1. Introduction

Single-wall carbon nanotubes (SWCNTs) are highly promising as semiconducting materials for printing thin film transistors (TFTs) due to their unique mechanical, electrical, and chemical properties [

1,

2]. Furthermore, thanks to their specific chirality (semiconducting or metallic characteristics) [

3], the mixed semiconducting and metallic SWCNTs are fascinating candidates as active materials in printed TFTs because of their low cost and robustness. Therefore, the printed SWCNT-based TFTs (pSWCNT-TFTs) are highly appropriate to integrate logic circuits or TFT active matrix-based sensors [

4,

5,

6,

7]. Various printing methods have been employed to develop flexible, light, and costless pSWCNT-TFT-based devices [

8]. In general, the back-gated pSWCNT-TFTs exposed the SWCNT channels to surroundings (water and oxygen), resulting in unstable electrical performance. For example, when the electrical properties of pSWCNT-TFTs were measured in a vacuum, the on currents were lower than those measured in ambient conditions [

1]. Moreover, since the back-gate pSWCNT-TFTs have typically unipolar p-type properties, it seems difficult to create n-type SWCNT-TFTs. However, the n-type SWCNT-TFTs are indispensable in pSWCNT-TFTs because it allows pSWCNT-TFT-based complementary metal–oxide–semiconductor (CMOS)-like logic gates and analog circuits to operate with lower power [

9,

10,

11]. In recent years, we have reported that the conversion from p-type to n-type SWCNTs can be achieved by simply printing n-doping ink on printed p-type SWCNTs via a roll-to-roll (R2R) gravure or roll-to-plate (R2P) printing methods [

9,

12]. However, unfortunately, as soon as one exposes the n-type SWCNT-TFT to the surrounding environment, it starts to slowly revert to a p-type one, causing device failures.

In pSWCNT-TFTs, especially for n-type pSWCNT-TFTs, instability is caused by two main reasons: electronic ink impurities and environmental factors. Electronic ink impurities can be removed by selecting better materials, including polymer binders. However, after removing the impurities, environmental factors such as water, oxygen, and light are inevitable during the operation of the device in ambient conditions by generating the trapped charges at the interface between the dielectric and the SWCNT semiconducting layers. Moreover, such trapped charges are generated via electron transfer from the SWCNT to water/oxygen due to the redox potential difference between water/oxygen and the fermi level of the SWCNT [

13,

14]. Since the valence band of the SWCNTs lies close to the redox potential of the oxygen-dissolved water, the electrons can transfer easily from the SWCNT to the oxygen/water layer, causing large hysteresis and instability in the pSWCNTs. Therefore, to prevent such charge transfer from the SWCNT and make devices robust against environmental factors, a dense passivation method is needed to isolate the printed device from water and oxygen molecules.

Regarding the passivation of pSWCNT-TFTs, many research groups have reported methods to provide device stability. Zhang et al. reported polymer-based passivation using SU-8 and polymethyl-methacrylate (PMMA) with thicknesses of 2 µm and 200 nm for pSWCNT-TFTs. However, when the SU-8- and PMMA-passivated samples were tested under nitrogen conditions, the diffusion through the layer within 1 h caused variations in devices [

15]. Similarly, Dai et al. have also passivated SWCNT-TFTs using PMMA [

16], but water molecules still affect the TFTs’ performance through the PMMA layers. Furthermore, Kamim et al. and Kim et al., respectively, employed Si

3N

4 via chemical vapor deposition (CVD) at 270 °C and Al

2O

3 deposited via atomic layer deposition (ALD) at 300 °C for showing stable SWCNT-based devices [

3,

16]. Similar observations were made by Qu et al., who passivated sputtered SnO channels by Al

2O

3 thin films using the ALD method to protect the degradation of p-type SnO-based TFTs [

17]. Even though they attained stable performance, high temperatures cannot be used to passivate flexible substrates such as polyethylene terephthalate (PET) or polyethylene naphthalate (PEN) film. In addition, previously, our group reported stable performance by printing the passivation layers of CYTOP and FG-3650 on the top of the pSWCNT-TFT-based devices, which showed stable output signals using six layers of passivation [

9]. However, the devices became unstable when continuous bias stress was applied [

9]. F. Iqbal et al. reported alleviating the degradation under bias stress by depositing perylene over the device [

18]. Even though the method showed stable characteristics of the device under ambient conditions, it is hard to apply in the R2R-printed devices directly. Since the R2R-printed devices should be passivated with a continuous in-line deposition method, we need to integrate an R2R passivation method with the R2R printing system. Since the R2R-printed flexible electronic devices should experience minimized exposure time to surroundings, the passivation method should be connected with the R2R printing system. Among available methods to integrate with the R2R printing system, a plasma-enhanced chemical vapor deposition (PECVD) method has been widely used to provide high-quality passivation layers. However, since PECVD is fabricated by the collision between energetic electrons and molecules of source gases, induced defects or extra-doping on pSWCNTs would often be observed.

