Effects of Shellac Treatment on Wood Hygroscopicity, Dimensional Stability and Thermostability

Abstract

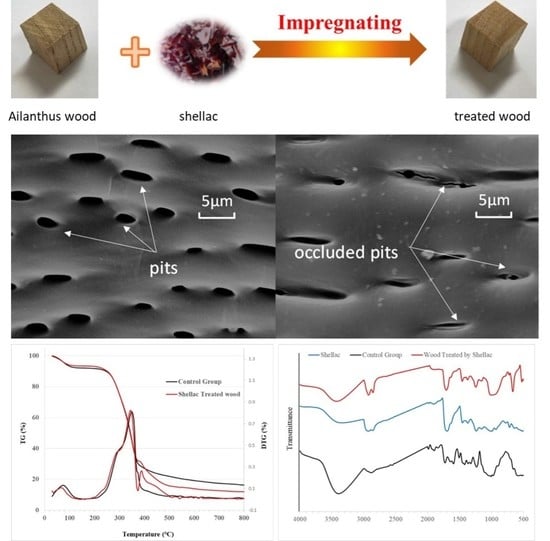

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Impregnating the Wood with Shellac

2.3. Weight Percentage Gain (WPG)

2.4. Estimation of Wood Dimensional Stability

2.5. Moisture Absorption (MA)

2.6. Chemical Structure Analysis Using FTIR Spectroscopy

2.7. Thermogravimetric Analysis

2.8. Morphological Characteristics

3. Results and Discussion

3.1. Weight Percentage Gain (WPG)

3.2. Estimation of Wood Dimensional Stability and Moisture Absorption (MA)

3.2.1. Wood Dimensional Stability

3.2.2. Moisture Absorption (MA)

3.3. Chemical Structure Analysis Using FTIR Spectroscopy

3.4. Thermostability

3.5. Morphology

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Popescu, C.M.; Popescu, M.C. A near infrared spectroscopic study of the structural modifications of lime (Tilia cordata Mill.) wood during hydro-thermal treatment. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2013, 115, 227–233. [Google Scholar] [CrossRef] [PubMed]

- Li, T.; Cheng, D.L.; Avramidis, S.; Wålinder, M.E.P.; Zhou, D.G. Response of hygroscopicity to heat treatment and its relation to durability of thermally modified wood. Constr. Build. Mater. 2017, 144, 671–676. [Google Scholar] [CrossRef]

- Liu, L.; Kong, S.; Zhang, Y.; Wang, Y.; Liang, X.; Yan, Q.; Lingaswamy, A.P.; Shi, Z.; Lv, S.; Niu, H.; et al. Morphology, composition, and mixing state of primary particles from combustion sources—Crop residue, wood, and solid waste. Sci. Rep. 2017, 7, 5047. [Google Scholar] [CrossRef] [PubMed]

- Kržišnik, D.; Lesar, B.; Thaler, N.; Humar, M. Micro and material climate monitoring in wooden buildings in sub-Alpine environments. Constr. Build. Mater. 2018, 166, 188–195. [Google Scholar] [CrossRef]

- Wang, J.; Chen, L.; He, Y. Preparation of environmental friendly coatings based on natural shellac modified by diamine and its applications for copper protection. Prog. Org. Coat. 2008, 62, 307–312. [Google Scholar] [CrossRef]

- Okon, K.E.; Lin, F.; Chen, Y.; Huang, B. Effect of silicone oil heat treatment on the chemical composition, cellulose crystalline structure and contact angle of Chinese parasol wood. Carbohydr. Polym. 2017, 164, 179–185. [Google Scholar] [CrossRef]

- Rostand, M.P.; Dubois, F.; Sauvat, N.; Fournely, E. Strain analysis in dried green wood: Experimentation and modelling approaches. Eng. Fract. Mech. 2013, 105, 182–199. [Google Scholar] [CrossRef]

- Saeed, M.A.; Andrews, G.E.; Phylaktou, H.N.; Gibbs, B.M. Raw and steam exploded pine wood: Possible enhanced reactivity with gasification hydrogen. Int. J. Hydrog. Energy 2016, 41, 16566–16576. [Google Scholar] [CrossRef]

- Li, M.Y.; Cheng, S.C.; Li, D.; Wang, S.N.; Huang, A.M.; Sun, S.Q. Structural characterization of steam-heat treated Tectona grandis wood analyzed by FT-IR and 2D-IR correlation spectroscopy. Chin. Chem. Lett. 2015, 26, 221–225. [Google Scholar] [CrossRef]

