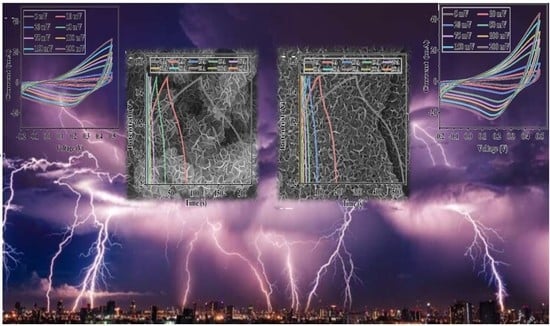

Electrodeposition of CoxNiVyOz Ternary Nanopetals on Bare and rGO-Coated Nickel Foam for High-Performance Supercapacitor Application

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals

2.2. Material Characterization

2.3. Electrochemical Instruments and Measurement

2.4. Electrochemical Deposition of CoxNiVyOz Nanocomposite on Bare Ni Foam and Ni foam@rGO

2.4.1. Preparation of Ni Foam Substrate

2.4.2. Preparation of the rGO-Coated Ni Foam (Ni foam@rGO) Substrate

2.4.3. Electrodeposition of Nanocomposite on Bare and rGO-Coated Ni Foam Substrates

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Abdallah, L.; El-Shennawy, T. Reducing Carbon Dioxide Emissions from Electricity Sector Using Smart Electric Grid Applications. J. Eng. 2013, 2013, 845051. [Google Scholar] [CrossRef] [Green Version]

- Abbas, Q.; Mirzaeian, M.; Hunt, M.R.C.; Hall, P.; Raza, R. Current State and Future Prospects for Electrochemical Energy Storage and Conversion Systems. Energies 2020, 13, 5847. [Google Scholar] [CrossRef]

- Luo, X.; Wang, J.; Dooner, M.; Clarke, J. Overview of current development in electrical energy storage technologies and the application potential in power system operation. Appl. Energy 2015, 137, 511–536. [Google Scholar] [CrossRef] [Green Version]

- Yang, S.; Cho, K.; Kim, S. Energy devices generating and storing electricity from finger and solar thermal energy. Nano Energy 2020, 69, 104458. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, F.; Yu, M.; Zhuang, X.; Feng, X. Two-dimensional materials for miniaturized energy storage devices: From individual devices to smart integrated systems. Chem. Soc. Rev. 2018, 47, 7426–7451. [Google Scholar] [CrossRef] [Green Version]

- Kumaravel, V.; Bartlett, J.; Pillai, S.C. Solid Electrolytes for High-Temperature Stable Batteries and Supercapacitors. Adv. Energy Mater. 2021, 11, 2002869. [Google Scholar] [CrossRef]

- Dubal, D.P.; Ayyad, O.; Ruiz, V.; Gómez-Romero, P. Hybrid energy storage: The merging of battery and supercapacitor chemistries. Chem. Soc. Rev. 2015, 44, 1777–1790. [Google Scholar] [CrossRef]

- Panda, P.K.; Grigoriev, A.; Mishra, Y.K.; Ahuja, R. Progress in supercapacitors: Roles of two dimensional nanotubular materials. Nanoscale Adv. 2020, 2, 70–108. [Google Scholar] [CrossRef] [Green Version]

- Nie, G.; Zhao, X.; Jiang, J.; Luan, Y.; Shi, J.; Liu, J.; Kou, Z.; Wang, J.; Long, Y.-Z. Flexible supercapacitor of high areal performance with vanadium/cobalt oxides on carbon nanofibers as a binder-free membrane electrode. Chem. Eng. J. 2020, 402, 126294. [Google Scholar] [CrossRef]

- Liu, W.; Niu, H.; Yang, J.; Cheng, K.; Ye, K.; Zhu, K.; Wang, G.; Cao, D.; Yan, J. Ternary Transition Metal Sulfides Embedded in Graphene Nanosheets as Both the Anode and Cathode for High-Performance Asymmetric Supercapacitors. Chem. Mater. 2018, 30, 1055–1068. [Google Scholar] [CrossRef]

