Optimal Biomechanical Performance in Upper-Limb Gestures Depends on Velocity and Carried Load

Abstract

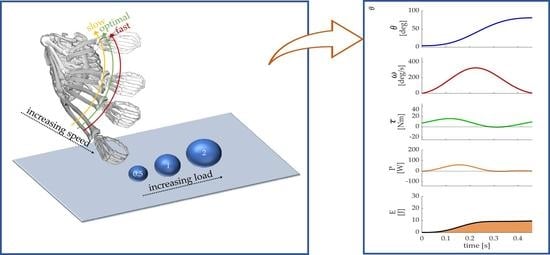

:Simple Summary

Abstract

1. Introduction

2. Materials and Methods

2.1. Data Acquisition

2.2. Biomechanical Model

2.3. Simulations

2.4. Outcome Measures and Statistics

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lu, Y. Industry 4.0: A survey on technologies, applications and open research issues. J. Ind. Inf. Integr. 2017, 6, 1–10. [Google Scholar] [CrossRef]

- Alcácer, V.; Cruz-Machado, V. Scanning the Industry 4.0: A Literature Review on Technologies for Manufacturing Systems. Eng. Sci. Technol. Int. J. 2019, 22, 899–919. [Google Scholar] [CrossRef]

- Longo, F.; Nicoletti, L.; Padovano, A. Smart operators in industry 4.0: A human-centered approach to enhance operators’ capabilities and competencies within the new smart factory context. Comput. Ind. Eng. 2017, 113, 144–159. [Google Scholar] [CrossRef]

- Pacifico, I.; Molteni, F.; Giovacchini, F.; Vitiello, N.; Crea, S.; Scano, A.; Guanziroli, E.; Moise, M.; Morelli, L.; Chiavenna, A.; et al. An experimental evaluation of the proto-mate: A novel ergonomic upper-limb exoskeleton to reduce workers’ physical strain. IEEE Robot. Autom. Mag. 2020, 27, 54–65. [Google Scholar] [CrossRef]

- Bejarano, R.; Ferrer, B.R.; Mohammed, W.M.; Martinez Lastra, J.L. Implementing a Human-Robot Collaborative Assembly Workstation. In Proceedings of the 2019 IEEE 17th International Conference on Industrial Informatics (INDIN), Helsinki, Finland, 22–25 July 2019; Volume 2019, pp. 557–564. [Google Scholar]

- Pedrocchi, N.; Vicentini, F.; Malosio, M.; Tosatti, L.M. Safe human-robot cooperation in an industrial environment. Int. J. Adv. Robot. Syst. 2013, 10, 27. [Google Scholar] [CrossRef]

- Csikszentmihalyi, M.; LeFevre, J. Optimal Experience in Work and Leisure. J. Pers. Soc. Psychol. 1989, 56, 815–822. [Google Scholar] [CrossRef]

- Delle Fave, A.; Massimini, F. The investigation of optimal experience and apathy: Developmental and psychosocial implications. Eur. Psychol. 2005, 10, 264–274. [Google Scholar] [CrossRef]

- Xing, X.; Zhong, B.; Luo, H.; Rose, T.; Li, J.; Antwi-Afari, M.F. Effects of physical fatigue on the induction of mental fatigue of construction workers: A pilot study based on a neurophysiological approach. Autom. Constr. 2020, 120, 103381. [Google Scholar] [CrossRef]

- Marcora, S.M.; Staiano, W.; Manning, V. Mental fatigue impairs physical performance in humans. J. Appl. Physiol. 2009, 106, 857–864. [Google Scholar] [CrossRef] [PubMed]

- Leijten, F.R.M.; van den Heuvel, S.G.; van der Beek, A.J.; Ybema, J.F.; Robroek, S.J.W.; Burdorf, A. Associations of Work-Related Factors and Work Engagement with Mental and Physical Health: A 1-Year Follow-up Study Among Older Workers. J. Occup. Rehabil. 2015, 25, 86–95. [Google Scholar] [CrossRef] [PubMed]

- Nicora, M.L.; Andre, E.; Berkmans, D.; Carissoli, C.; D’Orazio, T.; Fave, A.D.; Gebhard, P.; Marani, R.; Mira, R.M.; Negri, L.; et al. A human-driven control architecture for promoting good mental health in collaborative robot scenarios. In Proceedings of the 2021 30th IEEE International Conference on Robot and Human Interactive Communication, RO-MAN 2021, Vancouver, BC, Canada, 8–12 August 2021; Institute of Electrical and Electronics Engineers Inc.: Vancouver, BC, Canada, 2021; pp. 285–291. [Google Scholar]

