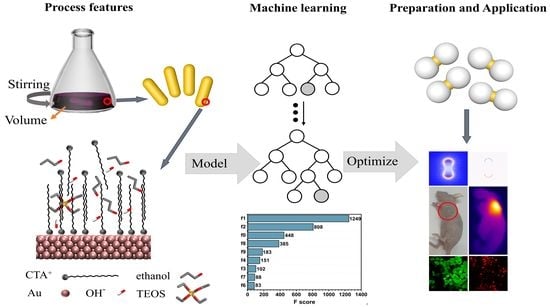

Machine Learning Predicting Optimal Preparation of Silica-Coated Gold Nanorods for Photothermal Tumor Ablation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation and Characterization

2.3. Experimental Parameter Preprocessing and Feature Engineering

2.4. Machine Learning Models and Evaluation Metrics

2.5. Time Domain Finite Difference Simulation

2.6. In Vivo and In Vitro Photothermal Experiments

3. Results and Discussion

3.1. Machine Learning Predictions

3.2. Analysis and Optimization of the Preparation Process

3.3. Dumbbell Silica-Coated GNRs for Photothermal Applications

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pearce, A.K.; Wilks, T.R.; Arno, M.C.; O’Reilly, R.K. Synthesis and applications of anisotropic nanoparticles with precisely defined dimensions. Nat. Rev. Chem. 2021, 5, 21–45. [Google Scholar] [CrossRef]

- Xie, Z.; Fan, T.; An, J.; Choi, W.; Duo, Y.; Ge, Y.; Zhang, B.; Nie, G.; Xie, N.; Zheng, T.; et al. Emerging combination strategies with phototherapy in cancer nanomedicine. Chem. Soc. Rev. 2020, 49, 8065–8087. [Google Scholar] [CrossRef]

- Wu, Y.; Ali, M.R.K.; Chen, K.; Fang, N.; El-Sayed, M.A. Gold nanoparticles in biological optical imaging. Nano Today 2019, 24, 120–140. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, L.; Liu, J.; Li, R.; Huang, M. Tunable surface plasma resonance of gold nanorods superstructure and their SERS properties. Micro Nano Lett. 2018, 13, 1265–1268. [Google Scholar] [CrossRef]

- Chen, Y.S.; Zhao, Y.; Yoon, S.J.; Gambhir, S.S.; Emelianov, S. Miniature gold nanorods for photoacoustic molecular imaging in the second near-infrared optical window. Nat. Nanotechnol. 2019, 14, 465–472. [Google Scholar] [CrossRef] [PubMed]

- Wood, C.S.; Stevens, M.M. Improving the image of nanoparticles. Nature 2016, 539, 505–506. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- de la Encarnacion, C.; Jimenez de Aberasturi, D.; Liz-Marzan, L.M. Multifunctional plasmonic-magnetic nanoparticles for bioimaging and hyperthermia. Adv. Drug Deliv. Rev. 2022, 189, 114484. [Google Scholar] [CrossRef] [PubMed]

- Dai, X.; Zhao, X.; Liu, Y.; Chen, B.; Ding, X.; Zhao, N.; Xu, F.J. Controlled Synthesis and Surface Engineering of Janus Chitosan-Gold Nanoparticles for Photoacoustic Imaging-Guided Synergistic Gene/Photothermal Therapy. Small 2021, 17, e2006004. [Google Scholar] [CrossRef]

- Wang, Y.; Cui, Q.; Zhao, X.; Qin, T.; Wang, W.; Sun, H.; Zhu, H.; Guo, H.; Sun, H. Gold nanorod-based multifunctional nanocarrier for synergistic chemo-photothermal therapy in tumors. RSC Adv. 2018, 8, 41454–41463. [Google Scholar] [CrossRef] [Green Version]

- Shi, H.; Lin, S.; Wang, Y.; Lou, J.; Hu, Y.; Chen, Y.; Zhang, Q. Ruthenium photosensitizer anchored gold nanorods for synergistic photodynamic and photothermal therapy. Dalton Trans. 2022, 51, 6846–6854. [Google Scholar] [CrossRef]

