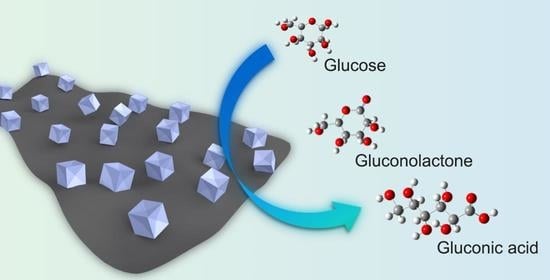

The Synthesis of Carbon Black-Loaded Pt Concave Nanocubes with High-Index Facets and Their Enhanced Electrocatalytic Properties toward Glucose Oxidation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals

2.2. Synthesis of Pt CNC/CB Catalysts

2.3. Characterization

2.4. Electrochemical Measurements

3. Results and Discussion

3.1. Physicochemical Characterizations

3.2. Electrochemical Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cosnier, S.; Le Goff, A.; Holzinger, M. Towards glucose biofuel cells implanted in human body for powering artificial organs: Review. Electrochem. Commun. 2014, 38, 19–23. [Google Scholar] [CrossRef]

- Bahari, M.; Malmberg, M.A.; Brown, D.M.; Nazari, S.H.; Lewis, R.S.; Watt, G.D.; Harb, J.N. Oxidation efficiency of glucose using viologen mediators for glucose fuel cell applications with non-precious anodes. Appl. Energy 2020, 261, 114382. [Google Scholar] [CrossRef]

- Li, Q.; Shao, Z.; Han, T.; Zheng, M.; Pang, H. A high-efficiency electrocatalyst for oxidizing glucose: Ultrathin nanosheet Co-based organic framework assemblies. ACS Sustain. Chem. Eng. 2019, 7, 8986–8992. [Google Scholar] [CrossRef]

- Yao, S.J.; Appleby, A.J.; Geisel, A.; Cash, H.R.; Wolfson, S.K. Anodic oxidation of carbohydrates and their derivatives in neutral saline solution. Nature 1969, 224, 921–922. [Google Scholar] [CrossRef]

- Santiago, Ó.; Navarro, E.; Raso, M.A.; Leo, T.J. Review of implantable and external abiotically catalysed glucose fuel cells and the differences between their membranes and catalysts. Appl. Energy 2016, 179, 497–522. [Google Scholar] [CrossRef]

- Siva, G.; Aziz, M.A.; Gnana Kumar, G. Engineered tubular nanocomposite electrocatalysts based on CuS for high-performance, durable glucose fuel cells and their stack. ACS Sustain. Chem. Eng. 2018, 6, 5929–5939. [Google Scholar] [CrossRef]

- Mello, G.A.B.; Cheuquepán, W.; Feliu, J.M. Investigation of reactivity of Pt basal planes towards glucose electro-oxidation in neutral solution (pH 7): Structure-sensitivity dependence and mechanistic study. J. Electroanal. Chem. 2020, 878, 114549. [Google Scholar] [CrossRef]

- Gonzalez-Solino, C.; Bernalte, E.; Metcalfe, B.; Moschou, D.; Di Lorenzo, M. Power generation and autonomous glucose detection with an integrated array of abiotic fuel cells on a printed circuit board. J. Power Sources 2020, 472, 228530. [Google Scholar] [CrossRef]

- Huang, J.; Simons, P.; Sunada, Y.; Rupp, J.L.M.; Yagi, S. Pt-catalyzed D-glucose oxidation reactions for glucose fuel cells. J. Electrochem. Soc. 2021, 168, 64511. [Google Scholar] [CrossRef]

- Kerzenmacher, S.; Ducrée, J.; Zengerle, R.; von Stetten, F. Energy harvesting by implantable abiotically catalyzed glucose fuel cells. J. Power Sources 2008, 182, 1–17. [Google Scholar] [CrossRef]

- Chu, T.-F.; Lin, F.-Y.; Kuznetsova, I.; Wang, G.-J. A novel neutral non-enzymatic glucose biofuel cell based on a Pt/Au nano-alloy anode. J. Power Sources 2021, 486, 229374. [Google Scholar] [CrossRef]

