Microstructure and Fluctuation-Induced Conductivity Analysis of Bi2Sr2CaCu2O8+δ (Bi-2212) Nanowire Fabrics

Abstract

:1. Introduction

2. Experimental Procedures

2.1. Sample Preparation

2.2. Resistance Measurements

2.3. Microscopy

3. Results and Discussion

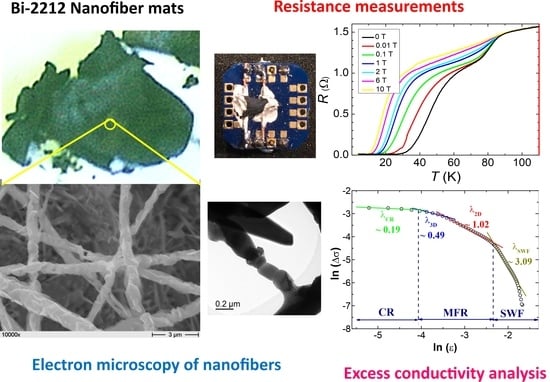

3.1. Microstructure of the Nanowire Network Fabrics

3.2. Resistance Measurements

3.3. FIC Analysis

3.4. Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bezryadin, A. Superconductivity in Nanowires; Wiley-VCH: Weinheim, Germany, 2013. [Google Scholar]

- Altomare, F.; Chang, A.M. One-Diemsional Superconductivity in Nanowires; Wiley-VCH: Weinheim, Germany, 2013. [Google Scholar]

- Dam, B.; Huijbregtse, J.M.; Klaasen, F.C.; van der Geest, R.C.F.; Doornbos, G.; Rector, J.H.; Testa, A.M.; Freisem, S.; Martinez, J.C.; Stäuble-Pümpin, B.; et al. Origin of high critical currents in YBa2Cu3O7−δ superconducting thin films. Nature 1999, 399, 439–442. [Google Scholar] [CrossRef] [Green Version]

- Awaji, S.; Suzuki, T.; Oguro, H.; Watanabe, K.; Matsumoto, K. Strain-controlled critical temperature in REBa2Cu3Oy-coated conductors. Sci. Rep. 2015, 5, 11156. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, D.; Xia, Y.N. Electrospinning of nanofibers: Reinventing the wheel? Adv. Mater. 2004, 16, 1151–1170. [Google Scholar] [CrossRef]

- Li, D.; McCann, J.T.; Xia, Y.N. Electrospinning: A simple and versatile technique for producing ceramic nanofibers and nanotubes. J. Am. Ceram. Soc. 2006, 89, 1861–1869. [Google Scholar] [CrossRef]

- Wu, H.; Pan, W.; Lin, D.; Li, H. Electrospinning of ceramic nanofibers: Fabrication, assembly and applications. J. Adv. Ceram. 2012, 1, 2–23. [Google Scholar] [CrossRef] [Green Version]

- Daristotle, J.L.; Behrens, A.M.; Sandler, A.D.; Kofinas, P. A review of the fundamental principles and applications of solution blow spinning. ACS Appl. Mater. Interf. 2016, 8, 34951–34963. [Google Scholar] [CrossRef] [Green Version]

- Cheng, B.; Tao, X.; Shi, L.; Yan, G.; Zhuang, X. Fabrication of ZrO2 ceramic fiber mats by solution blowing process. Ceram. Int. 2014, 40, 15013–15018. [Google Scholar] [CrossRef]

- Sharma, D.; Kumar, R.; Awana, V.P.S. DC and AC susceptibility study of sol-gel synthezied Bi2Sr2CaCu2O8+δ superconductor. Ceram. Int. 2013, 39, 1143–1152. [Google Scholar] [CrossRef]

- Deguchi, Y.; Kikuchi, H.; Mori, N.; Yamada, Y.; Atsumi, T.; Yoshida, K.; Ishibashi, T. Fluctuation-conductivity characterization of superconducting Bi2Sr2CaCu2O8+δ thinfilms prepared by the metal-organic decomposition method. Phys. Proc. 2013, 45, 193–196. [Google Scholar] [CrossRef] [Green Version]

