Exploring the Interrelationship between Additive Manufacturing and Industry 4.0

Abstract

:1. Introduction

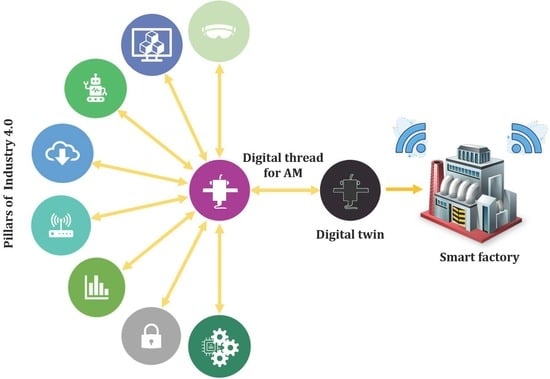

2. Interrelationship between Additive Manufacturing and Industry 4.0

2.1. Augmented Reality and Additive Manufacturing

2.2. Simulation and Additive Manufacturing

2.3. Autonomous Robots and Additive Manufacturing

2.4. Industrial Internet of Things and Additive Manufacturing

2.5. Big Data Analytics and Additive Manufacturing

2.6. Cloud Computing and Additive Manufacturing

2.7. Cyber Security and Additive Manufacturing

2.8. Horizontal/Vertical Integration and Additive Manufacturing

3. Digital Thread for Additive Manufacturing

4. Conclusions

Funding

Conflicts of Interest

References

- Kagermann, H.; Wahlster, W.; Helbig, J. Recommendations for implementing the strategic initiative Industrie 4.0: Final report of the Industrie 4.0 Working Group. Acatech München 2013, 8, 19–26. [Google Scholar]

- Lasi, H.; Fettke, P.; Kemper, H.G.; Feld, T.; Hoffmann, M. Industry 4.0. Bus. Inf. Syst. Eng. 2014, 6, 239–242. [Google Scholar] [CrossRef]

- Lu, Y. Industry 4.0: A survey on technologies, applications and open research issues. J. Ind. Inf. Integr. 2017, 6, 1–10. [Google Scholar] [CrossRef]

- Lee, J.; Kao, H.A.; Yang, S. Service Innovation and Smart Analytics for Industry 4.0 and Big Data Environment. Procedia CIRP 2014, 16, 3–8. [Google Scholar] [CrossRef] [Green Version]

- Gorecky, D.; Schmitt, M.; Loskyll, M.; Zühlke, D.; Schmitt, M. Human-machine-interaction in the industry 4.0 era. In Proceedings of the 2014 12th IEEE International Conference on Industrial Informatics (INDIN), Porto Alegre, Brazil, 27–30 July 2014; pp. 289–294. [Google Scholar]

- Roblek, V.; Meško, M.; Krapež, A. A Complex View of Industry 4.0. SAGE Open 2016, 6. [Google Scholar] [CrossRef] [Green Version]

- Posada, J.; Toro, C.; Barandiaran, I.; Oyarzun, D.; Stricker, D.; De Amicis, R.; Pinto, E.B.; Eisert, P.; Döllner, J.; Vallarino, I. Visual Computing as a Key Enabling Technology for Industrie 4.0 and Industrial Internet. IEEE Eng. Med. Boil. Mag. 2015, 35, 26–40. [Google Scholar] [CrossRef]

- Büchi, G.; Cugno, M.; Castagnoli, R. Smart factory performance and Industry 4.0. Technol. Forecast. Soc. Chang. 2020, 150, 119790. [Google Scholar] [CrossRef]

- Chiarello, F.; Trivelli, L.; Bonaccorsi, A.; Fantoni, G. Extracting and mapping industry 4.0 technologies using wikipedia. Comput. Ind. 2018, 100, 244–257. [Google Scholar] [CrossRef]

- Rüßmann, M.; Lorenz, M.; Gerbert, P.; Waldner, M.; Justus, J.; Engel, P.; Harnisch, M. Industry 4.0: The future of productivity and growth in manufacturing industries. Boston Consult. Group 2015, 9, 54–89. [Google Scholar]

- Wan, J.; Cai, H.; Zhou, K. Industrie 4.0: Enabling technologies. In Proceedings of the 2015 International Conference on Intelligent Computing and Internet of Things, Harbin, China, 17–18 January 2015; pp. 135–140. [Google Scholar]

