Top-Emitting Active-Matrix Quantum Dot Light-Emitting Diode Array with Optical Microcavity for Micro QLED Display

Abstract

:1. Introduction

2. Experimental Section

2.1. Fabrication of TEQLED

2.2. Characterizations

3. Results and Discussion

3.1. Selection of Appropriate Type of QDs for AMQLED Array and Panel

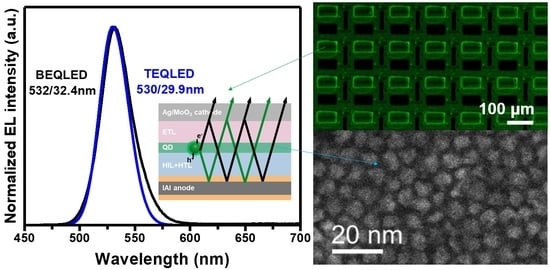

3.2. QLED with the Top-Emission Structure

3.3. Fabrication of Bottom Reflective Anode in the IAI Structure

3.4. Top Ag Cathode with MoO3 Capping Layer

3.5. Design of Optical Microcavity for TEQLEDs

3.6. QLED Array Fabricated on a 1.49 Inch LTPS-TFT Substrate for Micro Display

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, P.R.; Hoang, M.S.; Lai, K.Y.; Chen, H.S. Metal Oleate Treatment for Amine-capped InP QDs with Etching for Surface Oxidation. Nanomaterials 2022, 12, 573. [Google Scholar] [CrossRef] [PubMed]

- Yeh, C.W.; Wang, Y.K.; Wu, I.H.; Yang, Y.C.; Chen, P.R.; Chen, H.S. Large Stokes Shifts over Visible Infrared Wavelengths from Multicore/Shell Quantum Dots for Solar-Harvesting Applications. ACS Appl. Nano Mater. 2022, 5, 3572–3580. [Google Scholar] [CrossRef]

- Pagano, L.; Caldara, M.; Villani, M.; Zappettini, A.; Marmiroli, N.; Marmiroli, M. In Vivo-in Vitro Comparative Toxicology of Cadmium Sulphide Quantum Dots in The Model Organism Saccharomyces Cerevisiae. Nanomaterials 2019, 9, 512. [Google Scholar] [CrossRef] [Green Version]

- Mazumder, S.; Dey, R.; Mitra, M.K.; Mukherjee, S.; Das, G.C. Biofunctionalized Quantum Dots in Biology and Medicine. J. Nanomater. 2009, 815734. [Google Scholar] [CrossRef] [Green Version]

- Chen, H.; He, J.; Wu, S. Recent Advances on Quantum-Dot-Enhanced Liquid-Crystal Displays. IEEE J. Sel. Top. Quantum Electron. 2017, 23, 1–11. [Google Scholar] [CrossRef]

- Yeh, C.W.; Chen, G.H.; Ho, S.J.; Chen, H.S. Inhibiting the Surface Oxidation of Low-Cadmium-Content ZnS:(Cd,Se) Quantum Dots for Enhancing Application Reliability. ACS Appl. Nano Mater. 2019, 2, 5290–5301. [Google Scholar] [CrossRef]

- Kim, H.J.; Shin, M.H.; Lee, J.Y.; Kim, J.H.; Kim, Y.J. Realization of 95% of the Rec. 2020 Color Gamut in A Highly Efficient LCD using A Patterned Quantum Dot Film. Opt. Express. 2017, 25, 10724–10734. [Google Scholar] [CrossRef]

- Chen, G.H.; Yang, S.H.; Yeh, C.W.; Ho, S.J.; Liu, M.C.; Chen, H.S. Polycarbonate Light Guide Pates with Embedded Quantum Dots Fabricated by Large-Scale Injection Moulding for Wide Colour Gamut Displays. Mater. Des. 2021, 201, 109504. [Google Scholar] [CrossRef]

