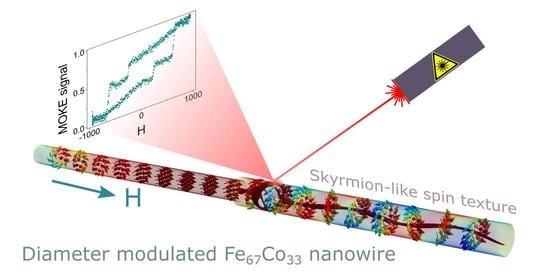

Narrow Segment Driven Multistep Magnetization Reversal Process in Sharp Diameter Modulated Fe67Co33 Nanowires

Abstract

:1. Introduction

2. Materials and Methods

2.1. Bisegmented Nanowires Fabrication

2.2. Characterization Techniques

2.3. First Order Reversal Curve (FORC) Method

2.4. Micromagnetic Simulations of Magnetization Reversal

3. Results

3.1. Morphological and Compositional Characterization

3.2. Magnetic Properties

3.3. Micromagnetic Modelling of the Reversal Process and MOKE Model

3.4. Comparison between Experimental and Modelled Magneto-Optical Kerr Effects

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Heck, C. Magnetic Materials and Their Applications, 1st ed.; Heck, C., Ed.; Butterworth-Heinemann: Oxford, UK, 1974; ISBN 9780408703994. [Google Scholar]

- Krishnan, K.M. Fundamentals and Applications of Magnetic Materials; Oxford University Press: Oxfrod, UK, 2016; ISBN 9780199570447. [Google Scholar]

- L Liao, J.-W.; Zhang, H.-W.; Lai, C.-H. Magnetic Nanomaterials for Data Storage. In Magnetic Nanomaterials; Wiley Online Books: Hoboken, NJ, USA, 2017; pp. 439–472. ISBN 9783527803255. [Google Scholar]

- Dudek, M.R.; Dudek, K.K.; Wolak, W.; Wojciechowski, K.W.; Grima, J.N. Magnetocaloric materials with ultra-small magnetic nanoparticles working at room temperature. Sci. Rep. 2019, 9, 17607. [Google Scholar] [CrossRef]

- Chiolerio, A.; Allia, P. Magnetic Nanostructures and Spintronics BT. In Encyclopedia of Nanotechnology; Bhushan, B., Ed.; Springer: Dordrecht, The Netherlands, 2012; pp. 1248–1256. ISBN 9789048197514. [Google Scholar]

- Karmakar, S.; Kumar, S.; Rinaldi, R.; Maruccio, G. Nano-electronics and spintronics with nanoparticles. J. Phys. Conf. Ser. 2011, 292, 012002. [Google Scholar] [CrossRef]

- Fert, A.; Piraux, L. Magnetic nanowires. J. Magn. Magn. Mater. 1999, 200, 338–358. [Google Scholar] [CrossRef]

- Méndez, M.; Vega, V.; González, S.; Caballero-Flores, R.; García, J.; Prida, V.M. Effect of Sharp Diameter Geometrical Modulation on the Magnetization Reversal of Bi-Segmented FeNi Nanowires. Nanomaterials 2018, 8, 595. [Google Scholar] [CrossRef] [Green Version]

- García Fernández, J.; Vega Martínez, V.; Thomas, A.; De La Prida Pidal, V.M.; Nielsch, K.; Fernández, J.G.; Martínez, V.V.; Thomas, A.; Nielsch, K. Two-Step Magnetization Reversal FORC Fingerprint of Coupled Bi-Segmented Ni/Co Magnetic Nanowire Arrays. Nanomaterials 2018, 8, 548. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Seo, K.; Varadwaj, K.S.K.; Mohanty, P.; Lee, S.; Jo, Y.; Jung, M.-H.; Kim, J.; Kim, B. Magnetic Properties of Single-Crystalline CoSi Nanowires. Nano Lett. 2007, 7, 1240–1245. [Google Scholar] [CrossRef] [PubMed]