- Chen, D.; Wang, Q.; Wang, R.; Shen, G. Ternary oxide nanostructured materials for supercapacitors: A review. J. Mater. Chem. A 2015, 3, 10158–10173. [Google Scholar] [CrossRef]

- Mohd Abdah, M.A.A.; Azman, N.H.N.; Kulandaivalu, S.; Sulaiman, Y. Review of the use of transition-metal-oxide and conducting polymer-based fibres for high-performance supercapacitors. Mater. Des. 2020, 186, 108199. [Google Scholar] [CrossRef]

- Minakshi, M.; Higley, S.; Baur, C.; Mitchell, D.R.G.; Jones, R.T.; Fichtner, M. Calcined chicken eggshell electrode for battery and supercapacitor applications. RSC Adv. 2019, 9, 26981–26995. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cui, M.; Meng, X. Overview of transition metal-based composite materials for supercapacitor electrodes. Nanoscale Adv. 2020, 2, 5516–5528. [Google Scholar] [CrossRef]

- Wang, P.; Ding, X.; Zhe, R.; Zhu, T.; Qing, C.; Liu, Y.; Wang, H. -E. Synchronous Defect and Interface Engineering of NiMoO4 Nanowire Arrays for High-Performance Supercapacitors. Nanomaterials 2022, 12, 1094. [Google Scholar] [CrossRef]

- Liu, L.; Zhao, H.; Le, Y. Advances on three-dimensional electrodes for micro-supercapacitors: A mini-review. InfoMat 2019, 1, 74–84. [Google Scholar] [CrossRef] [Green Version]

- Chu, X.; Meng, F.; Zhang, W.; Yang, H.; Zou, X.; Molin, S.; Jasinski, P.; Sun, X.; Zheng, W. A dual-control strategy based on electrode material and electrolyte optimization to construct an asymmetric supercapacitor with high energy density. Nanotechnology 2022, 33, 205403. [Google Scholar] [CrossRef]

- Hai Alami, A.; Aokal, K.; Faraj, M. Investigating nickel foam as photoanode substrate for potential dye-sensitized solar cells applications. Energy 2020, 11, 118689. [Google Scholar] [CrossRef]

- Zhang, Y.; Xia, X.; Liu, B.; Deng, S.; Xie, D.; Liu, Q.; Wang, Y.; Wu, J.; Wang, X.; Tu, J. Multiscale Graphene-Based Materials for Applications in Sodium Ion Batteries. Adv. Energy Mater. 2019, 9, 1803342. [Google Scholar] [CrossRef]

- Li, W.; Yang, Y.J. The reduction of graphene oxide by elemental copper and its application in the fabrication of graphene supercapacitor. J. Solid State Electrochem. 2014, 18, 1621–1626. [Google Scholar] [CrossRef]

- Wang, S.; Liu, N.; Su, J.; Li, L.; Long, F.; Zou, Z.; Jiang, X.; Gao, Y. Highly Stretchable and Self-Healable Supercapacitor with Reduced Graphene Oxide Based Fiber Springs. ACS Nano 2017, 11, 2066–2074. [Google Scholar] [CrossRef] [PubMed]

- Li, F.; Jiang, X.; Zhao, J.; Zhang, S. Graphene oxide: A promising nanomaterial for energy and environmental applications. Nano Energy 2015, 16, 488–515. [Google Scholar] [CrossRef] [Green Version]

- Choi, S.; Kim, C.; Suh, J.M.; Jang, H.W. Reduced graphene oxide-based materials for electrochemical energy conversion reactions. Carbon Energy 2019, 1, 85–108. [Google Scholar] [CrossRef] [Green Version]