- Wu, T.; Sher, C.W.; Lin, Y.; Lee, C.F.; Liang, S.; Lu, Y.; Huang Chen, S.W.; Guo, W.; Kuo, H.C.; Chen, Z. Mini-LED and Micro-LED: Promising Candidates for the Next Generation Display Technology. Appl. Sci. 2018, 8, 1557. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.M.; Ryu, M.; Cha, J.H.J.; Kim, H.S.; Jeong, T.; Jang, J. Ten Micrometer Pixel, Quantum Dots Color Conversion Layer for High Resolution and Full Color Active Matrix Micro-LED Display. J. Soc. Inf. Disp. 2019, 27, 347–353. [Google Scholar] [CrossRef]

- Xuan, T.; Shi, S.; Wang, L.; Kuo, H.C.; Xie, R.J. Inkjet-Printed Quantum Dot Color Conversion Films for High-Resolution and Full-Color Micro Light-Emitting Diode Displays. J. Phys. Chem. Lett. 2020, 11, 5184–5191. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.S.; Wang, S.J.J.; Lo, C.J.; Chi, J.Y. White-Light Emission from Organics-Capped ZnSe Quantum Dots and Application in White-Light-Emitting Diodes. Appl. Phys. Lett. 2005, 86, 131905. [Google Scholar] [CrossRef] [Green Version]

- Jung, N.T.; Chen, P.R.; Ho, S.J.; Tung, C.C.; Chen, P.Y.; Chen, H.S. 3D Quantum Dot Lens Fabricated by Stereolithographic Printing with In-situ UV Curing for Lighting and displays. Composites Part B 2021, 226, 109350. [Google Scholar] [CrossRef]

- Chen, H.S.; Hong, H.Y.; Kumar, R.V. White Light Emission from Semiconductor Nanocrystals by In Situ Colour Tuning in An Alternating Thermodynamic–Kinetic Fashion. J. Mater. Chem. 2011, 21, 5928–5932. [Google Scholar] [CrossRef]

- Chen, G.H.; Yeh, C.W.; Yeh, M.H.; Ho, S.J.; Chen, H.S. Wide Gamut White Light Emitting Diodes using Quantum Dot-Silicone Film Protected by An Atomic Layer Deposited TiO2 Barrier. Chem. Commun. 2015, 51, 14750–14753. [Google Scholar] [CrossRef]

- Huang, S.C.; Yeh, C.W.; Chen, G.H.; Liu, M.C.; Chen, H.S. Investigation of Luminescence Enhancement and Decay of QD-LEDs: Interface Reactions between QDs and Atmospheres. ACS Appl. Mater. Interfaces 2019, 11, 2516–2525. [Google Scholar] [CrossRef]

- Ho, S.J.; Chen, H.S. Inverse μ-Photonic Crystals Enhanced the Features of Mini-Sized Quantum Dot LEDs. J. Mater. Chem. C 2020, 8, 4309–4313. [Google Scholar] [CrossRef]

- Colvin, V.L.; Schlamp, M.C.; Alivisatos, A.P. Light-Emitting Diodes Made from Cadmium Selenide Nanocrystals and A Semionducting Polymer. Nature 1994, 370, 354–357. [Google Scholar] [CrossRef]

- Mashford, B.S.; Stevenson, M.; Popovic, Z.; Hamilton, C.; Zhou, Z.; Breen, C.; Steckel, J.; Bulovic, V.; Bawendi, M.; Coe-Sullivan, S.; et al. High-Efficiency Quantum-Dot Light-Emitting Devices with Enhanced Charge Injection. Nat. Photonics 2013, 7, 407–412. [Google Scholar] [CrossRef]

- Chen, G.H.; Ho, S.J.; Chen, H.S. Cubic Zincblende ZnSe Nanowires with An Entangling Structure Grown via Oriented Attachment and Their Application in Organic–Inorganic Heterojunction Light-Emitting Diodes. J. Phys. Chem. C 2014, 118, 25816–25822. [Google Scholar] [CrossRef]