- Lykidis, C.; Bak, M.; Mantanis, G.; Németh, R. Biological resistance of pine wood treated with nano-sized zinc oxide and zinc borate against brown-rot fungi. Holz Als Roh Und Werkstoff 2016, 74, 909–911. [Google Scholar] [CrossRef] [Green Version]

- Sandberg, D.; Kutnar, A.; Mantanis, G. Wood modification technologies—A review. Iforest Biogeosciences For. 2017, 10, 895–908. [Google Scholar] [CrossRef] [Green Version]

- Lykidis, C.; De Troya, T.; María, C.; Galván, J.; Mantanis, G. Termite resistance of beech wood treated with zinc oxide and zinc borate nanocompounds. Wood Mater. Ence Eng. 2016, 1–5. [Google Scholar] [CrossRef]

- Yin, J.P.; Yuan, T.Q.; Lu, Y.; Song, K.L.; Li, H.Y.; Zhao, G.J.; Yin, Y.F. Effect of compression combined with steam treatment on the porosity, chemical compositon and cellulose crystalline structure of wood cell walls. Carbohydr. Polym. 2017, 155, 163–172. [Google Scholar] [CrossRef] [PubMed]

- Ziegler, I.M.; Tánczos, I.; Hórvölgyi, Z.; Agoston, B. Water-repellent acylated and silylated wood samples and their surface analytical characterization. Colloids Surf. A-Physicochem. Eng. Asp. 2008, 319, 204–212. [Google Scholar] [CrossRef]

- Broda, M.; Mazela, B. Application of methyltrimethoxysilane to increase dimensional stability of waterlogged wood. J. Cult. Herit. 2017, 25, 149–156. [Google Scholar] [CrossRef]

- Devi, R.; Maji, R.; Ali, T.K.I. Chemical modification of rubber wood with styrene in combination with a crosslinker: Effect on dimensional stability and strength property. Bioresour. Technol. 2003, 88, 185–188. [Google Scholar] [CrossRef]

- Ayrilmis, N. Combined effects of boron and compatibilizer on dimensional stability and mechanical properties of wood/HDPE composites. Compos. Part B Eng. 2013, 44, 745–749. [Google Scholar] [CrossRef]

- Giudice, C.A.; Alfieri, P.V.; Canosa, G. Decay resistance and dimensional stability of Araucaria angustifolia using siloxanes synthesized by sol–gel process. Int. Biodeterior. Biodegrad. 2013, 83, 166–170. [Google Scholar] [CrossRef]

- Broda, J.; Majka, M.; Olek, W.; Mazela, B. Dimensional stability and hygroscopic properties of waterlogged archaeological wood treated with alkoxysilanes. Int. Biodeterior. Biodegrad. 2018, 133, 34–41. [Google Scholar] [CrossRef]

- He, Z.B.; Qu, L.J.; Wang, Z.Y.; Qian, J.; Yi, S.L. Effects of zinc chloride–silicone oil treatment on wood dimensional stability, chemical components, thermal decomposition and its mechanism. Sci. Rep. 2019, 9, 1601. [Google Scholar] [CrossRef]

- Popescu, M.C.; Jones, D.; Krzisnik, D.; Humar, M. Determination of the effectiveness of a combined thermal/chemical wood modification by the use of FTIR spectroscopy and chemometric methods. J. Mol. Struct. 2020, 1200, 127–133. [Google Scholar] [CrossRef]

- Esteves, B.; Videira, R.; Pereira, H. Chemistry and ecotoxicity of heat-treated pine wood extractives. Wood Sci. Technol. 2011, 45, 661–676. [Google Scholar] [CrossRef] [Green Version]

- Esteves, B.; Pereira, H. Wood modification by heat treatment: A review. BioResources 2009, 4, 340–404. [Google Scholar]

- Esteves, B.; Graça, J.; Pereira, H. Extractive composition and summative chemical analysis of thermally treated eucalypt wood. Holzforschung 2008, 62, 344–351. [Google Scholar] [CrossRef]

- Weththimuni, M.L.; Capsoni, D.; Malagodi, M.; Milanese, C.; Licchelli, M. Shellac/nanoparticles dispersions as protective materials for wood. Appl. Phys. A 2016, 122, 1058. [Google Scholar] [CrossRef]

