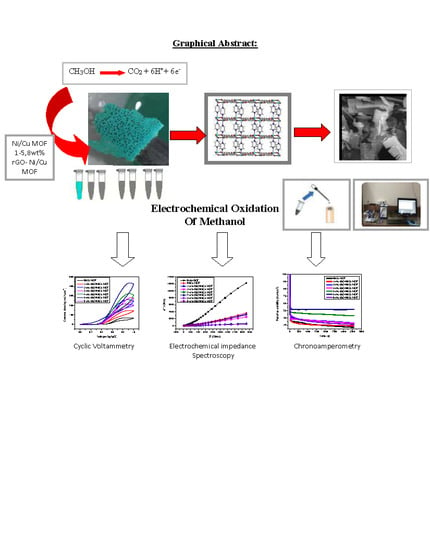

Nanocomposites of NiO/CuO Based MOF with rGO: An Efficient and Robust Electrocatalyst for Methanol Oxidation Reaction in DMFC

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Synthesis of Bimetallic Nickel Oxide/Copper Oxide Metal–Organic Framework (NiO/CuO MOF)

2.3. Synthesis of Graphene Oxide (GO)

2.4. Synthesis of Reduced Graphene Oxide (rGO)

2.5. Synthesis of rGO-NiO/CuO MOF Composites

3. Material Characterization

4. Electrochemical Measurements of the Electrocatalysts

Preparation of Working Electrode

5. Results and Discussion

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Debe, M.K. Electrocatalyst approaches and challenges for automotive fuel cells. Nature 2012, 486, 43–51. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Higgins, D.; Yu, A.; Zhang, L.; Zhang, J. A review on non-precious metal electrocatalysts for PEM fuel cells. Energy Environ. Sci. 2011, 4, 3167–3192. [Google Scholar] [CrossRef]

- Winter, M.; Brodd, R.J. What Are Batteries, Fuel Cells, and Supercapacitors? ACS Publications: Washington, DC, USA, 2004. [Google Scholar]

- Kordesch, K.; Simader, G. Fuel Cells and Their Applications; VCh: Weinheim, Germany, 1996; Volume 117. [Google Scholar]

- Walker, C.W. Pollution Control through Fuel Treatment; Google Patents: Washington, DC, USA, 1987. [Google Scholar]

- Rahmanifar, M.S.; Hesari, H.; Noori, A.; Masoomi, M.Y.; Morsali, A.; Mousavi, M.F. A dual Ni/Co-MOF-reduced graphene oxide nanocomposite as a high performance supercapacitor electrode material. Electrochim. Acta 2018, 275, 76–86. [Google Scholar] [CrossRef]

- Baronia, R.; Goel, J.; Gautam, G.; Singh, D.; Singhal, S.K. Synthesis and Characterization of Nitrogen Doped Reduced Graphene Oxide (N-rGO) Supported PtCu Anode Catalysts for Direct Methanol Fuel Cell. J. Nanosci. Nanotechnol. 2019, 19, 3832–3843. [Google Scholar] [CrossRef]

- Crabtree, G.W.; Dresselhaus, M.S.; Buchanan, M.V. The hydrogen economy. Phys. Today 2004, 57, 39–44. [Google Scholar] [CrossRef]

- Porter, N.S.; Wu, H.; Quan, Z.; Fang, J. Shape-control and electrocatalytic activity-enhancement of Pt-based bimetallic nanocrystals. Acc. Chem. Res. 2013, 46, 1867–1877. [Google Scholar] [CrossRef]

- Wu, J.; Yang, H. Platinum-based oxygen reduction electrocatalysts. Acc. Chem. Res. 2013, 46, 1848–1857. [Google Scholar] [CrossRef]

- Li, J.S.; Li, S.L.; Tang, Y.J.; Li, K.; Zhou, L.; Kong, N.; Lan, Y.Q.; Bao, J.C.; Dai, Z.H. Heteroatoms ternary-doped porous carbons derived from MOFs as metal-free electrocatalysts for oxygen reduction reaction. Sci. Rep. 2014, 4, 5130. [Google Scholar] [CrossRef] [Green Version]

- Amin, R.; Hameed, R.A.; El-Khatib, K.; Youssef, M.E.; Elzatahry, A. Pt–NiO/C anode electrocatalysts for direct methanol fuel cells. Electrochim. Acta 2012, 59, 499–508. [Google Scholar] [CrossRef]

