Impact-Type Sunflower Yield Sensor Signal Denoising Method Based on CEEMD-WTD

Abstract

:1. Introduction

2. Materials and Methods

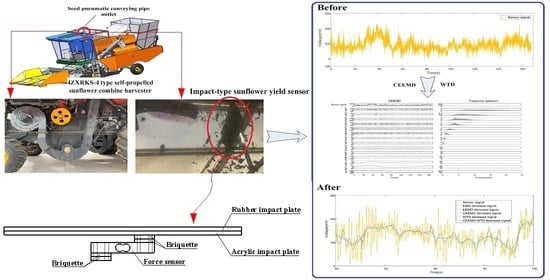

2.1. Impact-Type Sunflower Yield Sensor

2.2. Sunflower Yield Signal Characteristics

2.3. Algorithm Theory

2.3.1. Complementary Ensemble Empirical Mode Decomposition (CEEMD)

2.3.2. Wavelet Threshold Denoising (WTD)

2.3.3. WTD Denoising Method Based on CEEMD

2.3.4. Criteria for Judging Denoising Effect

3. Results and Discussion

3.1. Simulation Signal Verification

3.2. Sensor Real Signal Verification

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yang, H.; Duan, X.; Wei, L.; Liu, B.; Qu, Y.; Lian, J. Demand of Sunflower Market and Breeding Direction. J. Shanxi Agric. Sci. 2018, 46, 1057–1060+1064. [Google Scholar]

- China Telecom Smart Agriculture Research Group. Smart Agriculture: ICT Leads to Green Development; Publishing House of Electronics Industry: Beijing, China, 2013; pp. 50–51. [Google Scholar]

- Araujo Zanella, A.R.; Silva, E.; Albini, L.C.P. Security challenges to smart agriculture: Current state, key issues, and future directions. Array 2020, 8, 100048. [Google Scholar] [CrossRef]

- Tzounis, A.; Katsoulas, N.; Bartzanas, T.; Kittas, C. Internet of Things in agriculture, recent advances and future challenges. Biosyst. Eng. 2017, 164, 31–48. [Google Scholar] [CrossRef]

- Torky, M.; Hassanein, A.E. Integrating blockchain and the internet of things in precision agriculture: Analysis, opportunities, and challenges. Comput. Electron. Agric. 2020, 178, 105476. [Google Scholar] [CrossRef]

- Shankarnarayan, V.K.; Ramakrishna, H. Paradigm change in Indian agricultural practices using Big Data: Challenges and opportunities from field to plate. Inf. Process. Agric. 2020, 7, 355–368. [Google Scholar]

- Tang, Y.; Dananjayan, S.; Hou, C.; Guo, Q.; Luo, S.; He, Y. A survey on the 5G network and its impact on agriculture: Challenges and opportunities. Comput. Electron. Agric. 2021, 180, 105895. [Google Scholar] [CrossRef]

- Li, M. The technique of crop yield monitor and key equipment. Agric. Netw. Inf. 2004, 4, 34–38. [Google Scholar]

- Wang, M. Thinking Through the Experiment, Demonstration and Development Research on Precision Agriculture. Rev. China Agric. Sci. Technol. 2003, 5, 7–12. [Google Scholar]

- Wang, S.; Yu, Z.; Zhang, W.; Yang, L.; Zhang, Z.; Aorigele. Review of recent advances in online yield monitoring for grain combine harvester. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2021, 37, 58–70. [Google Scholar]

- Zhou, J.; Zhou, G.; Miao, Y.; Liu, C. Damping design of impact-based grain yield sensor. Trans. Chin. Soc. Agric. Mach. 2005, 36, 127–129+133. [Google Scholar]

- Zhou, J.; Cong, B.; Liu, C. Elimination of vibration noise from an impact-type grain mass flow sensor. Precis. Agric. 2014, 15, 627–638. [Google Scholar] [CrossRef]

- Hu, J.; Luo, X.; Ruan, H.; Chen, S.; Li, Y. Design of a dual-plate differential impact-based yield sensor. Trans. Chin. Soc. Agric. Mach. 2009, 40, 69–72. [Google Scholar]

- Maertens, K.; Reyns, P.; Baerdemaeker, J.D. Double adaptive notch filter for mechanical grain flow sensors. J. Sound Vib. 2003, 266, 645–654. [Google Scholar] [CrossRef]

- Shoji, K.; Miyamoto, M. Improving the accuracy of estimating grain weight by discriminating each grain impact on the yield sensor. Precis. Agric. 2013, 15, 31–43. [Google Scholar] [CrossRef]

