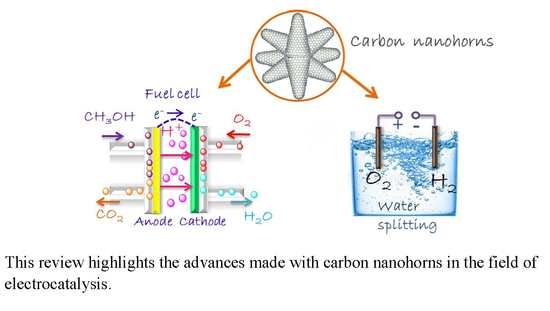

Carbon Nanohorn-Based Electrocatalysts for Energy Conversion

Abstract

:1. Introduction

2. CNHs in Electrocatalysis

2.1. Oxygen Reduction

2.2. Methanol Oxidation

2.3. Water Splitting—Hydrogen Evolution and Oxygen Evolution

| H3O+ + e− → Hads + H2O | (Volmer adsorption) |

| Hads + H3O+ + e− → H2 + H2O | (Heyrovsky desorption) |

| Hads + Hads → H2 | (Tafel desorption) |

2.4. Other Electrocatalytic Reactions

3. Conclusions

Funding

Conflicts of Interest

References

- Karousis, N.; Suarez-Martinez, I.; Ewels, C.P.; Tagmatarchis, N. Structure, Properties, Functionalization, and Applications of Carbon Nanohorns. Chem. Rev. 2016, 116, 4850–4883. [Google Scholar] [CrossRef] [PubMed]

- Pagona, G.; Mountrichas, G.; Rotas, G.; Karousis, N.; Pispas, S.; Tagmatarchis, N. Properties, Applications and Functionalization of Carbon Nanohorns. Int. J. Nanotechnol. 2009, 6, 176–195. [Google Scholar] [CrossRef]

- Pagona, G.; Tagmatarchis, N.; Fan, J.; Yudasaka, M.; Iijima, S. Cone-End Functionalization of Carbon Nanohorns. Chem. Mater. 2006, 18, 3918–3920. [Google Scholar] [CrossRef]

- Voiry, D.; Pagona, G.; Del Canto, E.; Noé, L.; Ortolani, L.; Morandi, V.; Monthioux, M.; Tagmatarchis, N.; Pénicaud, A. Reductive dismantling and functionalization of carbon nanohorns. Chem. Commun. 2015, 51, 5017–5019. [Google Scholar] [CrossRef]

- Stergiou, A.; Liu, Z.; Xu, B.; Kaneko, T.; Ewels, C.P.; Suenaga, K.; Zhang, M.; Yudasaka, M.; Tagmatarchis, N. Individualized p-Doped Carbon Nanohorns. Angew. Chem. Int. Ed. 2016, 55, 10468–10472. [Google Scholar] [CrossRef]

- Ajima, K.; Yudasaka, M.; Murakami, T.; Maigne, A.; Shiba, K.; Iijima, S. Carbon Nanohorns as Anticancer Drug Carriers. Mol. Pharm. 2005, 2, 475–480. [Google Scholar] [CrossRef]

- Sandanayaka, A.S.D.; Pagona, G.; Fan, J.; Tagmatarchis, N.; Yudasaka, M.; Iijima, S.; Araki, Y.; Ito, O. Photoinduced electron-transfer processes of carbon nanohorns with covalently linked pyrene chromophores: Charge-separation and electron-migration systems. J. Mater. Chem. 2007, 17, 2540. [Google Scholar] [CrossRef]

- Pagona, G.; Sandanayaka, A.S.D.; Araki, Y.; Fan, J.; Tagmatarchis, N.; Charalambidis, G.; Coutsolelos, A.G.; Boitrel, B.; Yudasaka, M.; Iijima, S.; et al. Covalent Functionalization of Carbon Nanohorns with Porphyrins: Nanohybrid Formation and Photoinduced Electron and Energy Transfer. Adv. Funct. Mater. 2007, 17, 1705–1711. [Google Scholar] [CrossRef]

- Pagona, G.; Sandanayaka, A.S.D.; Hasobe, T.; Charalambidis, G.; Coutsolelos, A.G.; Yudasaka, M.; Iijima, S.; Tagmatarchis, N. Characterization and Photoelectrochemical Properties of Nanostructured Thin Film Composed of Carbon Nanohorns Covalently Functionalized with Porphyrins. J. Phys. Chem. C 2008, 112, 15735–15741. [Google Scholar] [CrossRef]

- Rotas, G.; Sandanayaka, A.S.D.; Tagmatarchis, N.; Ichihashi, T.; Yudasaka, M.; Iijima, S.; Ito, O. (Terpyridine)copper(II)−Carbon Nanohorns: Metallo-nanocomplexes for Photoinduced Charge Separation. J. Am. Chem. Soc. 2008, 130, 4725–4731. [Google Scholar] [CrossRef]

- Vizuete, M.; Gomez-Escalonilla, M.J.; Fierro, J.L.G.; Ohkubo, K.; Fukuzumi, S.; Yudasaka, M.; Iijima, S.; Nierengarten, J.-F.; Langa, F. Photoinduced electron transfer in a carbon nanohorn–C60 conjugate. Chem. Sci. 2014, 5, 2072–2080. [Google Scholar] [CrossRef] [Green Version]

- Karousis, N.; Ichihashi, T.; Chen, S.; Shinohara, H.; Yudasaka, M.; Iijima, S.; Tagmatarchis, N. Imidazolium modified carbon nanohorns: Switchable solubility and stabilization of metal nanoparticles. J. Mater. Chem. 2010, 20, 2959. [Google Scholar] [CrossRef]

- Zhang, M.; Yudasaka, M.; Ajima, K.; Miyawaki, J.; Iijima, S. Light-Assisted Oxidation of Single-Wall Carbon Nanohorns for Abundant Creation of Oxygenated Groups That Enable Chemical Modifications with Proteins To Enhance Biocompatibility. ACS Nano 2007, 1, 265–272. [Google Scholar] [CrossRef] [PubMed]

- Mountrichas, G.; Tagmatarchis, N.; Pispas, S. Functionalization of carbon nanohorns with polyethylene oxide: Synthesis and incorporation in a polymer matrix. J. Nanosci. Nanotechnol. 2009, 9, 3775–3779. [Google Scholar] [CrossRef]

- Petsalakis, I.D.; Pagona, G.; Tagmatarchis, N.; Theodorakopoulos, G. Theoretical study in donor–acceptor carbon nanohorn-based hybrids. Chem. Phys. Lett. 2007, 448, 115–120. [Google Scholar] [CrossRef]

- Tagmatarchis, N.; Maigne, A.; Yudasaka, M.; Iijima, S. Functionalization of Carbon Nanohorns with Azomethine Ylides: Towards Solubility Enhancement and Electron-Transfer Processes. Small 2006, 2, 490–494. [Google Scholar] [CrossRef]

- Cioffi, C.; Campidelli, S.; Brunetti, F.G.; Meneghetti, M.; Prato, M. Functionalisation of carbon nanohorns. Chem. Commun. 2006, 10, 2129–2131. [Google Scholar] [CrossRef]

- Pagona, G.; Karousis, N.; Tagmatarchis, N. Aryl diazonium functionalization of carbon nanohorns. Carbon 2008, 46, 604–610. [Google Scholar] [CrossRef]

- Nakamura, E.; Koshino, M.; Tanaka, T.; Niimi, Y.; Harano, K.; Nakamura, Y.; Isobe, H. Imaging of Conformational Changes of Biotinylated Triamide Molecules Covalently Bonded to a Carbon Nanotube Surface. J. Am. Chem. Soc. 2008, 130, 7808–7809. [Google Scholar] [CrossRef]

- Lacotte, S.; García, A.; Decossas, M.; Al-Jamal, W.T.; Li, S.; Kostarelos, K.; Muller, S.; Prato, M.; Dumortier, H.; Bianco, A. Interfacing Functionalized Carbon Nanohorns with Primary Phagocytic Cells. Adv. Mater. 2008, 20, 2421–2426. [Google Scholar] [CrossRef]

- Economopoulos, S.; Pagona, G.; Yudasaka, M.; Iijima, S.; Tagmatarchis, N. Solvent-free microwave-assisted Bingel reaction in carbon nanohorns. J. Mater. Chem. 2009, 19, 7326–7331. [Google Scholar] [CrossRef]

