Estimating the Cost-Competitiveness of Recycling-Based Geopolymer Concretes

Abstract

:1. Introduction

1.1. Recycling-Based Low-Carbon Concretes

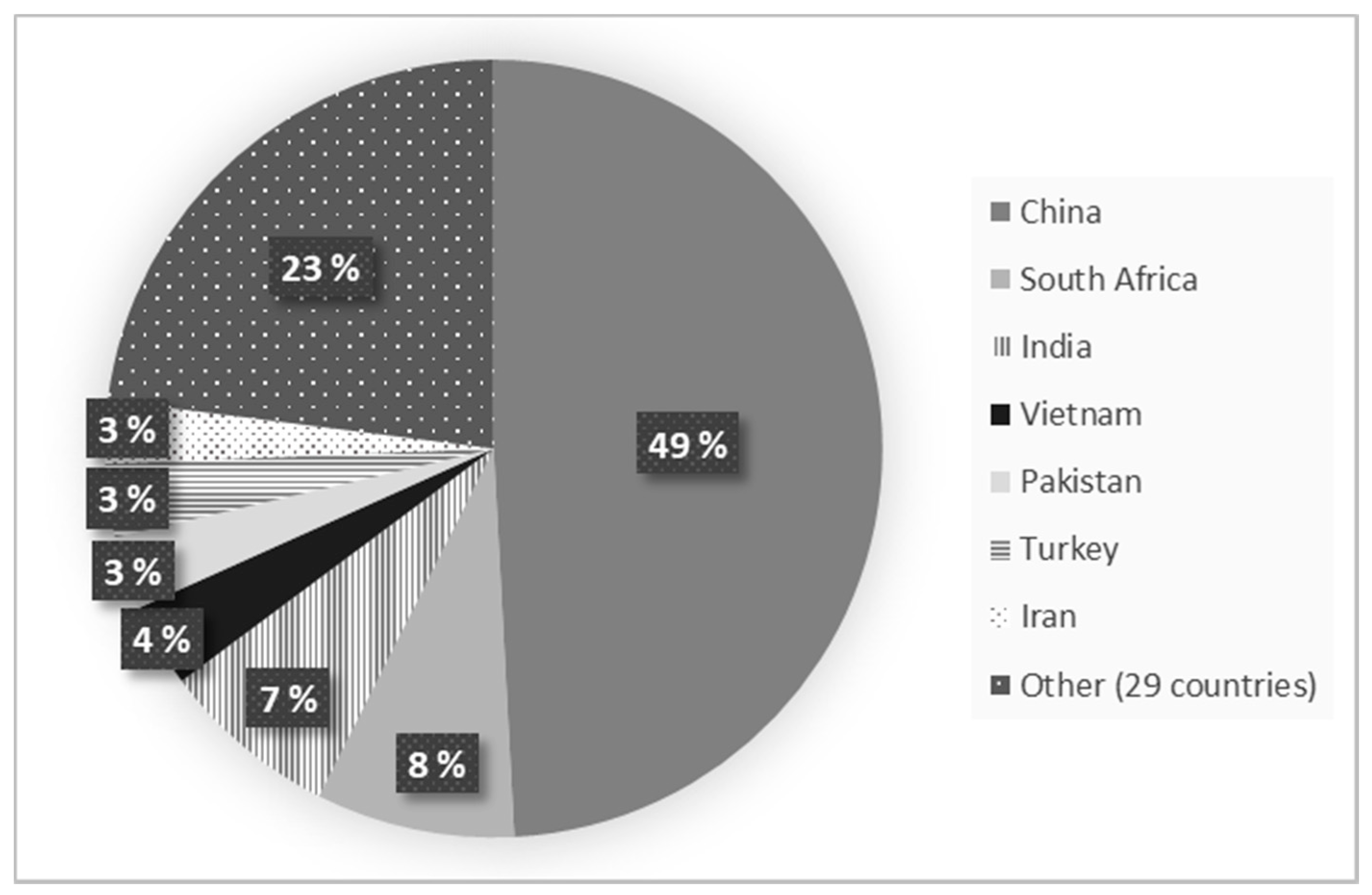

1.2. The Markets of Low-Carbon Concretes

1.3. Price-Estimations Concerning Low-Carbon Concretes

1.4. Carbon Pricing

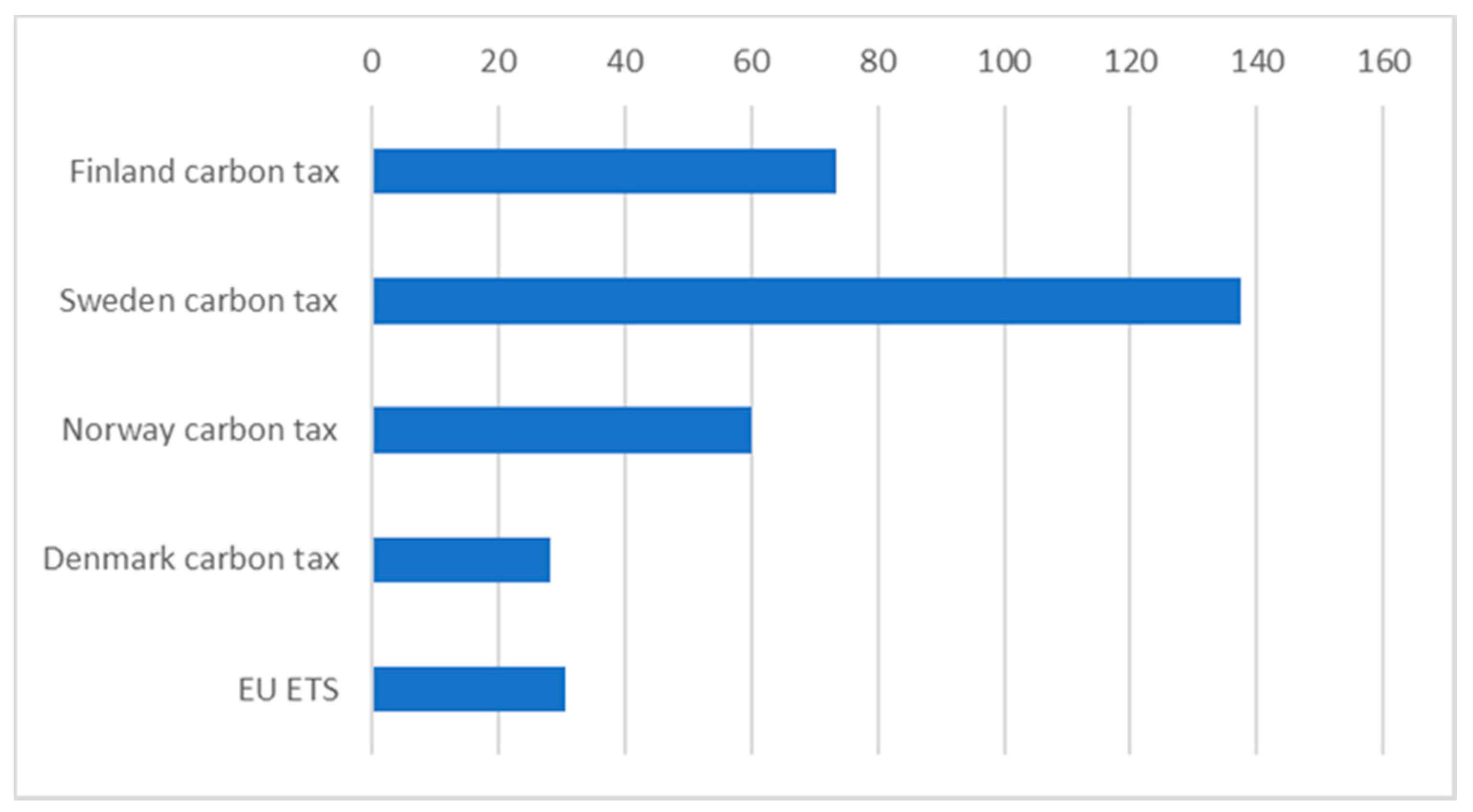

1.5. Prices of Carbon Allowances and Carbon Taxes

2. Results

2.1. Estimates of Material Purchase Prices

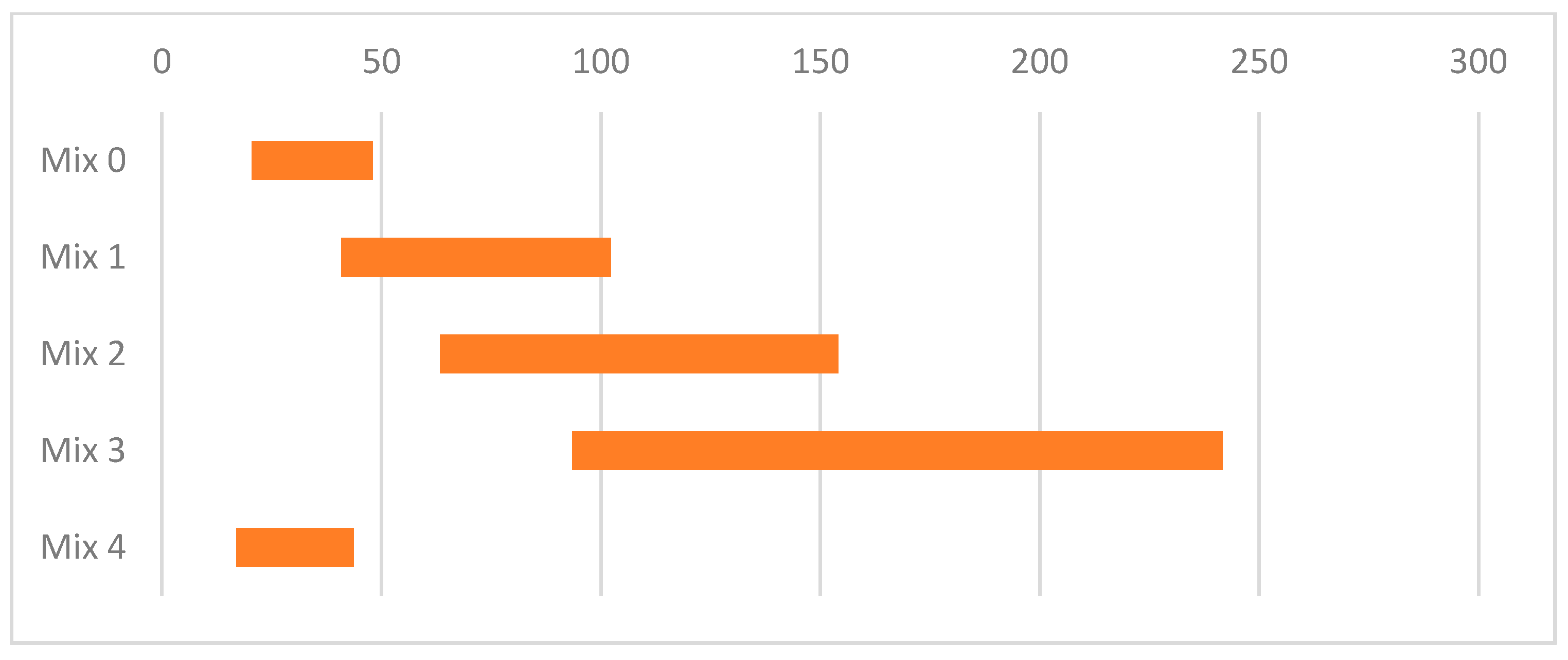

2.2. Cost Price Estimates for Example Mixes

2.3. The Impact of Carbon Pricing on Cost Prices

3. Discussion

4. Materials and Methods

Data Collection and Analysis