- Qian, P.; Lu, T.; Shen, C.; Chen, S. Influence of vibration on the grain flow sensor during the harvest and the difference elimination method. Int. J. Agric. Biol. Eng. 2021, 14, 149–162. [Google Scholar] [CrossRef]

- Cong, B.; Zhou, J. Vibration Noise Elimination for a Grain Flow Sensor of Dual Parallel Beam Load Cells. Chin. J. Sens. Actuators 2013, 26, 377–381. [Google Scholar]

- Wei, X.; Zhang, J.; Dan, Z.; Liu, C. Signal processing method of impact-based grain flow sensor for predicted yield. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2014, 30, 222–228. [Google Scholar]

- Wang, H. Development of Data Processing System for Impact-based Grain Flow Sensor Based on DSP. Master’s Thesis, Nanjing Agricultural University, Nanjing, China, 2015. [Google Scholar]

- Chen, J.; Wang, K.; Li, Y. Wavelet denoising method for grain flow signal based on Mallat algorithm. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2017, 33, 190–197. [Google Scholar]

- Li, X.; Li, M.; Wang, X.; Zheng, L.; Zhang, M.; Sun, M.; Sun, H. Development and denoising test of grain combine with remote yield monitoring system. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2014, 30, 1–8. [Google Scholar]

- Li, Y.; Xu, L.; Lv, L.; Shi, Y.; Yu, X. Study on Modeling Method of a Multi-Parameter Control System for Threshing and Cleaning Devices in the Grain Combine Harvester. Agriculture 2022, 12, 1483. [Google Scholar] [CrossRef]

- Ding, Y.; Yu, G.; Tian, R.; Sun, Y. Application of a Hybrid CEEMD-LSTM Model Based on the Standardized Precipitation Index for Drought Forecasting: The Case of the Xinjiang Uygur Autonomous Region, China. Atmosphere 2022, 13, 1504. [Google Scholar] [CrossRef]

- Niu, D.; Wang, J. Elevator Car Vibration Signal Denoising Method Based on CEEMD and Bilateral Filtering. Sensors 2022, 22, 6602. [Google Scholar] [CrossRef] [PubMed]

- Chen, N.; Sun, H.; Zhang, Q.; Li, S. A Short-Term Wind Speed Forecasting Model Based on EMD/CEEMD and ARIMA-SVM Algorithms. Appl. Sci. 2022, 12, 6085. [Google Scholar] [CrossRef]

- Yang, M.; Wang, J.; Zhou, X.; Guo, Q. De-noising method based on CEEMD and wavelet packet. J. Nanjing Univ. Posts Telecommun. (Nat. Sci. Ed.) 2018, 38, 41–47. [Google Scholar]

- Ghosh, S.K.; Ponnalagu, R. Investigation of Discrete Wavelet Transform Domain Optimal Parametric Approach for Denoising of Phonocardiogram Signal. J. Mech. Med. Biol. 2022, 22, 2250046. [Google Scholar] [CrossRef]

- Branco, N.W.; Cavalca, M.S.M.; Stefenon, S.F.; Leithardt, V.R.Q. Wavelet LSTM for Fault Forecasting in Electrical Power Grids. Sensors 2022, 22, 8323. [Google Scholar] [CrossRef]

- Wu, F.; Ma, C.; Cheng, K. Study on wavelet denoising method of vibration signal based on improved threshold. J. Hefei Univ. Technol. (Nat. Sci.) 2022, 45, 873–877+900. [Google Scholar]

- Liu, Y.; Liu, J.; Cao, Y. An improved method for wavelet threshold de-noising. J. Hebei North Univ. (Nat. Sci. Ed.) 2012, 28, 30–33. [Google Scholar]

- Peng, S.; Chen, R.; Yu, B.; Xiang, M.; Lin, X.; Liu, E. Daily natural gas load forecasting based on the combination of long short term memory, local mean decomposition, and wavelet threshold denoising algorithm. J. Nat. Gas Sci. Eng. 2021, 95, 104175. [Google Scholar] [CrossRef]

- Shi, Y.; Zhang, J.; Jiao, J.; Zhao, R.; Cao, H. Calibration Analysis of High-G MEMS Accelerometer Sensor Based on Wavelet and Wavelet Packet Denoising. Sensors 2021, 21, 1231. [Google Scholar] [CrossRef]

- Wang, B.; Wang, Z.; He, D.; Yang, H.; Gao, X. A multiscale local pattern filtering method for noise mode identification of dynamic signals in bridges. Meas. Sci. Technol. 2022, 33, 125102. [Google Scholar] [CrossRef]

