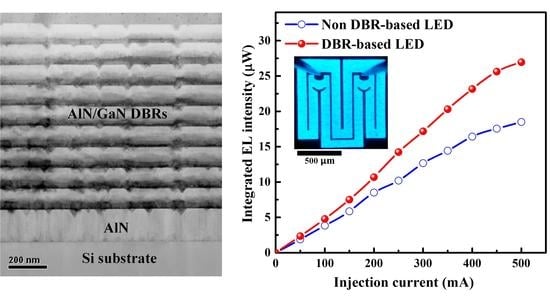

Light Output Enhancement of GaN-Based Light-Emitting Diodes Based on AlN/GaN Distributed Bragg Reflectors Grown on Si (111) Substrates

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Byrne, D.; Natali, F.; Damilano, B.; Dussaigne, A.; Grandjean, N.; Massies, J. Blue Resonant Cavity Light Emitting Diodes with a High-Al-Content GaN/AlGaN Distributed Bragg Reflector. Jpn. J. Appl. Phys. 2003, 42, L1509–L1511. [Google Scholar] [CrossRef]

- Ishikawa, H.; Zhang, B.; Asano, K.; Egawa, T.; Jimbo, T. Characterization of GaInN light-emitting diodes with distributed Bragg reflector grown on Si. J. Cryst. Growth 2004, 272, 322–326. [Google Scholar] [CrossRef]

- Cai, L.-E.; Zhang, B.-P.; Zhang, J.-Y.; Wu, C.-M.; Jiang, F.; Hu, X.-L.; Chen, M.; Wang, Q.-M. Improvement of efficiency droop of GaN-based light-emitting devices by a rear nitride reflector. Phys. E 2010, 43, 289–292. [Google Scholar] [CrossRef]

- Wen, F.; Huang, L.; Jiang, B.; Tong, L.; Xu, W.; Liu, D. Near white light emission from GaN based light emitting diode with GaN/AlGaN distributed Bragg reflector. Mater. Sci. Semicond. Process. 2010, 13, 147–150. [Google Scholar] [CrossRef]

- Sari, E.; Nizamoglu, S.; Ozel, T.; Demir, H.V. Blue quantum electroabsorption modulators based on reversed quantum confined Stark effect with blueshift. Appl. Phys. Lett. 2007, 90, 011101. [Google Scholar] [CrossRef]

- Yao, H.H.; Lin, C.F.; Kuo, H.C.; Wang, S.C. MOCVD growth of AlN/GaN DBR structures under various ambient conditions. J. Cryst. Growth 2004, 262, 151–156. [Google Scholar] [CrossRef]

- Ive, T.; Brandt, O.; Ploog, K.H. Conductive and crack-free AlN/GaN:Si distributed Bragg reflectors grown on 6H-SiC(0001). J. Cryst. Growth 2005, 278, 355–360. [Google Scholar] [CrossRef]

- Mastro, M.A.; Holm, R.T.; Bassim, N.D.; Gaskill, D.K.; Culbertson, J.C.; Fatemi, M.; Eddy, C.R.; Henry, R.L.; Twigg, M.E. Metal-organic chemical-vapor deposition of high-reflectance III-nitride distributed Bragg reflectors on Si substrates. J. Vac. Sci. Technol. A 2006, 24, 1631. [Google Scholar] [CrossRef]

- Wu, C.M.; Zhang, B.P.; Shang, J.Z.; Cai, L.E.; Zhang, J.Y.; Yu, J.Z.; Wang, Q.M. High-reflectivity AlN/GaN distributed Bragg reflectors grown on sapphire substrates by MOCVD. Semicond. Sci. Technol. 2011, 26, 055013. [Google Scholar] [CrossRef]

- Gačević, Z.; Eljarrat, A.; Peiró, F.; Calleja, E. Insight into high-reflectivity AlN/GaN Bragg reflectors with spontaneously formed (Al,Ga)N transient layers at the interfaces. J. Appl. Phys. 2013, 113, 183106. [Google Scholar] [CrossRef]

- Dartsch, H.; Figge, S.; Aschenbrenner, T.; Pretorius, A.; Rosenauer, A.; Hommel, D. Strain compensated AlGaN/GaN-Bragg-reflectors with high Al content grown by MOVPE. J. Cryst. Growth 2008, 310, 4923–4926. [Google Scholar] [CrossRef]

