An Overview of Grease Water Resistance

Abstract

:1. Introduction

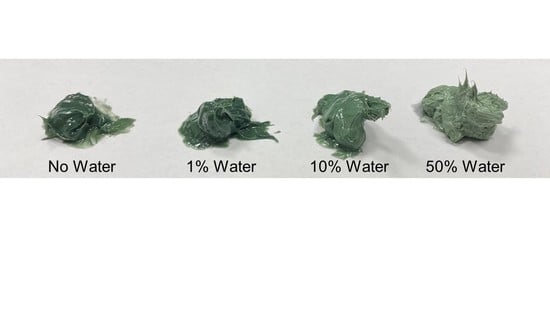

2. Details of Water Contamination

2.1. Interaction of Grease and Water

2.2. Water Contamination Leading to Machinery Failure

3. Relevant Standardized Tests

3.1. Standards Directly Involving Water

3.2. Tests Capable of Describing Changes Due to Water

4. Typical Test Results

4.1. Test Results

4.2. Discussion

5. Future Recommendations

5.1. Recommended Tests

5.2. Additional Research

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Fitch, J. How Water Causes Bearing Failure. In Machinery Lubrication Magazine; Noria Corporation: Tulsa, OK, USA, 2008. [Google Scholar]

- Duncanson, M. Detecting and Controlling Water in Oil. In Machinery Lubrication Magazine; Noria Corporation: Tulsa, OK, USA, 2005. [Google Scholar]

- Cantley, R.E. The Effect of Water in Lubricating Oil on Bearing Fatigue Life. ASLE Trans. 1977, 20, 244–248. [Google Scholar] [CrossRef]

- Sedelmeier, G. Managing Water Contamination to Maintain Effective Steel Mill Lubrication. In Machinery Lubrication Magazine; Noria Corporation: Tulsa, OK, USA, 2008. [Google Scholar]

- Nagarkoti, B.; Johnson, B.; Shah, R. Water Washout Remedies. NLGI Spokesm. 2020, 84, 75–83. [Google Scholar]

- Faci, H.; Haspert, J. Effect of Water on Grease Performance and Lubrication for Life in Sealed Bearings. NLGI Spokesm. 2014, 77, 8–15. [Google Scholar]

- Hink, R. Best Lubrication Practices for the Paper Industry. In Machinery Lubrication Magazine; Noria Corporation: Tulsa, OK, USA, 2005. [Google Scholar]

- Kaperick, J.; Aguilar, G.; Lennon, M. “Rust Never Sleeps” An Investigation of Corrosion in Lubricating Grease. NLGI Spokesm. 2016, 79, 8–15. [Google Scholar]

- Lugt, P. Modern advancements in lubricating grease technology. Tribol. Int. 2016, 97, 467–477. [Google Scholar] [CrossRef]

- NSK. Roll Neck Bearing Manual; NSK: Shinagawa City, Tokyo, Japan, 2015. [Google Scholar]

- Cyriac, F.; Lugt, P.M.; Bosman, R. Impact of Water on the Rheology of Lubricating Greases. Tribol. Trans. 2016, 59, 679–689. [Google Scholar] [CrossRef] [Green Version]

- Authier, D.; Herman, A. Calcium Sulfonate Carbonate Greases: A Solution to Water Resistance. In Proceedings of the 25th Annual Elgi Meeting, Amsterdam, The Netherlands, 20–23 April 2013. [Google Scholar]

- Mistry, A. Performance of Lubricating Greases in the Presence of Water. NLGI Spokesm. 2005, 68, 9–15. [Google Scholar]

- Dittes, N.; Marklund, P.; Pettersson, A. Mixing Grease with Water. In Proceedings of the European Conference on Improvement in Bearing Technology, Nieuwegein, The Netherlands, February 23–24 2015. [Google Scholar]

- DIN 51907-1. Testing of Lubricants—Test of the Behaviour of Lubricating Greases in the Presence of Water—Part 1: Static Test; Deutsches Institut Fur Normung: Berlin, Germany, 2020. [Google Scholar]

- ASTM D7342-15. Standard Test Method for Prolonged Worked Stability of Lubricating Grease in Presence of Water (Water Stability Test); ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM D8022-15. Standard Test Method for Roll Stability of Lubricating Grease in Presence of Water (Wet Roll Stability Test); ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM D1264-18e1. Standard Test Method for Determining the Water Washout Characteristics of Lubricating Greases; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- ASTM D4049-16. Standard Test Method for Determining the Resistance of Lubricating Grease to Water Spray; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- ASTM D1743-13. Standard Test Method for Determining Corrosion Preventive Properties of Lubricating Greases; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- ASTM D6138-19. Standard Test Method for Determination of Corrosion-Preventive Properties of Lubricating Greases Under Dynamic Wet Conditions (Emcor Test); ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- ASTM D5969-11. Standard Test Method for Corrosion-Preventive Properties of Lubricating Greases in Presence of Dilute Synthetic Sea Water Environments; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- ASTM D7038-19. Standard Test Method for Evaluation of Moisture Corrosion Resistance of Automotive Gear Lubricants; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- ASTM D4048-19a. Standard Test Method for Detection of Copper Corrosion from Lubricating Grease; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- Hudedagaddi, C.; Raghav, A.; Tortora, A.; Veeregowda, D. Water molecules influence the lubricity of greases and fuel. Wear 2017, 376–377, 831–835. [Google Scholar] [CrossRef]