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Miller, S.A.; Horvath, A.; Monteiro, P.J.M. Readily implementable techniques can cut annual CO2 emissions from the production of concrete by over 20%. Environ. Res. Lett. 2016, 11, 074029. [Google Scholar] [CrossRef] [Green Version]

- Imbabi, M.S.; Carrigan, C.; McKenna, S. Trends and developments in green cement and concrete technology. Int. J. Sustain. Built Environ. 2012, 1, 194–216. [Google Scholar] [CrossRef] [Green Version]

- Van Deventer, J.S.J.; Provis, J.L.; Duxson, P. Technical and commercial progress in the adoption of geopolymer cement. Miner. Eng. 2012, 29, 89–104. [Google Scholar] [CrossRef]

- Miller, S.A.; John, V.M.; Pacca, S.A.; Horvath, A. Carbon dioxide reduction potential in the global cement industry by 2050. Cem. Concr. Res. 2018, 114, 115–124. [Google Scholar] [CrossRef]

- Salas, D.A.; Ramirez, A.D.; Rodríguez, C.R.; Petroche, D.M.; Boero, A.J.; Duque-Rivera, J. Environmental impacts, life cycle assessment and potential improvement measures for cement production: A literature review. J. Clean. Prod. 2016, 113, 114–122. [Google Scholar] [CrossRef]

- Cembureau. Reaching Climate Neutrality along the Cement and Concrete Value Chain by 2050—Cementing the European Green Deal. 2020. Available online: https://cembureau.eu/media/w0lbouva/cembureau-2050-roadmap_executive-summary_final-version_web.pdf (accessed on 8 July 2020).