- Karousis, N.; Ichihashi, T.; Yudasaka, M.; Iijima, S.; Tagmatarchis, N. Microwave-assisted functionalization of carbon nanohornsvia [2+1] nitrenes cycloaddition. Chem. Commun. 2011, 47, 1604–1606. [Google Scholar] [CrossRef] [PubMed]

- Pagona, G.; Katerinopoulos, H.E.; Tagmatarchis, N. Synthesis, characterization, and photophysical properties of a carbon nanohorn–coumarin hybrid material. Chem. Phys. Lett. 2011, 516, 76–81. [Google Scholar] [CrossRef]

- Vizuete, M.; Fierro, J.L.G.; Vartanian, M.; Iehl, J.; Nierengarten, J.-F.; Langa, F.; Gómez-Escalonilla, M.J.; Yudasaka, M.; Iijima, S. A soluble hybrid material combining carbon nanohorns and C60. Chem. Commun. 2011, 47, 12771. [Google Scholar] [CrossRef] [PubMed]

- Karousis, N.; Sato, Y.; Suenaga, K.; Tagmatarchis, N. Direct evidence for covalent functionalization of carbon nanohorns by high-resolution electron microscopy imaging of C60 conjugated onto their skeleton. Carbon 2012, 50, 3909–3914. [Google Scholar] [CrossRef]

- Pagona, G.; Zervaki, G.E.; Sandanayaka, A.S.D.; Ito, O.; Charalambidis, G.; Hasobe, T.; Coutsolelos, A.G.; Tagmatarchis, N. Carbon Nanohorn–Porphyrin Dimer Hybrid Material for Enhancing Light-Energy Conversion. J. Phys. Chem. C 2012, 116, 9439–9449. [Google Scholar] [CrossRef]

- Chronopoulos, D.; Karousis, N.; Ichihashi, T.; Yudasaka, M.; Iijima, S.; Tagmatarchis, N. Benzyne cycloaddition onto carbon nanohorns. Nanoscale 2013, 5, 6388. [Google Scholar] [CrossRef]

- Miyako, E.; Russier, J.; Mauro, M.; Cebrian, C.; Yawo, H.; Ménard-Moyon, C.; Hutchison, J.; Yudasaka, M.; Iijima, S.; De Cola, L.; et al. Photofunctional Nanomodulators for Bioexcitation. Angew. Chem. Int. Ed. 2014, 53, 13121–13125. [Google Scholar] [CrossRef]

- Chronopoulos, D.D.; Liu, Z.; Suenaga, K.; Yudasaka, M.; Tagmatarchis, N. [3 + 2] cycloaddition reaction of azomethine ylides generated by thermal ring opening of aziridines onto carbon nanohorns. RSC Adv. 2016, 6, 44782–44787. [Google Scholar] [CrossRef]

- Pagona, G.; Sandanayaka, A.S.D.; Maigne, A.; Fan, J.; Papavassiliou, G.C.; Petsalakis, I.D.; Steele, B.R.; Yudasaka, M.; Iijima, S.; Tagmatarchis, N.; et al. Photoinduced Electron Transfer on Aqueous Carbon Nanohorn–Pyrene–Tetrathiafulvalene Architectures. Chem.-A Eur. J. 2007, 13, 7600–7607. [Google Scholar] [CrossRef]

- Petsalakis, I.D.; Pagona, G.; Theodorakopoulos, G.; Tagmatarchis, N.; Yudasaka, M.; Iijima, S. Unbalanced strain-directed functionalization of carbon nanohorns: A theoretical investigation based on complementary methods. Chem. Phys. Lett. 2006, 429, 194–198. [Google Scholar] [CrossRef]

- Mountrichas, G.; Pispas, S.; Tagmatarchis, N. Grafting Living Polymers onto Carbon Nanohorns. Chem.-A Eur. J. 2007, 13, 7595–7599. [Google Scholar] [CrossRef] [PubMed]

- Pagona, G.; Rotas, G.; Petsalakis, I.D.; Theodorakopoulos, G.; Fan, J.; Maigne, A.; Yudasaka, M.; Iijima, S.; Tagmatarchis, N. Soluble functionalized carbon nanohorns. J. Nanosci. Nanotechnol. 2007, 7, 3468–3472. [Google Scholar] [CrossRef] [PubMed]

- Mountrichas, G.; Pispas, S.; Ichihasi, T.; Yudasaka, M.; Iijima, S.; Tagmatarchis, N. Polymer Covalent Functionalization of Carbon Nanohorns Using Bulk Free Radical Polymerization. Chem.-A Eur. J. 2010, 16, 5927–5933. [Google Scholar] [CrossRef]

- Vizuete, M.; Gomez-Escalonilla, M.J.; Fierro, J.L.G.; Sandanayaka, A.S.D.; Hasobe, T.; Yudasaka, M.; Iijima, S.; Ito, O.; Langa, F. A Carbon Nanohorn Porphyrin Supramolecular Assembly for Photoinduced Electron-Transfer Processes. Chem.-A Eur. J. 2010, 16, 10752–10763. [Google Scholar] [CrossRef]

- Jiang, B.P.; Hu, L.F.; Shen, X.C.; Ji, S.C.; Shi, Z.; Liu, C.-J.; Zhang, L.; Liang, H. One-Step Preparation of a Water-Soluble Carbon Nanohorn/Phthalocyanine Hybrid for Dual-Modality Photothermal and Photodynamic Therapy. ACS Appl. Mater. Interfaces 2014, 6, 18008–18017. [Google Scholar] [CrossRef]

- Pippa, N.; Stangel, C.; Kastanas, I.; Triantafyllopoulou, E.; Naziris, N.; Stellas, D.; Zhang, M.; Yudasaka, M.; Demetzos, C.; Tagmatarchis, N. Carbon nanohorn/liposome systems: Preformulation, design and in vitro toxicity studies. Mater. Sci. Eng. C 2019, 105, 110114. [Google Scholar] [CrossRef]

- Pagona, G.; Sandanayaka, A.S.D.; Araki, Y.; Fan, J.; Tagmatarchis, N.; Yudasaka, M.; Iijima, S.; Ito, O. Electronic Interplay on Illuminated Aqueous Carbon Nanohorn−Porphyrin Ensembles. J. Phys. Chem. B 2006, 110, 20729–20732. [Google Scholar] [CrossRef]

- Pagona, G.; Fan, J.; Maigne, A.; Yudasaka, M.; Iijima, S.; Tagmatarchis, N. Aqueous carbon nanohorn–pyrene–porphyrin nanoensembles: Controlling charge-transfer interactions. Diam. Relat. Mater. 2007, 16, 1150–1153. [Google Scholar] [CrossRef]

- Mountrichas, G.; Ichihashi, T.; Pispas, S.; Yudasaka, M.; Iijima, S.; Tagmatarchis, N. Solubilization of Carbon Nanohorns by Block Polyelectrolyte Wrapping and Templated Formation of Gold Nanoparticles. J. Phys. Chem. C 2009, 113, 5444–5449. [Google Scholar] [CrossRef]

- Zhang, Z.; Han, S.; Wang, C.; Li, J.; Xu, G. Single-Walled Carbon Nanohorns for Energy Applications. Nanomaterials 2015, 5, 1732–1755. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, X.; Lou, M.; Yuan, X.; Dong, W.; Dong, C.; Bi, H.; Huang, F. Nitrogen and oxygen dual-doped carbon nanohorn for electrochemical capacitors. Carbon 2017, 118, 511–516. [Google Scholar] [CrossRef]

- Baptista, F.; Belhout, S.A.; Giordani, S.; Quinn, S.J. Recent developments in carbon nanomaterial sensors. Chem. Soc. Rev. 2015, 44, 4433–4453. [Google Scholar] [CrossRef] [PubMed]

- Sano, N.; Taniguchi, K.; Tamon, H. Hydrogen Storage in Porous Single-Walled Carbon Nanohorns Dispersed with Pd–Ni Alloy Nanoparticles. J. Phys. Chem. C 2014, 118, 3402–3408. [Google Scholar] [CrossRef]