- Farag, Y.; Leopold, C.S. Physicochemical Properties of Various Shellac Types. Dissolution Technol. 2007, 16, 33–39. [Google Scholar] [CrossRef]

- Wang, Y.L.; Ishida, H.; Ohtani, S.; Tsuge, T. Nakayama, Characterization of Natural Resin Shellac by Reactive Pyrolysis−Gas Chromatography in the Presence of Organic Alkali. Anal. Chem. 1999, 71, 1316–1322. [Google Scholar] [CrossRef]

- Licchelli, M.; Malagodi, M.; Somaini, M.; Weththimuni, M.; Zanchi, C. Surface treatments of wood by chemically modified shellac. Surf. Eng. 2013, 29, 121–127. [Google Scholar] [CrossRef]

- Simunková, K.; Pánek, M.; Ales, Z. Comparison of Selected Properties of Shellac Varnish for Restoration and Polyurethane Varnish for Reconstruction of Historical Artefacts. Coatings 2018, 8, 119. [Google Scholar] [CrossRef] [Green Version]

- Chang, Y.J.; Yan, X.X. Preparation and self-repairing properties of MF-coated shellac water-based microcapsules. Coatings 2020, 10, 778. [Google Scholar] [CrossRef]

- Remadevi, O.K.; Mahtab, Z.S.; Nagaveni, H.C.; Ranganathan, R.; Venkateswara, R.M.; Shiny, K.S. Efficacy of shellac-based varnishes for protection of wood against termite, borer and fungal attack. J. Indian Acad. Wood Sci. 2015, 12, 9–14. [Google Scholar] [CrossRef]

- Pearnchob, N.; Dashevsky, A.; Bodmeier, R. Improvement in the disintegration of shellac-coated soft gelatin capsules in simulated intestinal fluid. J. Control. Release 2004, 94, 313–332. [Google Scholar] [CrossRef] [PubMed]

- Kennedy, J.F.; Knill, C.J. Edible Coatings and Films to Improve Food Quality. Carbohydr. Polym. 1997, 33, 86–87. [Google Scholar] [CrossRef]

- The, D.P.; Debeaufort, F.; Luu, D.; Voilley, A. Moisture barrier, wetting and mechanical properties of shellac/agar or shellac/cassava starch bilayer bio-membrane for food applications. J. Membr. Sci. 2008, 325, 277–283. [Google Scholar]

- Bai, J.; Hagenmaier, R.D.; Baldwin, E.A. Volatile Response of Four Apple Varieties with Different Coatings during Marketing at Room Temperature. J. Agric. Food Chem. 2002, 50, 7660–7668. [Google Scholar] [CrossRef] [PubMed]

- Hedva, B.; Havazelet, B.P. Modification of shellac coating using Jeffamine for enhanced mechanical properties and stability. Prog. Org. Coat. 2020, 141, 105559. [Google Scholar]

- Tai, L.I.; Kuo, Y.C.; Yu, C. Modeling shallow gravity-driven solid-fluid mixtures over arbitrary topography. Commun. Math. Ences 2009, 7, 1–36. [Google Scholar]

- He, Z.B.; Qian, J.; Qu, L.J.; Yan, N.; Yi, S.L. Effects of Tung oil treatment on wood hygroscopicity, dimensional stability and thermostability. Ind. Crop. Prod. 2019, 140, 111647. [Google Scholar] [CrossRef]

- Zhao, R.J.; Fei, B.H.; Lv, J.X.; Yu, H.Q.; Huang, R.F.; Zhao, Y.Q.; Huang, A.M.; Cui, Y.Z. Wood Moisture Content Measuring Method. Wood-determination of Moisture Content for Physical and Mechanical Test. Chin. Stand. 2009; MOD, CN-GB, GB/T 1931–2009. [Google Scholar]

- Humara, M.; Lesara, B. Efficacy of linseed- and tung-oil-treated wood against wood-decay fungi and water uptake. Int. Biodeterior. Biodegrad. 2013, 85, 223–227. [Google Scholar] [CrossRef]

- He, Z.B.; Yang, F.; Wang, Z.Y.; Zhao, Z.J.; Yi, S.L. Reducing wood drying time by application of ultrasound pretreatment. Dry. Technol. 2016, 34, 1141–1146. [Google Scholar] [CrossRef]