- Lu, X.; Wang, T.; Qi, Y. Crystalline characteristics and superconducting properties of Bi2212 thin films by Pechini dol-gel method: Effect of heating rate on the film growth. J. Sol-Gel Sci. Technol. 2016, 77, 100–108. [Google Scholar] [CrossRef]

- Liu, X.; Zhao, G. One step preparation of photosensitive Bi2Sr2CaCu2O8+x films and their fine patterns by a photosensitive sol-gel method. Supercond. Sci. Technol. 2018, 31, 125017. [Google Scholar] [CrossRef]

- Reyntjens, S.; Puers, R. A review of focused-ion beam applications in microsystem technology. J. Micromech. Microeng. 2001, 11, 287–300. [Google Scholar] [CrossRef]

- Li, J.M.; Zeng, X.L.; Mo, A.D.; Xu, Z.A. Fabrication of cuprate superconducting La1.85Sr0.15CuO4 nanofibers by electrospinning and subsequent calcination in oxygen. CrystEngComm 2011, 13, 6964–6967. [Google Scholar] [CrossRef]

- Duarte, E.A.; Quintero, P.A.; Meisel, M.W.; Nino, J.C. Electrospinning of superconducting BSCCO nanowires. Physica C 2013, 495, 109–113. [Google Scholar] [CrossRef]

- Duarte, E.A.; Rudawski, N.G.; Quintero, P.A.; Meisel, M.W.; Nino, J.C. Electrospinning of superconducting YBCO nanowires. Supercond. Sci. Technol. 2015, 28, 015006. [Google Scholar] [CrossRef]

- Zeng, X.L.; Koblischka, M.R.; Hartmann, U. Synthesis and characterization of electrospun superconducting (La,Sr)CuO4 nanowires and nanoribbons. Mater. Res. Express 2015, 2, 095022. [Google Scholar] [CrossRef]

- Koblischka, M.R.; Zeng, X.L.; Karwoth, T.; Hauet, T.; Hartmann, U. Transport and magnetic measurements on Bi-2212 nanowire networks prepared via electrospinning. IEEE Trans. Appl. Supercond. 2016, 26, 1800605. [Google Scholar] [CrossRef] [Green Version]

- Koblischka, M.R.; Zeng, X.L.; Karwoth, T.; Hauet, T.; Hartmann, U. Magnetic properties of electrospun nonwoven superconducting fabrics. AIP Adv. 2016, 6, 035115. [Google Scholar] [CrossRef] [Green Version]

- Zeng, X.L.; Koblischka, M.R.; Karwoth, T.; Hauet, T.; Hartmann, U. Preparation of granular Bi-2212 nanowires by electrospinning. Supercond. Sci. Technol. 2017, 30, 035014. [Google Scholar] [CrossRef] [Green Version]

- Cena, C.R.; Torsoni, G.B.; Zadorosny, L.; Malmonge, L.F.; Carvalho, C.; Malmonge, J.A. BSCCO superconductor micro/nanofibers produced by solution blow spinning technique. Ceram Int. 2017, 43, 7663–7667. [Google Scholar] [CrossRef] [Green Version]

- Rotta, M.; Zadorosny, L.; Carvalho, C.L.; Malmonge, J.A.; Malmonge, I.F.; Zadorosny, R. YBCO ceramic nanofibers obtained by the new technique of solution blow spinning. Ceram. Int. 2016, 42, 16230–16234. [Google Scholar] [CrossRef] [Green Version]

- Rotta, M.; Motta, M.; Pessoa, A.L.; Carvalho, C.L.; Ortiz, W.A.; Zadorosny, R. Solution blow spinning control of morphology and production rate of complex superconducting YBa2Cu3O7−x nanowires. J. Mater. Sci. Mater. Electron. 2019, 30, 9045–9050. [Google Scholar] [CrossRef] [Green Version]