- Heydon, G.P.; Hoon, S.R.; Farley, A.N.; Tomlinson, S.L.; Valera, M.S.; Attenborough, K.; Schwarzacher, W. Magnetic properties of electrodeposited nanowires. J. Phys. D. Appl. Phys. 1997, 30, 1083–1093. [Google Scholar] [CrossRef]

- Michel, A.K.; Niemann, A.C.; Boehnert, T.; Martens, S.; Montero Moreno, J.M.; Goerlitz, D.; Zierold, R.; Reith, H.; Vega, V.; Prida, V.M.; et al. Temperature gradient-induced magnetization reversal of single ferromagnetic nanowires. J. Phys. D. Appl. Phys. 2017, 50, 494007. [Google Scholar] [CrossRef]

- Proenca, M.P.; Merazzo, K.J.; Vivas, L.G.; Leitao, D.C.; Sousa, C.T.; Ventura, J.; Araujo, J.P.; Vazquez, M. Co nanostructures in ordered templates: Comparative FORC analysis. Nanotechnology 2013, 24, 475703. [Google Scholar] [CrossRef] [Green Version]

- Vázquez, M.; Pirota, K.; Torrejón, J.; Navas, D.; Hernández-Vélez, M. Magnetic behaviour of densely packed hexagonal arrays of Ni nanowires: Influence of geometric characteristics. J. Magn. Magn. Mater. 2005, 294, 174–181. [Google Scholar] [CrossRef]

- Raposo, V.; Garcia, J.M.; González, J.M.; Vázquez, M. Long-range magnetostatic interactions in arrays of nanowires. J. Magn. Magn. Mater. 2000, 222, 227–232. [Google Scholar] [CrossRef]

- Clime, L.; Ciureanu, P.; Yelon, A. Magnetostatic interactions in dense nanowire arrays. J. Magn. Magn. Mater. 2006, 297, 60–70. [Google Scholar] [CrossRef]

- Bae, C.; Zierold, R.; Montero Moreno, J.M.; Kim, H.; Shin, H.; Bachmann, J.; Nielsch, K. Multisegmented nanotubes by surface-selective atomic layer deposition. J. Mater. Chem. C 2013, 1, 621–625. [Google Scholar] [CrossRef]

- Irfan, M.; Wang, C.J.; Khan, U.; Li, W.J.; Zhang, X.M.; Kong, W.J.; Liu, P.; Wan, C.H.; Liu, Y.W.; Han, X.F. Controllable synthesis of ferromagnetic–antiferromagnetic core–shell NWs with tunable magnetic properties. Nanoscale 2017, 9, 5694–5700. [Google Scholar] [CrossRef]

- Chen, J.Y.; Ahmad, N.; Shi, D.W.; Zhou, W.P.; Han, X.F. Synthesis and magnetic characterization of Co-NiO-Ni core-shell nanotube arrays. J. Appl. Phys. 2011, 110, 73912. [Google Scholar] [CrossRef]

- Cisternas, E.; Vogel, E.E. Improving information storage by means of segmented magnetic nanowires. J. Magn. Magn. Mater. 2015, 388, 35–39. [Google Scholar] [CrossRef]

- Prida, V.M.; García, J.; Iglesias, L.; Vega, V.; Görlitz, D.; Nielsch, K.; Barriga-Castro, E.D.; Mendoza-Reséndez, R.; Ponce, A.; Luna, C. Electroplating and magnetostructural characterization of multisegmented Co54Ni46/Co85Ni15 nanowires from single electrochemical bath in anodic alumina templates. Nanoscale Res. Lett. 2013, 8, 263. [Google Scholar] [CrossRef]

- Berganza, E.; Jaafar, M.; Bran, C.; Fernández-Roldán, J.A.; Chubykalo-Fesenko, O.; Vázquez, M.; Asenjo, A. Multisegmented Nanowires: A Step towards the Control of the Domain Wall Configuration. Sci. Rep. 2017, 7, 11576. [Google Scholar] [CrossRef] [Green Version]