- Leckner, J. Water + Grease = Fatal Attraction? In Proceedings of the 25th ELGI Annual General Meeting, Amsterdam, The Netherlands, 20–23 April 2013. [Google Scholar]

- Larsson, J.; Ardai, R. The Effect of Water Ingress on the Thickener Structure in Bio-Based Greases. NLGI Spokesm. 2018, 81, 6–18. [Google Scholar]

- Eachus, A.C. The trouble with water. Lubr. Eng. 2005, 61, 34–38. [Google Scholar]

- Noria Corporation. Water in Oil Contamination. In Machinery Lubrication Magazine; Noria Corporation: Tulsa, OK, USA, 2001. [Google Scholar]

- FAG Kugelfischer Georg Schäfer, A.G. Rolling Bearing Lubrication; Publ. No. WL 81 115/4 EA; FAG Kugelfischer Georg Schäfer AG: Schweinfurt, Germany, 2002. [Google Scholar]

- Ducom Instruments. The Effect of Water Molecules on Lubricity of Greases and Fuel; AZoM: Mona Vale, Australia, 2017. [Google Scholar]

- Schatzberg, P.; Felsen, I. Effects of water and oxygen during rolling contact lubrication. Wear 1968, 12, 331–342. [Google Scholar] [CrossRef]

- Echin, A.I.; Novosartov, T.; Kondrat’eva, T. Effect of Water on Lubricating Properties of Synthetic Oils. Chem. Technol. Fuels Oils 1983, 19, 80–83. [Google Scholar] [CrossRef]

- Fish, G. Calcium Sulfonate Greases: Performance and Application Overview; Lubrisense White Paper #16; The Lubrizol Corporation: Wickliffe, OH, USA, 2014. [Google Scholar]

- Cyriac, F.; Lugt, P.; Bosman, R. The Impact of Water on the Yield Stress and Startup Torque of Lubricating Greases. Tribol. Trans. 2017, 60, 824–831. [Google Scholar] [CrossRef] [Green Version]

- Axel Christiernsson. H2O, Friend or Foe? Lubrisense White Paper #8; Axel Christiernsson: Nol, Sweden, 2008. [Google Scholar]

- Nagarkoti, B. Water resistance property of greases—An outlook. In Proceedings of the NLGI-India 12th Lubricating Grease Conference, Panaji, India, 28–30 January 2010. [Google Scholar]

- Cyriac, F.; Lugt, P.; Bosman, R.; Venner, C. Impact of Water on EHL Film Thickness of Lubricating. Tribol. Lett. 2016, 61, 23. [Google Scholar] [CrossRef] [Green Version]

- Bosman, R.; Lugt, P.M. The Microstructure of Calcium Sulfonate Complex Lubricating Grease and Its Change in the Presence of Water. Tribol. Trans. 2018, 61, 842–849. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Y.; Bosman, R.; Lugt, P. On the Shear Stability of Dry and Water-Contaminated Calcium Sulfonate Complex Lubricating Greases. Tribol. Trans. 2019, 62, 626–634. [Google Scholar] [CrossRef] [Green Version]

- ASTM D217-19b. Standard Test Methods for Cone Penetration of Lubricating Grease; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- ASTM D1831-19a. Standard Test Method for Roll Stability of Lubricating Grease; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- ASTM D6184-17. Standard Test Method for Oil Separation from Lubricating Grease (Conical Sieve Method); ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- ASTM D1478-20. Standard Test Method for Low-Temperature Torque of Ball Bearing Grease; ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar]

- ASTM D2783-19. Standard Test Method for Measurement of Extreme-Pressure Properties of Lubricating Fluids (Four-Ball Method); ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- ASTM D2509-20. Standard Test Method for Measurement of Load-Carrying Capacity of Lubricating Grease (Timken Method); ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar]

- Lugt, P. Grease Qualification Testing. In Grease Lubrication in Rolling Bearings; Wiley: Hoboken, NJ, USA, 2013; pp. 339–375. [Google Scholar]

- Cyriac, F.; Lugt, P.; Bosman, R. On a New Method to Determine the Yield Stress in Lubricating Grease. Tribol. Trans. 2015, 58, 1021–1030. [Google Scholar] [CrossRef] [Green Version]

- Gurt, A.; Khonsari, M. The Use of Entropy in Modeling the Mechanical Degradation of Grease. Lubricants 2019, 7, 82. [Google Scholar] [CrossRef] [Green Version]