- Leong, G.J.; Schulze, M.C.; Strand, M.B.; Maloney, D.; Frisco, S.L.; Dinh, H.N.; Pivovar, B.; Richards, R.M. Shape-directed platinum nanoparticle synthesis: Nanoscale design of novel catalysts. Appl. Organomet. Chem. 2014, 28, 1–17. [Google Scholar] [CrossRef]

- Duan, S.; Du, Z.; Fan, H.; Wang, R. Nanostructure optimization of platinum-based nanomaterials for catalytic applications. Nanomaterials 2018, 8, 949. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Poerwoprajitno, A.R.; Gloag, L.; Cheong, S.; Gooding, J.J.; Tilley, R.D. Synthesis of low- and high-index faceted metal (Pt, Pd, Ru, Ir, Rh) nanoparticles for improved activity and stability in electrocatalysis. Nanoscale 2019, 11, 18995–19011. [Google Scholar] [CrossRef] [PubMed]

- Yu, T.; Kim, D.Y.; Zhang, H.; Xia, Y. Platinum concave nanocubes with high-index facets and their enhanced activity for oxygen reduction reaction. Angew. Chem. Int. Ed. 2011, 50, 2773–2777. [Google Scholar] [CrossRef] [PubMed]

- Jeyaraj, M.; Gurunathan, S.; Qasim, M.; Kang, M.-H.; Kim, J.-H. A comprehensive review on the synthesis, characterization, and biomedical application of platinum nanoparticles. Nanomaterials 2019, 9, 1719. [Google Scholar] [CrossRef] [Green Version]

- de Andrade, R.N.; Perini, N.; Vieira, J.L.; Gallo, J.M.R.; Sitta, E. Glycerol electrooxidation catalyzed by Pt-Sb supported in periodic mesoporous carbon CMK-3 and CMK-5. J. Electroanal. Chem. 2021, 896, 115158. [Google Scholar] [CrossRef]

- Wei, L.; Liu, F.; Jiang, X.; Yang, Y.-H.; Sheng, T.; Xu, Q.-Q.; Zhao, X.-S.; Fan, Y.-J. High-index faceted Pt-Ru alloy concave nanocubes with enhancing ethanol and CO electro-oxidation. Electrochim. Acta 2021, 396, 139266. [Google Scholar] [CrossRef]

- Shen, M.; Xie, M.; Slack, J.; Waldrop, K.; Chen, Z.; Lyu, Z.; Cao, S.; Zhao, M.; Chi, M.; Pintauro, P.N.; et al. Pt–Co truncated octahedral nanocrystals: A class of highly active and durable catalysts toward oxygen reduction. Nanoscale 2020, 12, 11718–11727. [Google Scholar] [CrossRef]

- Lai, J.; Niu, W.; Li, S.; Wu, F.; Luque, R.; Xu, G. Concave and duck web-like platinum nanopentagons with enhanced electrocatalytic properties for formic acid oxidation. J. Mater. Chem. A 2016, 4, 807–812. [Google Scholar] [CrossRef]

- Wang, Y.; Zhuo, H.; Sun, H.; Zhang, X.; Dai, X.; Luan, C.; Qin, C.; Zhao, H.; Li, J.; Wang, M.; et al. Implanting Mo atoms into surface lattice of Pt3Mn alloys enclosed by high-indexed facets: Promoting highly active sites for ethylene glycol oxidation. ACS Catal. 2018, 9, 442–455. [Google Scholar] [CrossRef]

- Meng, T.; Shang, N.; Zhao, J.; Su, M.; Wang, C.; Zhang, Y. Facile one-pot synthesis of Co coordination polymer spheres doped macroporous carbon and its application for electrocatalytic oxidation of glucose. J. Colloid Interface Sci. 2021, 589, 135–146. [Google Scholar] [CrossRef]

