Optimization of Plastic Scintillator for Detection of Gamma-Rays: Simulation and Experimental Study

Abstract

:1. Introduction

2. Materials and Methods

2.1. Fabrication of Plastic Scintillator and Spectroscopic Analysis

2.2. Simulation

2.3. Radiological Measurement

3. Results and Discussion

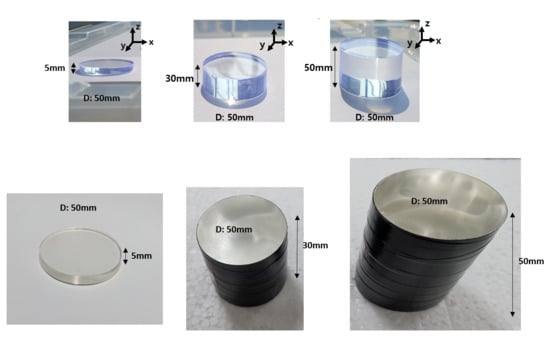

3.1. Characteristic Analysis of Plastic Scintillator Fabricated

3.2. Simulations for Optimum Thickness of Plastic Scintillator

3.3. Detection and Measurement of Gamma-Rays

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Schorr, M.G.; Torney, F.L. Solid non-crystalline scintillation phosphors. Phys. Rev. 1950, 80, 474–475. [Google Scholar] [CrossRef]

- Buck, W.L.; Swank, R.K. Efficient Plastic Scintillators. Nucleonics 1953, 11, 48–52. [Google Scholar]

- Hayes, F.N.; Ott, D.G.; Kerr, V.N. Pulse height comparison of primary solutes. Nucleonics 1955, 13, 38–41. [Google Scholar]

- Ott, D.G.; Hayes, O.F.; Hansbury, E.; Kerr, V.N. Liquid scintillators. V. Absorption and Fluorescence spectra of 2,5-Diaryloxazoles and related compounds. J. Am. Chem. Soc. 1957, 79, 5448–5454. [Google Scholar] [CrossRef]

- Hajagos, T.J.; Liu, C.; Cherepy, N.J.; Pei, Q. High Z Sensitized plastic scintillators: A review. Adv. Mater. 2018, 30, 1706956. [Google Scholar] [CrossRef]

- Murugadoss, G.; Rajesh Kumar, M. Optical and structural characterization of CdS/ZnS CdS:Cu2+/ZnS core-shell nanoparticles. Luminescence 2014, 29, 663–668. [Google Scholar] [CrossRef]

- Youn, H.C.; Baral, S.; Fendler, J.H. Dihexadecyl phosphate, vesiclestabilized and in situ generated mixed cadmium sulfide and zinc sulfide semiconductor particles: Preparation and utilization for photosensitized charge separation and hydrogen generation. J. Phys. Chem. 1988, 92, 6320–6327. [Google Scholar] [CrossRef]

- Kortan, A.R.; Hull, R.; Opila, R.L.; Bawendi, M.G.; Steigerwald, M.L.; Carroll, P.J.; Brus, L.E. Nucleation and Growth of CdSe on ZnS Quantum crystallite seeds, and Vice versa, in Inverse Micelle media. J. Am. Chem. Soc. 1990, 112, 1327–1332. [Google Scholar] [CrossRef]

- Danek, M.; Jensen, K.F.; Murray, C.B.; Bawendi, M.G. Synthesis of luminescent thin-film CdSe/ZnSe quantum dot composites using CdSe quantum dots passivated with an overlayer of ZnSe. Chem. Mater. 1996, 8, 173–180. [Google Scholar] [CrossRef]

- Littau, K.A.; Szajowski, P.J.; Muller, A.J.; Kortan, A.R.; Brus, L.E. A luminescent silicon nanocrystal colloid via a high-temperature aerosol reaction. J. Phys. Chem. 1993, 97, 1224–1230. [Google Scholar] [CrossRef]

- Wilson, W.L.; Szajowski, P.J.; Brus, L.E. Quantum confinement in size-selected, surface-oxidized silicon nanocrystals. Science 1993, 262, 1242–1244. [Google Scholar] [CrossRef]

- Hines, M.A.; Guyot-Sionnest, P. Synthesis and characterization of strongly luminescing ZnS-capped CdSe nanocrystals. J. Phys. Chem. 1996, 100, 468–471. [Google Scholar] [CrossRef]

- Chang, K.S. Structural and Optical Characteristics of ZnS/CdS powders and thin films. J. Korean Inst. Mil. Sci. Technol. 2010, 13, 659–664. [Google Scholar]

- Rajakrishna, K.; Dhanasekaran, A.; Yuvaraj, N.; Ajoy, K.C.; Venkatraman, B. Effect of high Z materials loading in the performance of polystyrene-based thin-film plastic scintillators. Nucl. Instrum. Methods Phys. Res. Sect. A 2021, 1008, 165454. [Google Scholar] [CrossRef]

- Kagami, K.; Koshimizu, M.; Fujimoto, Y.; Kishimoto, S.; Haruki, R.; Nishikido, F.; Asai, K. X-ray detection properties of Bi-loaded plastic scintillators synthesized via solvent evaporation. Radiat. Meas. 2020, 135, 106361. [Google Scholar] [CrossRef]