- Fu, Y.; Jiang, W.; Kim, D.; Lee, W.; Chae, H. Highly Efficient and Fully Solution-Processed Inverted Light-Emitting Diodes with Charge Control Interlayers. ACS Appl. Mater. Interfaces 2018, 10, 17295–17300. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Ye, Y.; Pu, C.; Deng, Y.; Dai, X.; Chen, X.; Chen, D.; Zheng, X.; Gao, Y.; Fang, W.; et al. High-Performance, Solution-Processed, and Insulating-Layer-Free Light-Emitting Diodes Based on Colloidal Quantum Dots. Adv. Mater. 2018, 30, 1801387. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.; Lai, K.Y.; Yeh, C.W.; Chen, P.R.; Ho, S.J.; Chen, H.S. Dual-Wavelength Electroluminescent QLEDs Composed of Mixed Alloyed Quantum Dots. ACS Appl. Nano Mater. 2020, 3, 8763–8770. [Google Scholar] [CrossRef]

- Kim, T.; Kim, K.H.; Kim, S.; Choi, S.M.; Jang, H.; Seo, H.K.; Lee, H.; Chung, D.Y.; Jang, E. Efficient and Stable Blue Quantum Dot Light-Emitting Diode. Nature 2020, 586, 385–389. [Google Scholar] [CrossRef]

- Huang, Y.; Xu, D.; Chen, S. P-9.1: Investigation of Electroluminescent Response of Quantum Dot Light-Emitting Diodes. SID Symp. Dig. Tech. Pap. 2018, 49, 656–659. [Google Scholar] [CrossRef]

- Manders, J.R.; Qian, L.; Titov, A.; Hyvonen, J.; Tokarz-Scott, J.; Acharya, K.P.; Yang, Y.; Cao, W.; Zheng, Y.; Xue, J.; et al. High Efficiency and Ultra-Wide Color Gamut Quantum Dot LEDs for Next Generation Displays. J. Soc. Inf. Disp. 2015, 23, 523–528. [Google Scholar] [CrossRef]

- Kang, Y.; Song, Z.; Jiang, X.; Yin, X.; Fang, L.; Gao, J.; Su, Y.; Zhao, F. Quantum Dots for Wide Color Gamut Displays from Photoluminescence to Electroluminescence. Nanoscale Res. Lett. 2017, 12, 154. [Google Scholar] [CrossRef] [Green Version]

- Ho, S.J.; Hsu, H.C.; Yeh, C.W.; Chen, H.S. Inkjet-Printed Salt-Encapsulated Quantum Dot Film for UV-Based RGB Color-Converted Micro-Light Emitting Diode Displays. ACS Appl. Mater. Interfaces 2020, 12, 33346–33351. [Google Scholar] [CrossRef]

- Coe Sullivan, S.; Zhou, Z.; Niu, Y.; Perkins, J.; Stevenson, M.; Breen, C.; Kazlas, P.T.; Steckel, J.S. 12.2: Invited Paper: Quantum Dot Light Emitting Diodes for Near-to-eye and Direct View Display Applications. SID Symp. Dig. Tech. Pap. 2011, 42, 135–138. [Google Scholar] [CrossRef]

- Kim, T.H.; Cho, K.S.; Lee, E.K.; Lee, S.J.; Chae, J.; Kim, J.W.; Kim, D.H.; Kwon, J.Y.; Amaratunga, G.; Lee, S.Y.; et al. Full-Colour Quantum Dot Displays Fabricated by Transfer Printing. Nat. Photonics 2011, 5, 176–182. [Google Scholar] [CrossRef]

- Li, Y.; Chen, Z.; Kristal, B.; Zhang, Y.; Li, D.; Yu, G.; Wang, X.; Wang, L.; Shi, Y.; Wang, Z.; et al. 80-1: Invited Paper: Developing AMQLED Technology for Display Applications. SID Symp. Dig. Tech. Pap. 2018, 49, 1076–1079. [Google Scholar] [CrossRef]

- Kim, J.; Lee, J.; Jang, J. 80-2: AMQLED Display with Solution-Processed Oxide TFT Backplane. SID Symp. Dig. Tech. Pap. 2018, 49, 1080–1083. [Google Scholar] [CrossRef]

- Nakanishi, Y.; Takeshita, T.; Qu, Y.; Imabayashi, H.; Okamoto, S.; Utsumi, H.; Kanehiro, M.; Angioni, E.; Boardman, E.A.; Hamilton, I.; et al. Active Matrix QD-LED with Top Emission Structure by UV Lithography for RGB Patterning. J. Soc. Inf. Disp. 2020, 28, 499–508. [Google Scholar] [CrossRef]