- Dumas, R.; Chèze, L. 3D inverse dynamics in non-orthonormal segment coordinate system. Med. Biol. Eng. Comput. 2007, 45, 315–322. [Google Scholar] [CrossRef]

- Romeo, L.; Marani, R.; Malosio, M.; Perri, A.G.; D’Orazio, T. Performance analysis of body tracking with the microsoft azure kinect. In Proceedings of the 2021 29th Mediterranean Conference on Control and Automation, MED 2021, Puglia, Italy, 22–25 June 2021; Institute of Electrical and Electronics Engineers Inc.: Puglia, Italy, 2021; pp. 572–577. [Google Scholar]

- Jiang, Y.; Jiang, Z.P.; Qian, N. Optimal control mechanisms in human arm reaching movements. In Proceedings of the Proceedings of the 30th Chinese Control Conference, CCC 2011, Yantai, China, 22–24 July 2011; pp. 1377–1382. [Google Scholar]

- Flash, T.; Hogan, N. The coordination of arm movements: An experimentally confirmed mathematical model. J. Neurosci. 1985, 5, 1688–1703. [Google Scholar] [CrossRef] [PubMed]

- Uno, Y.; Kawato, M.; Suzuki, R. Formation and control of optimal trajectory in human multijoint arm movement. Biol. Cybern. 1989, 61, 89–101. [Google Scholar] [CrossRef] [PubMed]

- Harris, C.M.; Wolpert, D.M. Signal-dependent noise determines motor planning. Nature 1998, 394, 780–784. [Google Scholar] [CrossRef] [PubMed]

- Alexander, R.M.N. A minimum energy cost hypothesis for human arm trajectories. Biol. Cybern. 1997, 76, 97–105. [Google Scholar] [CrossRef]

- Zhou, L.; Bai, S.; Hansen, M.R.; Rasmussen, J. Modeling of human arm energy expenditure for predicting energy optimal trajectories. Model. Identif. Control 2011, 32, 91–101. [Google Scholar] [CrossRef] [Green Version]

- Gaveau, J.; Papaxanthis, C. The temporal structure of vertical arm movements. PLoS ONE 2011, 6, e22045. [Google Scholar] [CrossRef] [PubMed]

- Le Seac’h, A.B.; McIntyre, J. Multimodal reference frame for the planning of vertical arms movements. Neurosci. Lett. 2007, 423, 211–215. [Google Scholar] [CrossRef]

- Berret, B.; Darlot, C.; Jean, F.; Pozzo, T.; Papaxanthis, C.; Gauthier, J.P. The inactivation principle: Mathematical solutions minimizing the absolute work and biological implications for the planning of arm movements. PLoS Comput. Biol. 2008, 4, e1000194. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rickham, P.P. Human Experimentation Code of Ethics of the World Medical Association. Br. Med. J. 1964, 2, 177. [Google Scholar] [CrossRef] [Green Version]

- Stone, N.J.; Alex, C.; Keebler, J.R.; Chaparro, B.S.; McConnell, D.S. Anthropometry and Biomechanics. In Introduction to Human Factors; CRC Press: Boca Raton, FL, USA, 2018; pp. 257–294. [Google Scholar]

- Yamamoto, S.; Kushiro, K. Direction-dependent differences in temporal kinematics for vertical prehension movements. Exp. Brain Res. 2014, 232, 703–711. [Google Scholar] [CrossRef] [PubMed]

- Atkeson, C.G.; Hollerbach, J.M. Kinematic features of untreated vertical arm movements. J. Neurosci. 1985, 5, 2318–2330. [Google Scholar] [CrossRef] [Green Version]

- Caimmi, M.; Pedrocchi, N.; Scano, A.; Malosio, M.; Vicentini, F.; Tosatti, L.M.; Molteni, F. Proprioceptivity and upper-extremity dynamics in robot-assisted reaching movement. In Proceedings of the IEEE RAS and EMBS International Conference on Biomedical Robotics and Biomechatronics, Rome, Italy, 24–27 June 2012; pp. 1316–1322. [Google Scholar]

- Mira, R.M.; Molinari Tosatti, L.; Sacco, M.; Scano, A. Detailed characterization of physiological EMG activations and directional tuning of upper-limb and trunk muscles in point-to-point reaching movements. Curr. Res. Physiol. 2021, 4, 60–72. [Google Scholar] [CrossRef]

- Papaxanthis, C.; Pozzo, T.; Schieppati, M. Trajectories of arm pointing movements on the sagittal plane vary with both direction and speed. Exp. Brain Res. 2003, 148, 498–503. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.; Oh, J.; Kim, Y.; Kwon, M.; Kim, J. Estimation of the upper limb lifting movement under varying weight and movement speed. In Proceedings of the 2nd International Conference on Engineering and Industries, ICEI 2011, Seogwipo, Korea, 29–30 June 2011; pp. 151–156. [Google Scholar]

