Growth of High Quality GaN on Si (111) Substrate by Using Two-Step Growth Method for Vertical Power Devices Application

Abstract

:1. Introduction

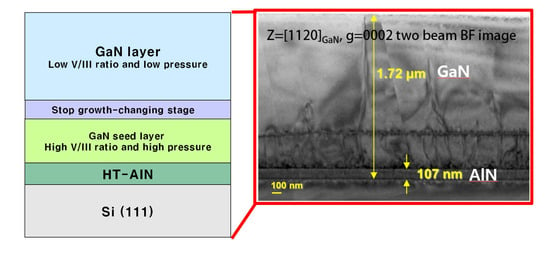

2. Experiments

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Uemoto, Y.; Hikita, M.; Ueno, H.; Matsuo, H.; Ishida, H.; Yanagihara, M.; Ueda, T.; Tanaka, T.; Ueda, D. Gate injection transistor (GIT)-A normally-off AlGaN/GaN power transistor using conductivity modulation. IEEE Trans. Electron Devices 2007, 54, 3393. [Google Scholar] [CrossRef]

- Lee, J.-H.; Lee, D.Y.; Oh, B.W.; Lee, J.-H. Comparison of InGaN-based LEDs grown on conventional sapphire and cone-shape-patterned sapphire substrate. IEEE Trans. Electron Devices 2010, 57, 157. [Google Scholar] [CrossRef]

- Lee, J.-H.; Lee, J.-H. Abnormal Electrical and Optical Characteristics of InGaN-Based LEDs by Current Stress-Time-Dependent Annihilation. IEEE J. Quantum Electron. 2012, 48, 635. [Google Scholar] [CrossRef]

- Wu, Y.-F.; Kapolnek, D.; Ibbetson, J.P.; Parikh, P.; Keller, B.P.; Mishra, U.K. Very-high power density AlGaN/GaN HEMTs. IEEE Trans. Electron Devices 2001, 48, 586. [Google Scholar]

- Semond, F.; Lorenzini, P.; Grandjean, N.; Massies, J. High electron mobility AlGaN/GaN heterostructures grown on Si(111) by molecular beam epitaxy. Appl. Phys. Lett. 2001, 82, 335. [Google Scholar] [CrossRef]

- Wang, K.; Li, M.D.; Yang, Z.J.; Wu, J.J.; Yu, T.J. Stress control and dislocation reduction in the initial growth of GaN on Si (111) substrates by using a thin GaN transition layer. CrystEngComm 2019, 21, 4792. [Google Scholar] [CrossRef]

- Ma, J.; Zhu, X.; Wong, K.M.; Zou, X.; Lau, K.M. Improved GaN-based LED grown on silicon (111) substrates using stress/dislocation-engineered interlayers. J. Cryt. Growth 2013, 370, 265. [Google Scholar] [CrossRef]

- Cheng, K.; Leys, M.; Degroote, S.; Daele, B.; Boeykens, S.; Derluyn, J.; Germain, M.; Tendeloo, G.; Engelen, J.; Borghs, G. Flat GaN Epitaxial Layers Grown on Si(111) by Metalorganic Vapor Phase Epitaxy Using Step-Graded AlGaN Intermediate Layers. J. Electron. Mater. 2006, 35, 592. [Google Scholar] [CrossRef]

- Egawa, T.; Moku, T.; Ishikawa, H.; Ohtsuka, K.; Jimbo, T. Improved Characteristics of Blue and Green InGaN-Based Light-Emitting Diodes on Si Grown by Metalorganic Chemical Vapor Deposition. Jpn. J. Appl. Phys. 2002, 41, L663. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, M.; Piedra, D.; Azize, M.; Zhang, X.; Fujishima, T.; Palacios, T. GaN-on-Si Vertical Schottky and p-n Diodes. IEEE Electron Device Lett. 2014, 35, 618. [Google Scholar]

- Khadar, R.A.; Liu, C.; Zhang, L.; Xiang, P.; Cheng, K.; Matioli, E. 820-V GaN-on-Si Quasi-Vertical p-i-n Diodes With BFOM of 2.0 GW/cm2. IEEE Electron Device Lett. 2018, 39, 401. [Google Scholar] [CrossRef] [Green Version]

- Zou, X.; Zhang, X.; Lu, X.; Tang, C.W.; Lau, K.M. Fully Vertical GaN p-i-n Diodes Using GaN-on-Si Epilayers. IEEE Electron Device Lett. 2016, 37, 636. [Google Scholar] [CrossRef]

- Zhang, E.; Yuan, M.; Chowdhury, N.; Cheng, K.; Palacios, T. 720-V/0.35-mcm2 Fully Vertical GaN-on-Si Power Diodes by Selective Removal of Si Substrates and Buffer Layers. IEEE Electron Device Lett. 2018, 39, 715. [Google Scholar] [CrossRef]

- Lee, J.H.; Park, C.; Kim, K.W.; Kim, D.S.; Lee, J.-H. Performance of fully recessed AlGaN/GaN MOSFET prepared on GaN buffer layer grown with AlSiC precoverage on silicon substrate. IEEE Electron Device Lett. 2013, 34, 975. [Google Scholar] [CrossRef]

- Chen, P.; Zhang, R.; Zhao, Z.; Xi, D.; Shen, B.; Chen, Z.; Zhou, Y.; Xie, S.; Lu, W.; Zheng, Y. Growth of high quality GaN layers with AIN buffer on Si(111) substrates. J. Cryst. Growth 2001, 225, 2. [Google Scholar] [CrossRef]

- Lee, J.H.; Lee, J.H.; Cho, H.I. Nitride Based Semiconductor Device and Process for Preparing the Same. U.S. Patent No. 7319064 B2, 15 January 2008. [Google Scholar]

- Tripathy, S.; Chua, S.J.; Chen, P.; Miao, Z.L. Micro-Raman investigation of strain in GaN and AlxGa1−xN/GaN heterostructures grown on Si (111). J. Appl. Phys. 2002, 92, 3503. [Google Scholar] [CrossRef]

- Langea, A.P.; Mahajan, S. Influence of trimethylaluminum predoses on the growth morphology, filmsubstrate interface, and microstructure of MOCVD-grown AlN on (111) Si. J. Cryst. Growth 2019, 511, 106. [Google Scholar] [CrossRef]

- Lee, J.-H.; Lee, M.-B.; Hahm, S.-H.; Lee, Y.-H.; Lee, J.-H.; Bae, Y.-H.; Cho, H.K. Growth of Semi-insulating GaN Layer by Controlling Size of Nucleation Sites for SAW Device Applications. MRS Internet J. Nitride Semicond. Res. 2003, 8, 5. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J.-H.; Im, K.-S. Growth of High Quality GaN on Si (111) Substrate by Using Two-Step Growth Method for Vertical Power Devices Application. Crystals 2021, 11, 234. https://0-doi-org.brum.beds.ac.uk/10.3390/cryst11030234

Lee J-H, Im K-S. Growth of High Quality GaN on Si (111) Substrate by Using Two-Step Growth Method for Vertical Power Devices Application. Crystals. 2021; 11(3):234. https://0-doi-org.brum.beds.ac.uk/10.3390/cryst11030234

Chicago/Turabian StyleLee, Jae-Hoon, and Ki-Sik Im. 2021. "Growth of High Quality GaN on Si (111) Substrate by Using Two-Step Growth Method for Vertical Power Devices Application" Crystals 11, no. 3: 234. https://0-doi-org.brum.beds.ac.uk/10.3390/cryst11030234