- Liu, G.; Zhou, X.; Chen, S. Very Bright and Efficient Microcavity Top-Emitting Quantum Dot Light-Emitting Diodes with Ag Electrodes. ACS Appl. Mater. Interfaces 2016, 8, 16768–16775. [Google Scholar] [CrossRef] [PubMed]

- Tang, Z.; Lin, J.; Wang, L.; Lv, Y.; Hu, Y.; Fan, Y.; Guo, X.; Zhao, J.; Wang, Y.; Liu, X. High Performance, Top-Emitting, Quantum Dot Light-Emitting Diodes with All Solution-Processed Functional Layers. J. Mater. Chem. C 2017, 5, 9138–9145. [Google Scholar] [CrossRef]

- Lee, T.; Hahm, D.; Kim, K.; Bae, W.K.; Lee, C.; Kwak, J. Highly Efficient and Bright Inverted Top-Emitting InP Quantum Dot Light-Emitting Diodes Introducing a Hole-Suppressing Interlayer. Small 2019, 15, 1905162. [Google Scholar] [CrossRef]

- Lu, M.; Guo, J.; Sun, S.; Lu, P.; Wu, J.; Wang, Y.; Kershaw, S.V.; Yu, W.W.; Rogach, A.L.; Zhang, Y. Bright CsPbI3 Perovskite Quantum Dot Light-Emitting Diodes with Top-Emitting Structure and a Low Efficiency Roll-Off Realized by Applying Zirconium Acetylacetonate Surface Modification. Nano Lett. 2020, 20, 2829–2836. [Google Scholar] [CrossRef]

- Lee, J.; Hofmann, S.; Furno, M.; Thomschke, M.; Kim, Y.H.; Lüssem, B.; Leo, K. Influence of Organic Capping Layers on The Performance of Transparent Organic Light-Emitting Diodes. Opt. Lett. 2011, 36, 1443–1445. [Google Scholar] [CrossRef]

- Park, M.; Park, J.; Kim, S.; Ha, J.; Lee, C. 72-2: Highly Efficient Cadmium-Free Quantum Dot Light-Emitting Diodes Employing Top-Emitting Architecture. SID Symp. Dig. Tech. Pap. 2020, 51, 1075–1077. [Google Scholar] [CrossRef]

- Liu, S.; Liu, W.; Ji, W.; Yu, J.; Zhang, W.; Zhang, L.; Xie, W. Top-Emitting Quantum Dots Light-Emitting Devices Employing Microcontact Printing with Electricfield-Independent Emission. Sci. Rep. 2016, 6, 22530. [Google Scholar] [CrossRef] [Green Version]

- Lai, K.Y.; Yang, S.; Chen, P.R.; Yeh, M.H.; Liao, M.L.; Yeh, C.W.; Ho, S.J.; Chang, Y.T.; Chen, H.S. Patterned-Bank-Free Electroluminescent Quantum Dot Emitting Array for Passive-Matrix QLED Display. Adv. Mater. Technol. 2021, 7, 2100889. [Google Scholar] [CrossRef]

- Zhang, H.; Su, Q.; Chen, S. Suppressing Förster Resonance Energy Transfer in Close-Packed Quantum-Dot Thin Film: Toward Efficient Quantum-Dot Light-Emitting Diodes with External Quantum Efficiency over 21.6%. Adv. Opt. Mater. 2020, 8, 1902092. [Google Scholar] [CrossRef]

- Shen, H.; Lin, Q.; Cao, W.; Yang, C.; Shewmon, N.T.; Wang, H.; Niu, J.; Li, L.S.; Xue, J. Efficient and Long-Lifetime Full-Color Light-Emitting Diodes using High Luminescence Quantum Yield Thick-Shell Quantum Dots. Nanoscale 2017, 9, 13583–13591. [Google Scholar] [CrossRef] [PubMed]