- Maurice, P.; Huber, M.E.; Hogan, N.; Sternad, D. Velocity-Curvature Patterns Limit Human-Robot Physical Interaction. IEEE Robot. Autom. Lett. 2018, 3, 249–256. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Huber, M.; Rickert, M.; Knoll, A.; Brandt, T.; Glasauer, S. Human-robot interaction in handing-over tasks. In Proceedings of the 17th IEEE International Symposium on Robot and Human Interactive Communication, RO-MAN, Munich, Germany, 1–3 August 2008; pp. 107–112. [Google Scholar]

- Blais, A.R.; Gillet, N.; Houle, S.A.; Comeau, C.A.; Morin, A.J.S. Work Fatigue Profiles: Nature, Implications, and Associations With Psychological Empowerment. Front. Psychol. 2020, 11, 3394. [Google Scholar] [CrossRef] [PubMed]

- Xu, R.; Zhang, C.; He, F.; Zhao, X.; Qi, H.; Zhou, P.; Zhang, L.; Ming, D. How Physical Activities Affect Mental Fatigue Based on EEG Energy, Connectivity, and Complexity. Front. Neurol. 2018, 9, 915. [Google Scholar] [CrossRef]

- Yu, Y.; Li, H.; Yang, X.; Kong, L.; Luo, X.; Wong, A.Y.L. An automatic and non-invasive physical fatigue assessment method for construction workers. Autom. Constr. 2019, 103, 1–12. [Google Scholar] [CrossRef]

- Ma, L.; Zhang, W.; Wu, S.; Zhang, Z. A new simple local muscle recovery model and its theoretical and experimental validation. Int. J. Occup. Saf. Ergon. 2015, 21, 86–93. [Google Scholar] [CrossRef] [PubMed]

- Seth, D.; Chablat, D.; Sakka, S.; Bennis, F. Experimental validation of a new dynamic muscle fatigue model. In Proceedings of the International Conference on Digital Human Modeling and Applications in Health, Safety, Ergonomics and Risk Management, Toronto, ON, Canada, 17–22 July 2016; Volume 9745, pp. 54–65. [Google Scholar]

- Downey, R.J.; Bellman, M.J.; Kawai, H.; Gregory, C.M.; Dixon, W.E. Comparing the Induced Muscle Fatigue Between Asynchronous and Synchronous Electrical Stimulation in Able-Bodied and Spinal Cord Injured Populations. IEEE Trans. Neural Syst. Rehabil. Eng. 2015, 23, 964–972. [Google Scholar] [CrossRef] [PubMed]

- Yang, C.; Leitkam, S.; Coté, J.N. Effects of different fatigue locations on upper body kinematics and inter-joint coordination in a repetitive pointing task. PLoS ONE 2019, 14, e0227247. [Google Scholar] [CrossRef]

- Forestier, N.; Nougier, V. The effects of muscular fatigue on the coordination of a multijoint movement in human. Neurosci. Lett. 1998, 252, 187–190. [Google Scholar] [CrossRef]

- Merlo, A.; Longhi, M.; Giannotti, E.; Prati, P.; Giacobbi, M.; Ruscelli, E.; Mancini, A.; Ottaviani, M.; Montanari, L.; Mazzoli, D. Upper limb evaluation with robotic exoskeleton. Normative values for indices of accuracy, speed and smoothness. NeuroRehabilitation 2013, 33, 523–530. [Google Scholar] [CrossRef] [PubMed]

- Gaveau, J.; Berret, B.; Demougeot, L.; Fadiga, L.; Pozzo, T.; Papaxanthis, C. Energy-related optimal control accounts for gravitational load: Comparing shoulder, elbow, and wrist rotations. J. Neurophysiol. 2014, 111, 4–16. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Scano, A.; Dardari, L.; Molteni, F.; Giberti, H.; Tosatti, L.M.; D’Avella, A. A comprehensive spatial mapping of muscle synergies in highly variable upper-limb movements of healthy subjects. Front. Physiol. 2019, 10, 1231. [Google Scholar] [CrossRef]