- Rotta, M.; Namburi, D.K.; Shi, Y.; Pessoa, A.L.; Carvalho, C.L.; Durrell, J.H.; Cardwell, D.A.; Zadorosny, R. Synthesis of Y2BaCuO5 nano-whiskers by a solution blow spinning technique and their successful introduction into single-grain, YBCO bulk superconductors. Ceram. Int. 2019, 45, 3948–3953. [Google Scholar] [CrossRef]

- Koblischka, M.R.; Koblischka-Veneva, A. Porous high-Tc superconductors and their applications. AIMS Mater. Sci. 2018, 5, 1199–1213. [Google Scholar] [CrossRef]

- Koblischka, M.R.; Koblischka-Veneva, A. The possible applications of superconducting nanowire networks. Mater. Today Proc. submitted.

- Zeng, X.L.; Karwoth, T.; Koblischka, M.R.; Hartmann, U.; Gokhfeld, D.; Chang, C.; Hauet, T. Analysis of magnetization loops of electrospun nonwoven superconducting fabrics. Phys. Rev. Mater. 2017, 1, 044802. [Google Scholar] [CrossRef] [Green Version]

- Mikheenko, P.N.; Uprety, K.K.; Dou, S.X. BSCCO. In Handbook of Superconducting Materials; Cardwell, D.A., Ginley, D.S., Eds.; IOP Publishing: Bristol, UK, 2003; Volume I. [Google Scholar]

- Kametani, F.; Jiang, J.; Matras, M.; Abraimov, D.; Hellstrom, E.E.; Larbalestier, D.C. Comparison of growth texture in round Bi2Sr2CaCu2O8 and flat Bi2Sr2Ca2Cu3O10 wires at its relation to high critical current density development. Sci. Rep. 2015, 5, 8285. [Google Scholar] [CrossRef] [PubMed]

- Oh, B.; Char, K.; Kent, A.D.; Naito, M.; Beasley, M.R.; Geballe, T.H.; Hammond, R.H.; Kapitulnik, A.; Graybeal, J.M. Upper critical field, fluctuation conductivity, and dimensionality of YBa2Cu3O7−x. Phys. Rev. B 1988, 37, 7861–7864. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, A.K.; Bandyopadhyay, S.K.; Basu, A.N. Generalization of fluctuation induced conductivity in polyscrystalline Y1−xCaxBa2Cu3Oy and Bi2Sr2CaCu2O8+δ superconductors. J. Appl. Phys. 1999, 86, 3247–3252. [Google Scholar] [CrossRef]

- Fanfarillo, L.; Benfatto, L.; Caprara, S.; Castellani, C.; Grilli, M. Theory of fluctuation conductivity from interband pairing in pnictide superconductors. Phys. Rev. B 2009, 79, 172508. [Google Scholar] [CrossRef] [Green Version]

- Jurelo, A.R.; Costa, R.M.; Rodrigues Junior, P.; Serbena, F.C. Fluctuation conductivity and phase separation in polycrystalline Y1−xCexBa2Cu3O7−δ. J. Supercond. Novel Magn. 2010, 23, 247–252. [Google Scholar] [CrossRef]

- Roa-Rojas, J.; Costa, R.M.; Pureur, P.; Prieto, P. Pairing transition, coherence transition, and the irreversibility line in granular GdBa2Cu3O7−δ. Phys. Rev. B 2000, 61, 12457–12462. [Google Scholar] [CrossRef]

- Hannachi, E.; Slimani, Y.; Ben Salem, M.K.; Hamrita, A.; Al-Otaibi, A.L.; Almessiere, M.A.; Ben Salem, M.; Ben Azzouz, F. Fluctuation induced conductivity studies in YBa2Cu3Oy compound embedded by superconducting nano-particles Y-deficient YBa2Cu3Oy: Effect of silver inclusion. Indian J. Phys. 2016, 90, 1009–1018. [Google Scholar] [CrossRef]