- Pan, J.; Wei, C.; Wang, L.; Zhuang, J.; Huang, Q.; Su, W.; Cui, Z.; Nathan, A.; Lei, W.; Chen, J. Boosting the Efficiency of Inverted Quantum Dot Light-Emitting Diodes by Balancing Charge Densities and Suppressing Exciton Quenching through Band Alignment. Nanoscale 2018, 10, 592–602. [Google Scholar] [CrossRef]

- Chen, S.W.; Bai, C.Y.; Jain, C.C.; Zhan, C.J.; Koo, C.H. Durability of Indium Tin Oxide-Silver-Indium Tin Oxide Films against Moisture Investigated Through the Wettability of The Top Oxide Layer. Mater. Trans. 2007, 48, 2230–2234. [Google Scholar] [CrossRef] [Green Version]

- Kim, S.Y.; Lee, J.L.; Kim, K.B.; Tak, Y.H. Effect of Ultraviolet–Ozone Treatment of Indium–Tin–Oxide on Electrical Properties of Organic Light Emitting Diodes. J. Appl. Phys. 2004, 95, 2560–2563. [Google Scholar] [CrossRef] [Green Version]

- Han, S.; Feng, X.; Lu, Z.H.; Johnson, D.; Wood, R. Transparent-Cathode for Top-Emission Organic Light-Emitting Diodes. Appl. Phys. Lett. 2003, 82, 2715–2717. [Google Scholar] [CrossRef]

- Wang, W.; Peng, H.; Chen, S. Highly Transparent Quantum-Dot Light-Emitting Diodes with Sputtered Indium-Tin-Oxide Electrodes. J. Mater. Chem. C 2016, 4, 1838–1841. [Google Scholar] [CrossRef]

- Yeh, M.H.; Chen, P.H.; Yang, Y.C.; Chen, G.H.; Chen, H.S. Investigation of Ag-TiO2 Interfacial Reaction of Highly Stable Ag Nanowire Transparent Conductive Film with Conformal TiO2 Coating by Atomic Layer Deposition. ACS Appl. Mater. Interfaces 2017, 9, 10788–10797. [Google Scholar] [CrossRef]

- Chen, S.; Jie, Z.; Zhao, Z.; Cheng, G.; Wu, Z.; Zhao, Y.; Quan, B.; Liu, S.; Li, X.; Xie, W. Improved Light Outcoupling for Top-Emitting Organic Light-Emitting Devices. Appl. Phys. Lett. 2006, 89, 043505. [Google Scholar] [CrossRef]

- Zhang, M.; Chen, Z.; Xiao, L.; Qu, B.; Gong, Q. Optical Design for Improving Optical Properties of Top-Emitting Organic Light Emitting Diodes. J. Appl. Phys. 2013, 113, 113105. [Google Scholar] [CrossRef]

- Wang, Z.; Naka, S.; Okada, H. Improved Performance of Mixed Single Layer Top-Emission Organic Light Emitting Devices using Capping Layer. Solid-State Electron. 2011, 56, 155–158. [Google Scholar] [CrossRef]

- Yeh, T.H.; Lee, C.C.; Shih, C.J.; Kumar, G.; Biring, S.; Liu, S.W. Vacuum-Deposited MoO3/Ag/WO3 Multilayered Electrode for Highly Efficient Transparent and Inverted Organic Light-Emitting Diodes. Org. Electron. 2018, 59, 266–271. [Google Scholar] [CrossRef]

- Son, J.H.; Song, Y.H.; Yu, H.K.; Lee, J.L. Effects of Ni Cladding Layers on Suppression of Ag Agglomeration in Ag-based Ohmic Contacts on p-GaN. Appl. Phys. Lett. 2009, 95, 062108. [Google Scholar] [CrossRef] [Green Version]

- Kim, S.K.; Lampande, R.; Kwon, J.H. Electro-optically Efficient and Thermally Stable Multilayer Semitransparent Pristine Ag Cathode Structure for Top-Emission Organic Light-Emitting Diodes. ACS Photonics 2019, 6, 2957–2965. [Google Scholar] [CrossRef]