- Scano, A.; Mira, R.M.; D’Avella, A. Mixed matrix factorization: A novel algorithm for the extraction of kinematic-muscular synergies. J. Neurophysiol. 2022, 127, 529–547. [Google Scholar] [CrossRef] [PubMed]

| vsf (%) | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Load (kg) | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 110 | 120 | 130 | 140 | 150 | 160 | 170 | 180 | 190 | 200 | |

| Shoulder Flexion | ||||||||||||||||||||

| τ (N·m) | 0 | 13.1 | 12.9 | 12.8 | 12.6 | 12.3 | 11.9 | 11.6 | 11.7 | 13.0 | 14.4 | 16.1 | 17.9 | 19.7 | 21.5 | 23.3 | 25.1 | 26.9 | 28.7 | 30.5 |

| 0.5 | 16.1 | 15.9 | 15.74 | 15.5 | 15.1 | 14.6 | 14.4 | 15.7 | 17.8 | 20.1 | 22.5 | 25.0 | 27.6 | 30.2 | 32.8 | 35.3 | 37.9 | 40.5 | 43.0 | |

| 1 | 19.1 | 19.0 | 18.7 | 18.4 | 17.9 | 17.5 | 17.7 | 20.0 | 22.7 | 25.8 | 28.9 | 32.2 | 35.5 | 38.9 | 42.3 | 45.6 | 49.0 | 52.3 | 55.6 | |

| 2 | 25.2 | 25.0 | 24.6 | 24.2 | 23.5 | 23.1 | 24.9 | 28.5 | 32.7 | 37.2 | 41.8 | 46.6 | 51.5 | 56.4 | 61.3 | 66.3 | 71.2 | 76.1 | 80.9 | |

| P (W) | 0 | 11.5 | 16.5 | 20.5 | 23.6 | 26.1 | 28.9 | 33.2 | 39.1 | 46.3 | 54.7 | 64.2 | 74.7 | 86.1 | 98.4 | 111.4 | 125.1 | 139.5 | 154.6 | 170.2 |

| 0.5 | 14.1 | 20.0 | 24.7 | 28.1 | 31.1 | 35.4 | 41.9 | 50.4 | 60.6 | 72.3 | 85.5 | 100.1 | 115.9 | 132.8 | 150.9 | 170.0 | 189.9 | 210.7 | 232.3 | |

| 1 | 16.7 | 23.5 | 28.9 | 32.7 | 36.5 | 42.5 | 51.1 | 62.1 | 75.3 | 90.3 | 107.2 | 125.8 | 145.9 | 167.6 | 190.7 | 215.1 | 240.5 | 267.0 | 294.6 | |

| 2 | 21.9 | 30.7 | 37.3 | 42.1 | 47.9 | 57.1 | 70.0 | 86.0 | 104.9 | 126.6 | 150.8 | 177.4 | 206.4 | 237.6 | 270.6 | 305.4 | 341.9 | 380.2 | 420.0 | |

| E (J) | 0 | 12.7 | 12.5 | 12.2 | 11.8 | 11.3 | 10.7 | 10.1 | 9.3 | 8.5 | 8.6 | 9.6 | 11.1 | 12.9 | 14.9 | 16.9 | 19.1 | 21.2 | 23.5 | 25.7 |

| 0.5 | 15.8 | 15.5 | 15.1 | 14.5 | 13.7 | 12.9 | 11.9 | 10.8 | 10.4 | 11.7 | 13.8 | 16.2 | 18.9 | 21.8 | 24.7 | 27.8 | 30.9 | 34.1 | 37.3 | |

| 1 | 18.9 | 18.5 | 17.9 | 17.1 | 16.2 | 15.0 | 13.7 | 12.5 | 13.0 | 15.2 | 18.1 | 21.4 | 25.0 | 28.8 | 32.7 | 36.6 | 40.7 | 44.8 | 48.9 | |

| 2 | 25.1 | 24.5 | 23.6 | 22.4 | 21.0 | 19.3 | 17.4 | 16.6 | 18.8 | 22.5 | 27.0 | 32.0 | 37.3 | 42.9 | 48.6 | 54.4 | 60.3 | 66.3 | 72.3 | |

| Shoulder Abduction | ||||||||||||||||||||

| τ (N·m) | 0 | 4.8 | 4.8 | 4.8 | 5.0 | 5.3 | 5.8 | 6.3 | 6.9 | 7.5 | 8.1 | 8.7 | 9.4 | 10.0 | 10.6 | 11.2 | 11.8 | 12.4 | 13.0 | 13.6 |

| 0.5 | 5.6 | 5.5 | 5.6 | 6.0 | 6.5 | 7.1 | 7.8 | 8.5 | 9.3 | 10.1 | 10.9 | 11.7 | 12.6 | 13.4 | 14.2 | 15.0 | 15.8 | 16.6 | 17.3 | |