- Laurent, A.; Bakas, I.; Clavreul, J.; Bernstad, A.; Niero, M.; Gentil, E.; Hauschild, M.Z.; Christensen, T.H. Review of LCA studies of solid waste management systems—Part I: Lessons learned and perspectives. Waste Manag. 2014, 34, 573–588. [Google Scholar] [CrossRef]

- SFS-EN ISO 14040 Environmental Management—Life Cycle Assessment—Principles and Framework 2006; Finnish Standards Association ry: Helsinki, Finland, 2006.

- Singh, B.; Ishwarya, G.; Gupta, M.; Bhattacharyya, S.K. Geopolymer concrete: A review of some recent developments. Constr. Build. Mater. 2015, 85, 78–90. [Google Scholar] [CrossRef]

- Hasnaoui, A.; Ghorbel, E.; Wardeh, G. Optimization approach of granulated blast furnace slag and metakaolin based geopolymer mortars. Constr. Build. Mater. 2019, 198, 10–26. [Google Scholar] [CrossRef]

- Zhao, S.; Fan, J.; Sun, W. Utilization of iron ore tailings as fine aggregate in ultra-high performance concrete. Constr. Build. Mater. 2014, 50, 540–548. [Google Scholar] [CrossRef]

- İlker, B.T.; Selim, Ş. Properties of concretes produced with waste concrete aggregate. Cem. Concr. Res. 2004, 34, 1307–1312. [Google Scholar] [CrossRef]

- Yliniemi, J.; Nugteren, H.; Illikainen, M.; Tiainen, M.; Weststrate, R.; Niinimäki, J. Lightweight aggregates produced by granulation of peat-wood fly ash with alkali activator. Int. J. Miner. Process. 2016, 149, 42–49. [Google Scholar] [CrossRef]

- Suomen Erityisjäte Oy Lehdistötiedote “Yli 300 000 Tonnia Pohjakuonaa Hyötykäyttöön”. Available online: http://www.erityisjate.fi/yritys/uutiset-ja-ajankohtaiset/?newsid=309&newstitle=Lehdistötiedote+%22Yli+300+000+tonnia+pohjakuonaa+hyötykäyttöön%22 (accessed on 21 December 2018).

- Kovářík, T.; Rieger, D.; Kadlec, J.; Křenek, T.; Kullová, L.; Pola, M.; Bělský, P.; Franče, P.; Říha, J. Thermomechanical properties of particle-reinforced geopolymer composite with various aggregate gradation of fine ceramic filler. Constr. Build. Mater. 2017, 143, 599–606. [Google Scholar] [CrossRef]

- Aldred, J.; Day, J. Is geopolymer concrete a suitable alternative to traditional concrete. In Proceedings of the 37th Conference on Our World in Concrete, Singapore, 29–31 August 2012. [Google Scholar]

- Albitar, M.; Mohamed Ali, M.S.; Visintin, P.; Drechsler, M. Durability evaluation of geopolymer and conventional concretes. Constr. Build. Mater. 2017, 136, 374–385. [Google Scholar] [CrossRef]

- Valencia Saavedra, W.G.; Mejía de Gutiérrez, R. Performance of geopolymer concrete composed of fly ash after exposure to elevated temperatures. Constr. Build. Mater. 2017, 154, 229–235. [Google Scholar] [CrossRef]

- Yang, K.-H.; Lee, K.-H.; Song, J.-K.; Gong, M.-H. Properties and sustainability of alkali-activated slag foamed concrete. J. Clean. Prod. 2014, 68, 226–233. [Google Scholar] [CrossRef]

- Chan, C.C.S.; Thorpe, D.; Islam, M. An evaluation of life long fly ash based geopolymer cement and ordinary Portland cement costs using extended life cycle cost method in Australia. In Proceedings of the 2015 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Singapore, 6–9 December 2015; pp. 52–56. [Google Scholar]

- Vilamová, Š.; Piecha, M. Economic evaluation of using of geopolymer from coal fly ash in the industry. Acta Montan. Slovaca 2016, 21, 139–145. [Google Scholar]

- Ostwal, T.; Chitawadagi, M.V. Experimental investigations on strength, durability, sustainability & economic characteristics of geo-polymer concrete blocks. IJRET Int. J. Res. Eng. Technol. 2014, 3, 115–122. [Google Scholar]

- SFS-EN 197-1 Cement. Part 1: Composition, Specifications and Conformity Criteria for Common Cements 2012; Finnish Standards Association ry: Helsinki, Finland, 2012.

