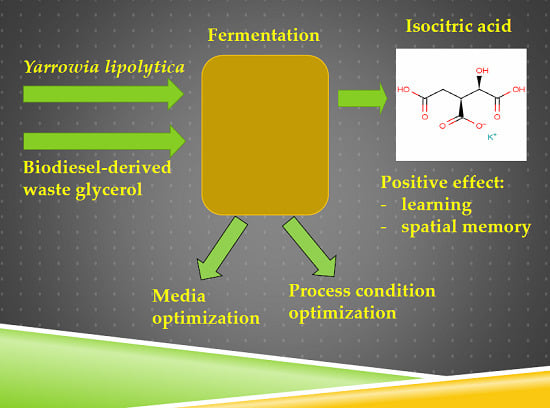

3.1. Production of ICA

Parameters characterizing the growth of strains under study and synthesis of ICA and other acids are shown in

Table 1. All three strains grew relatively well on the biodiesel waste and synthesized citric acids with the ICA/CA ratio between 1.1:1 and 1.3:1. The maximum amount of biomass (12.67 g/L) was accumulated by the wild strain

Y. lipolytica VKM Y-2373, while the biomasses accumulated by the mutant strain

Y. lipolytica UV/NNG and the recombinant strain

Y. lipolytica no. 20 (

ACO1) were lower by 36% and 29%, respectively. The poorer growth of the modified strains may be related to their higher sensitivity to impurities present in the waste glycerol. As a rule, the contaminating methanol does not influence the cellular membrane of growing microorganisms. In contrast, the free fatty acids (linoleic, stearic and oleic) and monovalent mineral salts present in sufficient amounts in the biodiesel-derived waste glycerol negatively affect the diffusion of necessary nutrients through the cellular membrane and thus reduce their availability [

42,

43,

44].

As seen from

Table 1, the wild strain VKM Y-2373 accumulated a higher amount of ICA (58.32 g/L) then the mutant UV/NNG and the transformant no. 20 (

ACO1) (44.6 and 33.6 g/L, respectively). On the other hand, acid production by the transformant and especially mutant shifted towards ICA (ICA/CA = 1.2:1 and 1.3:1, respectively, in comparison with 1.1:1 typical of the wild strain). In addition to CA and ICA, the strains excreted other organic acids (pyruvic, α-ketoglutaric, succinic, fumaric, and malic), whose content mas the maximum for the mutant. All further experiments were carried out with the wild strain because it showed the maximum values of the ICA yield (

Y = 0.79 g/g) and volume productivity (

Q = 0.62 g/L∙h).

Table 2 shows the effect of (NH

4)

2SO

4 as the nitrogen source on the growth of

Y. lipolytica VKM Y-2373 and the synthesis of ICA by this strain. At a low concentration of 1.5 g/L, (NH

4)

2SO

4 provided neither good growth nor good ICA production. At a high concentration of 10 g/L, ammonium sulfate provided good growth and relatively good ICA production. However, the best results were obtained when ammonium sulfate was added to the cultivation medium in the concentration 6 g/L. In this case, the strain accumulated the maximum amount of ICA (70.22 g/L) with the maximum ratio ICA/CA = 1.5:1.

Earlier, the positive effect of (NH

4)

2SO

4 on ICA production was also observed for another strain

Y. lipolytica IMUFRJ 50682, which accumulated 16.79 g/L ICA and 1.46 g/L CA in the cultivation medium supplemented with ammonium sulfate in comparison with 6.92 g/L ICA and 8.21 g/L CA accumulated in the medium without ammonium sulfate [

39]. The mechanism of the positive effect of ammonium sulfate on ICA productions needs further studies at the level of enzymes involved in the metabolism of ICA. It should be noted in this regard that the activity of isocitrate dehydrogenase (EC 1.1.1.42), an enzyme that catalyzes the conversion of isocitrate into α-ketoglutarate in the tricarboxylic acid (TCA) cycle, decreases by 66% in response to the excess of NH4

+ ions in the cultivation medium of the nitrogen-fixing bacterium

Azospirillum lipoferum [

45].

Further experiments were carried out with the optimal concentration of (NH4)2SO4 in the cultivation medium equal to 6 g/L.