- Kinsy, M.; Khan, O.; Čelanović, I.; Majstorovic, D.; Celanovic, N.; Devadas, S. Time-Predictable Computer Architecture for Cyber-Physical Systems: Digital Emulation of Power Electronics Systems. In Proceedings of the 2011 IEEE 32nd Real-Time Systems Symposium, Vienna, Austria, 29 November–2 December 2011; pp. 305–316. [Google Scholar] [CrossRef]

- Maksimchuk, O.; Pershina, T. A new paradigm of industrial system optimization based on the conception “Industry 4.0”. In Proceedings of the MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2017; Volume 129, p. 4006. [Google Scholar]

- Huxtable, J.; Schaefer, D. On Servitization of the Manufacturing Industry in the UK. Procedia CIRP 2016, 52, 46–51. [Google Scholar] [CrossRef] [Green Version]

- What is Factory in a Box? Available online: https://smartmanufacturingaccelerator.co.uk/what-is-factory-in-a-box/ (accessed on 11 March 2020).

- About the GrowIn 4.0 Project. Available online: https://northsearegion.eu/growin4/about-the-growin-40-project/ (accessed on 11 March 2020).

- Smart Manufacturing and Logistics for SMEs in an X-to-Order and Mass Customization Environment. Available online: https://www.sme40.eu/ (accessed on 11 March 2020).

- What Does the Fourth Industrial Revolution (4IR) Mean for UK Business? Available online: https://innovateuk.blog.gov.uk/2017/03/28/what-does-the-fourth-industrial-revolution-4ir-mean-for-uk-business/ (accessed on 11 March 2020).

- Urciuoli, L.; Hintsa, J.; Ahokas, J. Drivers and barriers affecting usage of e-Customs—A global survey with customs administrations using multivariate analysis techniques. Gov. Inf. Q. 2013, 30, 473–485. [Google Scholar] [CrossRef]

- Müller, J.M.; Däschle, S. Business Model Innovation of Industry 4.0 Solution Providers Towards Customer Process Innovation. Processes 2018, 6, 260. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Q.; Geng, Y. Drivers and barriers of extended supply chain practices for energy saving and emission reduction among Chinese manufacturers. J. Clean. Prod. 2013, 40, 6–12. [Google Scholar] [CrossRef]

- Butt, J.; Mebrahtu, H.; Shirvani, H. Rapid prototyping by heat diffusion of metal foil and related mechanical testing. Int. J. Adv. Manuf. Technol. 2015, 84, 2357–2366. [Google Scholar] [CrossRef] [Green Version]

- Enabling the Full Potential of 3D Printing. Available online: https://3mf.io/ (accessed on 11 March 2020).

- What is Happening with 3MF? An Update on 3D Printing’s Next Generation File Format. Available online: https://www.tctmagazine.com/3d-software-news/what-is-happening-with-3mf-3d-printing/ (accessed on 11 March 2020).

- 3MF File Format and Why It’s Great. Available online: https://blog.prusaprinters.org/3mf-file-format-and-why-its-great/ (accessed on 11 March 2020).

- Butt, J.; Mebrahtu, H.; Shirvani, H. Metal Rapid Prototyping Technologies. In Advances in Engineering Research; Petrova, V.M., Ed.; Nova Science Publishers, Inc.: New York, NY, USA, 2017; Volume 14, Chapter 2; pp. 13–52. [Google Scholar]

- Butt, J.; Mebrahtu, H.; Shirvani, H. Peel and tensile test investigation of aluminium 1050 foil parts made with a new additive manufacturing process. Int. J. Rapid Manuf. 2015, 5, 95. [Google Scholar] [CrossRef]

- Butt, J.; Hewavidana, Y.; Mohaghegh, V.; Sadeghi-Esfahlani, S.; Shirvani, H. Hybrid Manufacturing and Experimental Testing of Glass Fiber Enhanced Thermoplastic Composites. J. Manuf. Mater. Process. 2019, 3, 96. [Google Scholar] [CrossRef] [Green Version]

- Ngo, T.; Kashani, A.; Imbalzano, G.; Nguyen, Q.T.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part. B: Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- ISO/ASTM52900-15. Standard Terminology for Additive Manufacturing—General Principles—Terminology; ASTM International: West Conshohocken, PA, USA, 2015; Available online: www.astm.org (accessed on 11 March 2020).