- Bran, C.; Angel Fernandez-Roldan, J.; del Real, R.P.; Asenjo, A.; Chubykalo-Fesenko, O.; Vazquez, M.; Estevez, G. Magnetic Configurations in Modulated Cylindrical Nanowires. Nanomaterials 2021, 11, 600. [Google Scholar] [CrossRef] [PubMed]

- Núñez, A.; Pérez, L.; Abuín, M.; Araujo, J.P.; Proenca, M.P. Magnetic behaviour of multisegmented FeCoCu/Cu electrodeposited nanowires. J. Phys. D. Appl. Phys. 2017, 50, 155003. [Google Scholar] [CrossRef]

- Sergelius, P.; Lee, J.H.; Fruchart, O.; Salem, M.S.; Allende, S.; Escobar, R.A.; Gooth, J.; Zierold, R.; Toussaint, J.-C.; Schneider, S.; et al. Intra-wire coupling in segmented Ni/Cu nanowires deposited by electrodeposition. Nanotechnology 2017, 28, 065709. [Google Scholar] [CrossRef] [Green Version]

- Moraes, S.; Navas, D.; Béron, F.; Proenca, M.P.; Pirota, K.R.; Sousa, C.T.; Araújo, J.P. The role of Cu length on the magnetic behaviour of Fe/Cu multi-segmented nanowires. Nanomaterials 2018, 8, 490. [Google Scholar] [CrossRef] [Green Version]

- Groß, F.; Ilse, S.E.; Schütz, G.; Gräfe, J.; Goering, E. Interpreting first-order reversal curves beyond the Preisach model: An experimental permalloy microarray investigation. Phys. Rev. B 2019, 99, 064401. [Google Scholar] [CrossRef] [Green Version]

- Pike, R. First-order reversal-curve diagrams and reversible magnetization. Phys. Rev. B—Condens. Matter Mater. Phys. 2003, 68, 1–5. [Google Scholar] [CrossRef] [Green Version]

- Salem, M.S.; Tejo, F.; Zierold, R.; Sergelius, P.; Moreno, J.M.M.; Goerlitz, D.; Nielsch, K.; Escrig, J. Composition and diameter modulation of magnetic nanowire arrays fabricated by a novel approach. Nanotechnology 2018, 29, 065602. [Google Scholar] [CrossRef]

- Reyes, D.; Biziere, N.; Warot-Fonrose, B.; Wade, T.; Gatel, C. Magnetic Configurations in Co/Cu Multilayered Nanowires: Evidence of Structural and Magnetic Interplay. Nano Lett. 2016, 16, 1230–1236. [Google Scholar] [CrossRef] [PubMed]

- Goertz, J.J.W.; Ziemys, G.; Eichwald, I.; Becherer, M.; Swagten, H.J.M.; Breitkreutz-v. Gamm, S. Domain wall depinning from notches using combined in- and out-of-plane magnetic fields. AIP Adv. 2016, 6, 056407. [Google Scholar] [CrossRef] [Green Version]

- Kim, K.-J.; Gim, G.-H.; Lee, J.-C.; Ahn, S.-M.; Lee, K.-S.; Cho, Y.J.; Lee, C.-W.; Seo, S.; Shin, K.-H.; Choe, S.-B. Depinning Field at Notches of Ferromagnetic Nanowires With Perpendicular Magnetic Anisotropy. IEEE Trans. Magn. 2009, 45, 4056–4058. [Google Scholar] [CrossRef]

- Atkinson, D.; Allwood, D.A.; Xiong, G.; Cooke, M.D.; Faulkner, C.C.; Cowburn, R.P. Magnetic domain-wall dynamics in a submicrometre ferromagnetic structure. Nat. Mater. 2003, 2, 85–87. [Google Scholar] [CrossRef] [PubMed]

- Nasirpouri, F.; Peighambari-Sattari, S.M.; Bran, C.; Palmero, E.M.; Berganza Eguiarte, E.; Vazquez, M.; Patsopoulos, A.; Kechrakos, D. Geometrically designed domain wall trap in tri-segmented nickel magnetic nanowires for spintronics devices. Sci. Rep. 2019, 9, 1–11. [Google Scholar] [CrossRef]