- Jiang, J.; Li, J.; Gao, Q. Effect of flame retardant treatment on dimensional stability and thermal degradation of wood. Constr. Build. Mater. 2015, 75, 74–81. [Google Scholar] [CrossRef]

- Basso, M.C.; Pizzi, A.; Polesel, M.J.; Delmotte, L.; Colin, B.; Rogaume, Y. MALDI-TOF, 13C NMR and FTIR analysis of the cross-linking reaction of condensed tannins by triethyl phosphate. Ind. Crop. Prod. 2017, 95, 621–631. [Google Scholar] [CrossRef]

- Chen, W.; Yu, H.; Liu, Y.; Chen, P.; Zhang, M.; Hai, Y. Individualization of cellulose nanofibers from wood using high-intensity ultrasonication combined with chemical pretreatments. Carbohydr. Polym. 2011, 83, 1804–1811. [Google Scholar] [CrossRef]

- He, Z.; Wang, Z.; Zhao, Z.; Yi, S.; Mu, J.; Wang, X. Influence of ultrasound pretreatment on wood physiochemical structure. Ultrason. Sonochem. 2017, 34, 136–141. [Google Scholar] [CrossRef] [Green Version]

- Naron, D.R.; Collard, F.X.; Tyhoda, L.; Görgens, J.F. Characterisation of lignins from different sources by appropriate analytical methods: Introducing thermogravimetric analysis-thermal desorption-gas chromatography–mass spectroscopy. Ind. Crop. Prod. 2017, 101, 61–74. [Google Scholar] [CrossRef]

- Çetinkol, Ö.P.; Dibble, D.C.; Cheng, G.; Kent, M.S.; Knierim, B.; Auer, M.; Wemmer, D.E.; Pelton, J.G.; Melnichenko, Y.B.; Ralph, J. Understanding the impact of ionic liquid pretreatment on eucalyptus. Biofuels 2010, 1, 33–46. [Google Scholar] [CrossRef]

- Kumar, R.; Mago, G.; Balan, V.; Wyman, C.E. Physical and chemical characterizations of corn stover and poplar solids resulting from leading pretreatment technologies. Bioresour. Technol. 2009, 100, 3948–3962. [Google Scholar] [CrossRef]

- Kesik, H.I.; Korkut, S.; Hiziroglu, S.; Sevik, H. An evaluation of properties of four heat treated wood species. Ind. Crop. Prod. 2014, 60, 60–65. [Google Scholar] [CrossRef]

- Lin, B.J.; Colina, B.; Chen, W.H.; Pétrissansa, A.; Roussetd, P.; Pétrissans, M. Thermal degradation and compositional changes of wood treated in a semi-industrial scale reactor in vacuum. J. Anal. Appl. Pyrolysis 2018, 130, 8–18. [Google Scholar] [CrossRef]

- Giuntoli, J.; Jong, W.; Arvelakis, S.; Spliethoff, H.; Verkooijen, A.H.M. Quantitative and kinetic TG-FTIR study of biomass residue pyrolysis: Dry distiller’s grains with solubles (DDGS) and chicken manure. J. Anal. Appl. Pyrolysis 2009, 85, 301–312. [Google Scholar] [CrossRef]

| Wood Sample | Before Impregnation | After Impregnation |

|---|---|---|

| Weight (g) | 4.636 ± 0.221 | 5.239 ± 0.319 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, M.; Xu, G.; Wang, J.; Tu, X.; Liu, X.; Wu, Z.; Lv, J.; Xu, W. Effects of Shellac Treatment on Wood Hygroscopicity, Dimensional Stability and Thermostability. Coatings 2020, 10, 881. https://0-doi-org.brum.beds.ac.uk/10.3390/coatings10090881

Liu M, Xu G, Wang J, Tu X, Liu X, Wu Z, Lv J, Xu W. Effects of Shellac Treatment on Wood Hygroscopicity, Dimensional Stability and Thermostability. Coatings. 2020; 10(9):881. https://0-doi-org.brum.beds.ac.uk/10.3390/coatings10090881

Chicago/Turabian StyleLiu, Mihaela, Guanglin Xu, Jianan Wang, Xinwei Tu, Xinyou Liu, Zhihui Wu, Jiufang Lv, and Wei Xu. 2020. "Effects of Shellac Treatment on Wood Hygroscopicity, Dimensional Stability and Thermostability" Coatings 10, no. 9: 881. https://0-doi-org.brum.beds.ac.uk/10.3390/coatings10090881