The effect of biodiesel waste on ICA production was studied using the substrate in concentrations between 20 and 150 g/L (

Table 3).

As seen from this

Table 3, in all experiments,

Y. lipolytica VKM Y-2373 realizes the concurrent uptake of glycerol and the fatty acid fractions during the conversion of biodiesel waste, although glycerol was utilized at a higher rate than fatty acids. These data are comparable with those [

28] obtained for

Y. lipolytica cultivated on mixtures of saturated free fatty acids (an industrial derivative of animal fat called stearin) and technical glycerol (the main by-product of bio-diesel production facilities). As the concentration of biodiesel waste varied from 20 to 80 g/L, it does not inhibit the glycerol and fatty acids uptake. With the further increase in the concentration of added waste (up to 150 g/L), the glycerol and fatty acids uptake decreased twofold. When the medium was supplemented with 20 g/L biodiesel waste, the strain accumulated 70.22 g/L ICA with the ICA/CA ratio equal to 1.5:1. In the medium containing 40 to 80 g/L biodiesel waste, the strain produced ICA in concentrations between 76.65 and 80.12 g/L, with the maximum value of the ICA/CA ratio equal to 2:1. Still, higher biodiesel waste concentrations (100 and 150 g/L) suppress the growth of the strain and its production of CA and especially ICA, so that the ICA/CA ratio lowered to 1.1:1. In our opinion, high concentrations of biodiesel waste in the medium, such as 100 and 150 g/L, may suppress the growth of

Y. lipolytica VKM Y-2373 and its production of acids because of high foam formation. As a result, the yeast cells concentrated in the foam layer are excluded from the process of acid formation.

As for literature data on the effect of high concentrations of biodiesel waste, they are contradictory. Thus, the increase in the content of biodiesel waste in the cultivation medium of

Y. lipolytica IMUFRJ 50682 from 45 to 160 g/L shifted the ICA/CA ratio from 0.5:1 to 1.2:1 [

39]. At the same time, other researchers recommend avoiding high concentrations of waste glycerol in the medium and add it in portions of 20–50 g/L as it is consumed [

33,

34].

As seen from

Table 4, the strain grew well at pH values from 3 to 6. At higher pH values (6.5 and 7.0), the accumulated biomass was slightly lower, presumably because of culture dilution with the KOH solution used for maintenance of the culture pH. The production of acids took place within a wide range of pH values (from 3 to 7), the maximum production of ICA being observed at pH 6.0 and 6.5 (80.12 and 76.3 g/L ICA, respectively, with the ICA/CA ratio equal to 2:1 and 2.5:1). These results are in agreement with those obtained for the wild yeast

Y. lipolytica cultivated on ethanol or rapeseed oil [

14,

15], but contradict the results of the study of ICA production by the genetically modified

Y. lipolytica strain with the superexpressed

Gut1 and

Gut2 genes, which efficiently produced both CA and ICA at acidic pH values and hence did not require the maintenance of the culture pH during cultivation [

41].

In further studies, the pH of the culture medium was maintained at a level of 6.0.

Information on the pathway of ICA formation by wild and genetically modified microbial strains cultivated on n-alkanes, ethanol, or vegetable oils can be found in the literature [

9,

11,

13,

14,

15,

46]. The authors of these papers emphasize the key role of isocitrate lyase, an enzyme of the glyoxylate cycle involved in the metabolism of ICA. The inhibition of isocitrate lyase with itaconic or oxalic acids, structural analogues of succinate and glyoxylate, shifted the process of acid formation towards the preferential formation of ICA. The best results were observed with itaconic acid added to the medium at a concentration of 30–40 mM [

46].

The effect of itaconic acid on the production of ICA by yeasts (specifically,

Y. lipolytica VKM Y-2373) in the case of cultivation on biodiesel waste was first studied in this work. As evident from the comparison of biotechnological parameters (ICA concentration, Y, Q and the ICA/CA ratio) shown in

Table 5, itaconic acid at a concentration of 15 mM favorably influences the production of ICA by

Y. lipolytica VKM Y-2373 from biodiesel waste. In this case, however, itaconic acid elevated the ICA/CA ratio only by 1.5 times (from 2:1 to 3:1), whereas, in the case of ICA production from rapeseed oil, itaconic acid increased this ratio by 6 times [

14].