- Kim, D.G.; Lee, S.M.; Park, J.S.; Son, J.B.; Kim, T.H.; Kim, Y.H.; Pak, K.H.; Kim, Y.K. Performance of 3D printed plastic scintillators for gamma-ray detection. Nucl. Eng. Technol. 2020, 52, 2910–2917. [Google Scholar]

- Posar, J.A.; Davis, J.; Brace, O.; Sellin, P.; Griffith, M.J.; Dhez, O.; Wilkinson, D.; Lerch, M.L.F.; Rosenfeld, A.; Petasecca, M. Characterization of a plastic dosimeter based on organic semiconductor photodiodes and scintillator. Phys. Imaging Radiat. Oncol. 2020, 14, 45–52. [Google Scholar] [CrossRef]

- Ji, Y.Y.; Ochi, K.; Hong, S.B.; Nakama, S.; Sanada, Y.; Mikami, S. Performance of in situ gamma-ray spectrometry in the assessment of radioactive cesium deposition around the Fukushima Daiichi nuclear power plant. Radiat. Phys. Chem. 2021, 179, 109205. [Google Scholar] [CrossRef]

- Lee, C.K.; Park, S.W.; Kim, H.R. Development of mobile scanning system for effective in-situ spatial prediction of radioactive contamination at decommissioning sites. Nucl. Instrum. Methods Phys. Res. Sect. A 2020, 966, 163833. [Google Scholar] [CrossRef]

- Dufour, N.; Dumazert, J.; Barat, E.; Bertrand, G.H.V.; Carrel, F.; Dautremer, T.; Laine, F.; Sari, A. Measurement of low-activity uranium contamination by gamma-ray spectrometry for nuclear decommissioning. Nucl. Instrum. Methods Phys. Res. Sect. A 2020, 951, 162976. [Google Scholar] [CrossRef]

- Amgarou, K.; Aspe, F.; Idoeta, R.; Herranz, M. Recommendations for the selection of in situ measurement techniques for radiological characterization in nuclear/radiological installations under decommissioning and dismantling processes. Prog. Nucl. Energy 2021, 137, 103761. [Google Scholar] [CrossRef]

- Bae, J.W.; Kim, H.R. Plastic scintillator beta ray scanner for in-situ discrimination of beta ray and gamma ray radioactivity in soil. Nucl. Eng. Technol. 2020, 52, 1259–1265. [Google Scholar] [CrossRef]

- Knoll, G.F. Chapter 8 Scintillation Detector Principles. Radiation Detection and Measurement, 4th ed.; John Wiley & Sons, Inc.: New York, NY, USA, 2010; pp. 220–247. [Google Scholar]

- Xiao, B.; Lee, S.; Hagel, K.; Haddad, F.; Li, J.; Lou, Y.; Mdeiwayeh, N.; Tezkratt, R.; Wada, R.; Utley, D.; et al. Production and thickness determination of thin plastic scintillator foils. Nucl. Instrum. Methods Phys. Res. Sect. A 1995, 355, 258–260. [Google Scholar] [CrossRef]

- Ros, G.; Saez-Cano, G.; Medina-Tanco, G.A.; Supanitsky, A.D. On the design of experiments based on plastic scintillators using GEANT4 simulations. Radiat. Phys. Chem. 2018, 153, 140–151. [Google Scholar]

- Kim, K.H. Fabrication and a Study on the Tapered Scintillator Radiation Sensors. Master’s Thesis, Jeju National University, Jeju, Korea, December 2003. [Google Scholar]

- Moszynski, M.; Kapusta, M.; Mayhugh, M.; Wolski, D.; Flyckt, S.O. Absolute light output of scintillators. IEEE Trans. Nucl. Sci. 1997, 44, 1052–1061. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.W.; Lee, B.C.; Uhm, Y.R.; Miller, W.H. Enhancement of thermal neutron attenuation of nano-B4C, -BN dispersed neutron shielding polymer nanocomposites. J. Nucl. Mater. 2014, 453, 48–53. [Google Scholar] [CrossRef]

- Kang, J.K.; Lee, J.O.; Lee, D.J. Calculation of Dose Distribution for SBRT Patient Using Geant4 Simulation Code. Prog. Med. Phys. 2015, 26, 36–41. [Google Scholar] [CrossRef] [Green Version]

- Sung, S.H.; Kim, H.R. Optimization of airborne alpha beta detection system modeling using MCNP simulation. Nucl. Eng. Technol. 2020, 52, 841–845. [Google Scholar] [CrossRef]

- Childress, N.L.; Miller, W.H. MCNP analysis and optimization of a triple crystal phoswich detector. Nucl. Instrum. Methods Phys. Res. Sect. A 2002, 490, 263–270. [Google Scholar] [CrossRef] [Green Version]

- Tam, H.D.; Yen, N.T.H.; Tran, L.B.; Chuong, H.D.; Thanh, T.T. Optimization of the Monte Carlo simulation model of NaI(Tl) detector by Geant4 code. Appl. Radiat. Isot. 2017, 130, 75–79. [Google Scholar]