- Frazier, W.E. Metal Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Williams, S.W.; Martina, F.; Addison, A.C.; Ding, J.; Pardal, G.R.; Colegrove, P.A. Wire + Arc Additive Manufacturing. Mater. Sci. Technol. 2016, 32, 641–647. [Google Scholar] [CrossRef] [Green Version]

- Butt, J.; Shirvani, H. Experimental analysis of metal/plastic composites made by a new hybrid method. Addit. Manuf. 2018, 22, 216–222. [Google Scholar] [CrossRef]

- Butt, J.; Mebrahtu, H.; Shirvani, H. Microstructure and mechanical properties of dissimilar pure copper foil/1050 aluminium composites made with composite metal foil manufacturing. J. Mater. Process. Technol. 2016, 238, 96–107. [Google Scholar] [CrossRef]

- Butt, J.; Bhaskar, R. Investigating the Effects of Annealing on the Mechanical Properties of FFF-Printed Thermoplastics. J. Manuf. Mater. Process. 2020, 4, 38. [Google Scholar] [CrossRef]

- Thompson, M.K.; Moroni, G.; Vaneker, T.; Fadel, G.; Campbell, R.I.; Gibson, I.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B.; et al. Design for Additive Manufacturing: Trends, opportunities, considerations, and constraints. CIRP Ann. 2016, 65, 737–760. [Google Scholar] [CrossRef]

- Migler, K.D.; Ricker, R.E. Measurement Science Roadmap for Polymer-Based Additive Manufacturing (No. Advanced Manufacturing Series (NIST AMS)-100-5). 2016. Available online: https://www.nist.gov/publications/measurement-science-roadmap-polymer-based-additive-manufacturing (accessed on 15 March 2020).

- Makes, A. Technology Roadmap Workshop: Next-Gen 3DP Metal Alloys; America Makes: Youngstown, OH, USA, 2014. [Google Scholar]

- Srinivasan, V.; Bassan, J. 3D Printing and The Future of Manufacturing. In CSC Leading Edge Forum; Computer Sciences Corporation: Tysons, VA, USA, 2012; Available online: https://www.iotone.com/files/pdf/vendor/CSC_future_of_manufacturing_2012.pdf (accessed on 12 March 2020).

- Wohlers, T.T.; Campbell, I.; Diegel, O.; Kowen, J. Wohlers Report 2018, 344-Page Publication; Wohlers Associates. Inc.: Fort Collins, CO, USA, March 2018. [Google Scholar]

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Wang, C.C.L.; Shin, Y.C.; Zhang, S.; Zavattieri, P.D. The status, challenges, and future of additive manufacturing in engineering. Comput. Des. 2015, 69, 65–89. [Google Scholar] [CrossRef]

- Huang, Y.; Leu, M.; Mazumder, J.; Donmez, A. Additive Manufacturing: Current State, Future Potential, Gaps and Needs, and Recommendations. J. Manuf. Sci. Eng. 2015, 137, 014001. [Google Scholar] [CrossRef] [Green Version]

- Karre, H.; Hammer, M.; Kleindienst, M.; Ramsauer, C. Transition towards an Industry 4.0 State of the LeanLab at Graz University of Technology. Procedia Manuf. 2017, 9, 206–213. [Google Scholar] [CrossRef]

- Butt, J. A Novel Additive Manufacturing Process for the Production of Metal Parts. Ph.D. Thesis, Anglia Ruskin University, Cambridge, UK, 2016. [Google Scholar]

- Butt, J.; Shirvani, H. Additive, Subtractive, and Hybrid Manufacturing Processes. In Advances in Manufacturing and Processing of Materials and Structures; Informa UK Limited: London, UK, 2018; pp. 187–218. [Google Scholar]

- Tamura, H. Steady steps and giant leap toward practical mixed reality systems and applications. In Proceedings of the International Status Conference on Virtual and Augmented Reality, Leipzig, Germany, 5 November 2002; pp. 3–12. [Google Scholar]

- Akçayır, M.; Akçayır, G. Advantages and challenges associated with augmented reality for education: A systematic review of the literature. Educ. Res. Rev. 2017, 20, 1–11. [Google Scholar] [CrossRef]

- Lima, J.P.; Roberto, R.; Simões, F.; Almeida, M.; Figueiredo, L.S.; Teixeira, J.M.; Teichrieb, V. Markerless tracking system for augmented reality in the automotive industry. Expert Syst. Appl. 2017, 82, 100–114. [Google Scholar] [CrossRef]

- Poushneh, A.; Vasquez-Parraga, A.Z. Discernible impact of augmented reality on retail customer’s experience, satisfaction and willingness to buy. J. Retail. Consum. Serv. 2017, 34, 229–234. [Google Scholar] [CrossRef]