- Wang, D.; Liang, H.; Tao, P.; Zhang, K.; Song, S.; Liu, Y.; Xia, X.; Shen, R.; Du, G. Crack-free ultraviolet AlGaN/GaN distributed Bragg reflectors grown by MOVPE on 6H-SiC(0001). Superlattices Microstruct. 2014, 70, 54–60. [Google Scholar] [CrossRef]

- Xie, Z.L.; Zhang, R.; Liu, B.; Ji, X.L.; Li, L.; Liu, C.X.; Jiang, R.L.; Gong, H.M.; Zhao, H.; Han, P.; et al. High reflectivity AlGaN/AlN DBR mirrors grown by MOCVD. J. Cryst. Growth 2007, 298, 691–694. [Google Scholar] [CrossRef]

- Chen, J.; Ling, S.; Hung, C.; Ko, T.; Lu, T.; Kuo, H.; Wang, S. High-reflectivity ultraviolet AlN/AlGaN distributed Bragg reflectors grown by metalorganic chemical vapor deposition. J. Cryst. Growth 2008, 310, 4871–4875. [Google Scholar] [CrossRef]

- Ji, X.L.; Jiang, R.L.; Liu, B.; Xie, Z.L.; Zhou, J.J.; Li, L.; Han, P.; Zhang, R.; Zheng, Y.D.; Zheng, J.G. Structural characterization of AlGaN/AlN Bragg reflector grown by metalorganic chemical vapor deposition. Phys. Status Solidi A 2008, 205, 1572–1574. [Google Scholar] [CrossRef]

- Liu, B.; Zhang, R.; Zheng, J.G.; Ji, X.L.; Fu, D.Y.; Xie, Z.L.; Chen, D.J.; Chen, P.; Jiang, R.L.; Zheng, Y.D. Composition pulling effect and strain relief mechanism in AlGaN/AlN distributed Bragg reflectors. Appl. Phys. Lett. 2011, 98, 261916. [Google Scholar] [CrossRef]

- Ishikawa, H.; Jimbo, T.; Egawa, T. GaInN light emitting diodes with AlInN/GaN distributed Bragg reflector on Si. Phys. Status Solidi C 2008, 5, 2086–2088. [Google Scholar] [CrossRef]

- Krost, A.; Berger, C.; Bläsing, J.; Franke, A.; Hempel, T.; Dadgar, A.; Christen, J. Strain evaluation in AlInN/GaN Bragg mirrors by in situ curvature measurements and ex situ x-ray grazing incidence and transmission scattering. Appl. Phys. Lett. 2010, 97, 181105. [Google Scholar] [CrossRef]

- Cosendey, G.; Carlin, J.-F.; Kaufmann, N.A.K.; Butté, R.l.; Grandjean, N. Strain compensation in AlInN/GaN multilayers on GaN substrates: Application to the realization of defect-free Bragg reflectors. Appl. Phys. Lett. 2011, 98, 181111. [Google Scholar] [CrossRef]

- Feltin, E.; Carlin, J.F.; Dorsaz, J.; Christmann, G.; Butté, R.; Laügt, M.; Ilegems, M.; Grandjean, N. Crack-free highly reflective AlInN/AlGaN Bragg mirrors for UV applications. Appl. Phys. Lett. 2006, 88, 051108. [Google Scholar] [CrossRef]

- Berger, C.; Dadgar, A.; Bläsing, J.; Krost, A. In-situ growth monitoring of AlInN/AlGaN distributed Bragg reflectors for the UV-spectral range. J. Cryst. Growth 2013, 370, 87–91. [Google Scholar] [CrossRef]

- Ive, T.; Brandt, O.; Kostial, H.; Hesjedal, T.; Ramsteiner, M.; Ploog, K.H. Crack-free and conductive Si-doped AlN/GaN distributed Bragg reflectors grown on 6H-SiC(0001). Appl. Phys. Lett. 2004, 85, 1970. [Google Scholar] [CrossRef] [Green Version]

- Mastro, M.A.; Holm, R.T.; Bassim, N.D.; Eddy, C.R.; Henry, R.L.; Twigg, M.E.; Rosenberg, A. Wurtzite III-Nitride Distributed Bragg Reflectors on Si(100) Substrates. Jpn. J. Appl. Phys. 2006, 45, L814–L816. [Google Scholar] [CrossRef]