To understand the reason of less efficiency of itaconic acid in the production of ICA from biodiesel waste, the activities of enzymes involved in the metabolism of ICA were measured in the

Y. lipolytica VKM Y-2373 cells taken from the culture in the period of active acid formation (72 h of cultivation). The results of the enzyme assay are shown in the lower part of

Table 5. As seen from this information, citrate synthase has a high activity (2.1–2.91 U/mg protein) at all concentrations of itaconic acid in the cultivation medium, indicating an important role of this enzyme in the synthesis of both CA and ICA acids. The activity of aconitate hydratase was also relatively high (0.63–0.83 U/mg protein), especially in comparison with that of NAD-dependent isocitrate dehydrogenase (NAD-ICDH) (0.02–0.06 U/mg protein). Makri et al. [

47] also observed a low activity of NAD-ICDH during the biosynthesis of citric and isocitric acids in

Y. lipolytica cultivated on glycerol under nitrogen limitation. The activity of isocitrate lyase was low (0.081 U/mg protein) even in the absence of itaconic acid in the cultivation medium, being almost zero (0.002 U/mg protein) in the presence of 60-100 mM itaconic acid. Thus, despite the almost complete inhibition of the activity of isocitrate lyase by itaconic acid, the proportion between ICA and CA did not shift towards ICA, as was observed in the case of yeast cultivation on ethanol [

15] and rapeseed oil [

14]. These data are in agreement with the results of the study of the genetically modified strain

Y. lipolytica H222-41(JMP5)Z123 with the inactivated

ICL1 gene, which showed only a 4% increase in the ICA/CA ratio in comparison with the wild strain

Y. lipolytica H222 [

13].

Further experiments on the effect of aeration on the ICA production were carried out in the presence of 15 mM itaconic acid in the cultivation medium.

Literature data on the aeration effect are contradictory. The maximum yield of ICA in the

Y. lipolytica culture grown on

n-alkanes was observed only at high aeration (85–90% saturation) [

9]. In the medium with ethanol,

Y. lipolytica actively synthesized equal amounts of ICA and CA at high aeration (90–95% saturation); at an average level of aeration (60–65% saturation), the yeast predominantly produced ICA, while the synthesis of CA was suppressed; poor aeration (28%-30% saturation) suppressed both yeast growth and acid formation [

12]. In the medium with waste glycerol, the optimal yield of ICA was observed at 60–70% saturation [

32], while with pure glycerol no significant effect of pO

2 was found on citrate production [

48]. There are data that the agitation rates of 800 and 900 rpm and aeration rates within the range of 0.24–0.48 vvm generated the dissolved oxygen concentrations higher than 40%, which are the best for citric acid biosynthesis from glycerol [

49]. According to our data [

50], the requirement of the yeast

Y. lipolytica in oxygen considerably depends on the concentration of iron ions in the cultivation medium.

In this regard, the effect of aeration was studied by either adding or not adding Fe

2+ ions to the cultivation medium. The concentration of Fe

2+ ions was 1.2 mg/L because it is this concentration that provided the maximum yield of ICA during the cultivation of

Y. lipolytica VKM Y-2373 on rapeseed oil or ethanol [

14,

15].

As seen from

Table 6, the maximum production of ICA (90.2 g/L ICA; Y = 1.11 g/g substrate consumed; Q = 0.90 g/L·h) in the absence of iron ions in the cultivation medium is at pO

2 = 55–60% saturation. At lower aeration (25–30% saturation), the production of ICA is lower by 20%. The decrease in pO

2 to 5–10% diminishes both cell biomass and ICA production by 3.4 and 6.6 times, respectively. This dependence of biomass on pO

2 suggests that the yeast growth at pO

2 = 5–10% saturation is limited by oxygen. The presence of Fe

2+ ions in the cultivation medium at pO

2 =5–10% saturation stimulates both cell growth and ICA production by 3.3 and 2.8 times, respectively. This result suggests that the poor aeration and the absence of Fe

2+ ions in the medium cause double limitation (by iron and oxygen) or, in other words, limitation by metabolically available energy. At pO

2 between 25% and 60% saturation, the effect of iron ions on biomass and ICA production was negligible.