- Costa, R.D.; Feihl, S.; Kahnt, A.; Gambhir, S.; Officer, D.L.; Wallace, G.; Lucío, M.I.; Herrero, M.A.; Vazquez, E.; Syrgiannis, Z.; et al. Carbon Nanohorns as Integrative Materials for Efficient Dye-Sensitized Solar Cells. Adv. Mater. 2013, 25, 6513–6518. [Google Scholar] [CrossRef] [PubMed]

- Alaswad, A.; Baroutaji, A.; Achour, H.; Carton, J.; Al Makky, A.; Olabi, A.G. Developments in fuel cell technologies in the transport sector. Int. J. Hydrogen Energy 2016, 41, 16499–16508. [Google Scholar] [CrossRef]

- Shao, M.; Chang, Q.; Dodelet, J.-P.; Chenitz, R. Recent Advances in Electrocatalysts for Oxygen Reduction Reaction. Chem. Rev. 2016, 116, 3594–3657. [Google Scholar] [CrossRef] [Green Version]

- Wu, D.; Shen, X.; Pan, Y.; Yao, L.; Peng, Z. Platinum Alloy Catalysts for Oxygen Reduction Reaction: Advances, Challenges and Perspectives. ChemNanoMat 2019, 6, 32–41. [Google Scholar] [CrossRef] [Green Version]

- Jiang, K.; Back, S.; Akey, A.J.; Xia, C.; Hu, Y.; Liang, W.; Schaak, D.; Stavitski, E.; Nørskov, J.K.; Siahrostami, S.; et al. Highly selective oxygen reduction to hydrogen peroxide on transition metal single atom coordination. Nat. Commun. 2019, 10, 3997. [Google Scholar] [CrossRef] [Green Version]

- Perivoliotis, D.K.; Sato, Y.; Suenaga, K.; Tagmatarchis, N. Core-Shell Pd M (M = Ni, Cu, Co) Nanoparticles/Graphene Ensembles with High Mass Electrocatalytic Activity Toward the Oxygen Reduction Reaction. Chem.-A Eur. J. 2019, 25, 11105–11113. [Google Scholar] [CrossRef]

- Xue, Y.; Sun, S.; Wang, Q.; Donga, Z.; Liu, Z. Transition Metal Oxide-Based Oxygen Reduction Reaction Electrocatalysts for Energy Conversion Systems with Aueous Electrolytes. J. Mater. Chem. A 2018, 6, 10595–10626. [Google Scholar] [CrossRef]

- Perivoliotis, D.; Tagmatarchis, N. Recent advancements in metal-based hybrid electrocatalysts supported on graphene and related 2D materials for the oxygen reduction reaction. Carbon 2017, 118, 493–510. [Google Scholar] [CrossRef]

- Yang, L.; Shui, J.; Du, L.; Shao, Y.; Liu, J.; Dai, L.; Hu, Z. Carbon-Based Metal-Free ORR Electrocatalysts for Fuel Cells: Past, Present, and Future. Adv. Mater. 2019, 31, e1804799. [Google Scholar] [CrossRef] [PubMed]

- Perivoliotis, D.K.; Sato, Y.; Suenaga, K.; Tagmatarchis, N. Sulfur-Doped Graphene-Supported Nickel-Core Palladium-Shell Nanoparticles as Efficient Oxygen Reduction and Methanol Oxidation Electrocatalyst. ACS Appl. Energy Mater. 2018, 1, 3869–3880. [Google Scholar] [CrossRef]

- Stergiou, A.; Perivoliotis, D.K.; Tagmatarchis, N.; Perivoliotis, D. (Photo)electrocatalysis of molecular oxygen reduction by S-doped graphene decorated with a star-shaped oligothiophene. Nanoscale 2019, 11, 7335–7346. [Google Scholar] [CrossRef]

- Unni, S.M.; Illathvalappil, R.; Bhange, S.N.; Puthenpediakkal, H.; Kurungot, S. Carbon Nanohorn-Derived Graphene Nanotubes as a Platinum-Free Fuel Cell Cathode. ACS Appl. Mater. Interfaces 2015, 7, 24256–24264. [Google Scholar] [CrossRef]

- Wu, X.; Cui, L.; Tang, P.; Hu, Z.; Ma, D.; Shi, Z. Synthesis and catalytic activity of heteroatom doped metal-free single-wall carbon nanohorns. Chem. Commun. 2016, 52, 5391–5393. [Google Scholar] [CrossRef]

- Palaniselvam, T.; Aiyappa, H.B.; Kurungot, S. An efficient oxygen reduction electrocatalyst from graphene by simultaneously generating pores and nitrogen doped active sites. J. Mater. Chem. 2012, 22, 23799. [Google Scholar] [CrossRef]

- Zheng, Y.; Jiao, Y.; Chen, J.; Liu, J.; Liang, J.; Du, A.; Zhang, W.; Zhu, Z.; Smith, S.C.; Jaroniec, M.; et al. Nanoporous Graphitic-C3N4@Carbon Metal-Free Electrocatalysts for Highly Efficient Oxygen Reduction. J. Am. Chem. Soc. 2011, 133, 20116–20119. [Google Scholar] [CrossRef]

- Jiang, H.; Lee, P.S.; Li, C. 3D carbon based nanostructures for advanced supercapacitors. Energy Environ. Sci. 2013, 6, 41–53. [Google Scholar] [CrossRef]

- Simon, P.; Gogotsi, Y. Capacitive Energy Storage in Nanostructured Carbon–Electrolyte Systems. Accounts Chem. Res. 2012, 46, 1094–1103. [Google Scholar] [CrossRef] [PubMed]

- Zhu, S.; Xu, G. Single-walled carbon nanohorns and their applications. Nanoscale 2010, 2, 2538–2549. [Google Scholar] [CrossRef] [PubMed]

- Murata, K.; Kaneko, K.; Steele, W.A.; Kokai, F.; Takahashi, K.; Kasuya, D.; Hirahara, K.; Yudasaka, M.; Iijima, S. Molecular Potential Structures of Heat-Treated Single-Wall Carbon Nanohorn Assemblies. J. Phys. Chem. B 2001, 105, 10210–10216. [Google Scholar] [CrossRef]

- Utsumi, S.; Miyawaki, J.; Tanaka, H.; Hattori, Y.; Itoi, T.; Ichikuni, N.; Kanoh, H.; Yudasaka, M.; Iijima, S.; Kaneko, K. Opening Mechanism of Internal Nanoporosity of Single-Wall Carbon Nanohorn. J. Phys. Chem. B 2005, 109, 14319–14324. [Google Scholar] [CrossRef]

- Fan, J.; Yudasaka, M.; Miyawaki, J.; Ajima, K.; Murata, K.; Iijima, S. Control of Hole Opening in Single-Wall Carbon Nanotubes and Single-Wall Carbon Nanohorns Using Oxygen. J. Phys. Chem. B 2006, 110, 1587–1591. [Google Scholar] [CrossRef]

- Ebenezer, D.; Jagannatham, M.; Lahari, M.S.; Bhuwaneshswar, P.; Prathap, H. Nafion functionalized carbon nanohorns as catalyst support for proton exchange membrane fuel cells. Diam. Relat. Mater. 2016, 70, 26–32. [Google Scholar] [CrossRef]

- Kagkoura, A.; Pelaez-Fernandez, M.; Arenal, R.; Tagmatarchis, N. Sulfur-doped graphene/transition metal dichalcogenide heterostructured hybrids with electrocatalytic activity toward the hydrogen evolution reaction. Nanoscale Adv. 2019, 1, 1489–1496. [Google Scholar] [CrossRef] [Green Version]

- Unni, S.M.; Bhange, S.N.; Illathvalappil, R.; Mutneja, N.; Patil, K.R.; Kurungot, S. Nitrogen-Induced Surface Area and Conductivity Modulation of Carbon Nanohorn and Its Function as an Efficient Metal-Free Oxygen Reduction Electrocatalyst for Anion-Exchange Membrane Fuel Cells. Small 2014, 11, 352–360. [Google Scholar] [CrossRef]

- Wee, J.-H.; Kim, C.H.; Lee, H.-S.; Choi, G.B.; Kim, D.-W.; Yang, C.-M.; Kim, Y.A. Enriched Pyridinic Nitrogen Atoms at Nanoholes of Carbon Nanohorns for Efficient Oxygen Reduction. Sci. Rep. 2019, 9, 1–7. [Google Scholar] [CrossRef]