- Almessiere, M.A.; Hannachi, E.; Slimani, Y.; Ghulam, Y.; Mumtaz, M.; Koblischka, M.R.; Koblischka-Veneva, A.; Manikandan, A.; Baykal, A. Dimensionality and superconducting parameters of YBa2Cu3O7−δ/(WO3 NPs)x composites deduced from excess conductivity analysis. Mater. Chem. Phys. 2020, 243, 122665. [Google Scholar] [CrossRef]

- Aslamazov, L.G.; Larkin, A.L. The influence of fluctuation pairing of electrons on the conductivity of normal metal. Phys. Lett. A 1968, 26, 238–252. [Google Scholar] [CrossRef]

- Lawrence, W.E.; Doniach, S. Proceedings of the 12th International Conference on Low Temperature Physics, Kyoto, Tokyo, Japan; Kanda, E., Ed.; Academic Press of Japan: Tokyo, Japan, 1971; p. 361. [Google Scholar]

- Maki, K.; Thompson, R.S. Fluctuation conductivity of high-Tc superconductors. Phys. Rev. B 1989, 39, 2767–2771. [Google Scholar] [CrossRef]

- Larkin, A.; Varlamov, A. Theory of Fluctuations in Superconductors; Oxford University Press: Oxford, UK, 2005. [Google Scholar]

- Litvinov, Y.V.; Vovk, R.V.; Dobrovolskiy, O.V. Evolution of excess conductivity in YBCO single crystals after irradiation with fast electrons. Physica C 2020, 573, 1353645. [Google Scholar] [CrossRef]

- Nayak, P.K.; Ravi, S. Excess conductivity and magneto-conductivity studies in pure and Ag-doped (La1−xYx)2Ba2CaCu5Oz superconductors. Supercond. Sci. Technol. 2006, 19, 1209–1214. [Google Scholar] [CrossRef]

- Humphreys, F.J. Characterization of fine-scale microstructures by electron backscatter diffraction (EBSD). Scr. Mater. 2004, 51, 771–776. [Google Scholar] [CrossRef]

- Trimby, P.W. Orientation mapping of nanostructured materials using transmission Kikuchi diffraction in the scanning electron microscope. Ultramicroscopy 2012, 120, 16–24. [Google Scholar] [CrossRef]

- Keller, R.; Geiss, R. Transmission EBSD from 10 nm domains in a scanning electron microscope. J. Microsc. 2012, 245, 245–251. [Google Scholar] [CrossRef]

- Sneddon, G.C.; Trimby, P.W.; Cairney, J.M. Transmission Kikuchi diffraction in a scanning electron microscope: A review. Mater. Sci. Eng. R 2016, 110, 1–12. [Google Scholar] [CrossRef]

- Karwoth, T. Electronic Transport Measurements on Electrospun High-Tc Fibers. Master’s Thesis, Saarland University, Saarbrücken, Germany, 2016. [Google Scholar]

- Karwoth, T.; Furutani, K.; Koblischka, M.R.; Zeng, X.L.; Wiederhold, A.; Muralidhar, M.; Murakami, M.; Hartmann, U. Electrotransport and magnetic measurements on bulk FeSe superconductors. J. Phys. Conf. Ser. 2018, 1054, 012018. [Google Scholar] [CrossRef]

- Karwoth, T.; Zeng, X.L.; Koblischka, M.R.; Hartmann, U.; Chang, C.; Hauet, T.; Li, J.M. Magnetoresistance and structural characterization of electrospun La1−xSrxMnO3 nanowire networks. Solid State Commun. 2019, 290, 37–41. [Google Scholar] [CrossRef]

- Orientation Imaging Microscopy (OIM Analysis™) Software Version V8.1; User Manual; EDAX Inc.: Draper, UT, USA, 2018.

