serb. Chem. Soc. 2014, 79, 361–377. [Google Scholar] [CrossRef]

- Hashemian, S. Fenton-Like Oxidation of Malachite Green Solutions: Kinetic and Thermodynamic Study. J. Chem. 2013, 2013, 809318. [Google Scholar] [CrossRef] [Green Version]

- Ifelebuegu, A.O.; Ezenwa, C.P. Removal of Endocrine Disrupting Chemicals in Wastewater Treatment by Fenton-Like Oxidation. Water Air Soil Pollut. 2011, 217, 213–220. [Google Scholar] [CrossRef]

- Xu, H.-Y.; Prasad, M.; Liu, Y. Schorl: A novel catalyst in mineral-catalyzed Fenton-like system for dyeing wastewater discol-oration. J. Hazard. Mater. 2009, 165, 1186–1192. [Google Scholar] [CrossRef] [PubMed]

- Munoz, M.; Pliego, G.; De Pedro, Z.M.; Casas, J.A.; Rodriguez, J.J. Application of intensified Fenton oxidation to the treatment of sawmill wastewater. Chemosphere 2014, 109, 34–41. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Zhuan, R. Degradation of antibiotics by advanced oxidation processes: An overview. Sci. Total Environ. 2020, 701, 135023. [Google Scholar] [CrossRef] [PubMed]

- Nidheesh, P.V.; Gandhimathi, R.; Ramesh, S.T. Degradation of dyes from aqueous solution by Fenton processes: A review. Environ. Sci. Pollut. Res. 2013, 20, 2099–2132. [Google Scholar] [CrossRef]

- Wang, N.; Zheng, T.; Zhang, G.; Wang, P. A review on Fenton-like processes for organic wastewater treatment. J. Environ. Chem. Eng. 2016, 4, 762–787. [Google Scholar] [CrossRef] [Green Version]

- Qi, Y.; Mei, Y.; Li, J.; Yao, T.; Yang, Y.; Jia, W.; Tong, X.; Wu, J.; Xin, B. Highly efficient microwave-assisted Fenton degradation of metacycline using pine-needle-like CuCo2O4 nanocatalyst. Chem. Eng. J. 2019, 373, 1158–1167. [Google Scholar] [CrossRef]

- Gan, P.P.; Li, S.F.Y. Efficient removal of Rhodamine B using a rice hull-based silica supported iron catalyst by Fenton-like process. Chem. Eng. J. 2013, 229, 351–363. [Google Scholar] [CrossRef]

- Panda, N.; Sahoo, H.; Mohapatra, S. Decolourization of Methyl Orange using Fenton-like mesoporous Fe2O3–SiO2 composite. J. Hazard. Mater. 2011, 185, 359–365. [Google Scholar] [CrossRef]

- Jiang, C.; Pang, S.; Ouyang, F.; Ma, J.; Jiang, J. A new insight into Fenton and Fenton-like processes for water treatment. J. Hazard. Mater. 2010, 174, 813–817. [Google Scholar] [CrossRef]

- He, Z.; Liu, Y.; Wang, J.; Lv, Y.; Xu, Y.; Jia, S. Enhanced degradation of old landfill leachate in heterogeneous electro–Fenton catalyzed using Fe3O4 nano–particles encapsulated by metal organic frameworks. J. Clean. Prod. 2021, 321, 128947. [Google Scholar] [CrossRef]

- Makhatova, A.; Mazhit, B.; Sarbassov, Y.; Meiramkulova, K.; Inglezakis, V.J.; Poulopoulos, S.G. Effective photochemical treatment of a municipal solid waste landfill leachate. PLoS ONE 2020, 15, e0239433. [Google Scholar] [CrossRef]

- Poblete, R.; Perez, N. Use of sawdust as pretreatment of photo-Fenton process in the depuration of landfill leachate. J. Environ. Manag. 2019, 253, 109697. [Google Scholar] [CrossRef] [PubMed]

- Asaithambi, P.; Govindarajan, R.; Yesuf, M.B.; Alemayehu, E. Removal of color, COD and determination of power consumption from landfill leachate wastewater using an electrochemical advanced oxidation processes. Sep. Purif. Technol. 2020, 233, 115935. [Google Scholar] [CrossRef]

- Gallo-Cordova, A.; Castro, J.J.; Winkler, E.L.; Lima, E.; Zysler, R.D.; Morales, M.D.P.; Ovejero, J.G.; Streitwieser, D.A. Improving degradation of real wastewaters with self-heating magnetic nanocatalysts. J. Clean. Prod. 2021, 308, 127385. [Google Scholar] [CrossRef]

- Durai, N.J.; Gopalakrishna, G.V.T.; Padmanaban, V.C.; Selvaraju, N. Oxidative removal of stabilized landfill leachate by Fenton’s process: Process modeling, optimization & analysis of degraded products. RSC Adv. 2020, 10, 3916–3925. [Google Scholar] [CrossRef] [Green Version]

- Dantas, E.R.B.; Silva, E.J.; Lopes, W.S.; Nascimento, M.R.D.; Leite, V.D.; de Sousa, J.T. Fenton treatment of sanitary landfill leachate: Optimization of operational parameters, characterization of sludge and toxicology. Environ. Technol. 2019, 41, 2637–2647. [Google Scholar] [CrossRef]