- Macias, E.M.; Valenzuela-Muñiz, A.M.; Alonso-Núñez, G.; Sánchez, M.H.F.; Gauvin, R.; Gómez, Y.V. Sulfur doped carbon nanohorns towards oxygen reduction reaction. Diam. Relat. Mater. 2020, 103, 107671. [Google Scholar] [CrossRef]

- Ozaki, J.-I.; Kimura, N.; Anahara, T.; Ōya, A. Preparation and oxygen reduction activity of BN-doped carbons. Carbon 2007, 45, 1847–1853. [Google Scholar] [CrossRef]

- Zhao, Y.; Yang, L.; Chen, S.; Wang, X.; Ma, Y.; Wu, Q.; Jiang, Y.; Qian, W.; Hu, Z. Can Boron and Nitrogen Co-doping Improve Oxygen Reduction Reaction Activity of Carbon Nanotubes? J. Am. Chem. Soc. 2013, 135, 1201–1204. [Google Scholar] [CrossRef]

- Zheng, Y.; Jiao, Y.; Ge, L.; Jaroniec, M.; Qiao, S. Two-Step Boron and Nitrogen Doping in Graphene for Enhanced Synergistic Catalysis. Angew. Chem. Int. Ed. 2013, 52, 3110–3116. [Google Scholar] [CrossRef] [PubMed]

- Zhu, J.; He, C.; Li, Y.; Kang, S.; Shen, P.K. One-step synthesis of boron and nitrogen-dual-self-doped graphene sheets as non-metal catalysts for oxygen reduction reaction. J. Mater. Chem. A 2013, 1, 14700. [Google Scholar] [CrossRef]

- Yu, D.; Xue, Y.; Dai, L. Vertically Aligned Carbon Nanotube Arrays Co-doped with Phosphorus and Nitrogen as Efficient Metal-Free Electrocatalysts for Oxygen Reduction. J. Phys. Chem. Lett. 2012, 3, 2863–2870. [Google Scholar] [CrossRef] [PubMed]

- Xiaohui, W.; Lu, L.; Pei, T.; Meixian, L.; Zujin, S. Influence of nitrogen precursors on the structure, composition, and oxygen reduction reaction performance of dual heteroatom doped carbon nanohorns. RSC Adv. 2016, 6, 63730–63735. [Google Scholar] [CrossRef]

- Lefèvre, M.; Proietti, E.; Jaouen, F.; Dodelet, J.-P. Iron-Based Catalysts with Improved Oxygen Reduction Activity in Polymer Electrolyte Fuel Cells. Science 2009, 324, 71–74. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Zhou, W.; Wang, H.; Xie, L.; Liang, Y.; Wei, F.; Idrobo, J.-C.; Pennycook, S.J.; Dai, H. An oxygen reduction electrocatalyst based on carbon nanotube–graphene complexes. Nat. Nanotechnol. 2012, 7, 394–400. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, Y.; Yu, Z.; Huang, M.; Wu, C.; Jin, C.; Guan, L. Boosting the performance of the Fe–N–C catalyst for the oxygen reduction reaction by introducing single-walled carbon nanohorns as branches on carbon fibers. J. Mater. Chem. A 2019, 7, 23182–23190. [Google Scholar] [CrossRef]

- Martinez, U.; Babu, S.K.; Holby, E.F.; Chung, H.T.; Yin, X.; Zelenay, P. Progress in the Development of Fe-Based PGM-Free Electrocatalysts for the Oxygen Reduction Reaction. Adv. Mater. 2019, 31, 1806545. [Google Scholar] [CrossRef]

- Sravani, B.; Raghavendra, P.; Chandrasekhar, Y.; Reddy, Y.V.M.; Sivasubramanian, R.; Venkateswarlu, K.; Madhavi, G.; Sarma, L.S. Immobilization of platinum-cobalt and platinum-nickel bimetallic nanoparticles on pomegranate peel extract-treated reduced graphene oxide as electrocatalysts for oxygen reduction reaction. Int. J. Hydrogen Energy 2020, 45, 7680–7690. [Google Scholar] [CrossRef]

- Rethinasabapathy, M.; Kang, S.-M.; Haldorai, Y.; Jankiraman, M.; Jonna, N.; Choe, S.R.; Huh, Y.S.; Natesan, B. Ternary PtRuFe nanoparticles supported N-doped graphene as an efficient bifunctional catalyst for methanol oxidation and oxygen reduction reactions. Int. J. Hydrogen Energy 2017, 42, 30738–30749. [Google Scholar] [CrossRef]

- Negro, E.; Delpeuch, A.B.; Vezzu’, K.; Nawn, G.; Bertasi, F.; Ansaldo, A.; Pellegrini, V.; Dembinska, B.; Zoladek, S.; Miecznikowski, K.; et al. Toward Pt-Free Anion-Exchange Membrane Fuel Cells: Fe–Sn Carbon Nitride–Graphene Core–Shell Electrocatalysts for the Oxygen Reduction Reaction. Chem. Mater. 2018, 30, 2651–2659. [Google Scholar] [CrossRef] [Green Version]

- Pires, F.; Villullas, H. Pd-based catalysts: Influence of the second metal on their stability and oxygen reduction activity. Int. J. Hydrogen Energy 2012, 37, 17052–17059. [Google Scholar] [CrossRef]

- Yang, H.; Ko, Y.; Lee, W.; Züttel, A.; Kim, W. Nitrogen-doped carbon black supported Pt–M (M = Pd, Fe, Ni) alloy catalysts for oxygen reduction reaction in proton exchange membrane fuel cell. Mater. Today Energy 2019, 13, 374–381. [Google Scholar] [CrossRef]

- Tan, X.; Zhang, J.; Wu, X.; Wang, Y.; Li, M.; Shi, Z. Palladium nanoparticles loaded on nitrogen and boron dual-doped single-wall carbon nanohorns with high electrocatalytic activity in the oxygen reduction reaction. RSC Adv. 2018, 8, 33688–33694. [Google Scholar] [CrossRef] [Green Version]

- Eblagon, K.M.; Brandão, L. RuSe Electrocatalysts and Single Wall Carbon Nanohorns Supports for the Oxygen Reduction Reaction. J. Fuel Cell Sci. Technol. 2015, 12, 021006. [Google Scholar] [CrossRef] [Green Version]

- Shao, Y.; Yin, G.; Zhang, J.; Gao, Y. Comparative investigation of the resistance to electrochemical oxidation of carbon black and carbon nanotubes in aqueous sulfuric acid solution. Electrochimica Acta 2006, 51, 5853–5857. [Google Scholar] [CrossRef]

- Li, L.; Xing, Y. Electrochemical Durability of Carbon Nanotubes in Noncatalyzed and Catalyzed Oxidations. J. Electrochem. Soc. 2006, 153, A1823. [Google Scholar] [CrossRef]

- Hung, C.-C.; Lim, P.-Y.; Chen, J.-R.; Shih, H.C. Corrosion of carbon support for PEM fuel cells by electrochemical quartz crystal microbalance. J. Power Sources 2011, 196, 140–146. [Google Scholar] [CrossRef]

- Sui, S.; Wang, X.; Zhou, X.; Su, Y.; Riffat, S.; Liu, C.-J. A comprehensive review of Pt electrocatalysts for the oxygen reduction reaction: Nanostructure, activity, mechanism and carbon support in PEM fuel cells. J. Mater. Chem. A 2017, 5, 1808–1825. [Google Scholar] [CrossRef]

- Sano, N.; Kimura, Y.; Suzuki, T. Synthesis of carbon nanohorns by a gas-injected arc-in-water method and application to catalyst-support for polymer electrolyte fuel cell electrodes. J. Mater. Chem. 2008, 18, 1555. [Google Scholar] [CrossRef]

- Yoshitake, T.; Shimakawa, Y.; Kuroshima, S.; Kimura, H.; Ichihashi, T.; Kubo, Y.; Kasuya, D.; Takahashi, K.; Kokai, F.; Yudasaka, M.; et al. Preparation of fine platinum catalyst supported on single-wall carbon nanohorns for fuel cell application. Phys. B Condens. Matter 2002, 323, 124–126. [Google Scholar] [CrossRef]

- Sano, N.; Ukita, S.-I. One-step synthesis of Pt-supported carbon nanohorns for fuel cell electrode by arc plasma in liquid nitrogen. Mater. Chem. Phys. 2006, 99, 447–450. [Google Scholar] [CrossRef]