- Jamieson, E.J.; Penna, B.; van Riessen, A.; Nikraz, H. The development of Bayer derived geopolymers as artificial aggregates. Hydrometallurgy 2017, 170, 74–81. [Google Scholar] [CrossRef]

- Sun, T.; Chen, J.; Lei, X.; Zhou, C. Detoxification and immobilization of chromite ore processing residue with metakaolin-based geopolymer. J. Environ. Chem. Eng. 2014, 2, 304–309. [Google Scholar] [CrossRef]

- Torres-Carrasco, M.; Puertas, F. Waste glass in the geopolymer preparation. Mechanical and microstructural characterisation. J. Clean. Prod. 2015, 90, 397–408. [Google Scholar] [CrossRef]

- Yliniemi, J.; Kinnunen, P.; Karinkanta, P.; Illikainen, M.; Yliniemi, J.; Kinnunen, P.; Karinkanta, P.; Illikainen, M. Utilization of Mineral Wools as Alkali-Activated Material Precursor. Materials 2016, 9, 312. [Google Scholar] [CrossRef]

- Bernal, S.A.; Rodríguez, E.D.; Mejia De Gutiérrez, R.; Provis, J.L.; Delvasto, S. Activation of metakaolin/slag blends using alkaline solutions based on chemically modified silica fume and rice husk ash. Waste Biomass Valorization 2012, 3, 99–108. [Google Scholar] [CrossRef]

- Wu, Y.-H.; Huang, R.; Tsai, C.-J.; Lin, W.-T. Recycling of Sustainable Co-Firing Fly Ashes as an Alkali Activator for GGBS in Blended Cements. Materials 2015, 8, 784–798. [Google Scholar] [CrossRef] [Green Version]

- Heidrich, C.; Sanjayan, J.; Berndt, M.L.; Foster, S. Pathways and barriers for acceptance and usage of geopolymer concrete in mainstream construction. In Proceedings of the 2015 World of Coal Ash (WOCA) Conference, Nasvhille, TN, USA, 5–7 May 2015. [Google Scholar]

- RamaC References—RamaC. Available online: https://ramacreadymix.nl/en/references/ (accessed on 21 February 2020).

- Provis, J.L.; van Deventer, J.S.J. Alkali Activated Materials: State-of-the-Art Report, RILEM TC 224-AAM; Springer: Dordrecht, The Netherlands, 2013. [Google Scholar]

- van Deventer, J.S.J.; Provis, J.L.; Duxson, P.; Brice, D.G. Chemical Research and Climate Change as Drivers in the Commercial Adoption of Alkali Activated Materials. Waste Biomass Valorization 2010, 1, 145–155. [Google Scholar] [CrossRef]

- Wagners EFC Geopolymer Pavements in Wellcamp Airport|Our Projects|Main|Wagner. Available online: https://www.wagner.com.au/main/our-projects/efc-geopolymer-pavements-in-wellcamp-airport (accessed on 5 February 2020).

- Geocement.in. Kiran Global Green Geocement. Available online: http://www.geocement.in/product_details.php?id=25 (accessed on 21 February 2020).

- Nu-Core Nu-Core® A2FR Non-Combustible|ACM A2FR Fire Rating, Fire Proof, Non-Combustible, Fire Retardant, Fire Rated|Products|Nu-Core. Available online: http://nu-core.com.au/nucore-fr-plus-architectural-grade-fire-rated/ (accessed on 21 February 2020).

- Geopolymersolutions COLD FUSION CONCRETE®-FP250|Geopolymer Solutions. Available online: https://www.geopolymertech.com/fireproofing/cold-fusion-concrete-fp250/ (accessed on 5 February 2020).

- Sinnotec SINNOTEC—Sinnotec—Concrete Sealing und Concrete Protection—WHG-Tightened for HBV- und LAU-facilities—We Care about Concrete! Available online: http://www.sinnotec.eu/Sinnotec-Concrete-Sealing-und-Concrete-Protection-WHG-tightened-for-HBV-und-LAU-facilities/ (accessed on 21 February 2020).