- Wickramaarachchi, K.; Minakshi, M. Consequences of electrodeposition parameters on the microstructure and electrochemical behavior of electrolytic manganese dioxide (EMD) for supercapacitor. Ceram. Int. 2022, 48, 19913–19924. [Google Scholar] [CrossRef]

- Biswal, A.; Panda, P.K.; Acharya, A.N.; Mohapatra, S.; Swain, N.; Tripathy, B.C.; Jiang, Z.-T.; Sundaram, M.M. Role of Additives in Electrochemical Deposition of Ternary Metal Oxide Microspheres for Supercapacitor Applications. ACS Omega 2020, 5, 3405–3417. [Google Scholar] [CrossRef]

- Minakshi, M.; Schneider, P.A.; Ahuja, R. Suitable Electrode Materials for Hybrid Capacitors. Next-Generation Materials for Batteries; AIP Publishing LLC: New York, NY, USA, 2021; Chapter 10; pp. 1–30. [Google Scholar]

- Biswal, A.; Panda, P.K.; Acharya, A.N.; Tripathy, B.C.; Alenazey, F.; Jiang, Z.-T.; Sundaram, M.M. Tuning the morphology and redox behaviour by varying the concentration of Fe in a CoNiFe ternary oxide heterostructure for hybrid devices. New J. Chem. 2020, 44, 9921–9932. [Google Scholar] [CrossRef]

- Huang, Z.-H.; Sun, F.-F.; Batmunkh, M.; Li, W.-H.; Li, H.; Sun, Y.; Zhao, Q.; Liu, X.; Ma, T.Y. Zinc–nickel–cobalt ternary hydroxide nanoarrays for high-performance supercapacitors. J. Mater. Chem. A 2019, 7, 11826–11835. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhao, B.; Wang, J.; Qu, C.; Sun, H.; Zhang, K.; Liu, M. High-performance hybrid supercapacitors based on self-supported 3D ultrathin porous quaternary Zn-Ni-Al-Co oxide nanosheets. Nano Energy 2016, 28, 475–485. [Google Scholar] [CrossRef] [Green Version]

- Vidhya, M.S.; Ravi, G.; Yuvakkumar, R.; Velauthapillai, D.; Thambidurai, M.; Dang, C.; Saravanakumar, B. Nickel–cobalt hydroxide: A positive electrode for supercapacitor applications. RSC Adv. 2020, 10, 19410–19418. [Google Scholar] [CrossRef]

- Yang, L.; Lu, X.; Wang, S.; Wang, J.; Guan, X.; Guan, X.; Wang, G. Designed synthesis of nickel–cobalt-based electrode materials for high-performance solid-state hybrid supercapacitors. Nanoscale 2020, 12, 1921–1938. [Google Scholar] [CrossRef]

- Shahrokhian, S.; Rahimi, S.; Mohammadi, R. Nickel-cobalt layered double hydroxide ultrathin nanosheets coated on reduced graphene oxide nonosheets/nickel foam for high performance asymmetric supercapacitors. Int. J. Hydrogen Energy 2018, 43, 2256–2267. [Google Scholar] [CrossRef]

- Chen, H.; Hu, L.; Chen, M.; Yan, Y.; Wu, L. Nickel–Cobalt Layered Double Hydroxide Nanosheets for High-performance Supercapacitor Electrode Materials. Adv. Funct. Mater. 2014, 24, 934–942. [Google Scholar] [CrossRef]

- Lee, S.C.; Kim, M.; Park, J.-H.; Kim, E.S.; Liu, S.; Chung, K.Y.; Jun, S.C. An unexpected phase-transformation of cobalt–vanadium layered double hydroxides toward high energy density hybrid supercapacitor. J. Power Sources 2021, 486, 229341. [Google Scholar] [CrossRef]

- Jing, C.; Huang, Y.; Xia, L.; Chen, Y.; Wang, X.; Liu, X.; Dong, B.; Dong, F.; Li, S.; Zhang, Y. Growth of cobalt-aluminum layered double hydroxide nanosheets on graphene oxide towards high performance supercapacitors: The important role of layer structure. Appl. Surf. Sci. 2019, 496, 143700. [Google Scholar] [CrossRef]