- Zhang, L.; Zheng, N.; Gao, A.; Zhu, C.; Wang, Z.; Wang, Y.; Shi, Z.; Liu, Y. A robust fuel cell cathode catalyst assembled with nitrogen-doped carbon nanohorn and platinum nanoclusters. J. Power Sources 2012, 220, 449–454. [Google Scholar] [CrossRef]

- Li, H.; Jia, X.; Zhang, Q.; Wang, X. Metallic Transition-Metal Dichalcogenide Nanocatalysts for Energy Conversion. Chem 2018, 4, 1510–1537. [Google Scholar] [CrossRef] [Green Version]

- Chia, X.; Pumera, M. Characteristics and performance of two-dimensional materials for electrocatalysis. Nat. Catal. 2018, 1, 909–921. [Google Scholar] [CrossRef]

- Neergat, M.; Gunasekar, V.; Singh, R.K.; Okumura, Y.; Nose, Y.; Katayama, J.; Uda, T. Oxygen Reduction Reaction and Peroxide Generation on Ir, Rh, and their Selenides—A Comparison with Pt and RuSe. J. Electrochem. Soc. 2011, 158, B1060. [Google Scholar] [CrossRef]

- Han, C.; Li, Q.; Wang, D.; Lu, Q.; Xing, Z.; Yang, X. Cobalt Sulfide Nanowires Core Encapsulated by a N, S Codoped Graphitic Carbon Shell for Efficient Oxygen Reduction Reaction. Small 2018, 14, 1703642. [Google Scholar] [CrossRef]

- Liao, M.; Zeng, G.; Luo, T.; Jin, Z.; Wang, Y.; Kou, X.; Xiao, D. Three-dimensional coral-like cobalt selenide as an advanced electrocatalyst for highly efficient oxygen evolution reaction. Electrochim. Acta 2016, 194, 59–66. [Google Scholar] [CrossRef]

- Feng, Y.; Alonso-Vante, N. Carbon-supported cubic CoSe2 catalysts for oxygen reduction reaction in alkaline medium. Electrochim. Acta 2012, 72, 129–133. [Google Scholar] [CrossRef]

- Unni, S.M.; Mora-Hernandez, J.M.; Kurungot, S.; Alonso-Vante, N. CoSe2 Supported on Nitrogen-Doped Carbon Nanohorns as a Methanol-Tolerant Cathode for Air-Breathing Microlaminar Flow Fuel Cells. ChemElectroChem 2015, 2, 1339–1345. [Google Scholar] [CrossRef]

- Zhang, J.; Wu, C.; Huang, M.; Zhao, Y.; Li, J.; Guan, L. Conductive Porous Network of Metal-Organic Frameworks Derived Cobalt-Nitrogen-doped Carbon with the Assistance of Carbon Nanohorns as Electrocatalysts for Zinc-Air Batteries. ChemCatChem 2018, 10, 1336–1343. [Google Scholar] [CrossRef]

- Wang, L.; Ambrosi, A.; Pumera, M. “Metal-Free” Catalytic Oxygen Reduction Reaction on Heteroatom-Doped Graphene is Caused by Trace Metal Impurities. Angew. Chem. Int. Ed. 2013, 52, 13818–13821. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Chen, W.; Li, Z.; Chen, Y.; Zheng, L.; Gong, Y.; Li, Q.; Shen, R.; Han, Y.; Cheong, W.-C.; et al. Isolated Fe and Co dual active sites on nitrogen-doped carbon for a highly efficient oxygen reduction reaction. Chem. Commun. 2018, 54, 4274–4277. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Sun, X.; Song, P.; Zhang, Y.; Xing, W.; Xu, W.-L. High-Performance Oxygen Reduction Electrocatalysts based on Cheap Carbon Black, Nitrogen, and Trace Iron. Adv. Mater. 2013, 25, 6879–6883. [Google Scholar] [CrossRef]

- Unni, S.M.; Ramadas, S.; Illathvalappil, R.; Bhange, S.N.; Kurungot, S. Surface-modified single wall carbon nanohorn as an effective electrocatalyst for platinum-free fuel cell cathodes. J. Mater. Chem. A 2015, 3, 4361–4367. [Google Scholar] [CrossRef]

- Deng, L.; Zhu, M. Metal–nitrogen (Co-g-C3N4) doping of surface-modified single-walled carbon nanohorns for use as an oxygen reduction electrocatalyst. RSC Adv. 2016, 6, 25670–25677. [Google Scholar] [CrossRef]

- Čolić, V.; Yang, S.; Revay, Z.; Stephens, I.E.L.; Chorkendorff, I. Carbon catalysts for electrochemical hydrogen peroxide production in acidic media. Electrochim. Acta 2018, 272, 192–202. [Google Scholar] [CrossRef] [Green Version]

- Mounfield, W.P.; Garg, A.; Shao-Horn, Y.; Román-Leshkov, Y. Electrochemical Oxygen Reduction for the Production of Hydrogen Peroxide. Chem 2018, 4, 18–19. [Google Scholar] [CrossRef] [Green Version]

- Iglesias, D.; Giuliani, A.; Melchionna, M.; Marchesan, S.; Criado, A.; Nasi, L.; Bevilacqua, M.; Tavagnacco, C.; Vizza, F.; Prato, M.; et al. N-Doped Graphitized Carbon Nanohorns as a Forefront Electrocatalyst in Highly Selective O2 Reduction to H2O2. Chem 2018, 4, 106–123. [Google Scholar] [CrossRef]

- Huang, H.; Wang, X. Recent progress on carbon-based support materials for electrocatalysts of direct methanol fuel cells. J. Mater. Chem. A 2014, 2, 6266–6291. [Google Scholar] [CrossRef]

- Karousis, N.; Ichihashi, T.; Yudasaka, M.; Iijima, S.; Tagmatarchis, N. Decoration of carbon nanohorns with palladium and platinum nanoparticles. J. Nanosci. Nanotechnol. 2009, 9, 6047–6054. [Google Scholar] [CrossRef] [PubMed]

- Brandão, L.; Boaventura, M.; Passeira, C.; Gattia, D.M.; Marazzi, R.; Antisari, M.V.; Mendes, A. An electrochemical impedance spectroscopy study of polymer electrolyte membrane fuel cells electrocatalyst single wall carbon nanohorns-supported. J. Nanosci. Nanotechnol. 2011, 11, 9016–9024. [Google Scholar] [CrossRef]

- Brandão, L.; Gattia, D.M.; Marazzi, R.; Antisari, M.V.; Licoccia, S.; D’Epifanio, A.; Traversa, E.; Mendes, A. Improvement of DMFC Electrode Kinetics by Using Nanohorns Catalyst Support. Mater. Sci. Forum 2010, 638, 1106–1111. [Google Scholar] [CrossRef]

- Brandão, L.; Passeira, C.; Gattia, D.M.; Mendes, A. Use of single wall carbon nanohorns in polymeric electrolyte fuel cells. J. Mater. Sci. 2011, 46, 7198–7205. [Google Scholar] [CrossRef]

- Kosaka, M.; Kuroshima, S.; Kobayashi, K.; Sekino, S.; Ichihashi, T.; Nakamura, S.; Yoshitake, T.; Kubo, Y. Single-Wall Carbon Nanohorns Supporting Pt Catalyst in Direct Methanol Fuel Cells. J. Phys. Chem. C 2009, 113, 8660–8667. [Google Scholar] [CrossRef]

- Niu, B.; Xu, W.; Guo, Z.; Zhou, N.; Liu, Y.; Shi, Z.; Lian, Y. Controllable deposition of platinum nanoparticles on single-wall carbon nanohorns as catalyst for direct methanol fuel cells. J. Nanosci. Nanotechnol. 2012, 12, 7376–7381. [Google Scholar] [CrossRef]

- Zhu, C.; Liu, D.; Chen, Z.; Li, L.; You, T. Superior catalytic activity of Pt/carbon nanohorns nanocomposites toward methanol and formic acid oxidation reactions. J. Colloid Interface Sci. 2018, 511, 77–83. [Google Scholar] [CrossRef]