- Lei, Y.; Wan, H.; Tang, B.; Lan, S.; Miao, J.; Wan, Z.; Liu, Y.; Zhou, S. Optical Characterization of GaN-Based Vertical Blue Light-Emitting Diodes on P-Type Silicon Substrate. Crystals 2020, 10, 621. [Google Scholar] [CrossRef]

- Ishikawa, H.; Asano, K.; Zhang, B.; Egawa, T.; Jimbo, T. Improved characteristics of GaN-based light-emitting diodes by distributed Bragg reflector grown on Si. Phys. Status Solidi A 2004, 201, 2653–2657. [Google Scholar] [CrossRef]

- Yang, Y.; Xiang, P.; Liu, M.; Chen, W.; He, Z.; Han, X.; Ni, Y.; Yang, F.; Yao, Y.; Wu, Z.; et al. Effect of compositionally graded AlGaN buffer layer grown by different functions of trimethylaluminum flow rates on the properties of GaN on Si (111) substrates. J. Cryst. Growth 2013, 376, 23–27. [Google Scholar] [CrossRef]

- Hiramatsu, K.; Nishiyama, K.; Onishi, M.; Mizutani, H.; Narukawa, M.; Motogaito, A.; Miyake, H.; Iyechika, Y.; Maeda, T. Fabrication and characterization of low defect density GaN using facet-controlled epitaxial lateral overgrowth (FACELO). J. Cryst. Growth 2000, 221, 316–326. [Google Scholar] [CrossRef]

- Koukitu, A.; Kumagai, Y. Thermodynamic analysis of group III nitrides grown by metal-organic vapour-phase epitaxy (MOVPE), hydride (or halide) vapour-phase epitaxy (HVPE) and molecular beam epitaxy (MBE). J. Phys. Condens. Matter 2001, 13, 6907–6934. [Google Scholar] [CrossRef]

- Koukitu, A.; Mayumi, M.; Kumagai, Y. Surface polarity dependence of decomposition and growth of GaN studied using in situ gravimetric monitoring. J. Cryst. Growth 2002, 246, 230–236. [Google Scholar] [CrossRef]

- Eddy, C.R.; Holm, R.T.; Henry, R.L.; Culbertson, J.C.; Twigg, M.E. Investigation of three-step epilayer growth approach of GaN films to minimize compensation. J. Electron. Mater. 2005, 34, 1187–1192. [Google Scholar] [CrossRef]

- Sengupta, D.; Mazumder, S.; Kuykendall, W.; Lowry, S.A. Combined ab initio quantum chemistry and computational fluid dynamics calculations for prediction of gallium nitride growth. J. Cryst. Growth 2005, 279, 369–382. [Google Scholar] [CrossRef]

- Yang, T.; Uchida, K.; Mishima, T.; Kasai, J.; Gotoh, J. Control of Initial Nucleation by Reducing the V/III Ratio during the Early Stages of GaN Growth. Phys. Status Solidi A 2000, 180, 45–50. [Google Scholar] [CrossRef]

- Chen, Z.; Pei, Y.; Newman, S.; Brown, D.; Chung, R.; Keller, S.; DenBaars, S.P.; Nakamura, S.; Mishra, U.K. Growth of AlGaN/GaN/AlGaN double heterojunction field-effect transistors and the observation of a compositional pulling effect. Appl. Phys. Lett. 2009, 94, 171117. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Y.; Zhang, L.; Zhao, Y. Light Output Enhancement of GaN-Based Light-Emitting Diodes Based on AlN/GaN Distributed Bragg Reflectors Grown on Si (111) Substrates. Crystals 2020, 10, 772. https://0-doi-org.brum.beds.ac.uk/10.3390/cryst10090772

Yang Y, Zhang L, Zhao Y. Light Output Enhancement of GaN-Based Light-Emitting Diodes Based on AlN/GaN Distributed Bragg Reflectors Grown on Si (111) Substrates. Crystals. 2020; 10(9):772. https://0-doi-org.brum.beds.ac.uk/10.3390/cryst10090772

Chicago/Turabian StyleYang, Yibin, Lingxia Zhang, and Yu Zhao. 2020. "Light Output Enhancement of GaN-Based Light-Emitting Diodes Based on AlN/GaN Distributed Bragg Reflectors Grown on Si (111) Substrates" Crystals 10, no. 9: 772. https://0-doi-org.brum.beds.ac.uk/10.3390/cryst10090772