- He, W.; Ma, G.; Shen, Q.; Tang, Z. Engineering Gold Nanostructures for Cancer Treatment: Spherical Nanoparticles, Nanorods, and Atomically Precise Nanoclusters. Nanomaterials 2022, 12, 1738. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Liu, C.; Bai, J.; Wu, C.; Xiao, Y.; Li, Y.; Zheng, J.; Yang, R.; Tan, W. Silver nanoparticle gated, mesoporous silica coated gold nanorods (AuNR@MS@AgNPs): Low premature release and multifunctional cancer theranostic platform. ACS Appl. Mater. Interfaces 2015, 7, 6211–6219. [Google Scholar] [CrossRef] [PubMed]

- Lee, N.H.; You, S.; Taghizadeh, A.; Taghizadeh, M.; Kim, H.S. Cell Membrane-Cloaked Nanotherapeutics for Targeted Drug Delivery. Int. J. Mol. Sci. 2022, 23, 2223. [Google Scholar] [CrossRef]

- Mousavi, S.M.; Hashemi, S.A.; Mazraedoost, S.; Yousefi, K.; Gholami, A.; Behbudi, G.; Ramakrishna, S.; Omidifar, N.; Alizadeh, A.; Chiang, W.H. Multifunctional Gold Nanorod for Therapeutic Applications and Pharmaceutical Delivery Considering Cellular Metabolic Responses, Oxidative Stress and Cellular Longevity. Nanomaterials 2021, 11, 1868. [Google Scholar] [CrossRef] [PubMed]

- Guerrero-Martinez, A.; Perez-Juste, J.; Liz-Marzan, L.M. Recent progress on silica coating of nanoparticles and related nanomaterials. Adv. Mater. 2010, 22, 1182–1195. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Kan, C.; Cong, B.; Xu, H.; Ni, Y.; Li, Y.; Shi, D. Plasmonic Property and Stability of Core-Shell Au@SiO2 Nanostructures. Plasmonics 2014, 9, 1007–1014. [Google Scholar] [CrossRef]

- Yang, W.; Kaur, S.; Kim, Y.D.; Kim, J.M.; Lee, S.H.; Lim, D.K. Precise control over the silica shell thickness and finding the optimal thickness for the peak heat diffusion property of AuNR@SiO2. J. Mater. Chem. B 2022, 10, 364–372. [Google Scholar] [CrossRef]

- Yoon, S.; Lee, B.; Kim, C.; Lee, J.H. Controlled Heterogeneous Nucleation for Synthesis of Uniform Mesoporous Silica-Coated Gold Nanorods with Tailorable Rotational Diffusion and 1 nm-Scale Size Tunability. Cryst. Growth Des. 2018, 18, 4731–4736. [Google Scholar] [CrossRef]

- Chiang, Y.-D.; Lian, H.-Y.; Leo, S.-Y.; Wang, S.-G.; Yamauchi, Y.; Wu, K.C.W. Controlling Particle Size and Structural Properties of Mesoporous Silica Nanoparticles Using the Taguchi Method. J. Phys. Chem. C 2011, 115, 13158–13165. [Google Scholar] [CrossRef]

- Mai, H.; Le, T.C.; Chen, D.; Winkler, D.A.; Caruso, R.A. Machine Learning for Electrocatalyst and Photocatalyst Design and Discovery. Chem. Rev. 2022, 122, 13478–13515. [Google Scholar] [CrossRef]

- Moosavi, S.M.; Novotny, B.Á.; Ongari, D.; Moubarak, E.; Asgari, M.; Kadioglu, Ö.; Charalambous, C.; Ortega-Guerrero, A.; Farmahini, A.H.; Sarkisov, L.; et al. A data-science approach to predict the heat capacity of nanoporous materials. Nat. Mater. 2022, 21, 1419–1425. [Google Scholar] [CrossRef]

- Lunghi, A.; Sanvito, S. Computational design of magnetic molecules and their environment using quantum chemistry, machine learning and multiscale simulations. Nat. Rev. Chem. 2022, 6, 761–781. [Google Scholar] [CrossRef]

- Braham, E.J.; Davidson, R.D.; Al-Hashimi, M.; Arroyave, R.; Banerjee, S. Navigating the design space of inorganic materials synthesis using statistical methods and machine learning. Dalton Trans. 2020, 49, 11480–11488. [Google Scholar] [CrossRef] [PubMed]