- Zhang, L.; Gao, A.; Liu, Y.; Wang, Y.; Ma, J. PtRu nanoparticles dispersed on nitrogen-doped carbon nanohorns as an efficient electrocatalyst for methanol oxidation reaction. Electrochim. Acta 2014, 132, 416–422. [Google Scholar] [CrossRef]

- Aissa, B.; Hamoudi, Z.; Takahashi, H.; Tohji, K.; Mohamedi, M.; El Khakani, M.A. Carbon nanohorns-coated microfibers for use as free-standing electrodes for electrochemical power sources. Electrochem. Commun. 2009, 11, 862–866. [Google Scholar] [CrossRef]

- Hamoudi, Z.; Brahim, A.; El Khakani, M.A.; Mohamedi, M. Electroanalytical Study of Methanol Oxidation and Oxygen Reduction at Carbon Nanohorns-Pt Nanostructured Electrodes. Electroanalysis 2013, 25, 538–545. [Google Scholar] [CrossRef]

- Lobato, J.; Cañizares, P.; Rodrigo, M.; Linares, J.J.; López-Vizcaíno, R. Performance of a Vapor-Fed Polybenzimidazole (PBI)-Based Direct Methanol Fuel Cell. Energy Fuels 2008, 22, 3335–3345. [Google Scholar] [CrossRef]

- Brandão, L.; Boaventura, M.; Ribeirinha, P. Single wall nanohorns as electrocatalyst support for vapour phase high temperature DMFC. Int. J. Hydrogen Energy 2012, 37, 19073–19081. [Google Scholar] [CrossRef]

- Boaventura, M.; Brandão, L.; Mendes, A. Single-Wall Nanohorns as Electrocatalyst Support for High Temperature PEM Fuel Cells. J. Electrochem. Soc. 2011, 158, B394. [Google Scholar] [CrossRef]

- Su, F.; Tian, Z.; Poh, C.K.; Wang, Z.; Lim, S.H.; Liu, Z.; Lin, J. Pt Nanoparticles Supported on Nitrogen-Doped Porous Carbon Nanospheres as an Electrocatalyst for Fuel Cells†. Chem. Mater. 2010, 22, 832–839. [Google Scholar] [CrossRef]

- Dubouis, N.; Grimaud, A. The hydrogen evolution reaction: From material to interfacial descriptors. Chem. Sci. 2019, 10, 9165–9181. [Google Scholar] [CrossRef] [Green Version]

- Schalenbach, M.; Speck, F.D.; Ledendecker, M.; Kasian, O.; Goehl, D.; Mingers, A.M.; Breitbach, B.; Springer, H.; Cherevko, S.; Mayrhofer, K.J.J. Nickel-molybdenum alloy catalysts for the hydrogen evolution reaction: Activity and stability revised. Electrochim. Acta 2018, 259, 1154–1161. [Google Scholar] [CrossRef]

- Wu, Q.; Luo, M.; Han, J.; Peng, W.; Zhao, Y.; Chen, D.; Peng, M.; Liu, J.; De Groot, F.M.F.; Tan, Y. Identifying Electrocatalytic Sites of the Nanoporous Copper–Ruthenium Alloy for Hydrogen Evolution Reaction in Alkaline Electrolyte. ACS Energy Lett. 2019, 5, 192–199. [Google Scholar] [CrossRef]

- Jin, H.; Liu, X.; Chen, S.; Vasileff, A.; Li, L.; Jiao, Y.; Song, L.; Zheng, Y.; Qiao, S.-Z. Heteroatom-Doped Transition Metal Electrocatalysts for Hydrogen Evolution Reaction. ACS Energy Lett. 2019, 4, 805–810. [Google Scholar] [CrossRef]

- Kagkoura, A.; Canton-Vitoria, R.; Vallan, L.; Hernandez-Ferrer, J.; Benito, A.M.; Maser, W.; Arenal, R.; Tagmatarchis, N. Bottom-Up Synthesized MoS2 Interfacing Polymer Carbon Nanodots with Electrocatalytic Activity for Hydrogen Evolution. Chem. -A Eur. J. 2020, 26, 6635–6642. [Google Scholar] [CrossRef] [PubMed]

- Vitoria, R.C.; Vallan, L.; Urriolabeitia, E.P.; Benito, A.M.; Maser, W.; Tagmatarchis, N. Electronic Interactions in Illuminated Carbon Dot/MoS2 Ensembles and Electrocatalytic Activity towards Hydrogen Evolution. Chem. -A Eur. J. 2018, 24, 10468–10474. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Xiao, J.; Wang, H.; Shao, M. Carbon-Based Electrocatalysts for Hydrogen and Oxygen Evolution Reactions. ACS Catal. 2017, 7, 7855–7865. [Google Scholar] [CrossRef]

- Cui, W.; Liu, Q.; Cheng, N.; Asiri, A.M.; Sun, X. Activated carbon nanotubes: A highly-active metal-free electrocatalyst for hydrogen evolution reaction. Chem. Commun. 2014, 50, 9340–9342. [Google Scholar] [CrossRef] [PubMed]

- Das, R.K.; Wang, Y.; Vasilyeva, S.V.; Donoghue, E.; Pucher, I.; Kamenov, G.; Cheng, H.-P.; Rinzler, A.G. Extraordinary Hydrogen Evolution and Oxidation Reaction Activity from Carbon Nanotubes and Graphitic Carbons. ACS Nano 2014, 8, 8447–8456. [Google Scholar] [CrossRef] [Green Version]

- Zhuo, J.; Wang, T.; Zhang, G.; Liu, L.; Gan, L.; Li, M. Salts of C60(OH)8 Electrodeposited onto a Glassy Carbon Electrode: Surprising Catalytic Performance in the Hydrogen Evolution Reaction. Angew. Chem. Int. Ed. 2013, 52, 10867–10870. [Google Scholar] [CrossRef]

- Dong, G.; Fang, M.; Wng, H.; Yip, S.; Cheung, H.-Y.; Wang, F.; Wong, C.-Y.; Chu, S.; Ho, J. Insight into the electrochemical activZation of carbon-based cathodes for hydrogen evolution reaction. J. Mater. Chem. A 2015, 3, 13080–13086. [Google Scholar] [CrossRef]

- Kagkoura, A.; Skaltsas, T.; Tagmatarchis, N. Transition-Metal Chalcogenide/Graphene Ensembles for Light-Induced Energy Applications. Chem. -A Eur. J. 2017, 23, 12967–12979. [Google Scholar] [CrossRef]

- Devadas, B.; Imae, T. Hydrogen evolution reaction efficiency by low loading of platinum nanoparticles protected by dendrimers on carbon materials. Electrochem. Commun. 2016, 72, 135–139. [Google Scholar] [CrossRef]

- Devadas, B.; Chang, C.C.; Imae, T. Hydrogen evolution reaction efficiency of carbon nanohorn incorporating molybdenum sulfide and polydopamine/palladium nanoparticles. J. Taiwan Inst. Chem. Eng. 2019, 102, 378–386. [Google Scholar] [CrossRef]

- Wang, J.; Liu, J.; Zhang, B.; Ji, X.; Xu, K.; Chen, C.; Miao, L.; Jiang, J. The mechanism of hydrogen adsorption on transition metal dichalcogenides as hydrogen evolution reaction catalyst. Phys. Chem. Chem. Phys. 2017, 19, 10125–10132. [Google Scholar] [CrossRef] [PubMed]

- Zhu, J.; Wang, Z.-C.; Dai, H.; Wang, Q.; Yang, R.; Yu, H.; Liao, M.; Zhang, J.; Chen, W.; Wei, Z.; et al. Boundary activated hydrogen evolution reaction on monolayer MoS2. Nat. Commun. 2019, 10, 1348. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lai, B.; Singh, S.C.; Bindra, J.; Saraj, C.; Shukla, A.; Yadav, T.; Wu, W.; McGill, S.; Dalal, N.; Srivastava, A.; et al. Hydrogen evolution reaction from bare and surface-functionalized few-layered MoS2 nanosheets in acidic and alkaline electrolytes. Mater. Today Chem. 2019, 14, 100207. [Google Scholar] [CrossRef] [PubMed]

- Ren, X.; Yang, F.; Chen, R.; Ren, P.; Wang, Y. Improvement of HER activity for MoS2: Insight into the effect and mechanism of phosphorus post-doping. New J. Chem. 2020, 44, 1493–1499. [Google Scholar] [CrossRef]