| 1 | 6.3 | 6.3 | 6.5 | 7.0 | 7.6 | 8.3 | 9.2 | 10.1 | 11.0 | 12.0 | 13.0 | 14.1 | 15.1 | 16.2 | 17.2 | 18.2 | 19.2 | 20.2 | 21.1 | |

| 2 | 7.8 | 7.9 | 8.3 | 8.9 | 9.8 | 10.8 | 12.0 | 13.2 | 14.6 | 15.9 | 17.4 | 18.8 | 20.3 | 21.7 | 23.2 | 24.6 | 26.0 | 27.4 | 28.7 | |

| P (W) | 0 | 1.1 | 1.7 | 2.3 | 2.9 | 3.6 | 4.3 | 5.2 | 6.1 | 7.1 | 8.2 | 9.4 | 10.7 | 12.0 | 13.5 | 15.0 | 16.6 | 18.2 | 19.9 | 21.7 |

| 0.5 | 1.3 | 2.0 | 2.7 | 3.5 | 4.3 | 5.3 | 6.3 | 7.5 | 8.9 | 10.3 | 11.9 | 13.6 | 15.4 | 17.3 | 19.3 | 21.5 | 23.7 | 26.0 | 28.3 | |

| 1 | 1.5 | 2.3 | 3.1 | 4.0 | 5.1 | 6.2 | 7.5 | 9.0 | 10.6 | 12.4 | 14.4 | 16.5 | 18.8 | 21.2 | 23.7 | 26.3 | 29.1 | 32.0 | 35.0 | |

| 2 | 1.9 | 2.9 | 4.0 | 5.2 | 6.6 | 8.1 | 9.9 | 11.9 | 14.2 | 16.6 | 19.3 | 22.3 | 25.5 | 28.8 | 32.4 | 36.2 | 40.1 | 44.2 | 48.5 | |

| E (J) | 0 | 1.1 | 1.1 | 1.1 | 1.2 | 1.2 | 1.2 | 1.3 | 1.3 | 1.4 | 1.4 | 1.4 | 1.5 | 1.5 | 1.6 | 1.6 | 1.7 | 1.8 | 1.8 | 1.9 |

| 0.5 | 1.3 | 1.3 | 1.4 | 1.4 | 1.4 | 1.5 | 1.5 | 1.6 | 1.7 | 1.7 | 1.8 | 1.9 | 1.9 | 2.0 | 2.1 | 2.2 | 2.2 | 2.3 | 2.4 | |

| 1 | 1.5 | 1.6 | 1.6 | 1.6 | 1.7 | 1.7 | 1.8 | 1.9 | 2.0 | 2.1 | 2.1 | 2.2 | 2.3 | 2.4 | 2.5 | 2.6 | 2.7 | 2.8 | 3.0 | |

| 2 | 2.0 | 2.0 | 2.1 | 2.1 | 2.2 | 2.3 | 2.4 | 2.5 | 2.6 | 2.7 | 2.8 | 3.0 | 3.1 | 3.2 | 3.4 | 3.6 | 3.7 | 4.0 | 4.1 | |

| Elbow Flexion | ||||||||||||||||||||

| τ (N·m) | 0 | 3.7 | 3.9 | 4.1 | 4.4 | 4.8 | 5.4 | 6.0 | 6.8 | 7.5 | 8.3 | 9.1 | 10.0 | 10.9 | 11.8 | 12.7 | 13.7 | 14.6 | 15.5 | 16.5 |

| 0.5 | 5.4 | 5.6 | 6.0 | 6.5 | 7.2 | 8.1 | 9.1 | 10.2 | 11.5 | 12.8 | 14.1 | 15.5 | 16.9 | 18.4 | 19.8 | 21.3 | 22.8 | 24.3 | 25.7 | |

| 1 | 7.1 | 7.4 | 7.9 | 8.6 | 9.6 | 10.8 | 12.2 | 13.8 | 15.5 | 17.2 | 19.1 | 21.0 | 23.0 | 25.0 | 27.0 | 29.0 | 31.0 | 33.0 | 35.1 | |

| 2 | 10.6 | 11.0 | 11.7 | 12.8 | 14.4 | 16.3 | 18.5 | 20.9 | 23.5 | 26.3 | 29.1 | 32.1 | 35.1 | 38.1 | 41.2 | 44.3 | 47.5 | 50.6 | 53.7 | |

| P (W) | 0 | 2.1 | 3.4 | 4.9 | 6.7 | 8.9 | 11.6 | 14.8 | 18.6 | 22.9 | 27.9 | 33.4 | 39.6 | 46.4 | 53.8 | 61.8 | 70.4 | 79.5 | 89.3 | 99.6 |