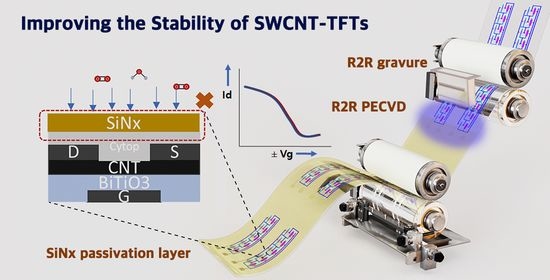

Here, we report R2R PECVD of SiNx on the R2R-printed p-type and n-type SWCNT-TFTs via primary coating of CYTOP to prevent defects and extra-doping. Since silicon nitride (SiNx) shows less permeability towards the water and oxygen material [

19], deposited SiNx layers will effectively prevent the further degradation caused by water and oxygen molecules. Observing the variation of threshold voltage (∆Vth) as a function of time, the SiNx-passivated pSWCNT-TFTs showed a very small ∆Vth. When the inverter test was also carried out by giving continuous electrical bias stress to the pSWCNT-TFTs for 1 hr, a minimal shifting of output signal was observed. The passivated pSWCNT-TFTs were also monitored through a Temperature Humidity Test (RH: 85%/85° C), where the ∆Vth of ±1.2 V was observed for 3 h. Furthermore, the R2R-passivated pSWCNT-TFT-based CMOS-like ring oscillator, called a 1-bit code generator, was stable even under 85/85 test conditions for 24 h. Those results showed a way of providing a long lifetime of R2R-printed SWCNT-TFT-based devices for practical applications.

3. Results and Discussion

For providing long-term stability of p-type and n-type pSWCNT-TFTs, water/oxygen molecules should be blocked from contacting the SWCNT layers. Otherwise, the ∆Vth of pSWCNT-TFTs will be large, primarily due to the donation of electrons to the semiconducting layer by adsorbing water and oxygen molecules (

Figure 1a). Therefore, to minimize the ∆Vth, an efficient passivation layer should be applied on top of the R2R pSWCNT-TFTs by using an R2R PECVD process with the R2R gravure printing system (

Figure 1b).

The p-type and n-type pSWCNT-TFTs were fabricated on PET film using an R2R gravure printing system (

Figure S1a). Starting from gate layer printing, continuously, the BaTiO3-based dielectric layer, SWCNT-based semiconducting layer, drain/source layers, and n-doping layer were printed with a web tension of 5 ± 0.3 kgf. First, gate layers were printed on a PET substrate using Ag nanoparticle-based ink. The detailed stage of the R2R gravure printing process and ink conditions can be found in our previous works [

9]. The average thickness of the printed gate layer was 450–550 nm with 50 nm of surface roughness. After printing the gate layer, BaTiO

3-based dielectric ink was printed on the printed Ag gate layer with a thickness of 2.0 µm. Then, SWCNT-based semiconducting ink and Ag nanoparticle-based ink for drain/source layers (~1.3 µm) were continuously printed on the dielectric layer to complete the pSWCNT-TFTs, as shown in

Figure S2a. As a final R2R printing step, n-doping ink was printed on SWCNT semiconducting layers to convert p-type pSWCNT-TFTs into n-type pSWCNT-TFTs. The R2R-printed n-doping layer had a thickness of 600 nm, as shown in

Figure S2b.

Following the fully R2R gravure printing process, the printed p-type and n-type SWCNT-TFTs were passivated using the R2R PECVD system (

Figure S1b). It has a process chamber and a load lock chamber. The process chamber has the main drum where samples are rolled during the deposition process, and the plasma source is used to evaporate the material on samples. In our work, R2R PECVD was used to deposit the SiNx on the p-type and n-type pSWCNT-TFTs with 200 nm thickness (See

Figure S2a). When the thickness of SiNx is over 300 nm, it does not improve further, reaching some critical points, as pointed out in our previous report [

23]. Corresponding to this result, SiNx with a thickness of 200 nm gives 0.0053 g/m

2 of day vapor transmission rate (WVTR). An outer bending fatigue test was performed to examine the possibility of cracks on SiNx films as a mechanical stability test. SiNx was coated with different thicknesses on a PET substrate. Then, an outer bending fatigue test was conducted with a radius of 10 mm, under a frequency 1 Hz, and 10,000 cycles. Among different thicknesses of SiNx layer, 300 and 400 nm showed bending failure after 3000 and 1000 cycles, respectively, whereas 200 and below 200 nm completed the test without failure, as shown in

Figure S3. That is why 200 nm was selected for the passivation. Thus, if the thickness is greater than this, it can cause cracks on the surface [

23]. Our results and previous studies on the passivation of pSWCNT-TFTs showed a good interface quality between the SWCNT random network and the passivation layer, which can significantly impact the device’s performance [

9]. The deposition temperature of the R2R PECVD process was maintained below 45 °C to be compatible with the flexible substrate.