- Bran, C.; Berganza, E.; Palmero, E.M.; Fernandez-Roldan, J.A.; Del Real, R.P.; Aballe, L.; Foerster, M.; Asenjo, A.; Fraile Rodríguez, A.; Vazquez, M. Spin configuration of cylindrical bamboo-like magnetic nanowires. J. Mater. Chem. C 2016, 4, 978–984. [Google Scholar] [CrossRef]

- Iglesias-Freire, Ó.; Bran, C.; Berganza, E.; Mínguez-Bacho, I.; Magén, C.; Vázquez, M.; Asenjo, A. Spin configuration in isolated FeCoCu nanowires modulated in diameter. Nanotechnology 2015, 26, 395702. [Google Scholar] [CrossRef]

- Van Thiem, L.; Tu, T.L.; Phan, M.-H. Magnetization Reversal and Magnetic Anisotropy in Ordered CoNiP Nanowire Arrays: Effects of Wire Diameter. Sensors 2015, 15, 5687–5696. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bran, C.; Palmero, E.M.; Li, Z.-A.; del Real, R.P.; Spasova, M.; Farle, M.; Vázquez, M. Correlation between structure and magnetic properties in CoxFe100−x nanowires: The roles of composition and wire diameter. J. Phys. D. Appl. Phys. 2015, 48, 145304. [Google Scholar] [CrossRef]

- Salem, M.S.; Sergelius, P.; Corona, R.M.; Escrig, J.; Görlitz, D.; Nielsch, K.; Gorlitz, D.; Nielsch, K. Magnetic properties of cylindrical diameter modulated Ni 80Fe20 nanowires: Interaction and coercive fields. Nanoscale 2013, 5, 3941–3947. [Google Scholar] [CrossRef] [PubMed]

- Prida, V.M.; Salaheldeen, M.; Pfitzer, G.; Hidalgo, A.; Vega, V.; González, S.; Teixeira, J.M.; Fernández, A.; Hernando, B. Template Assisted Deposition of Ferromagnetic Nanostructures: From Antidot Thin Films to Multisegmented Nanowires. Acta Phys. Pol. A 2017, 131, 822–827. [Google Scholar] [CrossRef]

- Vega, V.; García, J.; Montero-Moreno, J.M.; Hernando, B.; Bachmann, J.; Prida, V.M.; Nielsch, K. Unveiling the Hard Anodization Regime of Aluminum: Insight into Nanopores Self-Organization and Growth Mechanism. ACS Appl. Mater. Interfaces 2015, 7, 28682–28692. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, W.; Ji, R.; Gösele, U.; Nielsch, K. Fast fabrication of long-range ordered porous alumina membranes by hard anodization. Nat. Mater. 2006, 5, 741–747. [Google Scholar] [CrossRef]

- Vega, V.; Böhnert, T.; Martens, S.; Waleczek, M.; Montero-Moreno, J.M.; Görlitz, D.; Prida, V.M.; Nielsch, K. Tuning the magnetic anisotropy of Co–Ni nanowires: Comparison between single nanowires and nanowire arrays in hard-anodic aluminum oxide membranes. Nanotechnology 2012, 23, 465709. [Google Scholar] [CrossRef]

- Bachmann, J.; Zierold, R.; Chong, Y.T.; Hauert, R.; Sturm, C.; Schmidt-Grund, R.; Rheinländer, B.; Grundmann, M.; Gösele, U.; Nielsch, K. A Practical, Self-Catalytic, Atomic Layer Deposition of Silicon Dioxide. Angew. Chemie Int. Ed. 2008, 47, 6177–6179. [Google Scholar] [CrossRef]

- Dobrotă, C.-I.; Stancu, A. Tracking the individual magnetic wires’ switchings in ferromagnetic nanowire arrays using the first-order reversal curves (FORC) diagram method. Phys. B Condens. Matter 2015, 457, 280–286. [Google Scholar] [CrossRef]