- Frontera, P.; Kumita, M.; Malara, A.; Nishizawa, J.; Bonaccorsi, L. Manufacturing and assessment of electrospun PVP/TEOS microfibres for adsorptive heat transformers. Coatings 2019, 9, 443. [Google Scholar] [CrossRef] [Green Version]

- Zeng, X.L.; Koblischka, M.R.; Laurent, F.; Karwoth, T.; Koblischka-Veneva, A.; Hartmann, U.; Chang, C.; Kumar, P.; Eibl, O. Characterization of electrospun Bi2Sr2CaCu2O8+δ nanowires with reduced preparation temperature. IEEE Trans. Appl. Supercond. 2018, 28, 7200505. [Google Scholar] [CrossRef]

- Pessoa, A.L.; Koblischka-Veneva, A.; Carvalho, C.L.; Zadorosny, R.; Koblischka, M.R. Microstructure and paramagnetic Meissner effect of YBCO nanowire networks. J. Nanoparticle Res. in print.

- Koblischka-Veneva, A.; Koblischka, M.R.; Zeng, X.L.; Schmauch, J.; Hartmann, U. TEM and electron-backscatter analysis (EBSD) on superconducting nanowires. J. Phys. Conf. Ser. 2018, 1054, 012005. [Google Scholar] [CrossRef]

- Tinkham, M.; Lau, C.N. Quantum limit to phase coherence in thin superconducting wires. Appl. Phys. Lett. 2002, 80, 2946–2948. [Google Scholar] [CrossRef]

- Koblischka, M.R.; Roth, S.; Koblischka-Veneva, A.; Karwoth, T.; Wiederhold, A.; Zeng, X.L.; Fassoulas, S.; Murakami, M. Relation between Crystal Structure and Transition Temperature of Superconducting Metals and Alloys. Metals 2020, 10, 158. [Google Scholar] [CrossRef] [Green Version]

- Bollinger, A.T.; Rogachev, A.; Remeika, M.; Bezryadin, A. Effect of morphology on the superconductor-insulator transition in 1-dimensional nanowires. Phys. Rev. B 2004, 69, 180503. [Google Scholar] [CrossRef] [Green Version]

- Koblischka, M.R.; Sosnowski, J. Temperature-dependent scaling of pinning force data in Bi-based high-Tc superconductors. Eur. Phys. J. B 2005, 44, 277–280. [Google Scholar] [CrossRef]

- Musolino, N.; Bals, S.; van Tendeloo, G.; Clayton, N.; Walker, E.; Flükiger, R. Modulation-free phase in heavily Pb-doped (Bi,Pb)-2212 single crystals. Physica C 2003, 399, 1–7. [Google Scholar] [CrossRef]

- Clayton, N.; Musolino, N.; Giannini, E.; Garnier, V.; Flükiger, R. Growth and superconducting properties of Bi2Sr2Ca2Cu3O10 single crystals. Supercond. Sci. Technol. 2004, 17, S563–S567. [Google Scholar] [CrossRef]

- Mandal, P.; Poddar, A.; Das, A.N.; Ghosh, B.; Chaudhury, P. Excess conductivity and thermally activated dissipation studies in Bi2Sr2Ca1Cu2Ox single crystals. Physica C 1990, 169, 43–49. [Google Scholar] [CrossRef]

- Ghosh, A.K.; Basu, A.N. Fluctuation-induced conductivity in quenched and furnace-cooled Bi2Sr2CaCu2O8+δ: Aslamazov-Larkin or short-wavelength fluctuations. Phys. Rev. B 1999, 59, 11193–11196. [Google Scholar] [CrossRef]

- Ghosh, A.K.; Basu, A.N. Dimensional exponents of Gaussian and critical fluctuations in Bi2Sr2CaCu2O8+δ processed under different conditions. Supercond. Sci. Technol. 2000, 13, 343–348. [Google Scholar] [CrossRef]

- Ben Azzouz, F.; Zouaoui, M.; Annabi, M.; Ben Salem, M. Fluctuation conductivity analysis on the Bi-based superconductors processed under same conditions. Phys. Stat. Solidi 2006, 3, 3048–3051. [Google Scholar] [CrossRef]