For further experiments on laboratory animals, ICA was isolated from the culture liquid in the form of monopotassium salt; the isolated and purified product consisted of 99.9% ICA.

3.2. Effect of ICA on the Spatial Memory of Rats

To study the effect of pharmacological agents on the learning and spatial memory of rats, the experimental model of the formation of the conditioned active avoidance response (CAAR) is commonly used [

51,

52]. However, this model is not always efficient, and researchers use various impacts on the central nervous system (CNS), such as maximal electroshock and hypoxia [

53]. Researchers also use various functional CNS disorders not related to invasive physical impacts, among which are the experimental extremal disturbances of the definite causal and spatial relationship, which additionally allows for emotional stress effects to be studied [

54].

Table 7 shows the temporal event sequence of the experiment. First, the conditioned active avoidance response (CAAR) was developed in the test rats by the daily application of stimuli (25 trials per day) in a shuttle box as described in the previous work [

8]. The experimental chamber was equipped with an electrifiable floor and divided into two equal compartments by a wall with two holes. In this case, the far (relative the observer) hole in the wall between two box compartments was opened. Then, the developed CAAR was smashed as described in the previous work [

8]. Afterwards, two experiments were carried out. Within the second experiment, after 25 trials, the developed CAAR was subjected to spatial alteration by closing the far hole and opening the near hole in the wall. Then, the CAAR was tested in 20 trials under these altered spatial conditions.

Analysis of the data listed in

Table 8 shows that the reproduction of the CAAR in the control rats after spatial transformation dramatically decreased. By the end of the experiment, the CAAR values were close to the initial ones. ICA counteracted this inhibition, and the drop in the CAAR reproduction was not so dramatic as in the control rats. The reproduction of the CAAR returned to the initial level after 6-10 trials. Throughout the experiment, the CAAR values of tested rats were statistically higher than in the control.

Similar to the earlier results [

8], lead ions strongly inhibited the CAAR, which did not allow us to smash the CAAR and perform its subsequent spatial transformation. The injection of ICA prevented the lead-induced inhibition of the CAAR. As a result, the reproduction of the CAAR after spatial transformation was close to the control values (

Table 8).

Molybdenum ions turned out to be less inhibitory than lead ions, meaning that test rats performed almost seven avoidance responses from 10 possible ones before spatial transformation. Nevertheless, the number of CAARs within the last five trials of response restoration was less than in the control (

Table 8). ICA prevented the inhibitory effect of molybdenum, meaning that the number of avoidance responses were close to the control level before spatial transformation and exceeded it after the transformation.

The effects of molybdenum and ICA deserve special attention. As mentioned above, molybdenum inhibits the CAAR, their number being less than in control rats and rats treated with ICA. With the combined injection of molybdenum and ICA, the number of CAARs was higher than in the control rats and in rats treated with ICA alone. This result seems quite paradoxical because heavy metals usually reduce the activity of neurotropic substances. It should, however, be noted that a similar paradoxical effect was earlier observed upon the combined application of molybdenum and Semax (Met-Glu-His-Phe-Pro-Gly-Pro), an analog of the adrenocorticotropin fragment (4–10) [

55]. Namely, molybdenum and Semax inhibited the development of the CAAR when applied separately and stimulated it when applied together.

As shown earlier [

7,

8], ICA displays antioxidant properties and prevents oxidative stress caused by heavy metals. In particular, ICA counteracts the negative effect of oxidative stress on the learning and memory of animals. According to recent research, oxidative stress can be caused not only by detrimental factors, such as heavy metals or hypoxia, but also under normal conditions, for example, upon cognitive loads on CNS. The formation of the CAAR induces oxidative stress too. The antioxidant agent carnosine diminishes the stress and accelerates learning [

56,

57].

The spatial transformation of the CAAR used in this study is a more difficult task for animals than the development of avoidance responses. The drug Semax having antioxidant activity enhances the reproduction of avoidance responses after spatial transformation [

58]. Taking into account the above information, the results of this study suggest that the spatial transformation of the CAAR causes oxidative stress in the tested animals and that the observed beneficial effect of ICA is explained by its antioxidant activity.