- Wang, G.Q.; Gu, J.F.; Zhuo, S.P. High dispersion Pt nanoparticles using mesoporous carbon support for enhancing conversion efficiency of dye-sensitized solar cells. Chin. Chem. Lett. 2010, 21, 1513–1516. [Google Scholar] [CrossRef]

- Xie, B.; Zhang, Y.; Du, N.; Li, H.; Hou, W.; Zhang, R. Preparation of preferentially exposed poison-resistant Pt(111) nanoplates with a nitrogen-doped graphene aerogel. Chem. Commun. 2016, 52, 13815–13818. [Google Scholar] [CrossRef] [PubMed]

- Beltrán-Gastélum, M.; Salazar-Gastélum, M.I.; Félix-Navarro, R.M.; Pérez-Sicairos, S.; Reynoso-Soto, E.A.; Lin, S.W.; Flores-Hernández, J.R.; Romero-Castanon, T.; Albarrán-Sánchez, I.L.; Paraguay-Delgado, F. Evaluation of Pt-Au/MWCNT (Multiwalled Carbon Nanotubes) electrocatalyst performance as cathode of a proton exchange membrane fuel cell. Energy 2016, 109, 446–455. [Google Scholar] [CrossRef]

- Liu, J.; Li, C.; Niu, H.; Wang, D.; Xin, C.; Liang, C. Low-energy hemiacetal dehydrogenation pathway: Co-production of gluconic acid and green hydrogen via glucose dehydrogenation. Chem. Asian J. 2022, 17, 202200138. [Google Scholar] [CrossRef]

- Akiyama, S.; Nakagawa, K. Effect of mesopores in the Marimo nanocarbon anode material on the power generation performance of direct glucose fuel cell. Carbon Trends 2021, 4, 100058. [Google Scholar] [CrossRef]

- Sun, H.; Zeng, Q.; Ye, C.; Zhu, Y.; Chen, F.; Yang, M.; Fu, L.; Du, S.; Yu, J.; Jiang, N.; et al. Pt nanodendrites with (111) crystalline facet as an efficient, stable and pH-universal catalyst for electrochemical hydrogen production. Chin. Chem. Lett. 2020, 31, 2478–2482. [Google Scholar] [CrossRef]

- Xu, X.; Ma, Z.; Li, D.; Su, Z.; Dong, X.; Huang, H.; Qi, M. Pt concave nanocubes with high-index facets as electrocatalysts for glucose oxidation. ACS Appl. Nano Mater. 2022, 5, 4983–4990. [Google Scholar] [CrossRef]

- Zhou, Z.Y.; Huang, Z.Z.; Chen, D.J.; Wang, Q.; Tian, N.; Sun, S.G. High-index faceted platinum nanocrystals supported on carbon black as highly efficient catalysts for ethanol electrooxidation. Angew. Chem. Int. Ed. 2010, 49, 411–414. [Google Scholar] [CrossRef]

- Zhao, Y.; Fan, L.; Gao, D.; Ren, J.; Hong, B. High-power non-enzymatic glucose biofuel cells based on three-dimensional platinum nanoclusters immobilized on multiwalled carbon nanotubes. Electrochim. Acta 2014, 145, 159–169. [Google Scholar] [CrossRef]

- Zhang, X.; Zheng, J. High-index {hk0} facets platinum concave nanocubes loaded on multiwall carbon nanotubes and graphene oxide nanocomposite for highly sensitive simultaneous detection of dopamine and uric acid. Talanta 2020, 207, 120296. [Google Scholar] [CrossRef] [PubMed]

- Quan, Z.; Wang, Y.; Fang, J. High-index faceted noble metal nanocrystals. Acc. Chem. Res. 2013, 46, 191–202. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, Y.H.; Mohamed, A.T.; El-Shafei, A.; Al-Qaradawi, S.Y.; Aljaber, A.S. Facile one-step synthesis of supportless porous AuPtPd nanocrystals as high performance electrocatalyst for glucose oxidation reaction. Int. J. Hydrogen Energy 2020, 45, 19163–19173. [Google Scholar] [CrossRef]