From the optical image of R2R gravure-printed and R2R PECVD-passivated p-type and n-type pSWCNT-TFTs, we found out structural dimensions: W/L = 1920 µm/160 µm (p-type) and W/L = 1900 µm/180 µm (n-type), as shown in

Figure 2a. The thickness of the passivation layer can be controlled by adjusting the web speed and the number of repetitions of deposition. Two continuous magnetron microwave generators with a frequency of 2.46 GHz were used to generate the plasma. The deposition temperature of the SiNx passivation layer was maintained at lower than 45 °C to avoid direct damage to the printed samples. The transfer characteristics of p-type and n-type pSWCNT-TFTs with/without SiNx passivation layer (200 nm of thickness) were measured to confirm the passivation effect on printed SWCNT-TFTs. The mobility (µ

FE) was calculated from the maximum transconductance (µ

FE = 2L(g

m)

2/WCi), where Ci and g

m are the gate capacitance per unit and transconductance, respectively. The printed dielectric layer’s capacitance of 9 nF/cm

2 was obtained from the capacitance–voltage measurement method and used as the gate capacitance here. The printed p-type SWCNT-TFTs showed a carrier mobility of 0.010~0.015 cm

2/Vs, Vth of +10~+12.0 V, and Ion/Ioff ratio of ~10

3. For the n-type pSWCNT-TFTs, we obtained carrier mobility of 0.003~0.010 cm

2/Vs, Vth of −7.0~−9.0 V, and Ion/Ioff of ~10

2.5. Because of the low efficiency of the n-type converting process via the R2R gravure printing, some n-type pSWCNT-TFTs showed low mobilities. To confirm the passivation effect at the ambient conditions, the samples with and without passivation were monitored for 7 days, as shown in

Figure 2b,c. The ∆Vth was more noticeable for the n-type pSWCNT-TFT because exposure to air would directly influence the electron carriers. For the trapped charge density calculation in pSWCNT-TFTs, a simple equation (∆Vth = eNtr(t)/Co) was adopted, where e is the elementary charge, Ntr is the trapped charge density, and Co is gate capacitance [

24].

The ∆Vth of 1.73 V and 7.25 V were, respectively, observed for p-type and n-type pSWCNT-TFT samples without a SiNx passivation layer for 7 days (

Figure 2c). On the other hand, SiNx-passivated pSWCNT-TFTs showed stable transfer characteristics for 7 days, as shown in

Figure 2b. The passivated sample has the ∆Vth of 0.64 V of and 3.20 V for p-type and n-type under ambient conditions for 7 days. They did not change their ∆Vth value for 3 days, showing a good passivation effect for p-type and n-type pSWCNT-TFTs. The Vth shift was more noticeable for the n-type pSWCNT-TFTs than the p-type ones after the passivation. Thus, the different Vth shifts can be attributed to the adsorption of water and oxygen molecules from the surroundings. That is why the trapped charge density was found to be, respectively, 2.25 × 10

9/cm

3 and 6.52 × 10

9/cm

3 for passivated and non-passivated p-type pSWCNT-TFT samples, as shown in

Figure 2d,e. The trapped charge density of the non-passivated p-type pSWCNT-TFT showed three times higher values than the SiNx-passivated one. Similarly, the n-type pSWCNT-TFT had a trapped charge density of 1.8

× 10

8/cm

3 and 4.1 × 10

8/cm

3 with and without SiNx passivation layers, indicating the 50% suppressing effect. Non-passivated pSWCNT-TFT samples generally had a larger ∆Vth and higher trapped charge density than passivated samples. Furthermore,

Figure 2f shows the ∆Vth for three conditions: without the passivation layer, with the passivation layer of CYTOP, and with the passivation layer of SiNx for 7 days. The non-passivated n-type pSWCNT-TFT sample showed a larger ∆Vth value (±0.50 V for p-type and ± 1.7 V for n-type) than the passivated samples. By passivating the single CYTOP layer with 800 nm of thickness, the ∆Vth was reduced to ±1.0 V for p-type and n-type samples from those of the non-passivated one. By comparing the three conditions, the pSWCNT-TFTs with the passivation layer of SiNx showed the most stable characteristics among them. In particular, those results confirmed that the passivation of SiNx on the SWCNT semiconducting layer could improve the pSWCNT-TFT stability by attenuating the permeation of water and oxygen molecules from surroundings so that the trapped charge density was consequently reduced [