- Wu, C.; Zhu, Y.; Guan, C.; Jia, C.; Qin, W.; Wang, X.; Zhang, K. Mesoporous aluminium manganese cobalt oxide with pentahedron structures for energy storage devices. J. Mater. Chem. A 2019, 7, 18417–18427. [Google Scholar] [CrossRef]

- Du, Y.; Li, G.; Chen, M.; Yang, X.; Ye, L.; Liu, X.; Zhao, L. Hollow nickel-cobalt-manganese hydroxide polyhedra via MOF templates for high-performance quasi-solid-state supercapacitor. Chem. Eng. J. 2019, 378, 122210. [Google Scholar] [CrossRef]

- Song, L.; Du, J.; Xiao, Z.; Jiang, P.; Cao, Z.; Zhu, H. Research Progress on the Surface of High-Nickel Nickel–Cobalt Manganese Ternary Cathode Materials: A Mini Review. Front. Chem. 2020, 8, 761. [Google Scholar] [CrossRef]

- Zaaba, N.I.; Foo, K.L.; Hashim, U.; Tan, S.J.; Liu, W.-W.; Voon, C.H. Synthesis of Graphene Oxide using Modified Hummers Method: Solvent Influence. Procedia Eng. 2017, 184, 469–477. [Google Scholar] [CrossRef]

- Hummers, W.S.; Offeman, R.E. Preparation of Graphitic Oxide. J. Am. Chem. Soc. 1958, 80, 1339. [Google Scholar] [CrossRef]

- Pei, S.; Cheng, H.-M. The reduction of graphene oxide. Carbon 2012, 50, 3210–3228. [Google Scholar] [CrossRef]

- Zhu, J.; Xiao, X.; Zheng, K.; Li, F.; Ma, G.; Yao, H.-C.; Wang, X.; Chen, Y. KOH-treated reduced graphene oxide: 100% selectivity for H2O2 electroproduction. Carbon 2019, 153, 6–11. [Google Scholar] [CrossRef]

- Aragaw, B.A. Reduced graphene oxide-intercalated graphene oxide nano-hybrid for enhanced photoelectrochemical water reduction. J. Nanostruct. Chem. 2020, 10, 9–18. [Google Scholar] [CrossRef] [Green Version]

- Zhao, B.; Song, J.; Liu, P.; Xu, W.; Fang, T.; Jiao, Z.; Zhang, H.; Jiang, Y. Monolayer graphene/NiO nanosheets with two-dimension structure for supercapacitors. J. Mater. Chem. 2011, 21, 18792–18798. [Google Scholar] [CrossRef]

- Yousefi, R.; Cheraghizade, M. Chapter 2—Semiconductor/Graphene Nanocomposites: Synthesis, Characterization, and Applications. In Applications of Nanomaterials; Mohan Bhagyaraj, S., Oluwafemi, O.S., Kalarikkal, N., Thomas, S., Eds.; Woodhead Publishing: Cambridge, UK, 2018; pp. 23–43. [Google Scholar]

- Stobinski, L.; Lesiak-Orłowska, B.; Małolepszy, A.; Mazurkiewicz-Pawlicka, M.; Mierzwa, B.; Zemek, J.; Jiricek, P.; Bieloshapka, I. Graphene oxide and reduced graphene oxide studied by the XRD, TEM and electron spectroscopy methods. J. Electron Spectrosc. Relat. Phenom. 2014, 195, 145–154. [Google Scholar] [CrossRef]

- Tian, W.; Zhang, H.; Zhang, Y.; Wang, Y.; Cao, J. Enhanced triethylamine sensing performance of superfine NiO nanoparticles decoration by two-dimensional hexagonal boron nitride. Adv. Powder Technol. 2021, 32, 3801–3813. [Google Scholar] [CrossRef]