- Chetty, R.; Kundu, S.; Xia, W.; Bron, M.; Schuhmann, W.; Chirila, V.; Brandl, W.; Reinecke, T.; Muhler, M. PtRu nanoparticles supported on nitrogen-doped multiwalled carbon nanotubes as catalyst for methanol electrooxidation. Electrochim. Acta 2009, 54, 4208–4215. [Google Scholar] [CrossRef]

- Lee, S.R.; Park, J.; Gilroy, K.D.; Yang, X.; Figueroa-Cosme, L.; Ding, Y.; Xia, Y. Palladium@platinum concave nanocubes with enhanced catalytic activity toward oxygen reduction. ChemCatChem 2016, 8, 3082–3088. [Google Scholar] [CrossRef]

- Do, U.P.; Seland, F.; Wang, K.; Johannessen, E.A. Raney-platinum thin film electrodes for the catalysis of glucose in abiotically catalyzed micro-glucose fuel cells. J. Mater. Sci. 2019, 54, 14143–14156. [Google Scholar] [CrossRef]

- Łukaszewski, M.; Soszko, M.; Czerwiński, A. Electrochemical methods of real surface area determination of noble metal electrodes—An overview. Int. J. Electrochem. Sci. 2016, 11, 4442–4469. [Google Scholar] [CrossRef]

- Li, G.; Wang, Y.; Yu, F.; Lei, Y.; Hu, Z. Deep oxidization of glucose driven by 4-acetamido-TEMPO for a glucose fuel cell at room temperature. Chem. Commun. 2021, 57, 4051–4054. [Google Scholar] [CrossRef]

- Toghill, K.E.; Compton, R.G. Electrochemical non-enzymatic glucose sensors: A perspective and an evaluation. Int. J. Electrochem. Sci. 2010, 5, 1246–1301. [Google Scholar]

- Beden, B.; Largeaud, F.; Kokoh, K.B.; Lamy, C. Fourier transform infrared reflectance spectroscopic investigation of the electrocatalytic oxidation of D-glucose: Identification of reactive intermediates and reaction products. Electrochim. Acta 1996, 41, 701–709. [Google Scholar] [CrossRef]

- Torigoe, K.; Takahashi, M.; Tsuchiya, K.; Iwabata, K.; Ichihashi, T.; Sakaguchi, K.; Sugawara, F.; Abe, M. High-power abiotic direct glucose fuel cell using a gold–platinum bimetallic anode catalyst. ACS Omega 2018, 3, 18323–18333. [Google Scholar] [CrossRef] [PubMed]

- Burke, L.D. Premonolayer oxidation and its role in electrocatalysis. Electrochim. Acta 1994, 39, 1841–1848. [Google Scholar] [CrossRef]

- Tian, K.; Prestgard, M.; Tiwari, A. A review of recent advances in nonenzymatic glucose sensors. Mater. Sci. Eng. C 2014, 41, 100–118. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, X.; Ma, Z.; Su, Z.; Li, D.; Dong, X.; Huang, H.; Qi, M. The Synthesis of Carbon Black-Loaded Pt Concave Nanocubes with High-Index Facets and Their Enhanced Electrocatalytic Properties toward Glucose Oxidation. Nanomaterials 2022, 12, 3761. https://0-doi-org.brum.beds.ac.uk/10.3390/nano12213761

Xu X, Ma Z, Su Z, Li D, Dong X, Huang H, Qi M. The Synthesis of Carbon Black-Loaded Pt Concave Nanocubes with High-Index Facets and Their Enhanced Electrocatalytic Properties toward Glucose Oxidation. Nanomaterials. 2022; 12(21):3761. https://0-doi-org.brum.beds.ac.uk/10.3390/nano12213761

Chicago/Turabian StyleXu, Xin, Ze Ma, Zekun Su, Danqing Li, Xufeng Dong, Hao Huang, and Min Qi. 2022. "The Synthesis of Carbon Black-Loaded Pt Concave Nanocubes with High-Index Facets and Their Enhanced Electrocatalytic Properties toward Glucose Oxidation" Nanomaterials 12, no. 21: 3761. https://0-doi-org.brum.beds.ac.uk/10.3390/nano12213761