- Wagners Pinkenba Wharf|Our Projects|Main|Wagner. Available online: https://www.wagner.com.au/main/our-projects/pinkenba-wharf/ (accessed on 21 February 2020).

- Wagners North Haven Boat Ramp|Our Projects|Main|Wagner. Available online: https://www.wagner.com.au/main/our-projects/north-haven-boat-ramp/ (accessed on 21 February 2020).

- Schlumberger Cementing Services|Schlumberger. Available online: https://www.slb.com/drilling/drilling-fluids-and-well-cementing/well-cementing (accessed on 21 February 2020).

- CLOCKSPRING|NRI GeoSpray® AMS Geopolymer—ClockSpring|NRI ClockSpring|NRI. Available online: https://www.clockspring.com/product/geospray-ams-geopolymer/ (accessed on 21 February 2020).

- Omar Sore, S.; Messan, A.; Prud’homme, E.; Escadeillas, G.; Tsobnang, F. Stabilization of compressed earth blocks (CEBs) by geopolymer binder based on local materials from Burkina Faso. Constr. Build. Mater. 2018, 165, 333–345. [Google Scholar] [CrossRef]

- Habert, G.; Ouellet-Plamondon, C. Recent update on the environmental impact of geopolymers. RILEM Tech. Lett. 2016, 1, 17. [Google Scholar] [CrossRef]

- McLellan, B.C.; Williams, R.P.; Lay, J.; van Riessen, A.; Corder, G.D. Costs and carbon emissions for geopolymer pastes in comparison to ordinary portland cement. J. Clean. Prod. 2011, 19, 1080–1090. [Google Scholar] [CrossRef] [Green Version]

- Ma, C.-K.; Awang, A.Z.; Omar, W. Structural and material performance of geopolymer concrete: A review. Constr. Build. Mater. 2018, 186, 90–102. [Google Scholar] [CrossRef]

- Mehta, A.; Siddique, R. An overview of geopolymers derived from industrial by-products. Constr. Build. Mater. 2016, 127, 183–198. [Google Scholar] [CrossRef]

- Reddy, M.S.; Dinakar, P.; Rao, B.H. A review of the influence of source material’s oxide composition on the compressive strength of geopolymer concrete. Microporous Mesoporous Mater. 2016, 234, 12–23. [Google Scholar] [CrossRef]

- Ng, C.; Alengaram, U.J.; Wong, L.S.; Mo, K.H.; Jumaat, M.Z.; Ramesh, S. A review on microstructural study and compressive strength of geopolymer mortar, paste and concrete. Constr. Build. Mater. 2018, 186, 550–576. [Google Scholar] [CrossRef]

- World Bank Carbon Pricing Dashboard|Up-to-Date Overview of Carbon Pricing Initiatives. Available online: https://carbonpricingdashboard.worldbank.org/ (accessed on 4 September 2020).

- Companies and emissions: Carbon copy. Economist 2013, 322, 70.

- Bai, Q.; Gong, Y.; Jin, M.; Xu, X. Effects of carbon emission reduction on supply chain coordination with vendor-managed deteriorating product inventory. Int. J. Prod. Econ. 2019, 208, 83–99. [Google Scholar] [CrossRef]

- Fareeduddin, M.; Hassan, A.; Syed, M.N.; Selim, S.Z. The impact of carbon policies on closed-loop supply chain network design. Procedia CIRP 2015, 26, 335–340. [Google Scholar] [CrossRef] [Green Version]

- Jin, M.; Granda-Marulanda, N.A.; Down, I. The impact of carbon policies on supply chain design and logistics of a major retailer. J. Clean. Prod. 2014, 85, 453–461. [Google Scholar] [CrossRef]

- Xu, J.; Chen, Y.; Bai, Q. A two-echelon sustainable supply chain coordination under cap-and-trade regulation. J. Clean. Prod. 2016, 135, 42–56. [Google Scholar] [CrossRef]

- Zakeri, A.; Dehghanian, F.; Fahimnia, B.; Sarkis, J. Carbon pricing versus emissions trading: A supply chain planning perspective. Int. J. Prod. Econ. 2015, 164, 197–205. [Google Scholar] [CrossRef] [Green Version]