- Zhao, Y.; Le, Y.; Huang, J.; Wang, J.; Liu, C.; Liu, B. CEEMD and wavelet transform jointed de-noising method. Prog. Geophys. 2015, 30, 2870–2877. [Google Scholar]

- Bayer, F.M.; Kozakevicius, A.J.; Cintra, R.J. An iterative wavelet threshold for signal denoising. Signal Process. 2019, 162, 10–20. [Google Scholar] [CrossRef]

- Zhou, X.; Wang, X.; Yang, Y.; Guo, J.; Wang, P. De-noising of high-speed turnout vibration signals based on wavelet threshold. J. Vib. Shock. 2014, 33, 200–206. [Google Scholar]

- Chen, K.; Zhang, X.; Liu, Y.; Ma, J. An improved denoise method based on EEMD and optimal wavelet threshold for model building of OPAX. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2021, 235, 3530–3544. [Google Scholar] [CrossRef]

- Yu, X. Research on Anti-Noise Processing Method of Grain Production Signal Based on EEMD. Master’s Thesis, Northeast Agricultural University, Harbin, China, 2018. [Google Scholar]

- Gao, J.; Zhang, G.; Yu, L.; Li, Y. Chaos detection of grain impact at combine cleaning loss sensor. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2011, 27, 22–27. [Google Scholar]

| SNR | RMSE | S | WS | f | |

|---|---|---|---|---|---|

| EMD | 3.8455 | 98.4998 | 0.0015 | 0.7665 | 1.5096 |

| EEMD | 4.8594 | 99.9524 | 0.0010 | 0.8209 | 1.8248 |

| CEEMD | 5.2715 | 95.3205 | 0.0031 | 0.8385 | 1.9516 |

| WTD | 5.0185 | 98.1376 | 0.0023 | 0.8277 | 1.8737 |

| CEEMD-WTD | 5.3375 | 94.5993 | 0.0037 | 0.8412 | 1.9719 |

| IMF | EMD | EEMD | CEEMD |

|---|---|---|---|

| 1 | 0.0394 | 0.0193 | 0.0193 |

| 2 | 0.0762 | 0.0498 | 0.0009 |

| 3 | 0.0433 | 0.0298 | 0.0226 |

| 4 | 0.0255 | 0.0126 | 0.0350 |

| 5 | 0.0171 | 0.0081 | 0.0128 |

| 6 | 0.0236 | 0.0103 | 0.0139 |

| 7 | 0.0456 | 0.0193 | 0.0085 |

| 8 | 0.0662 | 0.0223 | 0.0108 |

| 9 | 0.1039 | 0.0378 | 0.0270 |

| 10 | 0.0205 | 0.0432 | 0.0153 |

| 11 | 0.0920 | 0.1949 | 0.0653 |

| 12 | 3.3800 | 1.4921 | 0.0328 |

| 13 | - | 0.0537 | 0.0630 |

| 14 | - | - | 3.1563 |

| SNR | RMSE | S | WS | f | |

|---|---|---|---|---|---|

| EMD | 12.6667 | 44.9673 | 0.00054 | 0.97257 | 4.0012 |

| EEMD | 12.9026 | 43.7625 | 0.00064 | 0.97404 | 4.0724 |

| CEEMD | 13.1225 | 42.6684 | 0.00136 | 0.97533 | 4.3384 |

| WTD | 13.7635 | 39.6329 | 0.01413 | 0.97876 | 4.5294 |

| CEEMD-WTD | 13.7715 | 39.5962 | 0.01412 | 0.97880 | 4.5318 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Zhao, X.; Liu, W.; Du, J.; Zhao, D.; Yu, Z. Impact-Type Sunflower Yield Sensor Signal Denoising Method Based on CEEMD-WTD. Agriculture 2023, 13, 166. https://0-doi-org.brum.beds.ac.uk/10.3390/agriculture13010166

Wang S, Zhao X, Liu W, Du J, Zhao D, Yu Z. Impact-Type Sunflower Yield Sensor Signal Denoising Method Based on CEEMD-WTD. Agriculture. 2023; 13(1):166. https://0-doi-org.brum.beds.ac.uk/10.3390/agriculture13010166

Chicago/Turabian StyleWang, Shuai, Xiaodong Zhao, Wenhang Liu, Jianqiang Du, Dongxu Zhao, and Zhihong Yu. 2023. "Impact-Type Sunflower Yield Sensor Signal Denoising Method Based on CEEMD-WTD" Agriculture 13, no. 1: 166. https://0-doi-org.brum.beds.ac.uk/10.3390/agriculture13010166