Effect of Filler Metal Type on Microstructure and Mechanical Properties of Fabricated NiAl Bronze Alloy Using Wire Arc Additive Manufacturing System

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Deposited Material

3.2. Mechanical Properties

3.3. Microstructure of Deposited NAB Wall Components

3.4. Fracture Morphology Analysis of Deposited NAB Wall Components

4. Conclusions

- A high-density NAB alloy product without defects was produced by the WAAM process using commercial filler metal. Through visual inspection and X-ray analysis, it was confirmed that there was no visual difference according to the wire type.

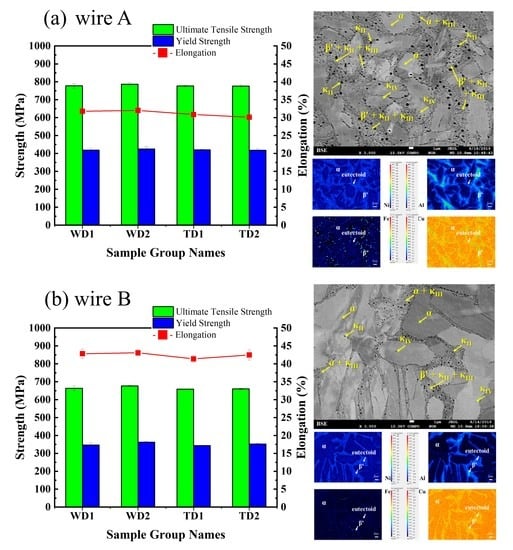

- The variations in mechanical properties between the wall’s components deposited with different filler metals type were significant. The deposited components made with filler metal wire A exhibited higher tensile and yield strength, but less elongation (approx. +71 MPa yield strength, +107.1 MPa ultimate tensile strength, −12.4% elongation).

- Through microstructural analysis and EPMA results identified differences in the size of α phase and the fraction of the β′and κ precipitates depending on the filler metal type. The as-fabricated wall made with filler metal wire A exhibited considerably finer microstructure as compared to that made with filler metal wire B. For this reason, it was judged that the tensile strength made of wire A was superior to that of wire B.

- It was considered through this study that it is necessary to select a filler metal wire that meets the requirements for product manufacturing.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| NAB | Nickel-Aluminum Bronze |

| WAAM | Wire Arc Additive Manufacturing |

| GMAW | Gas Metal Arc Welding |

| CMT | Cold Metal Transfer |

| DED | Direct Energy Deposition |

| CAD | Computer-aided Design |

| CTWD | Contact Tip to Work Distance |

| WD | Welding Direction |

| TD | Transverse Direction |

| OM | Optical Microscopy |

| SEM | Scanning Electron Microscopy |

References

- Dharmendra, C.; Hadadzadeh, A.; Amirkhiz, B.S.; Mohammadi, M. The Morphology, Crystallography, and Chemistry of Phases in Wire-Arc Additively Manufactured Nickel Aluminum Bronze. In TMS 2019 148th Annual Meeting & Exhibition Supplemental Proceedings; Springer: Cham, Switzerland, 2019; pp. 443–453. [Google Scholar] [CrossRef]

- Brezina, P. Heat treatment of complex aluminium bronzes. Int. Mater. Rev. 1982, 27, 77–120. [Google Scholar] [CrossRef]

- Cook, M.; Fentiman, W.P.; Davis, E. Observations on the structure and properties of wrought copper-aluminium-nickel-iron alloys. J. Inst. Met. 1952, 80, 419–429. [Google Scholar]

- Strang, J.R.C. Cast valve materials for seawater service nickel-aluminum bronze and its rivals. In Proceedings of the Valve World Conference at the Maastricht Exhibition and Congress Center, Maastricht, The Netherlands, 7–9 November 2006. [Google Scholar]

- Powell, C.; Stillman, H. Corrosion Behavior of Copper Alloys Used in Marine Aquaculture; International Copper Association, Ltd.: New York, NY, USA, 2009; pp. 1–3. [Google Scholar]

- Culpan, E.; Rose, G. Microstructural characterization of cast nickel aluminium bronze. J. Mater. Sci. 1978, 13, 1647–1657. [Google Scholar] [CrossRef]

- Wu, Z.; Cheng, Y.F.; Liu, L.; Lv, W.; Hu, W. Effect of heat treatment on microstructure evolution and erosion–corrosion behavior of a nickel–aluminum bronze alloy in chloride solution. Corros. Sci. 2015, 98, 260–270. [Google Scholar] [CrossRef]

- Callcut, V.A. Aluminium bronze for industrial use. Met. Mater. 1989, 53, 128–132. [Google Scholar]