| 0.5 | 3.1 | 5.0 | 7.2 | 9.9 | 13.3 | 17.4 | 22.3 | 28.1 | 34.9 | 42.5 | 51.2 | 60.7 | 71.3 | 82.8 | 95.2 | 108.5 | 122.7 | 137.8 | 153.7 | |

| 1 | 4.1 | 6.6 | 9.5 | 13.2 | 17.7 | 23.2 | 29.9 | 37.7 | 46.8 | 57.2 | 68.9 | 82.0 | 96.3 | 111.8 | 128.6 | 146.7 | 165.9 | 186.4 | 208.0 | |

| 2 | 6.1 | 9.8 | 14.2 | 19.7 | 26.5 | 34.9 | 45.0 | 57.0 | 70.8 | 86.7 | 104.6 | 124.4 | 146.2 | 169.9 | 195.6 | 223.1 | 252.5 | 283.9 | 316.8 | |

| E (J) | 0 | 2.4 | 2.5 | 2.6 | 2.8 | 3.0 | 3.2 | 3.4 | 3.6 | 3.9 | 4.3 | 4.8 | 5.3 | 5.8 | 6.4 | 6.9 | 7.54 | 8.1 | 8.7 | 9.3 |

| 0.5 | 3.5 | 3.7 | 3.9 | 4.1 | 4.4 | 4.7 | 5.1 | 5.4 | 5.9 | 6.5 | 7.3 | 8.1 | 9.0 | 9.9 | 10.8 | 11.7 | 12.6 | 13.6 | 14.5 | |

| 1 | 4.7 | 4.9 | 5.1 | 5.4 | 5.8 | 6.2 | 6.7 | 7.2 | 7.9 | 8.8 | 9.9 | 11.0 | 12.2 | 13.4 | 14.6 | 15.9 | 17.1 | 18.4 | 19.7 | |

| 2 | 7.0 | 7.2 | 7.6 | 8.1 | 8.7 | 9.3 | 10.1 | 10.8 | 11.9 | 13.4 | 15.0 | 16.7 | 18.5 | 20.4 | 22.3 | 24.2 | 26.1 | 28.1 | 30.0 | |

| vsf (%) | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| load (kg) | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 110 | 120 | 130 | 140 | 150 | 160 | 170 | 180 | 190 | 200 | |

| Shoulder Flexion | ||||||||||||||||||||

| τ (N·m) | 0 | 7.2 | 7.1 | 7.0 | 6.9 | 6.7 | 6.5 | 6.3 | 6.1 | 6.0 | 5.9 | 6.1 | 6.6 | 7.3 | 8.1 | 8.8 | 9.6 | 10.4 | 11.2 | 11.9 |

| 0.5 | 10.1 | 10.0 | 9.8 | 9.7 | 9.4 | 9.1 | 8.8 | 8.6 | 8.6 | 8.8 | 9.6 | 10.7 | 12.0 | 13.3 | 14.6 | 15.9 | 17.3 | 18.6 | 19.9 | |

| 1 | 13.0 | 12.9 | 12.7 | 12.4 | 12.1 | 11.8 | 11.4 | 11.2 | 11.3 | 12.0 | 13.4 | 15.2 | 17.0 | 18.8 | 20.7 | 22.6 | 24.5 | 26.4 | 28.3 | |

| 2 | 18.8 | 18.6 | 18.3 | 18.0 | 17.5 | 17.0 | 16.6 | 16.6 | 17.1 | 18.9 | 21.5 | 24.3 | 27.2 | 30.1 | 33.1 | 36.1 | 39.2 | 42.2 | 45.2 | |

| P (W) | 0 | 7.0 | 10.2 | 13.1 | 15.7 | 17.8 | 19.7 | 21.5 | 23.4 | 25.8 | 28.7 | 32.1 | 36.0 | 40.4 | 45.3 | 50.5 | 56.0 | 61.8 | 67.9 | 74.2 |

| 0.5 | 9.70 | 14.0 | 17.8 | 20.9 | 23.1 | 24.8 | 26.5 | 28.6 | 31.5 | 35.4 | 40.1 | 45.6 | 51.7 | 58.4 | 65.5 | 73.1 | 80.8 | 89.0 | 97.5 | |

| 1 | 12.4 | 17.9 | 22.6 | 26.1 | 28.5 | 30.1 | 31.9 | 34.6 | 38.5 | 43.6 | 49.9 | 57.1 | 65.0 | 73.6 | 82.7 | 92.4 | 102.5 | 113.0 | 123.8 | |

| 2 | 17.9 | 25.7 | 32.0 | 36.5 | 39.3 | 41.1 | 43.5 | 47.6 | 53.6 | 61.6 | 71.0 | 81.6 | 93.2 | 105.8 | 119.2 | 133.2 | 147.8 | 162.8 | 178.4 | |