- Zhang, N.; Bu, L.; Guo, S.; Guo, J.; Huang, X. Screw thread-like platinum–copper nanowires bounded with high-index facets for efficient electrocatalysis. Nano Lett. 2016, 16, 5037–5043. [Google Scholar] [CrossRef] [PubMed]

- Bu, L.; Guo, S.; Zhang, X.; Shen, X.; Su, D.; Lu, G.; Zhu, X.; Yao, J.; Guo, J.; Huang, X. Surface engineering of hierarchical platinum-cobalt nanowires for efficient electrocatalysis. Nat. Commun. 2016, 7, 11850. [Google Scholar] [CrossRef]

- MAskari, B.; Seifi, M.; Rozati, S.M.; Beheshti-Marnani, A. One-step hydrothermal synthesis of MoNiCoS nanocomposite hybridized with graphene oxide as a high-performance nanocatalyst toward methanol oxidation. Chem. Phys. Lett. 2018, 706, 164–169. [Google Scholar] [CrossRef]

- Raoof, J.B.; Ojani, R.; Hosseini, S.R. An electrochemical investigation of methanol oxidation on nickel hydroxide nanoparticles. S. Afr. J. Chem. 2013, 66, 47–53. [Google Scholar]

- Le, M.; Ren, M.; Zhang, Z.; Sprunger, P.T.; Kurtz, R.L.; Flake, J.C. Electrochemical reduction of CO2 to CH3OH at copper oxide surfaces. J. Electrochem. Soc. 2011, 158, E45–E49. [Google Scholar] [CrossRef]

- Kaichev, V.V.; Popova, G.Y.; Chesalov, Y.A.; Saraev, A.A.; Zemlyanov, D.Y.; Beloshapkin, S.A.; Knop-Gericke, A.; Schlögl, R.; Andrushkevich, T.V.; Bukhtiyarov, V.I. Selective oxidation of methanol to form dimethoxymethane and methyl formate over a monolayer V2O5/TiO2 catalyst. J. Catal. 2014, 311, 59–70. [Google Scholar] [CrossRef] [Green Version]

- Yeo, I.-H.; Johnson, D.C. Anodic response of glucose at copper-based alloy electrodes. J. Electroanal. Chem. 2000, 484, 157–163. [Google Scholar] [CrossRef]

- Danaee, I.; Jafarian, M.; Forouzandeh, F.; Gobal, F.; Mahjani, M. Electrocatalytic oxidation of methanol on Ni and NiCu alloy modified glassy carbon electrode. Int. J. Hydrog. Energy 2008, 33, 4367–4376. [Google Scholar] [CrossRef]

- Danaee, I.; Jafarian, M.; Forouzandeh, F.; Gobal, F.; Mahjani, M. Electrochemical impedance studies of methanol oxidation on GC/Ni and GC/NiCu electrode. Int. J. Hydrog. Energy 2009, 34, 859–869. [Google Scholar] [CrossRef]

- Motheo, A. Alkaline Media. J. Braz. Chem. Soc. 1994, 5, 161–165. [Google Scholar] [CrossRef]

- Khulbe, K.; Mann, R.; Manoogian, A. Behavior of nickel-copper alloy in hydrogenation, orthohydrogen-parahydrogen conversion and H2-D2 exchange reaction. Chem. Rev. 1980, 80, 417–428. [Google Scholar] [CrossRef]

- Zhu, Q.-L.; Xu, Q. Metal–organic framework composites. Chem. Soc. Rev. 2014, 43, 5468–5512. [Google Scholar] [CrossRef]

- Huang, X.; Qi, X.; Boey, F.; Zhang, H. Graphene-based composites. Chem. Soc. Rev. 2012, 41, 666–686. [Google Scholar] [CrossRef]

- Moon, I.K.; Lee, J.; Ruoff, R.S.; Lee, H. Reduced graphene oxide by chemical graphitization. Nat. Commun. 2010, 1, 73. [Google Scholar] [CrossRef] [Green Version]

- Gascon, J.; Aktay, U.; Hernandez-Alonso, M.D.; van Klink, G.P.M.; Kapteijn, F. Amino-based metal-organic frameworks as stable, highly active basic catalysts. J. Catal. 2009, 261, 75–87. [Google Scholar] [CrossRef]