- Li, D.; Wang, X.; Chan, H.K.; Manzini, R. Sustainable food supply chain management. Int. J. Prod. Econ. 2014, 152, 1–8. [Google Scholar] [CrossRef]

- Li, J.; Su, Q.; Ma, L. Production and transportation outsourcing decisions in the supply chain under single and multiple carbon policies. J. Clean. Prod. 2017, 141, 1109–1122. [Google Scholar] [CrossRef]

- Guo, J.; Bao, Y.; Wang, M. Steel slag in China: Treatment, recycling, and management. Waste Manag. 2018, 78, 318–330. [Google Scholar] [CrossRef]

- Luo, Y.; Wu, Y.; Ma, S.; Zheng, S.; Zhang, Y.; Chu, P.K. Utilization of coal fly ash in China: A mini-review on challenges and future directions. Environ. Sci. Pollut. Res. 2021, 28, 18727–18740. [Google Scholar] [CrossRef] [PubMed]

- Ganesan, N.; Abraham, R.; Deepa Raj, S. Durability characteristics of steel fibre reinforced geopolymer concrete. Constr. Build. Mater. 2015, 93, 471–476. [Google Scholar] [CrossRef]

- Khan, M.Z.N.; Hao, Y.; Hao, H.; Shaikh, F.U.A. Mechanical properties of ambient cured high strength hybrid steel and synthetic fibers reinforced geopolymer composites. Cem. Concr. Compos. 2018, 85, 133–152. [Google Scholar] [CrossRef]

- Al-mashhadani, M.M.; Canpolat, O.; Aygörmez, Y.; Uysal, M.; Erdem, S. Mechanical and microstructural characterization of fiber reinforced fly ash based geopolymer composites. Constr. Build. Mater. 2018, 167, 505–513. [Google Scholar] [CrossRef]

- Vijai, K.; Kumutha, R.; Vishnuram, B.G. Effect of Inclusion of Steel Fibres on the Properties of Geopolymer Concrete Composites. Asian J. Civ. Eng. (Build. Hous.) 2012, 13, 381–389. [Google Scholar]

- Vijai, K.; Kumutha, R.; Vishnuram, B.G. Properties of Glass Fibre Reinforced Geopolymer Concrete Composites. Asian J. Civ. Eng. (Build. Hous.) 2012, 13, 511–520. [Google Scholar]

- Nematollahi, B.; Sanjayan, J.; Chai, J.X.H.; Lu, T.M. Properties of Fresh and Hardened Glass Fiber Reinforced Fly Ash Based Geopolymer Concrete. Key Eng. Mater. 2014, 594–595, 629–633. [Google Scholar] [CrossRef]

- Ohno, M.; Li, V.C. An integrated design method of Engineered Geopolymer Composite. Cem. Concr. Compos. 2018, 88, 73–85. [Google Scholar] [CrossRef]

- Behera, P.; Baheti, V.; Militky, J.; Louda, P. Elevated temperature properties of basalt microfibril filled geopolymer composites. Constr. Build. Mater. 2018, 163, 850–860. [Google Scholar] [CrossRef]

- Li, W.; Xu, J. Mechanical properties of basalt fiber reinforced geopolymeric concrete under impact loading. Mater. Sci. Eng. A 2009, 505, 178–186. [Google Scholar] [CrossRef]

- Nematollahi, B.; Vijay, P.; Sanjayan, J.; Nazari, A.; Xia, M.; Naidu Nerella, V.; Mechtcherine, V.; Nematollahi, B.; Vijay, P.; Sanjayan, J.; et al. Effect of Polypropylene Fibre Addition on Properties of Geopolymers Made by 3D Printing for Digital Construction. Materials 2018, 11, 2352. [Google Scholar] [CrossRef] [Green Version]

- Panda, B.; Paul, S.C.; Hui, L.J.; Tay, Y.W.D.; Tan, M.J. Additive manufacturing of geopolymer for sustainable built environment. J. Clean. Prod. 2017, 167, 281–288. [Google Scholar] [CrossRef]

- Paul, S.C.; Tay, Y.W.D.; Panda, B.; Tan, M.J. Fresh and hardened properties of 3D printable cementitious materials for building and construction. Arch. Civ. Mech. Eng. 2018, 18, 311–319. [Google Scholar] [CrossRef]

- Abdulkareem, M.; Havukainen, J.; Horttanainen, M. How environmentally sustainable are fibre reinforced alkali-activated concretes? J. Clean. Prod. 2019, 236, 117601. [Google Scholar] [CrossRef]