| E (J) | 0 | 7.8 | 7.7 | 7.6 | 7.5 | 7.3 | 7.1 | 6.8 | 6.5 | 6.0 | 5.6 | 5.3 | 5.4 | 5.9 | 6.6 | 7.5 | 8.5 | 9.6 | 10.8 | 12.1 |

| 0.5 | 11.3 | 11.1 | 10.9 | 10.6 | 10.2 | 9.6 | 9 | 8.2 | 7.3 | 6.7 | 6.7 | 7.4 | 8.5 | 10.1 | 11.8 | 13.7 | 15.7 | 17.9 | 20.1 | |

| 1 | 14.8 | 14.5 | 14.1 | 13.6 | 13.0 | 12.1 | 11.1 | 10.0 | 8.8 | 8.1 | 8.6 | 9.9 | 11.8 | 14.1 | 16.7 | 19.5 | 22.4 | 25.5 | 28.7 | |

| 2 | 21.8 | 21.3 | 20.7 | 19.8 | 18.6 | 17.2 | 15.5 | 13.5 | 11.9 | 11.5 | 12.9 | 15.5 | 18.9 | 22.7 | 26.9 | 31.4 | 36.2 | 41.1 | 46.3 | |

| Shoulder Abduction | ||||||||||||||||||||

| τ (N·m) | 0 | 0.1 | 0.1 | 0.05 | 0.03 | 0.1 | 0.2 | 0.3 | 0.5 | 0.7 | 0.9 | 1.2 | 1.4 | 1.7 | 2.0 | 2.3 | 2.6 | 2.9 | 3.2 | 3.5 |

| 0.5 | 0.3 | 0.2 | 0.2 | 0.1 | 0.1 | 0.1 | 0.2 | 0.5 | 0.8 | 1.1 | 1.5 | 1.9 | 2.4 | 2.8 | 3.3 | 3.8 | 4.3 | 4.9 | 5.4 | |

| 1 | 0.5 | 0.4 | 0.3 | 0.2 | 0.1 | 0.1 | 0.3 | 0.6 | 1.1 | 1.6 | 2.1 | 2.7 | 3.4 | 4.1 | 4.8 | 5.5 | 6.2 | 7.0 | 7.7 | |

| 2 | 0.9 | 0.8 | 0.6 | 0.4 | 0.2 | 0.2 | 0.6 | 1.3 | 2.0 | 2.9 | 3.8 | 4.9 | 5.9 | 7.0 | 8.2 | 9.4 | 10.5 | 11.7 | 12.9 | |

| P (W) | 0 | 0.01 | 0.02 | 0.03 | 0.1 | 0.1 | 0.1 | 0.2 | 0.4 | 0.6 | 0.9 | 1.3 | 1.8 | 2.4 | 3.1 | 3.8 | 4.6 | 5.6 | 6.6 | 7.6 |

| 0.5 | 0.01 | 0.02 | 0.04 | 0.1 | 0.1 | 0.2 | 0.3 | 0.5 | 0.9 | 1.5 | 2.2 | 3.1 | 4.2 | 5.4 | 6.8 | 8.40 | 10.1 | 12.0 | 13.9 | |

| 1 | 0.02 | 0.03 | 0.1 | 0.1 | 0.1 | 0.2 | 0.4 | 0.7 | 1.4 | 2.3 | 3.5 | 4.9 | 6.5 | 8.4 | 10.5 | 12.8 | 15.4 | 18.1 | 21.1 | |

| 2 | 0.03 | 0.05 | 0.1 | 0.1 | 0.2 | 0.4 | 0.7 | 1.5 | 2.7 | 4.4 | 6.4 | 8.8 | 11.6 | 14.7 | 18.3 | 22.2 | 26.5 | 31.2 | 36.2 | |

| E (J) | 0 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.3 | 0.3 | 0.4 | 0.4 | 0.5 | 0.6 | 0.6 | 0.7 | 0.8 |

| 0.5 | 0.3 | 0.3 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 1.1 | 1.2 | 1.3 | |

| 1 | 0.4 | 0.4 | 0.3 | 0.3 | 0.2 | 0.2 | 0.2 | 0.2 | 0.3 | 0.4 | 0.6 | 0.7 | 0.9 | 1.0 | 1.2 | 1.4 | 1.6 | 1.8 | 2.0 | |

| 2 | 0.6 | 0.5 | 0.5 | 0.4 | 0.3 | 0.2 | 0.2 | 0.3 | 0.5 | 0.7 | 1.0 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.1 | 3.4 | |