- Wang, S.; Lai, S.; Li, P.; Gao, T.; Sun, K.; Ding, X.; Xie, T.; Wu, C.; Li, X.; Kuang, Y.; et al. Hierarchical cobalt oxide@Nickel-vanadium layer double hydroxide core/shell nanowire arrays with enhanced areal specific capacity for nickel–zinc batteries. J. Power Sources 2019, 436, 226867. [Google Scholar] [CrossRef]

- Fan, J.; Guerrero, M.; Carretero-Genevrier, A.; Baró, M.D.; Suriñach, S.; Pellicer, E.; Sort, J. Evaporation-induced self-assembly synthesis of Ni-doped mesoporous SnO2 thin films with tunable room temperature magnetic properties. J. Mater. Chem. C 2017, 5, 5517–5527. [Google Scholar] [CrossRef] [Green Version]

- Chen, S.; Yang, G.; Jia, Y.; Zheng, H. Three-dimensional NiCo2O4@NiWO4 core–shell nanowire arrays for high performance supercapacitors. J. Mater. Chem. A 2017, 5, 1028–1034. [Google Scholar] [CrossRef]

- Zhang, D.; Li, G.; Li, B.; Fan, J.; Chen, D.; Liu, X.; Li, L. Fast synthesis of Co1.8V1.2O4/rGO as a high-rate anode material for lithium-ion batteries. Chem. Commun. 2018, 54, 7689–7692. [Google Scholar] [CrossRef]

- Mahmood, N.; De Castro, I.A.; Pramoda, K.; Khoshmanesh, K.; Bhargava, S.K.; Kalantar-Zadeh, K. Atomically thin two-dimensional metal oxide nanosheets and their heterostructures for energy storage. Energy Storage Mater. 2019, 16, 455–480. [Google Scholar] [CrossRef]

- Cheraghizade, M.; Jamali-Sheini, F. Symmetric strain- and temperature-dependent optoelectronics performance of TiO2/SnS/Ag solar cell. Surf. Interfaces 2021, 25, 101223. [Google Scholar] [CrossRef]

- Zamani, M.; Jamali-Sheini, F.; Cheraghizade, M. Visible-range and self-powered bilayer p-Si/n-Bi2S3 heterojunction photodetector: The effect of Au buffer layer on the optoelectronics performance. J. Alloy. Compd. 2022, 905, 164119. [Google Scholar] [CrossRef]

- Wang, C.; Sun, P.; Qu, G.; Yin, J.; Xu, X. Nickel/cobalt based materials for supercapacitors. Chin. Chem. Lett. 2018, 29, 1731–1740. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Mohapatra, D.; Kumar, D.R.; Baynosa, M.; Sahoo, S.; Lee, J.; Shim, J.J. Direct growth of nickel cobalt layered double hydroxide on nickel foam via redox reaction between nitrate ion and ethanol for hybrid supercapacitors. Electrochim. Acta 2021, 367, 137226. [Google Scholar] [CrossRef]

- Oyedotun, K.O.; Masikhwa, T.M.; Mirghni, A.A.; Mutuma, B.K.; Manyala, N. Electrochemical properties of asymmetric supercapacitor based on optimized carbon-based nickel-cobalt-manganese ternary hydroxide and sulphur-doped carbonized iron-polyaniline electrodes. Electrochim. Acta 2020, 334, 135610. [Google Scholar] [CrossRef]

- Wang, J.; Zheng, F.; Yu, Y.; Hu, P.; Li, M.; Wang, J.; Fu, J.; Zhen, Q.; Bashir, S.; Liu, J.L. Symmetric supercapacitors composed of ternary metal oxides (NiO/V2O5/MnO2) nanoribbon electrodes with high energy storage performance. Chem. Eng. J. 2021, 426, 131804. [Google Scholar] [CrossRef]