- Galary, J. Bearing Corrosion Analysis Using Machine Vision and Computational Algorithms. NLGI Spokesm. 2018, 82, 16–29. [Google Scholar]

- The Timken Company. Timken Tapered Roller Bearing Catalog; The Timken Company: North Canton, OH, USA, 2016. [Google Scholar]

| Test | Procedure | Comments |

|---|---|---|

| Water stability (ASTM D7342) | Mix grease and water then subject to shear; record initial and final penetration | Mechanical stability also included in the results |

| Wet roll stability (ASTM D8022) | Add grease and water separately to cylinder then rotate for 2 h; record initial and final penetration | Mechanical stability included in results; does not consider water absorption capacity of grease |

| Water resistance (DIN 51807) | Dip grease-coated test strip in water; visually inspect for change | Result is not an indication of performance |

| Water washout (ASTM D1264) | Spray bearing shield with water; record initial and final weight of grease within bearing | Common test; inadvertently tests a grease’s ability to retain water |

| Water spray off (ASTM D4049) | Spray grease-coated plate directly with water; record initial and final weight | Inadvertently tests a grease’s ability to retain water |

| Corrosion prevention (ASTM D1743 & more) | Fill bearing with grease; submerge in water; place into oven; visually inspect for corrosion | Common test; does not fully describe grease’s interaction with water |

| Test | Procedure | Comments |

|---|---|---|

| Wet penetration change | Record cone penetration of grease; mix grease and water then work for 100,000 strokes; record new penetration | Effects of mechanical shear are included in results |

| Yield stress/flow point change | Use oscillatory tests in rheometer | Different yield stress definitions (crossover stress vs yield stress [48]) |

| Roll Stability | Record cone penetration of grease; add grease and water separately to cylinder then rotate for 2 h; record new penetration | Effects of mechanical shear are included in results |

| Film thickness | Film thickness machine used | Thick film does not directly indicate good lubricity |

| Oil bleed | Place grease above a mesh; apply pressure and record the weight of bled substance | The exact composition of bled substance is unclear |

| Lubricity | Use 4-ball test machinery, Timken load machinery, or FE8/R2F machinery | 4-ball tests are simple, but may not accurately reflect rolling bearing applications |

| Low temperature torque | Completely fill bearing with grease and allow to reach desired temperature; measure torque to start rotating bearing and torque after 60 min of rotation | Results can be heavily affected by water intrusion |

| Water absorption | Mix proportioned grease and water for sufficiently long time; look for and remove free water | No standardized test and difficult to find exact point of maximum emulsification |

| Test | Typical Results | Comments |

|---|---|---|

| Penetration change with water & shear (wet shear stability) | Most greases show increased penetration with water [12,27]; CaS can show reduced penetration [26] | Effects of mechanical shear are included in results |

| Yield stress/flow point change | Different trends are obtained even for similar grease types [11,12,26] | Results generally correlate with penetration measurements |

| Wet roll stability | Most results are similar to wet shear stability results [12,26,27] | Effects of mechanical shear are included in results |

| Water washout | All samples perform worse with water added [26] CaS typically performs the best [5] | CaS sample increased in mass due to water absorption |

| Water spray off | Samples generally perform worse with water added, though some perform marginally better [26] | CaS may perform better with water added |

| Water resistance | Samples often appear unchanged [26,27] | Test does not yield information on performance |

| Film thickness (flooded) | Adding water generally reduces central film thickness [38] | Contaminated and pristine results are similar |

| Film thickness (starved) | Numerous greases show marginally thicker films with water [38] | Thick film does not directly indicate good lubricity |

| Oil bleed | Minimal change with water added, but CaS shows decreased bleed with water [26,38] | Results appear to depend strongly on base oil [27] |

| Corrosion prevention | Absorbed water may not cause corrosive damage [26]; typically sea/process water yields more damage [12] | Performance may be significantly affected by additives |

| Lubricity | Samples perform worse: reduced weld load, increased wear scar, higher operating temperature [25,26] | 4-ball tests quickly quantify lubricity, but may not accurately reflect rolling bearing applications [9] |

| Low temperature torque | Greases generally show higher start-up and running torque at lower temperatures with water [13,35] | Results are particularly bad when free water is present |

| Water absorption | Some greases can absorb up to 80 wt.% water; others substantially less [11] | No standardized test and difficult to find exact saturation point |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gurt, A.; Khonsari, M. An Overview of Grease Water Resistance. Lubricants 2020, 8, 86. https://0-doi-org.brum.beds.ac.uk/10.3390/lubricants8090086

Gurt A, Khonsari M. An Overview of Grease Water Resistance. Lubricants. 2020; 8(9):86. https://0-doi-org.brum.beds.ac.uk/10.3390/lubricants8090086

Chicago/Turabian StyleGurt, Alan, and Michael Khonsari. 2020. "An Overview of Grease Water Resistance" Lubricants 8, no. 9: 86. https://0-doi-org.brum.beds.ac.uk/10.3390/lubricants8090086