- Dharmendra, C.; Hadadzadeh, A.; Amirkhiz, B.; Ram, G.J.; Mohammadi, M. Microstructural evolution and mechanical behavior of nickel aluminum bronze Cu-9Al-4Fe-4Ni-1Mn fabricated through wire-arc additive manufacturing. Addit. Manuf. 2019, 30, 100872. [Google Scholar] [CrossRef]

- Shahrubudin, N.; Lee, T.; Ramlan, R. An Overview on 3D Printing Technology: Technological, Materials, and Applications. Proc. Manuf. 2019, 35, 1286–1296. [Google Scholar] [CrossRef]

- Nichols, M.R. How does the automotive industry benefit from 3D metal printing? Met. Powder Rep. 2019, 74, 257–258. [Google Scholar] [CrossRef]

- Murr, L.E.; Gaytan, S.M.; Ramirez, D.A.; Martinez, E.; Hernandez, J.; Amato, K.N.; Shindo, P.W.; Medina, F.R.; Wicker, R.B. Metal Fabrication by Additive Manufacturing Using Laser and Electron Beam Melting Technologies. J. Mater. Sci. Technol. 2012, 28, 1–14. [Google Scholar] [CrossRef]

- Kim, S.; Lim, S.; Chun, C.-K. Repair Properties of Desulfurization Pump Part Layers by Direct Energy Deposited Additive Manufacturing Process. J. Weld. Join. Soc. 2020, 38, 92–97. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.; Suder, W.; Ding, J.; Williams, S. Wire based plasma arc and laser hybrid additive manufacture of Ti-6Al-4V. J. Mater. Process. Technol. 2021, 293, 117080. [Google Scholar] [CrossRef]

- Lee, H.; Lim, C.H.J.; Low, M.J.; Tham, N.; Murukeshan, V.M.; Kim, Y.J. Lasers in additive manufacturing: A review. Int. J. Precis. Eng. Manuf. Green Tech. 2017, 4, 307–322. [Google Scholar] [CrossRef]

- Byun, J.-G.; Cho, S.M. Trend of Metal 3D Printing by Welding. J. Weld. Join. Soc. 2016, 34, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Wharton, J.A.; Barik, R.; Kear, G.; Wood, R.J.K.; Stokes, K.; Walsh, F. The corrosion of nickel–aluminium bronze in seawater. Corros. Sci. 2005, 47, 3336–3367. [Google Scholar] [CrossRef]

- Hwa, L.C.; Rajoo, S.; Noor, A.M.; Ahmad, N.; Uday, M. Recent advances in 3D printing of porous ceramics: A review. Curr. Opin. Solid State Mater. Sci. 2017, 21, 323–347. [Google Scholar] [CrossRef]

- Kam, D.-H.; Kim, Y.-M.; Kim, C. Recent Studies of Laser Metal 3D Deposition with Wire Feeding. J. Weld. Join. Soc. 2016, 34, 35–40. [Google Scholar] [CrossRef] [Green Version]

- Karakurt, I.; Lin, L. 3D printing technologies: Techniques, materials, and post-processing. Curr. Opin. Chem. Eng. 2020, 28, 134–143. [Google Scholar] [CrossRef]

- Cunningham, C.; Flynn, J.; Shokrani, A.; Dhokia, V.; Newman, S. Invited review article: Strategies and processes for high quality wire arc additive manufacturing. Addit. Manuf. 2018, 22, 672–686. [Google Scholar] [CrossRef]

- Haizea, G.B.; Amaia, C.-O.; Lamikiz, A.; Lopez de Lacalle, L.N. Manufacturing Processes of Integral Blade Rotors for Turbomachinery, Processes and New Approaches. Appl. Sci. 2020, 10, 3063. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Van Duin, S.; Li, H.; Shen, C. Fabricating Superior NiAl Bronze Components through Wire Arc Additive Manufacturing. Materials 2016, 9, 652. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.; Kim, J.; Pyo, C. Comparison of Mechanical Properties of Ni-Al-Bronze Alloy Fabricated through Wire Arc Additive Manufacturing with Ni-Al-Bronze Alloy Fabricated through Casting. Metals 2020, 10, 1164. [Google Scholar] [CrossRef]

- Wahsh, L.M.; Elshater, A.E.; Mansour, A.K.; Hamdy, F.A.; Turky, M.A.; Azzam, M.O.; Salem, H.G. Parameter selection for wire arc additive manufacturing (WAAM) process. In Proceedings of the Materials Science and Technology 2018, Columbus, OH, USA, 14–18 October 2018; pp. 78–85. [Google Scholar] [CrossRef]