- Yehuda-Zada, Y.; Pritchard, K.; Ziegler, J.B.; Cooksey, C.; Siebein, K.; Jackson, M.; Hurlbut, C.; Kadmon, Y.; Cohen, Y.; Ibberson, R.M.; et al. Optimization of 6LiF:ZnS(Ag) scintillator light yield using GEANT4. Nucl. Instrum. Methods Phys. Res. Sect. A 2018, 892, 59–69. [Google Scholar] [CrossRef]

- Nam, J.S.; Kim, Y.E.; Hong, S.B.; Seo, B.K.; Kim, K.H. Performance Evaluation of a Plastic Scintillator for Making a In-situ Beta Detector. New Phy. SaeMulli 2017, 67, 1080–1085. [Google Scholar]

- Kang, H.R.; Min, S.J.; Seo, B.K.; Roh, C.H.; Hong, S.B.; Cheong, J.H. Preliminary Studies of Perovskite-Loaded Plastic Scintillator Prototypes for Radioactive Strontium Detection. Chemosensors 2021, 9, 53. [Google Scholar] [CrossRef]

- Min, S.J.; Kang, H.R.; Seo, B.K.; Roh, C.H.; Hong, S.B.; Cheong, J.H. Integrated and Portable Probe Based on Functional Plastic Scintillator for Detection of Radioactive Cesium. Appl. Sci. 2021, 11, 5210. [Google Scholar] [CrossRef]

- Healy, M.S.; Hanson, J.E. Fluorescence excitation spectroscopy of polystyrene near the critical concentration c*. J. Appl. Polym. Sci. 2007, 104, 360–364. [Google Scholar] [CrossRef]

- Park, J.M.; Kim, H.H.; Hwang, Y.S.; Kim, D.H.; Park, H.W. Scintillation properties of quantum-dot doped styrene based plastic scintillators. J. Lumin. 2014, 146, 157–161. [Google Scholar] [CrossRef]

- Madkour, M.; Salih, T.; Al-Sagheer, F.; Bumajdad, A. Nano heterostructured photo-stable CdZn1−xS heterojunction as a non-photocorrosive visible light active photocatalyst. Opt. Mater. Express 2016, 6, 2857–2870. [Google Scholar] [CrossRef]

- Xinmei, L.; Yang, J.; Xinzheng, L.; Yugang, Z.; Shanying, L.; Junwei, L.; Tingting, H.; Binbin, W.; Honghai, Z. Highly luminescent blue emitting CdS/ZnS core/shell quantum dots via a single-molecular precursor for shell growth. Mater. Chem. Phys. 2011, 130, 909–914. [Google Scholar]

| Material | Quantity | Bandgap (eV) | Emission Wavelength (nm) | |

|---|---|---|---|---|

| 1 | Styrene | >99 wt% | - | 300–350 [37] |

| 2 | PPO | 0.4 wt% | - | 340–380 [38] |

| 3 | POPOP | 0.01 wt% | - | 400–450 [39] |

| 4 | CdS/ZnS | 0.2 wt% | 3.3 [39] | 424–470 [40] |

| Simulation Codes | Characteristics |

|---|---|

| MCNP | The Monte Carlo N-Particle Transport Code (MCNP) was developed by Los Alamos National Laboratory for the transport of neutrons, photons, and electrons. It is applied in various fields such as radiation shielding, dosimetry, radiography, and medical physics, and it is also used in the design and analysis of the radiation measurement system. It is a time-dependent code and was produced using Fortran (425 Subroutines) and C. |

| GEANT4 | GEANT4 is a computer simulation toolkit that tracks the trajectory of particles as they pass through the material. This code is used not only in high-energy physics, nuclear physics, and accelerator physics, but also in medicine and aerospace. GEANT4 is designed with an object-oriented structure. It is produced using C++ and consists of 17 basic classes. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Min, S.; Kim, Y.; Ko, K.-H.; Seo, B.; Cheong, J.; Roh, C.; Hong, S. Optimization of Plastic Scintillator for Detection of Gamma-Rays: Simulation and Experimental Study. Chemosensors 2021, 9, 239. https://0-doi-org.brum.beds.ac.uk/10.3390/chemosensors9090239

Min S, Kim Y, Ko K-H, Seo B, Cheong J, Roh C, Hong S. Optimization of Plastic Scintillator for Detection of Gamma-Rays: Simulation and Experimental Study. Chemosensors. 2021; 9(9):239. https://0-doi-org.brum.beds.ac.uk/10.3390/chemosensors9090239

Chicago/Turabian StyleMin, Sujung, Youngsu Kim, Kwang-Hoon Ko, Bumkyung Seo, JaeHak Cheong, Changhyun Roh, and Sangbum Hong. 2021. "Optimization of Plastic Scintillator for Detection of Gamma-Rays: Simulation and Experimental Study" Chemosensors 9, no. 9: 239. https://0-doi-org.brum.beds.ac.uk/10.3390/chemosensors9090239