- Shi, W.; Hu, B.; Zhang, H.; Li, J.; Yang, J.; Liu, J. Carbon-Encapsulated Iron Oxide Nanoparticles in Self-Supporting Carbon Nanofiber for High-Performance Supercapacitor in Acid Electrolyte with Superior Stability. ACS Appl. Energy Mater. 2020, 3, 12652–12661. [Google Scholar] [CrossRef]

- Seyed-Talebi, S.M.; Kazeminezhad, I.; Motamedi, H. TiO2 hollow spheres as a novel antibiotic carrier for the direct delivery of gentamicin. Ceram. Int. 2018, 44, 13457–13462. [Google Scholar] [CrossRef]

- Seyed-Talebi, S.M.; Kazeminezhad, I.; Nematpour, M. Synthesis and characterization of Ag@Carbon core-shell spheres as a novel catalyst for room temperature N-arylation reaction. J. Catal. 2018, 361, 339–346. [Google Scholar] [CrossRef]

- Guimond, S.; Abu Haija, M.; Kaya, S.; Lu, J.; Weissenrieder, J.; Shaikhutdinov, S.; Kuhlenbeck, H.; Freund, H.-J.; Döbler, J.; Sauer, J. Vanadium oxide surfaces and supported vanadium oxide nanoparticles. Top. Catal. 2006, 38, 117–125. [Google Scholar] [CrossRef]

- Dubal, D.P.; Jagadale, A.D.; Patil, S.V.; Lokhande, C.D. Simple route for the synthesis of supercapacitive Co–Ni mixed hydroxide thin films. Mater. Res. Bull. 2012, 47, 1239–1245. [Google Scholar] [CrossRef]

- Xu, Y.; Han, X.; Zheng, L.; Wei, S.; Xie, Y. First investigation on charge-discharge reaction mechanism of aqueous lithium ion batteries: A new anode material of Ag2V4O11 nanobelts. Dalton Trans. 2011, 40, 10751–10757. [Google Scholar] [CrossRef] [PubMed]

- Kubra, K.T.; Javaid, A.; Sharif, R.; Ali, G.; Iqbal, F.; Salman, A.; Shaheen, F.; Butt, A.; Iftikhar, F.J. Facile synthesis and electrochemical study of a ternary hybrid PANI/GNP/MnO2 as supercapacitor electrode material. J. Mater. Sci. Mater. Electron. 2020, 31, 12455–12466. [Google Scholar] [CrossRef]

- Sarawutanuku, S.; Phattharasupakun, N.; Wutthiproma, J.; Sawangphruk, M. Oxidative chemical vapour deposition of a graphene oxide carbocatalyst on 3D nickel foam as a collaborative electrocatalyst towards the hydrogen evolution reaction in acidic electrolyte. Sustain. Energy Fuels 2018, 2, 1305–1311. [Google Scholar] [CrossRef]

- Zhang, S.; Li, Y.; Pan, N. Graphene based supercapacitor fabricated by vacuum filtration deposition. J. Power Sources 2012, 206, 476–482. [Google Scholar] [CrossRef]

- Wang, H.; Shi, X.; Zhang, W.; Yao, S. One-pot hydrothermal synthesis of flower-like -Ni(OH)2 encapsulated by reduced graphene oxide for high-performance supercapacitors. J. Alloy. Compd. 2017, 711, 643–651. [Google Scholar] [CrossRef]

- Liu, S.; Yin, Y.; Hui, K.S.; Hui, K.N.; Lee, S.C.; Jun, S.C. Nickel hydroxide/chemical vapor deposition-grown graphene/nickel hydroxide/nickel foam hybrid electrode for high performance supercapacitors. Electrochim. Acta 2019, 297, 479–487. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Xu, C.; Zhang, D. A three-dimensional electrode fabricated by electrophoretic deposition of graphene on nickel foam for structural supercapacitors. New J. Chem. 2021, 45, 18567–18574. [Google Scholar] [CrossRef]