- Kozamernik, N.; Bracun, D.; Klobcar, D. WAAM system with interpass temperature control and forced cooling for near-net-shaper printing of small metal components. Int. J. Adv. Manuf. Technol. 2020, 110, 1955–1968. [Google Scholar] [CrossRef]

- Li, Y.; Li, S.; Yang, L.; Zhong, H. Microstructure and properties of twinned dendrites in directionally solidified A356 alloy. Mater. Sci. Eng. A. 2018, 734, 7–19. [Google Scholar] [CrossRef]

- Wang, L.; Wei, Y.; Zhan, X.; Yu, F.; Cao, X.; Gu, C.; Ou, W. Simulation of dendrite growth in the laser welding pool of aluminum alloy 2024 under transient conditions. J. Mater. Process. Technol. 2017, 246, 22–29. [Google Scholar] [CrossRef]

- Wei, H.L.; Mazumder, J.; Debroy, T. Evolution of solidification texture during additive manufacturing. Sci. Rep. 2015, 5, 16446. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, J.-D.; Kim, J.W.; Cheon, J.Y.; Kim, Y.-D.; Ji, C. Effect of shielding gases on the wire arc additive manufacturability of 5 Cr-4 Mo tool steel for die casting mold making. Korean J. Met. Mater. 2020, 5812, 852–862. [Google Scholar] [CrossRef]

- Luo, Y.; Li, J.; Xu, J.; Zhu, L.; Han, J.; Zhang, C. Influence of pulsed arc on the metal droplet deposited by projected transfer mode in wire-arc additive manufacturing. Mater. Process. Tech. 2018, 259, 353–360. [Google Scholar] [CrossRef]

- Campbell, F.C. Inspection of Metals: Understanding the Basics; ASM International: Russell Township, OH, USA, 2013; pp. 411–417. [Google Scholar]

- Rodrigues, T.; Duarte, V.; Miranda, R.M.; Santos, T.G.; Oliveira, J.P. Current status and perspectives on wire and arc additive manufacturing (WAAM). Materials 2019, 12, 1121. [Google Scholar] [CrossRef] [Green Version]

- Yu, H.; Zheng, Y.; Yao, Z. Cavitation erosion corrosion behaviour of manganese-nickel-aluminum bronze in comparison with manganese-brass. J. Mater. Sci. Technol. 2009, 25, 758–766. [Google Scholar]

- Manikandan, R.; Kumaresh Babu, S.P.; Murali, M.; Vallimanalan, A. Investigation of microstructure and mechanical properties in Nickel aluminium Bronze alloy with Nb and Y for aqueous applications. Mater. Today Proc. 2020, 27, 2591–2595. [Google Scholar] [CrossRef]

| Composition [wt. %] | |||||

|---|---|---|---|---|---|

| Alloy | Al | Ni | Fe | Mn | Cu |

| CAC703 (Substrate) | 8.5−10.5 | 3.0−6.0 | 3.0−6.0 | 0.1−1.5 | 78.0−85.0 |

| ERCuNiAl (Wire A) | 8.5−9.5 | 4.0−5.5 | 3.0−5.0 | 0.6−3.5 | Balance |

| CuAl9Ni5Fe3Mn2 (Wire B) | 9.0 | 4.5 | 3.5 | 1.0 | Balance |

| Wire Feeding Rate (m/min) | Travel Speed (m/min) | CTWD * (mm) | Deposited Distance (mm) | Deposition Direction | Torch Angle (°) | Shielding Gas (L/min) |

|---|---|---|---|---|---|---|

| 7.8 | 0.2 | 15 | 100 | ZIG ZAG | 90 | 20 (Ar 99.99%) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.; Kim, J.; Cheon, J.; Ji, C. Effect of Filler Metal Type on Microstructure and Mechanical Properties of Fabricated NiAl Bronze Alloy Using Wire Arc Additive Manufacturing System. Metals 2021, 11, 513. https://0-doi-org.brum.beds.ac.uk/10.3390/met11030513

Kim J, Kim J, Cheon J, Ji C. Effect of Filler Metal Type on Microstructure and Mechanical Properties of Fabricated NiAl Bronze Alloy Using Wire Arc Additive Manufacturing System. Metals. 2021; 11(3):513. https://0-doi-org.brum.beds.ac.uk/10.3390/met11030513

Chicago/Turabian StyleKim, Jaewon, Jaedeuk Kim, Jooyoung Cheon, and Changwook Ji. 2021. "Effect of Filler Metal Type on Microstructure and Mechanical Properties of Fabricated NiAl Bronze Alloy Using Wire Arc Additive Manufacturing System" Metals 11, no. 3: 513. https://0-doi-org.brum.beds.ac.uk/10.3390/met11030513