- Férey, G. Hybrid porous solids: Past, present, future. Chem. Soc. Rev. 2008, 37, 191–214. [Google Scholar] [CrossRef]

- Yang, L.; Kinoshita, S.; Yamada, T.; Kanda, S.; Kitagawa, H.; Tokunaga, M.; Ishimoto, T.; Ogura, T.; Nagumo, R.; Miyamoto, A.; et al. A metal–organic framework as an electrocatalyst for ethanol oxidation. Angew. Chem. Int. Ed. 2010, 49, 5348–5351. [Google Scholar] [CrossRef]

- Abbasi, A.; Tarighi, S. Metal-organic frameworks of cobalt and nickel centers with carboxylate and pyridine functionality linkers: Thermal and physical properties; precursors for metal oxide nanoparticle preparation. J. Nanostructures 2012, 2, 379–388. [Google Scholar]

- Abbasi, A.; Soleimani, M.; Najafi, M.; Geranmayeh, S. New interpenetrated mixed (Co/Ni) metal–organic framework for dye removal under mild conditions. Inorg. Chim. Acta 2016, 439, 18–23. [Google Scholar] [CrossRef]

- Hummers, W.S., Jr.; Offeman, R.E. Preparation of graphitic oxide. J. Am. Chem. Soc. 1958, 80, 1339. [Google Scholar] [CrossRef]

- Wu, Z.-S.; Ren, W.; Gao, L.; Liu, B.; Jiang, C.; Cheng, H.-M. Synthesis of high-quality graphene with a pre-determined number of layers. Carbon 2009, 47, 493–499. [Google Scholar] [CrossRef]

- Cao, N.; Zhang, Y. Study of reduced graphene oxide preparation by Hummers’ method and related characterization. J. Nanomater. 2015, 2015, 2. [Google Scholar] [CrossRef] [Green Version]

- Slade, S.; Campbell, S.; Ralph, T.; Walsh, F. Ionic conductivity of an extruded Nafion 1100 EW series of membranes. J. Electrochem. Soc. 2002, 149, A1556–A1564. [Google Scholar] [CrossRef] [Green Version]

- Noor, T.; Zaman, N.; Nasir, H.; Iqbal, N.; Hussain, Z. Electro catalytic study of NiO-MOF/rGO composites for methanol oxidation reaction. Electrochim. Acta 2019, 307, 1–12. [Google Scholar] [CrossRef]

- Huang, F.; Zhong, Y.; Chen, J.; Li, S.; Li, Y.; Wang, F.; Feng, S. Nonenzymatic glucose sensor based on three different CuO nanomaterials. Anal. Methods 2013, 5, 3050–3055. [Google Scholar] [CrossRef]

- Andrijanto, E.; Shoelarta, S.; Subiyanto, G.; Rifki, S. Facile synthesis of graphene from graphite using ascorbic acid as reducing agent. In Proceedings of the AIP Conference, Semarang, Indonesia, 6–7 October 2016; p. 20003. [Google Scholar]

- Kurisingal, J.F.; Babu, R.; Kim, S.H.; Li, Y.X.; Chang, J.S.; Cho, S.J.; Park, D.W. Microwave-induced synthesis of a bimetallic charge-transfer metal organic framework: A promising host for the chemical fixation of CO2. Catal. Sci. Technol. 2018, 8, 591–600. [Google Scholar] [CrossRef]

- Hidayah, N.M.; Liu, W.W.; Lai, C.W.; Noriman, N.Z.; Khe, C.S.; Hashim, U.; Lee, H.C. Comparison on graphite, graphene oxide and reduced graphene oxide: Synthesis and characterization. In Proceedings of the AIP Conference, Bydgoszcz, Poland, 9–11 May 2017; p. 150002. [Google Scholar]

- Feng, H.; Cheng, R.; Zhao, X.; Duan, X.; Li, J. A low-temperature method to produce highly reduced graphene oxide. Nat. Commun. 2013, 4, 1539. [Google Scholar] [CrossRef] [Green Version]

- Mu, X.; Chen, Y.; Lester, E.; Wu, T. Optimized synthesis of nano-scale high quality HKUST-1 under mild conditions and its application in CO2 capture. Microporous Mesoporous Mater. 2018, 270, 249–257. [Google Scholar] [CrossRef] [Green Version]