- Beidaghi, M.; Wang, C. Micro-Supercapacitors Based on Interdigital Electrodes of Reduced Graphene Oxide and Carbon Nanotube Composites with Ultrahigh Power Handling Performance. Adv. Funct. Mater. 2012, 22, 4501–4510. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, W.; Guo, X.; Jin, K.; Chen, Z.; Liu, Y.; Yin, L.; Li, L.; Yin, K.; Sun, L.; et al. Ni-Co Selenide Nanosheet/3D Graphene/Nickel Foam Binder-Free Electrode for High-Performance Supercapacitor. ACS Appl. Mater. Interfaces 2019, 11, 7946–7953. [Google Scholar] [CrossRef]

- Chuminjak, Y.; Singjai, P.; Tuantranont, A.; Sriprachuabwong, C.; Wisitsoraat, A. High-capacity charge storage electrodes based on nickel oxide and nickel–cobalt double hydroxide nanocomposites on 3D nickel foam prepared by sparking and electrodeposition. J. Alloy. Compd. 2020, 841, 155793. [Google Scholar] [CrossRef]

- Yu, M.; Chen, J.; Liu, J.; Li, S.; Ma, Y.; Zhang, J.; An, J. Mesoporous NiCo2O4 nanoneedles grown on 3D graphene-nickel foam for supercapacitor and methanol electro-oxidation. Electrochim. Acta 2015, 151, 99–108. [Google Scholar] [CrossRef]

- Dharmadasaz, I.M.; Haigh, J. Strengths and Advantages of Electrodeposition as a Semiconductor Growth Technique for Applications in Macroelectronic Devices. J. Electrochem. Soc. 2006, 153, G47–G52. [Google Scholar] [CrossRef]

- Liu, D.; Wang, Q.; Qiao, L.; Li, F.; Wang, D.; Yang, Z.; He, D. Preparation of nano-networks of MnO2 shell/Ni current collector core for high-performance super-capacitor electrodes. J. Mater. Chem. 2012, 22, 483–487. [Google Scholar] [CrossRef]

- Minga, Z.; Yana, C.; Dingyua, Y.; Jitao, L. High performance MnO2 supercapacitor material prepared by modified electrodeposition method with different electrodeposition voltages. J. Energy Storage 2020, 29, 101363. [Google Scholar]

- Jokar, E.; Irajizad, A.; Shahrokhian, S. Growth control of cobalt oxide nanoparticles on reduced graphene oxide for enhancement of electrochemical capacitance. Int. J. Hydrogen Energy 2014, 39, 21068–21075. [Google Scholar] [CrossRef]

- Bi, W.; Wang, J.; Jahrman, E.P.; Seidler, G.T.; Gao, G.; Wu, G.; Cao, G. Interface Engineering V2O5 Nanofibers for High-Energy and Durable Supercapacitors. Small 2019, 15, 1901747. [Google Scholar] [CrossRef]

- Li, L.; Zhang, Y.; Shi, F.; Zhang, Y.; Zhang, J.; Gu, C.; Wang, X.; Tu, J. Spinel Manganese–Nickel–Cobalt Ternary Oxide Nanowire Array for High-Performance Electrochemical Capacitor Applications. ACS Appl. Mater. Interfaces 2014, 6, 18040–18047. [Google Scholar] [CrossRef]

- Amir, A.; Ahmad, A.; Khan, Y.; Rehman, Z.; Ain, N.U.; Shah, S.K.; Mehmood, M.; Zaman, B. Electrodeposited thick coatings of V2O5 on Ni foam as binder free electrodes for supercapacitors. Bull. Mater. Sci. 2020, 43, 273. [Google Scholar] [CrossRef]

- Prusty, B.; Adhikary, M.C.; Das, C.K. Supercapacitor Electrode Material Based on Nickel Vanadium Oxide. Am. Chem. Sci. J. 2015, 6, 91–95. [Google Scholar] [CrossRef]