- Harabor, A.; Rotaru, P.; Harabor, N.A. Effect of Ni substitute in off-stoichiometric Bi(Pb)-Sr-Ca-Cu(Ni)-O superconductor. Excess conductivity, XRD analysis and thermal behaviour. Ceram. Int. 2019, 45, 2742–2750. [Google Scholar] [CrossRef]

- Sedky, A.; Salah, A. Excess conductivity, diamagnetic transition and FTIR spectra of Ca substituted by La in (Bi.Pb):2212 superconducting system. J. Low Temp. Phys. 2020. [Google Scholar] [CrossRef]

- Khir, F.L.M.; Mohamed, Z.; Yusuf, A.A.; Yusof, M.I.M.; Yahya, A.K. Effect of Pb and Cr substitutions on phase formation and excess conductivity of Bi-2212 superconductor. AIP Conf. Proc. 2010, 1250, 500–503. [Google Scholar] [CrossRef]

- Marconi, D.; Pop, M.; Pop, A.V. Normal state resistivity and excess of conductivity around the optimal doping of Bi-2212 thin films. J. Alloys Compd. 2012, 513, 586–591. [Google Scholar] [CrossRef]

- Slimani, Y.; Hannachi, E.; Ben Salem, M.K.; Hamrita, A.; Ben Salem, M.; Ben Azzouz, F. Excess conductivity study in nano-CoFe2O4-added YBa2Cu3O7−δ and Y3Ba5Cu8O18±x superconductors. J. Supercond. Nov. Magn. 2015, 28, 3001–3010. [Google Scholar] [CrossRef]

- Oh, J.Y.; Le, T.M.; Pham, A.T.; Tran, D.H.; Yang, D.S.; Kang, B. Role of interlayer coupling in alkaline-substituted (Bi,Pb)-2223 superconductors. J. Alloys Compd. 2019, 804, 348–352. [Google Scholar] [CrossRef]

| Notation | Values | |

|---|---|---|

| Normal state parameters | () | 1.72 ± 0.01 |

| () | 6.2 × 10 | |

| Conductivity exponents | 0.19 ± 0.02 | |

| 0.49 ± 0.04 | ||

| 1.02 ± 0.05 | ||

| 3.09 ± 0.1 | ||

| Crossover temperatures | (K) | 74.19 ± 0.1 |

| (K) | 44.37 ± 0.1 | |

| (K) | 75.70 ± 0.1 | |

| (K) | 76.59 ± 0.1 | |

| (K) | 81.35 ± 0.1 | |

| Superconducting parameters | (nm) | 0.93 ± 0.05 |

| d (nm) | 11.68 ± 0.05 | |

| 0.0257 | ||

| 0.0203 | ||

| 151.7 | ||

| (T) | 0.041 ± 0.002 | |

| (T) | 375.5 ± 0.2 | |

| (A/cm) | 671.1 ± 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koblischka, M.R.; Koblischka-Veneva, A.; Zeng, X.; Hannachi, E.; Slimani, Y. Microstructure and Fluctuation-Induced Conductivity Analysis of Bi2Sr2CaCu2O8+δ (Bi-2212) Nanowire Fabrics. Crystals 2020, 10, 986. https://0-doi-org.brum.beds.ac.uk/10.3390/cryst10110986

Koblischka MR, Koblischka-Veneva A, Zeng X, Hannachi E, Slimani Y. Microstructure and Fluctuation-Induced Conductivity Analysis of Bi2Sr2CaCu2O8+δ (Bi-2212) Nanowire Fabrics. Crystals. 2020; 10(11):986. https://0-doi-org.brum.beds.ac.uk/10.3390/cryst10110986

Chicago/Turabian StyleKoblischka, Michael Rudolf, Anjela Koblischka-Veneva, XianLin Zeng, Essia Hannachi, and Yassine Slimani. 2020. "Microstructure and Fluctuation-Induced Conductivity Analysis of Bi2Sr2CaCu2O8+δ (Bi-2212) Nanowire Fabrics" Crystals 10, no. 11: 986. https://0-doi-org.brum.beds.ac.uk/10.3390/cryst10110986