- Tkachev, S.; Buslaeva, E.Y.; Naumkin, A.; Kotova, S.; Laure, I.; Gubin, S. Reduced graphene oxide. Inorg. Mater. 2012, 48, 796–802. [Google Scholar] [CrossRef]

- Jiang, G.; Wu, T.; Zheng, S.T.; Zhao, X.; Lin, Q.; Bu, X.; Feng, P. A nine-connected mixed-ligand nickel-organic framework and its gas sorption properties. Cryst. Growth Des. 2011, 11, 3713–3716. [Google Scholar] [CrossRef]

- Kim, J.K. PEG-assisted Sol-gel Synthesis of Compact Nickel Oxide Hole-Selective Layer with Modified Interfacial Properties for Organic Solar Cells. Polymers 2019, 11, 120. [Google Scholar] [CrossRef] [Green Version]

- Duan, X.; Huang, H.; Xiao, S.; Deng, J.; Zhou, G.; Li, Q.; Wang, T. 3D hierarchical CuO mesocrystals from ionic liquid precursors: Towards better electrochemical performance for Li-ion batteries. J. Mater. Chem. A 2016, 4, 8402–8411. [Google Scholar] [CrossRef]

- Yaqoob, L.; Noor, T.; Iqbal, N.; Nasir, H.; Zaman, N. Development of Nickel-BTC-MOF-Derived Nanocomposites with rGO Towards Electrocatalytic Oxidation of Methanol and Its Product Analysis. Catalysts 2019, 9, 856. [Google Scholar] [CrossRef] [Green Version]

- Zhu, D.; Guo, C.; Liu, J.; Wang, L.; Du, Y.; Qiao, S.-Z. Two-dimensional metal–organic frameworks with high oxidation states for efficient electrocatalytic urea oxidation. Chem. Commun. 2017, 53, 10906–10909. [Google Scholar] [CrossRef] [PubMed]

- Thakur, A.; Kumar, S.; Rangra, V. Synthesis of reduced graphene oxide (rGO) via chemical reduction. In Proceedings of the AIP Conference, Ekateringburg, Russia, 14–18 May 2015; p. 80032. [Google Scholar]

- Mehek, R.; Iqbal, N.; Noor, T.; Nasir, H.; Mehmood, Y.; Ahmed, S. Novel Co-MOF/graphene oxide electrocatalyst for methanol oxidation. Electrochim. Acta 2017, 255, 195–204. [Google Scholar] [CrossRef]

- Chang, W.T.; Chao, Y.H.; Li, C.W.; Lin, K.L.; Wang, J.J.; Kumar, S.R.; Lue, S.J. Graphene oxide synthesis using microwave-assisted vs. modified Hummer′s methods: Efficient fillers for improved ionic conductivity and suppressed methanol permeability in alkaline methanol fuel cell electrolytes. J. Power Sources 2019, 414, 86–95. [Google Scholar] [CrossRef]

- Zhu, Y.; Murali, S.; Cai, W.; Li, X.; Suk, J.W.; Potts, J.R.; Ruoff, R.S. Graphene and graphene oxide: Synthesis, properties, and applications. Adv. Mater. 2010, 22, 3906–3924. [Google Scholar] [CrossRef]

- Hassan, H.; Rahim, M.A.; Khalil, M.; Mohammed, R. Ni modified MCM-41 as a catalyst for direct methanol fuel cells. Int. J. Electrochem. Sci. 2014, 9, 760–777. [Google Scholar]

- Zhang, X.; Jiang, Z.H.; Yao, Z.P.; Song, Y.; Wu, Z.D. Effects of scan rate on the potentiodynamic polarization curve obtained to determine the Tafel slopes and corrosion current density. Corros. Sci. 2009, 51, 581–587. [Google Scholar] [CrossRef]

- Shahid, M.M.; Pandikumar, A.; Golsheikh, A.M.; Huang, N.M.; Lim, H.N. Enhanced electrocatalytic performance of cobalt oxide nanocubes incorporating reduced graphene oxide as a modified platinum electrode for methanol oxidation. RSC Adv. 2014, 4, 62793–62801. [Google Scholar] [CrossRef] [Green Version]