- Zeng, Z.; Xiao, B.; Zhu, X.; Zhu, J.; Xiao, D.; Zhu, J. Flower-like binary cobalt-nickel oxide with high performance for supercapacitor electrode via cathodic electrodeposition. Ceram. Int. 2017, 43, S633–S638. [Google Scholar] [CrossRef]

- Pramanik, A.; Maiti, S.; Mahanty, S. Reduced Graphene Oxide Anchored Cu(OH)2 as A High Performance Electrochemical Supercapacitor. Dalton Trans. 2015, 44, 14604–14612. [Google Scholar] [CrossRef] [PubMed]

| Sample Deposited On | Coulombic Efficiency (%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 2 A/g | 5 A/g | 10 A/g | 15 A/g | 20 A/g | 30 A/g | 50 A/g | 75 A/g | 100 A/g | 150 A/g | |

| Ni foam | 92 | 93 | 90 | 99 | 100 | 105 | 102 | 100 | 75 | 30 |

| Ni foam@rGO | 83 | 84 | 88 | 94 | 98 | 101 | 99 | 101 | 108 | 60 |

| Electrode Materials | Synthesis/Deposition Method | Specific Capacitance (F/g) | Current Density or Scan Rate (A/g) | Electrolyte | Ref. |

|---|---|---|---|---|---|

| MnO2 | Layer by layer/electrodeposition | 304.00 | 2 A/g | 1 M Na2SO4 | [76] |

| MnO2 | electrodeposition | 469.00 | 1 A/g | 1 M Na2SO4 | [77] |

| Co3O4/rGO | Hydrothermal | 440.40 | 5 A/g | 2 M KOH | [78] |

| Vö-V2O5 nano-Fiber | polymerization process of poly-aniline (PANI) | 523.00 | 0.5 A/g | 1 M Na2SO4 | [79] |

| Mn-Ni-Co oxide | Hydrothermal | 638.00 | 1 A/g | 6 M KOH | [80] |

| V2O5 | Electrodeposition | 421.00 | 1 A/g | 0.1 M H2SO4 | [81] |

| Nickel Vanadium Oxide | Hydrothermal | 297.00 | 3 A/g | 1 M LiCl | [82] |

| Co3O4-NiO | Electrodeposition | 687.00 | 0.5 A/g | 2 M KOH | [83] |

| Cu(OH)2@rGO | Hydrothermal | 602 | 2 A/g | 6 M KOH | [84] |

| CoxNiVyOz | Electrodeposition | 701.08 | 1 A/g | 1 M KOH | This Work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Seyed-Talebi, S.M.; Cheraghizade, M.; Beheshtian, J.; Kuan, C.-H.; Diau, E.W.-G. Electrodeposition of CoxNiVyOz Ternary Nanopetals on Bare and rGO-Coated Nickel Foam for High-Performance Supercapacitor Application. Nanomaterials 2022, 12, 1894. https://0-doi-org.brum.beds.ac.uk/10.3390/nano12111894

Seyed-Talebi SM, Cheraghizade M, Beheshtian J, Kuan C-H, Diau EW-G. Electrodeposition of CoxNiVyOz Ternary Nanopetals on Bare and rGO-Coated Nickel Foam for High-Performance Supercapacitor Application. Nanomaterials. 2022; 12(11):1894. https://0-doi-org.brum.beds.ac.uk/10.3390/nano12111894

Chicago/Turabian StyleSeyed-Talebi, Seyedeh Mozhgan, Mohsen Cheraghizade, Javad Beheshtian, Chun-Hsiao Kuan, and Eric Wei-Guang Diau. 2022. "Electrodeposition of CoxNiVyOz Ternary Nanopetals on Bare and rGO-Coated Nickel Foam for High-Performance Supercapacitor Application" Nanomaterials 12, no. 11: 1894. https://0-doi-org.brum.beds.ac.uk/10.3390/nano12111894