- Mosconi, D.; Till, P.; Calvillo, L.; Kosmala, T.; Garoli, D.; Debellis, D.; Martucci, A.; Agnoli, S.; Granozzi, G. Effect of Ni Doping on the MoS2 Structure and Its Hydrogen Evolution Activity in Acid and Alkaline Electrolytes. Surfaces 2019, 2, 531–545. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Wu, J.; Guo, H.; Chen, W.; Yuan, J.; Martinez, U.; Gupta, G.; Mohite, A.; Ajayan, P.M.; Lou, J. Unveiling Active Sites for the Hydrogen Evolution Reaction on Monolayer MoS2. Adv. Mater. 2017, 29, 1701955. [Google Scholar] [CrossRef]

- Liu, Z.; Li, N.; Zhao, H.; Du, Y. Colloidally Synthesized MoSe2/Graphene Hybrid Nanostructures as Efficient Electrocatalysts for Hydrogen Evolution. J. Mater. Chem. A. 2015, 3, 19706–19710. [Google Scholar] [CrossRef]

- Kagkoura, A.; Tzanidis, I.; Dracopoulos, V.; Tagmatarchis, N.; Tasis, D. Template synthesis of defect-rich MoS2-based assemblies as electrocatalytic platforms for hydrogen evolution reaction. Chem. Commun. 2019, 55, 2078–2081. [Google Scholar] [CrossRef] [Green Version]

- Gnanasekara, P.; Periyanagounder, D.; Jeganathan, K. Vertically aligned MoS2 nanosheets on graphene for highly stable electrocatalytic hydrogen evolution reactions. Nanoscale 2019, 11, 2439–2446. [Google Scholar] [CrossRef]

- Guo, Y.; Zhou, Y.; Nan, Y.; Li, B.; Song, X. Ni-Based Nanoparticle-Embedded N-Doped Carbon Nanohorns Derived from Double Core–Shell CNH@PDA@NiMOFs for Oxygen Electrocatalysis. ACS Appl. Mater. Interfaces 2020, 12, 12743–12754. [Google Scholar] [CrossRef]

- Tao, Z.; Wang, T.; Wang, X.; Zheng, J.; Li, X. MOF-Derived Noble Metal Free Catalysts for Electrochemical Water Splitting. ACS Appl. Mater. Interfaces 2016, 8, 35390–35397. [Google Scholar] [CrossRef] [PubMed]

- Sivanantham, A.; Ganesan, P.; Shanmugam, S. Hierarchical NiCo2S4Nanowire Arrays Supported on Ni Foam: An Efficient and Durable Bifunctional Electrocatalyst for Oxygen and Hydrogen Evolution Reactions. Adv. Funct. Mater. 2016, 26, 4661–4672. [Google Scholar] [CrossRef]

- Xu, Y.; Tu, W.; Zhang, B.; Yin, S.; Huang, Y.; Kraft, M.; Xu, R. Nickel Nanoparticles Encapsulated in Few-Layer Nitrogen-Doped Graphene Derived from Metal-Organic Frameworks as Efficient Bifunctional Electrocatalysts for Overall Water Splitting. Adv. Mater. 2017, 29, 1605957. [Google Scholar] [CrossRef]

- Klaus, S.; Cai, Y.; Louie, M.W.; Trotochaud, L.; Bell, A.T. Effects of Fe Electrolyte Impurities on Ni(OH)2/NiOOH Structure and Oxygen Evolution Activity. J. Phys. Chem. C 2015, 119, 7243–7254. [Google Scholar] [CrossRef] [Green Version]

- Liu, T.; Sun, X.; Asiri, A.M.; He, Y. One-step electrodeposition of Ni–Co–S nanosheets film as a bifunctional electrocatalyst for efficient water splitting. Int. J. Hydrogen Energy 2016, 41, 7264–7269. [Google Scholar] [CrossRef]

- Das, D.; Santra, S.; Nanda, K.K. In Situ Fabrication of a Nickel/Molybdenum Carbide-Anchored N-Doped Graphene/CNT Hybrid: An Efficient (Pre)catalyst for OER and HER. ACS Appl. Mater. Interfaces 2018, 10, 35025–35038. [Google Scholar] [CrossRef]

- Zhu, D.D.; Liu, J.L.; Qiao, S. Recent Advances in Inorganic Heterogeneous Electrocatalysts for Reduction of Carbon Dioxide. Adv. Mater. 2016, 28, 3423–3452. [Google Scholar] [CrossRef]

- Melchionna, M.; Bracamonte, M.V.; Giuliani, A.; Nasi, L.; Montini, T.; Tavagnacco, C.; Bonchio, M.; Fornasiero, P.; Prato, M. Pd@TiO2/Carbon Nanohorns Electrocatalysts: Reversible CO2 Hydrogenation to Formic Acid. Energ. Environ. Sci. 2018, 11, 1571–1580. [Google Scholar] [CrossRef] [Green Version]

- DiMeglio, J.L.; Rosenthal, J. Selective Conversion of CO2 to CO with High Efficiency Using an Inexpensive Bismuth-Based Electrocatalyst. J. Am. Chem. Soc. 2013, 135, 8798–8801. [Google Scholar] [CrossRef] [Green Version]

- Min, X.; Kanan, M.W. Pd-Catalyzed Electrohydrogenation of Carbon Dioxide to Formate: High Mass Activity at Low Overpotential and Identification of the Deactivation Pathway. J. Am. Chem. Soc. 2015, 137, 4701–4708. [Google Scholar] [CrossRef]

| Electrocatalyst | Reaction/Conditions | ORR Performance | Maximum Power Density | Ref. |

|---|---|---|---|---|

| Fe-CNH/CNT | ORR/ LSV in 0.1 M HClO4 | Onset potential: 0.90 V vs. RHE Half-wave potential: 0.71 V vs. RHE Specific activity: 2.14 mA g/m2 at 0.7 V vs. RHE Electron transfer number: 3.89 Tafel slope: 77.4 mV decade−1 Durability: half-wave potential 0.67 V vs. RHE after 5000 cycles | 200 mW/cm2 | [56] |

| ORR/ LSV in 0.5 M H2SO4 | Onset potential: 0.90 V vs. RHE Half-wave potential: 0.75 V vs. RHE Tafel slope: 77.94 mV decade−1 Specific activity: 2.14 mA g/m2 at 0.7 V vs. RHE Electron transfer number: 3.95 Tafel slope: 77.94 mV decade−1 Durability: half-wave potential 0.73 V vs. RHE after 5000 cycles | |||

| ORR/ LSV in 0.1 M KOH | Onset potential: 0.1 V vs. RHE Half-wave potential: 0.85 V vs. RHE Specific activity: 17.39 mA g/m2 at 0.7 V vs. RHE Electron transfer number: 3.90 Tafel slope: 84.84 mV decade−1 Durability: half-wave potential 0.84 V vs. RHE after 5000 cycles | |||

| N-CNHs | ORR/ LSV in 0.1 M KOH | Onset potential: −0.026 V vs. Hg/HgO Half-wave potential: −0.036 V vs. Hg/HgO * JD: −3.75 mA cm−2 at 1600 rpm Electron transfer number: 3.6 Tafel slope: 77.4 mV decade−1 Durability: 6% JD loss after 1000 cycles | 30 mW/cm2 | [68] |

| N-doped CNHs | ORR/ LSV in 0.1 M KOH | Onset potential: 0.93 V vs. RHE Half-wave potential: ~0.84 V vs. RHE JD: ~−5 mA cm−2 at 1600 rpm Electron transfer number: 3.49 | - | [69] |

| Sulfur-doped CNHs | ORR/ LSV in 0.1 M KOH | Onset potential: 0.6 V vs. RHE Half-wave potential: ~0.66 V vs. RHE JD: ~−2 mA cm−2 at 1600 rpm | - | [70] |

| N-B-CNH | ORR/ LSV in 0.1 M KOH | Onset potential: ~−0.21 V vs. Ag/AgCl Half-wave potential: ~−0.28V vs. Ag/AgCl JD: ~−2.8 mA cm−2 at 1600 rpm Durability: 4% current loss after 10,000s | - | [76] |

| N-P-CNH | Onset potential: ~−0.21 V vs. Ag/AgCl Half-wave potential: ~−0.28 V vs. Ag/AgCl JD: ~−2.5 mA cm−2 at 1600 rpm | |||