- Ghouri, Z.K.; Barakat, N.A.; Kim, H.Y.; Park, M.; Khalil, K.A.; El-Newehy, M.H.; Al-Deyab, S.S. Nano-engineered ZnO/CeO2 dots@ CNFs for fuel cell application. Arab. J. Chem. 2016, 9, 219–228. [Google Scholar] [CrossRef] [Green Version]

- Noor, T.; Ammad, M.; Zaman, N.; Iqbal, N.; Yaqoob, L.; Nasir, H. A Highly Efficient and Stable Copper BTC Metal Organic Framework Derived Electrocatalyst for Oxidation of Methanol in DMFC Application. Catal. Lett. 2019, 149, 3312–3327. [Google Scholar] [CrossRef]

- Vetter, K.J. Electrochemical Kinetics: Theoretical Aspects; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Sarwar, E.; Noor, T.; Iqbal, N.; Mehmood, Y.; Ahmed, S.; Mehek, R. Effect of Co-Ni Ratio in Graphene Based Bimetallic Electro-catalyst for Methanol Oxidation. Fuel Cells 2018, 18, 189–194. [Google Scholar] [CrossRef]

- Noh, Y.; Kim, Y.; Lee, S.; Lim, E.J.; Kim, J.G.; Choi, S.M.; Seo, M.H.; Kim, W.B. Exploring the effects of the size of reduced graphene oxide nanosheets for Pt-catalyzed electrode reactions. Nanoscale 2015, 7, 9438–9442. [Google Scholar] [CrossRef] [PubMed]

- Tapan, N.A.; Prakash, J. Determination of the methanol decomposition mechanism on a polycrystalline platinum electrode. Turk. J. Eng. Environ. Sci. 2005, 29, 95–104. [Google Scholar]

- Wang, W.; Li, Y.; Wang, H. Tin oxide nanoparticle-modified commercial PtRu catalyst for methanol oxidation. Micro Nano Lett. 2013, 8, 23–26. [Google Scholar] [CrossRef]

- Seland, F.; Tunold, R.; Harrington, D.A. Impedance study of methanol oxidation on platinum electrodes. Electrochim. Acta 2006, 51, 3827–3840. [Google Scholar] [CrossRef]

- Behmenyar, G.; Akın, A.N. Investigation of carbon supported Pd–Cu nanoparticles as anode catalysts for direct borohydride fuel cell. J. Power Sources 2014, 249, 239–246. [Google Scholar] [CrossRef]

- Huang, W.; Wang, H.; Zhou, J.; Wang, J.; Duchesne, P.N.; Muir, D.; Zhang, P.; Han, N.; Zhao, F.; Zeng, M.; et al. Highly active and durable methanol oxidation electrocatalyst based on the synergy of platinum–nickel hydroxide–graphene. Nat. Commun. 2015, 6, 10035. [Google Scholar] [CrossRef]

- Daşdelen, Z.; Yıldız, Y.; Eriş, S.; Şen, F. Enhanced electrocatalytic activity and durability of Pt nanoparticles decorated on GO-PVP hybride material for methanol oxidation reaction. Appl. Catal. B: Environ. 2017, 219, 511–516. [Google Scholar]

- Hu, Y.; Wu, P.; Zhang, H.; Cai, C. Synthesis of graphene-supported hollow Pt–Ni nanocatalysts for highly active electrocatalysis toward the methanol oxidation reaction. Electrochim. Acta 2012, 85, 314–321. [Google Scholar] [CrossRef]

| Elements | NiO/CuO MOF | 1 wt% rGO–NiO/CuO MOF | 2 wt% rGO–NiO/CuO MOF | 3 wt% rGO–NiO/CuO MOF | 4 wt% rGO–NiO/CuO MOF | 5 wt% rGO–NiO/CuO MOF | 8 wt% rGO–NiO/CuO MOF |

|---|---|---|---|---|---|---|---|

| C wt% | 29.31 | 39.29 | 44.26 | 47.63 | 55.70 | 60.87 | 67.11 |

| O wt% | 18.69 | 17.79 | 14.93 | 10.97 | 10.57 | 10.28 | 10.37 |

| N wt% | 8.35 | 6.42 | 8.31 | 7.81 | 6.63 | 5.50 | 4.01 |

| Ni wt% | 25.95 | 22.19 | 8.24 | 21.27 | 14.92 | 13.02 | 12.38 |

| Cu wt% | 17.70 | 14.31 | 5.26 | 19.13 | 12.18 | 10.33 | 6.13 |

| Catalysts | Methanol Concentration (M) | Loaded Amount of Catalyst (mg) | Scan Rate (mV/sec) | Peak Current (mA/cm2) | Reference |