- Ruta, S.; Hovorka, O.; Huang, P.W.; Wang, K.; Ju, G.; Chantrell, R. First order reversal curves and intrinsic parameter determination for magnetic materials; Limitations of hysteron-based approaches in correlated systems. Sci. Rep. 2017, 7, 45218. [Google Scholar] [CrossRef]

- Vansteenkiste, A.; Van De Wiele, B. MuMax A new high-performance micromagnetic simulation tool. J. Magn. Magn. Mater. 2011, 323, 2585–2591. [Google Scholar] [CrossRef] [Green Version]

- Viñas, S.L.; Salikhov, R.; Bran, C.; Palmero, E.M.; Vazquez, M.; Arvan, B.; Yao, X.; Toson, P.; Fidler, J.; Spasova, M.; et al. Magnetic hardening of Fe 30 Co 70 nanowires. Nanotechnology 2015, 26, 415704. [Google Scholar] [CrossRef] [PubMed]

- Fernandez-Roldan, J.A.; Ivanov, Y.P.; Chubykalo-Fesenko, O. Micromagnetic Modeling of Magnetic Domain Walls and Domains in Cylindrical Nanowires. In Magnetic Nano—Microwires; Woodhead Publishing: Sawston, UK, 2020; pp. 403–426. [Google Scholar] [CrossRef]

- Fernandez-Roldan, J.; Perez del Real, R.; Bran, C.; Vazquez, M.; Chubykalo-Fesenko, O. Magnetization pinning in modulated nanowires: From topological protection to the “corkscrew” mechanism. Nanoscale 2018, 10, 5923–5927. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Vázquez, M.; Vivas, L.G. Magnetization reversal in Co-base nanowire arrays. Phys. Status Solidi 2011, 248, 2368–2381. [Google Scholar] [CrossRef] [Green Version]

- Raposo, V.; Zazo, M.; Flores, A.G.; Garcia, J.; Vega, V.; Iñiguez, J.; Prida, V.M. Ferromagnetic resonance in low interacting permalloy nanowire arrays. J. Appl. Phys. 2016, 119, 143903. [Google Scholar] [CrossRef]

- Berganza, E.; Bran, C.; Jaafar, M.; Vázquez, M.; Asenjo, A. Domain wall pinning in FeCoCu bamboo-like nanowires. Sci. Rep. 2016, 6, 29702. [Google Scholar] [CrossRef] [PubMed]

- Berganza, E.; Marqués-Marchán, J.; Bran, C.; Vazquez, M.; Asenjo, A.; Jaafar, M. Evidence of Skyrmion-Tube Mediated Magnetization Reversal in Modulated Nanowires. Materials 2021, 14, 5671. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

García, J.; Fernández-Roldán, J.A.; González, R.; Méndez, M.; Bran, C.; Vega, V.; González, S.; Vázquez, M.; Prida, V.M. Narrow Segment Driven Multistep Magnetization Reversal Process in Sharp Diameter Modulated Fe67Co33 Nanowires. Nanomaterials 2021, 11, 3077. https://0-doi-org.brum.beds.ac.uk/10.3390/nano11113077

García J, Fernández-Roldán JA, González R, Méndez M, Bran C, Vega V, González S, Vázquez M, Prida VM. Narrow Segment Driven Multistep Magnetization Reversal Process in Sharp Diameter Modulated Fe67Co33 Nanowires. Nanomaterials. 2021; 11(11):3077. https://0-doi-org.brum.beds.ac.uk/10.3390/nano11113077

Chicago/Turabian StyleGarcía, Javier, Jose A. Fernández-Roldán, Roque González, Miguel Méndez, Cristina Bran, Víctor Vega, Silvia González, Manuel Vázquez, and Víctor M. Prida. 2021. "Narrow Segment Driven Multistep Magnetization Reversal Process in Sharp Diameter Modulated Fe67Co33 Nanowires" Nanomaterials 11, no. 11: 3077. https://0-doi-org.brum.beds.ac.uk/10.3390/nano11113077