| Elbow Flexion | ||||||||||||||||||||

| τ (N·m) | 0 | 1.8 | 1.8 | 1.9 | 2.0 | 2.2 | 2.4 | 2.7 | 3.0 | 3.3 | 3.7 | 4.1 | 4.5 | 5.0 | 5.4 | 5.9 | 6.4 | 6.9 | 7.4 | 7.9 |

| 0.5 | 3.1 | 3.2 | 3.4 | 3.7 | 4.0 | 4.5 | 5.0 | 5.6 | 6.3 | 7.0 | 7.80 | 8.60 | 9.50 | 10.3 | 11.3 | 12.2 | 13.2 | 14.1 | 15.1 | |

| 1 | 4.5 | 4.7 | 4.9 | 5.3 | 5.8 | 6.5 | 7.3 | 8.3 | 9.3 | 10.4 | 11.5 | 12.8 | 14.0 | 15.4 | 16.7 | 18.1 | 19.6 | 21.0 | 22.5 | |

| 2 | 7.3 | 7.5 | 7.9 | 8.6 | 9.5 | 10.7 | 12.1 | 13.6 | 15.3 | 17.1 | 19.1 | 21.1 | 23.2 | 25.5 | 27.7 | 30.0 | 32.4 | 34.8 | 37.2 | |

| P (W) | 0 | 1.1 | 1.8 | 2.6 | 3.6 | 4.9 | 6.4 | 8.2 | 10.4 | 12.9 | 15.9 | 19.3 | 23.1 | 27.4 | 32.2 | 37.4 | 43.2 | 49.4 | 56.0 | 63.2 |

| 0.5 | 2.1 | 3.4 | 4.9 | 6.8 | 9.1 | 12.0 | 15.5 | 19.8 | 24.7 | 30.4 | 37.0 | 44.4 | 52.7 | 61.9 | 72.0 | 83.0 | 94.9 | 107.7 | 121.4 | |

| 1 | 3.0 | 4.9 | 7.1 | 9.9 | 13.4 | 17.7 | 22.9 | 29.2 | 36.6 | 45.1 | 54.9 | 65.9 | 78.3 | 91.9 | 106.8 | 123.1 | 140.7 | 159.6 | 179.9 | |

| 2 | 4.9 | 7.9 | 11.6 | 16.2 | 21.9 | 29.1 | 37.7 | 48.1 | 60.3 | 74.5 | 90.7 | 109.0 | 129.4 | 151.9 | 176.6 | 203.5 | 232.5 | 263.7 | 297.1 | |

| E (J) | 0 | 2.5 | 2.5 | 2.5 | 2.5 | 2.6 | 2.6 | 2.7 | 2.7 | 2.7 | 2.8 | 2.9 | 3.1 | 3.3 | 3.7 | 4.1 | 4.6 | 5.1 | 5.6 | 6.1 |

| 0.5 | 4.4 | 4.5 | 4.5 | 4.5 | 4.6 | 4.6 | 4.6 | 4.6 | 4.7 | 4.7 | 4.9 | 5.3 | 5.9 | 6.7 | 7.6 | 8.5 | 9.5 | 10.5 | 11.6 | |

| 1 | 6.4 | 6.4 | 6.5 | 6.5 | 6.6 | 6.6 | 6.6 | 6.6 | 6.6 | 6.7 | 7.0 | 7.7 | 8.7 | 9.9 | 11.3 | 12.7 | 14.2 | 15.8 | 17.4 | |

| 2 | 10.3 | 10.4 | 10.4 | 10.5 | 10.5 | 10.6 | 10.6 | 10.5 | 10.5 | 10.7 | 11.4 | 12.7 | 14.5 | 16.6 | 18.9 | 21.3 | 23.8 | 26.4 | 29.1 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brambilla, C.; Malosio, M.; Reni, G.; Scano, A. Optimal Biomechanical Performance in Upper-Limb Gestures Depends on Velocity and Carried Load. Biology 2022, 11, 391. https://0-doi-org.brum.beds.ac.uk/10.3390/biology11030391

Brambilla C, Malosio M, Reni G, Scano A. Optimal Biomechanical Performance in Upper-Limb Gestures Depends on Velocity and Carried Load. Biology. 2022; 11(3):391. https://0-doi-org.brum.beds.ac.uk/10.3390/biology11030391

Chicago/Turabian StyleBrambilla, Cristina, Matteo Malosio, Gianluigi Reni, and Alessandro Scano. 2022. "Optimal Biomechanical Performance in Upper-Limb Gestures Depends on Velocity and Carried Load" Biology 11, no. 3: 391. https://0-doi-org.brum.beds.ac.uk/10.3390/biology11030391