|---|---|---|---|---|---|

| ZnO(40%)/CeO2(60%)dots@CNFs | 3 | 2 | 50 | 16.3 | [56] |

| 5 wt%GO/Co–MOF-71 | 3 | 2 | 50 | 29.1 | [50] |

| 5 wt% GO/Cu–MOF | 3 | 2 | 50 | 120 | [57] |

| 5 wt% rGO/NiO–MOF | 3 | 2 | 50 | 275.85 | [36] |

| NiO/CuO MOF | 3 | 2 | 50 | 67.48 | This work |

| 1 wt% rGO–NiO/CuO MOF | 3 | 2 | 50 | 145.5 | This work |

| 2 wt% rGO–NiO/CuO MOF | 3 | 2 | 50 | 259.0 | This work |

| 3 wt% rGO–NiO/CuO MOF | 3 | 2 | 50 | 264.57 | This work |

| 4 wt% rGO–NiO/CuO MOF | 3 | 2 | 50 | 324 | This work |

| 5 wt% rGO–NiO/CuO MOF | 3 | 2 | 50 | 437.28 | This work |

| Catalyst | Tafel Slopes at 0.45 V |

|---|---|

| NiO/CuO MOF | 45.7 |

| 1 wt% rGO–NiO/CuO MOF | 48.1 |

| 2 wt% rGO–NiO/CuO MOF | 52 |

| 3 wt% rGO–NiO/CuO MOF | 55 |

| 4 wt% rGO–NiO/CuO MOF | 59 |

| 5 wt% rGO–NiO/CuO MOF | 65 |

| 8 wt% rGO–NiO/CuO MOF | 50 |

| Catalyst | Rct (Ohm) | Ru (Ohm) | Cf (F) |

|---|---|---|---|

| Bare GCE | 14.06 × 103 | 18.68 | 13.37 × 10−6 |

| NiO/CuO MOF | 634.6 | 12.77 | 1.221 × 10−3 |

| 1 wt% rGO–NiO/CuO MOF | 416.6 | 13.16 | 1.515 × 10−3 |

| 2 wt% rGO–NiO/CuO MOF | 379.4 | 13.03 | 1.547 × 10−3 |

| 3 wt% rGO–NiO/CuO MOF | 337.6 | 12.84 | 1.511 × 10−3 |

| 4 wt% rGO–NiO/CuO MOF | 341.7 | 12.99 | 1.517 × 10−3 |

| 5 wt% rGO–NiO/CuO MOF | 317.4 | 12.97 | 1.597 × 10−3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Noor, T.; Pervaiz, S.; Iqbal, N.; Nasir, H.; Zaman, N.; Sharif, M.; Pervaiz, E. Nanocomposites of NiO/CuO Based MOF with rGO: An Efficient and Robust Electrocatalyst for Methanol Oxidation Reaction in DMFC. Nanomaterials 2020, 10, 1601. https://0-doi-org.brum.beds.ac.uk/10.3390/nano10081601

Noor T, Pervaiz S, Iqbal N, Nasir H, Zaman N, Sharif M, Pervaiz E. Nanocomposites of NiO/CuO Based MOF with rGO: An Efficient and Robust Electrocatalyst for Methanol Oxidation Reaction in DMFC. Nanomaterials. 2020; 10(8):1601. https://0-doi-org.brum.beds.ac.uk/10.3390/nano10081601

Chicago/Turabian StyleNoor, Tayyaba, Sadaf Pervaiz, Naseem Iqbal, Habib Nasir, Neelam Zaman, Muhammad Sharif, and Erum Pervaiz. 2020. "Nanocomposites of NiO/CuO Based MOF with rGO: An Efficient and Robust Electrocatalyst for Methanol Oxidation Reaction in DMFC" Nanomaterials 10, no. 8: 1601. https://0-doi-org.brum.beds.ac.uk/10.3390/nano10081601