7]. Moreover, pSWCNT-TFTs passivated with SiNx measured the transfer characteristics under mechanical stress (bending test) for the flexible electronics application. It was found that the transfer characteristics of the p-type under an outer bending radius of 2.5 cm showed a similar property with the non-bending pSWCNT-TFT shown in

Figure S4a. At the same time, the SiNx-passivated n-type pSWCNT-TFT was also tested for its electrical properties with and without the bending (radius of 2.7 cm) and showed similar electrical properties to the non-bending devices, as shown in

Figure S4b. This result showed the practical potential of R2R gravure-printed devices to be employed in real fields.

To confirm the stability, the operation test of the pSWCNT-TFT-based inverter with a commercial resistor was carried out under ambient conditions of 70% humidity and 23 °C for one hour. SiNx-passivated p-type pSWCNT-TFTs showed a 0.1 V change in Vp-p (peak-to-peak) output value and shifted slightly upward during continuous operation for 1 h, as shown in

Figure 3a. In addition, the inverting property of the n-type pSWCNT-TFT was also measured for 1 h to check the stability under ambient conditions (

Figure 3b). The stable inverting property of the n-type pSWCNT-TFT was observed as well. In this case, the Vp-p output decreased by only 0.3 V and shifted slightly downwards. On the other hand, non-passivated samples showed that the signal was shifted up quickly for both p-type and n-type pSWCNT-TFTs even in a short time (approximately 10 min), as shown in

Figure S5a,b. To further test the stability of a simple integrated logic gate, five series of CMOS-like inverters, the R2R-printed and passivated SWCNT-TFT-based ring oscillators (1-bit code generator) were fabricated, as shown in

Figure 3c. Three samples of 1-bit code generator (non-passivated, CYTOP-passivated, and SiNx-passivated sample) were tested under ambient conditions.

Figure 3d shows the output characteristics of a bare (non-passivated sample) printed 1-bit code generator for 3 h of running time, while

Figure 3e shows the output characteristic of a SiNx-passivated 1-bit code generator, tested under ambient conditions. It was found that the non-passivated 1-bit code generator shrank by 28% from the initial Vp-p output by continuously running for 3 h under ambient conditions. On the other hand, the SiNx-passivated 1-bit code generator showed only a 4% change from the initial Vp-p output for 3 h of running time. Based on the stability test on the printed 1-bit code generator, the non-passivated printed 1-bit code generator was more shrunken and shifted in output voltage than the passivated one, because of the trapped charges caused by water and oxygen molecules. Thus, the SiNx layer can effectively block the permeation of water and oxygen molecules to provide device stability. For testing the long-term stability of the SiNx-passivated 1-bit code generator, we also monitored the output characteristics, including frequency and Vp-p of the output signal, and found good stability under ambient conditions for 5 days, as shown in

Figure S6.

The standard method (IEC 60,068) for the environmental reliability test for Si-based devices is an 85/85 (85% of humidity at 85 °C) test, a Temperature Humidity Test. Thus, the R2R-printed and passivated SWCNT-TFT-based ring oscillator also tested its stability under the 85/85 test condition. For the 85/85 testing, both passivated p-type and n-type pSWCNT-TFTs with the CYTOP and the SiNx passivation were kept inside the 85/85 chamber to see the environmental reliability. Then, we measured its transfer characteristics every hour. By investigating the ∆Vth and trapped charge density after the 85/85 test, the ∆Vth of the SiNx-passivated p-type pSWCNT-TFT was 0.8 V while it was 3.7 V for the n-type, as shown in

Figure 4a. On the other hand, the CYTOP-passivated p-type pSWCNT-TFT showed 5 V of ∆Vth in 3 h while the n-type pSWCNT-TFT changed to the p-type property quickly and completely lost its n-type property, shown as a block dotted line in

Figure 4b. Finally, we monitored the output characteristic of a device with and without the SiNx-passivated 1-bit code generator under the 85/85 test. As shown in

Figure 4c, the device maintained almost the initial output signal after the 85/85 test for 24 h. However, the non-passivated and CYTOP-passivated 1-bit code generators showed no output characteristics under the 85/85 test (see

Figure S7). Those results from the 85/85 test demonstrated that SiNx passivation by R2R PECVD is an efficient way to provide the practical stability of the printed device.