| Fe-N-CNH | ORR/ LSV in 0.1 M KOH | Onset potential: 1.015 V vs. RHE Half-wave potential: 0.925 V vs. RHE JD: ~−5.6 mA cm−2 at 1600 rpm Electron transfer number: ~4 Durability: 4% loss of current density after 12h operation | 250 mW/cm2/125 mW/cm2 | [79] |

| Pd-N-B-CNHs | ORR/ LSV in 0.1 M KOH | Onset potential: −0.01 V vs. SCE Half-wave potential: −0.152 V vs. SCE JD: ~−5.8 mA cm−2 at 1600 rpm Electron transfer number: 4.2 Durability: 4.7% current loss after 9000 s | - | [86] |

| Pt/CNHs | - | - | 2.5 mW/cm2 | [92] |

| Pt/N-CNHs | ORR/ LSV in 0.1 M HClO4 | Onset potential: ~1.0 V vs. RHE Half-wave potential: 0.904 V vs. RHE JD: ~−5.5 mA cm−2 at 1600 rpm ** Jk: 2.15 mA cm−2 at 1600 rpm Mass activity: 0.305 A mgPt−1 at 0.9 V vs. RHE Durability: half-wave potential 0.902 V vs. RHE after 15,000 cycles, Jk: 2.09 mA cm−2 at 1600 rpm after 15,000 cycles | - | [95] |

| CoSe2/N-CNHs | ORR/ LSV in 0.1 M KOH | Onset potential: 0.9 V vs. RHE Half-wave potential: 0.81 V vs. RHE JD: ~−5.2 mA cm−2 at 1600 rpm Jk: 8.08 mA cm−2 at 1600 rpm Mass activity: 13.8 A g−1 Electron transfer number: 4 Tafel slope: 52 mV decade−1 Durability: negligible losses for onset and half-wave potential after 2000 cycles | 10.05 mW/cm/2 | [102] |

| CNHs/MOF | ORR/ LSV in 0.1 M KOH | Onset potential: 0.97 V vs. RHE Half-wave potential: 0.87 V vs. RHE JD: ~−5.0 mA cm−2 at 1600 rpm Electron transfer number: ~3.7 Durability: 7% loss of current density after 12h operation | 185 mW/cm2 | [103] |

| N-Fe-doped CNH | ORR/ LSV in 0.1 M KOH | Onset potential: −0.09 V vs. Hg/HgO Half-wave potential: −0.026 V vs. Hg/HgO JD: ~−3.8 mA cm−2 at 1600 rpm Electron transfer number: 4 Tafel slope: 84 mV decade−1 Durability: Almost unchanged activity | 35 mW/cm2 | [107] |

| Co-g-C3N4/CNHs | ORR/ LSV in 0.1 M KOH | Onset potential: −0.066 V vs. Ag/AgCl Half-wave potential: −0.157 V vs. Ag/AgCl JD: ~−4.8 mA cm−2 at 1600 rpm Electron transfer number: 3.98 Durability: negligible activity loss after 12 h operation | - | [108] |

| g-N-CNHs | ORR-H2O2 production/CV-LSV in 0.1 M NaOH | Onset potential: 0.71 V vs. RHE Peak potential: 0.40 V vs. RHE Peak current density: −2.3 mA cm−2 Tafel slope: 71 mV decade−1 Electron transfer number: 3.1 | - | [111] |

| ORR-H2O2 production/CV-LSV in 0.1 M phosphate buffer solution | Onset potential: 0.53 V vs. RHE Peak potential: 0.59 V vs. RHE Peak current density: −1.79 mA cm−2 Tafel slope: 84 mV decade−1 Electron transfer number: 2.1 | |||

| ORR-H2O2 production/CV-LSV in 0.1 M H2SO4 | Onset potential: 0.40 V vs. RHE Peak potential: 0.18 V vs. RHE Peak current density: −3.6 mA cm−2 Tafel slope: 95 mV decade−1 Electron transfer number: 2.4 | |||

| Pt/CNHs | ORR/ CV in 0.5 M H2SO4 | Peak potential: 0.33 V vs. Ag/AgCl | - | [121] |

| Pt/CNHs | ORR/ LSV in 0.5 M H2SO4 | Onset potential: 0.77 V vs. Ag/AgCl Half-wave potential: 0.67 V vs. Ag/AgCl Current density: 34.54 mAcm−2 Mass activity: 50.06 mA mgPt−1 | - | [122] |

| Electrocatalyst | Reaction/Conditions | MOR Performance | Ref. |

|---|---|---|---|

| Pt/CNHs | MOR/CV in 0.5 M H2SO4/1.0 M CH3OH | Oxidation peak: 0.7 V vs. SCE Mass activity: 350 mA mg−1 Durability: 90% mass activity loss after 1800 s | [118] |

| Pt/CNHs | MOR/CV in 1.0 M KOH/1.0 M CH3OH | Oxidation peak: −0.22 V vs. Ag/AgCl Mass activity: 0.49 mA μg−1 Durability: 13% peak current loss after 100 cycles | [119] |

| Formic acid oxidation reaction/CV in 0.5 M H2SO4/0.5 M HCOOH | Oxidation peak: 0.35 V vs. Ag/AgCl Mass activity: 81 mA mg−1 Durability: 60% mass activity loss after 3600 s | ||

| PtRu/N-CNHs | MOR/CV in 0.5 M H2SO4/1 M CH3OH | Oxidation peak: 0.7 V vs. RHE Mass activity: 850 mA mg−1 | [120] |

| Pt/CNHs | MOR/CV in 0.5 M H2SO4/1 M CH3OH | Oxidation peak: 0.7 V vs. Ag/AgCl | [121] |

| Pt/CNHs | MOR/CV in 0.5 M H2SO4/1 M CH3OH | Oxidation peak: 0.69 V vs. Ag/AgCl Current density: 127 mA cm−2 Mass activity: 184 mA mgPt−1 | [122] |

| Electrocatalyst | Reaction/Conditions | Reaction Performance | Ref. |

|---|---|---|---|

| CNHs | HER/LSV in 0.5 M H2SO4 | Onset potential: ~0.53 V vs. RHE | [137] |

| CNH/PAMAM-Pt | HER/LSV in 0.5 M H2SO4 | Onset potential: −0.016 V vs. RHE Current density at 50 mV: 2.5 mA cm−2 Tafel slope: 42 mV decade−1 Durability: Same HER activity after 500 cycles | [139] |

| PDA-Pd/CNHs | HER/LSV in 0.5 M H2SO4 | Onset potential: ~−0.01 V vs. RHE Potential at 10 mA cm2: ~−0.12 vs. RHE Tafel slope: 61 mV decade−1 | [140] |

| MoS2/CNHs | Onset potential: ~−0.22 V vs. RHE Potential at 10 mA cm2: −0.246 V vs. RHE vs. RHE Tafel slope: 86 mV decade−1 | ||

| N-CNH-Ni-MOF | OER/LSV in 1.0 M KOH | Onset potential: 0.07 V vs. RHE Potential at 10 mA cm2: 0.320 V vs. RHE Tafel slope: 85.3 mV decade−1 Durability: Same electrocatalytic activity after 15 h | [150] |

| Pd@TiO2/ox-CNHs | CO2RR/CV in 0.1 M phosphate buffer solution | Onset potential: −0.05 V vs. RHE Tafel slope: 149 mV decade−1 Durability: Same electrocatalytic activity after 48 h of electrolysis | [158] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kagkoura, A.; Tagmatarchis, N. Carbon Nanohorn-Based Electrocatalysts for Energy Conversion. Nanomaterials 2020, 10, 1407. https://0-doi-org.brum.beds.ac.uk/10.3390/nano10071407

Kagkoura A, Tagmatarchis N. Carbon Nanohorn-Based Electrocatalysts for Energy Conversion. Nanomaterials. 2020; 10(7):1407. https://0-doi-org.brum.beds.ac.uk/10.3390/nano10071407

Chicago/Turabian StyleKagkoura, Antonia, and Nikos Tagmatarchis. 2020. "Carbon Nanohorn-Based Electrocatalysts for Energy Conversion" Nanomaterials 10, no. 7: 1407. https://0-doi-org.brum.beds.ac.uk/10.3390/nano10071407