- Xie, Y.; Zhang, C.; Hu, X.; Zhang, C.; Kelley, S.P.; Atwood, J.L.; Lin, J. Machine Learning Assisted Synthesis of Metal-Organic Nanocapsules. J. Am. Chem. Soc. 2020, 142, 1475–1481. [Google Scholar] [CrossRef] [Green Version]

- Raccuglia, P.; Elbert, K.C.; Adler, P.D.; Falk, C.; Wenny, M.B.; Mollo, A.; Zeller, M.; Friedler, S.A.; Schrier, J.; Norquist, A.J. Machine-learning-assisted materials discovery using failed experiments. Nature 2016, 533, 73–76. [Google Scholar] [CrossRef]

- Yin, J.; Wu, H.; Zhang, J.; Wu, S.; Zheng, H.; Zhao, F.; Shao, Y. Quantum Chemical Calculations and Machine Learning Predictions Innovate Synthesis for High-Performance Optical Gold Nanorods. Chem. Mater. 2022, 34, 5928–5937. [Google Scholar] [CrossRef]

- Gorbunova, M.; Apyari, V.; Dmitrienko, S.; Zolotov, Y. Gold nanorods and their nanocomposites: Synthesis and recent applications in analytical chemistry. TrAC Trends Anal. Chem. 2020, 130, 115974. [Google Scholar] [CrossRef]

- Yin, J.; Chen, D.; Wu, S.; Li, C.; Liu, L.; Shao, Y. Tumor-targeted nanoprobes for enhanced multimodal imaging and synergistic photothermal therapy: Core-shell and dumbbell Gd-tailored gold nanorods. Nanoscale 2017, 9, 16661–16673. [Google Scholar] [CrossRef] [PubMed]

- Jokerst, J.V.; Thangaraj, M.; Kempen, P.J.; Sinclair, R.; Gambhir, S.S. Photoacoustic Imaging of Mesenchymal Stem Cells in Living Mice via Silica-Coated Gold Nanorods. ACS Nano 2012, 6, 5920–5930. [Google Scholar] [CrossRef] [Green Version]

- Pargent, F.; Pfisterer, F.; Thomas, J.; Bischl, B. Regularized target encoding outperforms traditional methods in supervised machine learning with high cardinality features. Comput. Stat. 2022, 37, 2671–2692. [Google Scholar] [CrossRef]

- Lever, J.; Krzywinski, M.; Altman, N. Logistic regression. Nat. Methods 2016, 13, 541–542. [Google Scholar] [CrossRef]

- Bzdok, D.; Krzywinski, M.; Altman, N. Machine learning: Supervised methods. Nat. Methods 2018, 15, 5–6. [Google Scholar] [CrossRef] [PubMed]

- Zhao, H.Y. The Analysis and Application of the C4.5 Algorithm in Decision Tree Technology. Adv. Mater. Res. 2012, 457–458, 754–757. [Google Scholar] [CrossRef]

- Feng, D.-C.; Liu, Z.-T.; Wang, X.-D.; Chen, Y.; Chang, J.-Q.; Wei, D.-F.; Jiang, Z.-M. Machine learning-based compressive strength prediction for concrete: An adaptive boosting approach. Constr. Build. Mater. 2020, 230, 117000. [Google Scholar] [CrossRef]

- Fanourgakis, G.S.; Gkagkas, K.; Tylianakis, E.; Froudakis, G.E. A Universal Machine Learning Algorithm for Large-Scale Screening of Materials. J. Am. Chem. Soc. 2020, 142, 3814–3822. [Google Scholar] [CrossRef]

- Zhang, H.; Barnard, A.S. Impact of atomistic or crystallographic descriptors for classification of gold nanoparticles. Nanoscale 2021, 13, 11887–11898. [Google Scholar] [CrossRef]

- Chen, T.; Guestrin, C. XGBoost: Scalable Tree Boosting System. In Proceedings of the 22nd ACM SIGKDD International Conference on Knowledge Discovery and Data Mining, New York, NY, USA, 13 August 2016; pp. 785–794. [Google Scholar] [CrossRef] [Green Version]

- Han, Y.; Tang, B.; Wang, L.; Bao, H.; Lu, Y.; Guan, C.; Zhang, L.; Le, M.; Liu, Z.; Wu, M. Machine-Learning-Driven Synthesis of Carbon Dots with Enhanced Quantum Yields. ACS Nano 2020, 14, 14761–14768. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.; Hoff, A.; Doebler, J.E.; Emory, S.R.; Bao, Y. Dumbbell-Like Silica Coated Gold Nanorods and Their Plasmonic Properties. Langmuir 2019, 35, 16886–16892. [Google Scholar] [CrossRef]