- Van Aken, J.; Chandrasekaran, A.; Halman, J. Conducting and publishing design science research: Inaugural essay of the design science department of the Journal of Operations Management. J. Oper. Manag. 2016, 47–48, 1–8. [Google Scholar] [CrossRef]

- Yin, R.K. Case Study Research: Design and Methods, 5th ed.; SAGE: Thousand Oaks, CA, USA, 2014. [Google Scholar]

- Karttunen, E.; Tsytsyna, E.; Lintukangas, K.; Rintala, A.; Abdulkareem, M.; Havukainen, J.; Nuortila-Jokinen, J. Toward environmental innovation in the cement industry: A multiple-case study of incumbents and new entrants. J. Clean. Prod. 2021, 314, 127981. [Google Scholar] [CrossRef]

- Abdulkareem, M.; Havukainen, J.; Nuortila-Jokinen, J.; Horttanainen, M. Life cycle assessment of a low-height noise barrier for railway traffic noise. J. Clean. Prod. 2021. submitted. [Google Scholar]

| Cement Type | Description |

|---|---|

| CEM I Portland cement | Portland cement and up to 5% of minor additional constituents (the original OPC) |

| CEM II Portland composite cement | Portland cement with up to 35% of other SCM, such as ground limestone, fly ash, or GGBS |

| CEM III blast furnace cement | Portland cement with a higher percentage of blast furnace slag, up to 95% |

| CEM IV pozzolanic cement | Portland cement with up to 55% of selected pozzolanic constituents |

| CEM V composite cement | Portland cement blended with GGBS or fly ash and pozzolanic material |

| Concrete Reinforcement Material | Price |

|---|---|

| Steel Fiber | 698–1300 USD/t |

| Polypropylene fiber | 1699–2699 USD/t |

| Glass fiber | 540–1500 USD/t |

| Polyvinyl alcohol fiber | 1999–2999 USD/t |

| Basalt fiber | 2200–2800 USD/t |

| Constituent | Mix 0 | Mix 1 | Mix 2 | Mix 3 | Mix 4 |

|---|---|---|---|---|---|

| Cement | 27% | ||||

| Calcium aluminate cement | 4% | ||||

| Activator | 10% | 15% | 19% | 0.3% | |

| Waste precursor (CFA and GBFS) | 25% | 4% | 37% | ||

| Metakaolin | 9% | 13% | |||

| Fine aggregates | 9% | 13% | 19% | 13% | 17% |

| Coarse aggregates | 52% | 45% | 48% | 43% | 30% |

| Water | 12% | 6% | 4% | 6% | 16% |

| Polypropylene fiber | 0.14% | 0.14% | 0.14% | 0.14% | 0.14% |

| Material Property | Mix 0 | Mix 1 | Mix 2 | Mix 3 | Mix 4 |

| Compressive strength (28 days) [MPa] | 50 | 25 | 37 | 30 | 14 |

| Measure | Mix 0 | Mix 1 | Mix 2 | Mix 3 | Mix 4 |

|---|---|---|---|---|---|

| Carbon footprint [kg CO2/m3] | 247 | 119 | 220 | 342 | 5 |

| Carbon footprint [kg CO2/t] * | 107.20 | 51.61 | 95.64 | 148.79 | 2.08 |

| reduction potential compared with OPC 1 | 52% | 11% | −39% | 98% | |

| reduction potential compared with OPC 2 | 20% | −11% | −48% | 55% | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rintala, A.; Havukainen, J.; Abdulkareem, M. Estimating the Cost-Competitiveness of Recycling-Based Geopolymer Concretes. Recycling 2021, 6, 46. https://0-doi-org.brum.beds.ac.uk/10.3390/recycling6030046

Rintala A, Havukainen J, Abdulkareem M. Estimating the Cost-Competitiveness of Recycling-Based Geopolymer Concretes. Recycling. 2021; 6(3):46. https://0-doi-org.brum.beds.ac.uk/10.3390/recycling6030046

Chicago/Turabian StyleRintala, Annastiina, Jouni Havukainen, and Mariam Abdulkareem. 2021. "Estimating the Cost-Competitiveness of Recycling-Based Geopolymer Concretes" Recycling 6, no. 3: 46. https://0-doi-org.brum.beds.ac.uk/10.3390/recycling6030046