- Mahtab, M.S.; Islam, D.T.; Farooqi, I.H. Optimization of the process variables for landfill leachate treatment using Fenton based advanced oxidation technique. Eng. Sci. Technol. Int. J. 2021, 24, 428–435. [Google Scholar] [CrossRef]

- Niveditha, S.; Gandhimathi, R. Flyash augmented Fe3O4 as a heterogeneous catalyst for degradation of stabilized landfill leachate in Fenton process. Chemosphere 2020, 242, 125189. [Google Scholar] [CrossRef]

- Wang, F.; Gu, Z.; Hu, Y.; Li, Q. Split dosing of H2O2 for enhancing recalcitrant organics removal from landfill leachate in the Fe0/H2O2 process: Degradation efficiency and mechanism. Sep. Purif. Technol. 2021, 278, 119564. [Google Scholar] [CrossRef]

- Taşcı, S.; Özgüven, A.; Yıldız, B. Multi-Response/Multi-Step Optimization of Heterogeneous Fenton Process with Fe3O4 Catalyst for the Treatment of Landfill Leachate. Water Air Soil Pollut. 2021, 232, 1–19. [Google Scholar] [CrossRef]

- Sun, Y.; Tian, P.; Ding, D.; Yang, Z.; Wang, W.; Xin, H.; Xu, J.; Han, Y.-F. Revealing the active species of Cu-based catalysts for heterogeneous Fenton reaction. Appl. Catal. B Environ. 2019, 258, 117985. [Google Scholar] [CrossRef]

- Sun, B.; Li, H.; Li, X.; Liu, X.; Zhang, C.; Xu, H.; Zhao, X.S. Degradation of Organic Dyes over Fenton-Like Cu2O–Cu/C Catalysts. Ind. Eng. Chem. Res. 2018, 57, 14011–14021. [Google Scholar] [CrossRef]

- EPA United States Environmental Protection Agency. Clean Water Act. Available online: https://www.epa.gov/laws-regulations/summary-clean-water-act (accessed on 6 June 2021).

- European Council. Directive 2000/60/EC of the European Parliament and of the Council of 23 October 2000 Establishing a Frame-Work for Community Action in the Field of Water Policy. Available online: https://eur-lex.europa.eu/eli/dir/2000/60/oj (accessed on 6 June 2021).

- APHA; AWWA; WEF. Standard Methods for the Examination of Water and Wastewater, 20th ed.; American Public Health Association, American Water Works Association, Water Environment Federation: Washington, DC, USA, 1999. [Google Scholar]

| Parameters | Value |

|---|---|

| pH | 8.5 |

| Chlorine | 80 mg/L |

| Hardness (CaCO3) | 360 mg/L |

| COD | 8700 mg/L |

| TOC | 970 mg/L |

| AOX | 13 mg/L |

| Total Nitrogen (TN) | 1.94 g/L |

| Color | Dark brown |

| Al | 5 mg/L |

| Ca | 38.2 mg/L |

| Cr | 0.7 mg/L |

| Fe | 2.7 mg/L |

| Mn | 0.1 mg/L |

| Mg | 55.8 mg/L |

| Ni | 0.4 mg/L |

| Zn | 0.3 mg/L |

| Method | pH | TOC Abatement (%) | COD Abatement (%) | Ref |

|---|---|---|---|---|

| electro–Fenton | 3 | / | 67 | [71] |

| photo-Fenton | 3 | 69 | / | [72] |

| photo-Fenton | 3 | / | 61 | [73] |

| photo-electro Fenton | 3 | / | 97 | [74] |

| magnetic Fenton | / | 75 | / | [75] |

| homogeneous Fenton | 3 | 74 | 98 | [76] |

| homogeneous Fenton | 2 | / | 87 | [77] |

| homogeneous Fenton | 3 | / | 61 | [78] |

| heterogeneous Fenton | 3 | 68 | 85 | [79] |

| heterogeneous Fenton | 5 | 65 | 70 | This work |

| heterogeneous Fenton | 3 | 56 | / | [80] |

| heterogeneous Fenton | 3 | / | 75 | [81] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hussain, S.; Aneggi, E.; Trovarelli, A.; Goi, D. Removal of Organics from Landfill Leachate by Heterogeneous Fenton-like Oxidation over Copper-Based Catalyst. Catalysts 2022, 12, 338. https://0-doi-org.brum.beds.ac.uk/10.3390/catal12030338

Hussain S, Aneggi E, Trovarelli A, Goi D. Removal of Organics from Landfill Leachate by Heterogeneous Fenton-like Oxidation over Copper-Based Catalyst. Catalysts. 2022; 12(3):338. https://0-doi-org.brum.beds.ac.uk/10.3390/catal12030338

Chicago/Turabian StyleHussain, Sajid, Eleonora Aneggi, Alessandro Trovarelli, and Daniele Goi. 2022. "Removal of Organics from Landfill Leachate by Heterogeneous Fenton-like Oxidation over Copper-Based Catalyst" Catalysts 12, no. 3: 338. https://0-doi-org.brum.beds.ac.uk/10.3390/catal12030338