- Wu, K.C.W.; Yamauchi, Y. Controlling physical features of mesoporous silicananoparticles (MSNs) for emerging applications. J. Mater. Chem. 2012, 22, 1251–1256. [Google Scholar] [CrossRef]

- Pellas, V.; Blanchard, J.; Guibert, C.; Krafft, J.-M.; Miche, A.; Salmain, M.; Boujday, S. Gold Nanorod Coating with Silica Shells Having Controlled Thickness and Oriented Porosity: Tailoring the Shells for Biosensing. ACS Appl. Nano Mater. 2021, 4, 9842–9854. [Google Scholar] [CrossRef]

- Liang, A.; Liu, Q.; Wen, G.; Jiang, Z. The surface-plasmon-resonance effect of nanogold/silver and its analytical applications. TrAC Trends Anal. Chem. 2012, 37, 32–47. [Google Scholar] [CrossRef]

- Hou, W.; Cronin, S.B. A Review of Surface Plasmon Resonance-Enhanced Photocatalysis. Adv. Funct. Mater. 2013, 23, 1612–1619. [Google Scholar] [CrossRef]

- Zhi, D.; Yang, T.; O’Hagan, J.; Zhang, S.; Donnelly, R.F. Photothermal therapy. J. Controlled Release 2020, 325, 52–71. [Google Scholar] [CrossRef] [PubMed]

- Ali, M.R.K.; Wu, Y.; El-Sayed, M.A. Gold-Nanoparticle-Assisted Plasmonic Photothermal Therapy Advances toward Clinical Application. J. Phys. Chem. C 2019, 123, 15375–15393. [Google Scholar] [CrossRef]

| Code Name | Process Parameters |

|---|---|

| f0 | The number of gold nanorods |

| f1 | The concentration of cetyltrimethylammonium bromide (CTAB) in the solution |

| f2 | The volume of tetraethyl orthosilicate (TEOS) in a single injection |

| f3 | The concentration of the TEOS solution |

| f4 | The solvent of the TEOS solution |

| f5 | The concentration of the sodium hydroxide (NaOH) solution |

| f6 | The rate of stirring mixtures in the solution |

| f7 | The interval between drops of the TEOS solution |

| f8 | The total volume of the solution |

| f9 | The age of the solution |

| AUC | ACC | Precision | Recall | F1 Score | |

|---|---|---|---|---|---|

| ADA | 0.892706 | 0.854736 | 0.59784 | 0.752517 | 0.665029 |

| RF | 0.933072 | 0.917686 | 0.774662 | 0.752517 | 0.763268 |

| GBDT | 0.921759 | 0.898529 | 0.727928 | 0.772071 | 0.748218 |

| LR | 0.89211 | 0.848096 | 0.593264 | 0.518264 | 0.551995 |

| XGboost | 0.943967 | 0.917935 | 0.812165 | 0.768881 | 0.786131 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Yin, J.; Lai, R.; Wang, Y.; Mao, B.; Wu, H.; Tian, L.; Shao, Y. Machine Learning Predicting Optimal Preparation of Silica-Coated Gold Nanorods for Photothermal Tumor Ablation. Nanomaterials 2023, 13, 1024. https://0-doi-org.brum.beds.ac.uk/10.3390/nano13061024

Zhang J, Yin J, Lai R, Wang Y, Mao B, Wu H, Tian L, Shao Y. Machine Learning Predicting Optimal Preparation of Silica-Coated Gold Nanorods for Photothermal Tumor Ablation. Nanomaterials. 2023; 13(6):1024. https://0-doi-org.brum.beds.ac.uk/10.3390/nano13061024

Chicago/Turabian StyleZhang, Jintao, Jinchang Yin, Ruiran Lai, Yue Wang, Baorui Mao, Haonan Wu, Li Tian, and Yuanzhi Shao. 2023. "Machine Learning Predicting Optimal Preparation of Silica-Coated Gold Nanorods for Photothermal Tumor Ablation" Nanomaterials 13, no. 6: 1024. https://0-doi-org.brum.beds.ac.uk/10.3390/nano13061024