- Deng, L.; Zhou, H.; Chen, S.; Shi, H.; Liu, B.; Wang, L.; Huang, W. Influences of Wide-Angle and Multi-Beam Interference on The Chromaticity and Efficiency of Top-Emitting White Organic Light-Emitting Diodes. J. Appl. Phys. 2015, 117, 083113. [Google Scholar] [CrossRef]

- Lin, C.L.; Lin, H.W.; Wu, C.C. Examining Microcavity Organic Light-Emitting Devices Having Two Metal Mirrors. Appl. Phys. Lett. 2005, 87, 021101. [Google Scholar] [CrossRef] [Green Version]

- Lu, J.H.; Lin, Y.H.; Jiang, B.H.; Yeh, C.H.; Kao, J.C.; Chen, C.P. Microcavity Structure Provides High Performance (>8.1%) Semitransparent and Colorful Organic Photovoltaics. Adv. Funct. Mater. 2018, 28, 1703398. [Google Scholar] [CrossRef]

- Alsaad, A.M.; Al-Bataineh, Q.M.; Ahmad, A.A.; Albataineh, Z.; Telfah, A. Optical Band Gap and Refractive Index Dispersion Parameters of Boron-Doped ZnO Thin Films: A Novel Derived Mathematical Model from the Experimental Transmission Spectra. Optik 2020, 211, 164641. [Google Scholar] [CrossRef]

- Hu, B.; Yang, Z.; Karasz, F.E. Electroluminescence of Pure Poly(N vinylcarbazole) and Its Blends with A Multiblock Copolymer. J. Appl. Phys. 1994, 76, 2419–2422. [Google Scholar] [CrossRef]

| BEQLED | TEQLED | |

|---|---|---|

| Aperture ratio | Low | High |

| Microcavity effect | Weak | Strong |

| Emission peak/FWHM | Depends on QD film | Sensitive to layer thickness |

| TEQLED | Von (V) | Lmax (cd·m−2) | CEmax (cd·A−1) | EL (nm) |

|---|---|---|---|---|

| ZnO 20 nm | 2.5 | 64,200 | 17.0 | 526/28.5 |

| ZnO 40 nm | 3.2 | 18,410 | 5.5 | 540/42.3 |

| ZnO 60 nm | 4.2 | 3,320 | 1.6 | 535/35.9 |

| Ref. device | 2.5 | 23,550 | 9.4 | 532/32.4 |

| QD Thickness (nm) | Von (V) | Lmax (cd·m−2) | CEmax (cd·A−1) | EL (nm) |

|---|---|---|---|---|

| 8 | 2.5 | 81,100 | 18.4 | 529/30.7 |

| 17 | 2.5 | 129,200 | 22.2 | 530/29.9 |

| 25 | 2.6 | 106,700 | 28.4 | 539/29.8 |

| 33 | 2.7 | 30,600 | 14.8 | 539/34.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lai, K.-Y.; Yang, S.; Tsai, T.-C.; Yao, I.-A.; Yang, C.-L.; Chang, C.-C.; Chen, H.-S. Top-Emitting Active-Matrix Quantum Dot Light-Emitting Diode Array with Optical Microcavity for Micro QLED Display. Nanomaterials 2022, 12, 2683. https://0-doi-org.brum.beds.ac.uk/10.3390/nano12152683

Lai K-Y, Yang S, Tsai T-C, Yao I-A, Yang C-L, Chang C-C, Chen H-S. Top-Emitting Active-Matrix Quantum Dot Light-Emitting Diode Array with Optical Microcavity for Micro QLED Display. Nanomaterials. 2022; 12(15):2683. https://0-doi-org.brum.beds.ac.uk/10.3390/nano12152683

Chicago/Turabian StyleLai, Kuo-Yang, Shuan Yang, Tung-Chang Tsai, I-An Yao, Chiu-Lien Yang, Chih-Ching Chang, and Hsueh-Shih Chen. 2022. "Top-Emitting Active-Matrix Quantum Dot Light-Emitting Diode Array with Optical Microcavity for Micro QLED Display" Nanomaterials 12, no. 15: 2683. https://0-doi-org.brum.beds.ac.uk/10.3390/nano12152683