- Chen, Y.P.; Ko, J.C. CryptoAR Wallet: A Blockchain Cryptocurrency Wallet Application that Uses Augmented Reality for On-chain User Data Display. In Proceedings of the 21st International Conference on Human-Computer Interaction with Mobile Devices and Services, Taipei, Taiwan, 1–4 October 2019; pp. 1–5. [Google Scholar]

- Kounavis, C.D.; Kasimati, A.E.; Zamani, E.D. Enhancing the tourism experience through mobile augmented reality: Challenges and prospects. Int. J. Eng. Bus. Manag. 2012, 4, 10. [Google Scholar] [CrossRef]

- Jung, T.; Tom Dieck, M.C. Augmented Reality and Virtual Reality. Empowering Human, Place and Business; Springer International Publishing: Cham, Switzerland, 2018. [Google Scholar]

- Tepper, O.; Rudy, H.L.; Lefkowitz, A.; Weimer, K.A.; Marks, S.M.; Stern, C.S.; Garfein, E.S. Mixed Reality with HoloLens. Plast. Reconstr. Surg. 2017, 140, 1066–1070. [Google Scholar] [CrossRef] [PubMed]

- Bonetti, F.; Warnaby, G.; Quinn, L. Augmented Reality and Virtual Reality in Physical and Online Retailing: A Review, Synthesis and Research Agenda. In Progress in IS; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2017; pp. 119–132. [Google Scholar]

- Chavan, S.R. Augmented reality vs. virtual reality: Differences and similarities. Int. J. Adv. Res. Comput. Eng. Technol. (IJARCET) 2016, 5, 212611467. [Google Scholar]

- Thomas, P.C.; David, W.M. Augmented reality: An application of heads-up display technology to manual manufacturing processes. In Hawaii International Conference on System Sciences; ACM SIGCHI Bulletin: New York, NY, USA, 1992; pp. 659–669. [Google Scholar]

- Milgram, P.; Kishino, F. A taxonomy of mixed reality visual displays. IEICE Trans. Inf. Syst. 1994, 77, 1321–1329. [Google Scholar]

- Yung, R.; Khoo-Lattimore, C. New realities: A systematic literature review on virtual reality and augmented reality in tourism research. Curr. Issues Tour. 2017, 22, 2056–2081. [Google Scholar] [CrossRef]

- Flavián, C.; Ibáñez-Sánchez, S.; Orús, C. The impact of virtual, augmented and mixed reality technologies on the customer experience. J. Bus. Res. 2019, 100, 547–560. [Google Scholar] [CrossRef]

- Zhang, J.; Ong, S.; Nee, A. A Volumetric Model-Based CNC Simulation and Monitoring System in Augmented Environments. In Proceedings of the 2006 International Conference on Cyberworlds, Lausanne, Switzerland, 28–29 November 2006; pp. 33–42. [Google Scholar]

- Kollatsch, C.; Schumann, M.; Klimant, P.; Wittstock, V.; Putz, M. Mobile Augmented Reality Based Monitoring of Assembly Lines. Procedia CIRP 2014, 23, 246–251. [Google Scholar] [CrossRef]

- Eiriksson, E.R.; Pedersen, D.B.; Frisvad, J.R.; Skovmand, L.; Heun, V.; Maes, P.; Aanæs, H.; Sharma, P.; Bianchi, F.M. Augmented Reality Interfaces for Additive Manufacturing. In Proceedings of the Intelligent Tutoring Systems; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2017; Volume 10269, pp. 515–525. [Google Scholar]

- Peng, H.; Briggs, J.; Wang, C.Y.; Guo, K.; Kider, J.; Mueller, S.; Baudisch, P.; Guimbretière, F. RoMA: Interactive fabrication with augmented reality and a robotic 3D printer. In Proceedings of the 2018 CHI Conference on Human Factors in Computing Systems, Montreal, QC, Canada, 21–26 April 2018; pp. 1–12. [Google Scholar]

- Malik, A.; Lhachemi, H.; Ploennigs, J.; Ba, A.; Shorten, R. An Application of 3D Model Reconstruction and Augmented Reality for Real-Time Monitoring of Additive Manufacturing. Procedia CIRP 2019, 81, 346–351. [Google Scholar] [CrossRef]

- Liverani, A.; Ceruti, A.; Bombardi, T.; University of Bologna. Device and Monitoring Method for Prototyping and Similar Machines, 102015000057858, Italy [Online]. 2015. Available online: https://worldwide.espacenet.com/publicationDetails/biblio?locale=en_EP&II=0&date=20170402&CC=IT&NR=UB20154128A1&ND=3&KC=A1&rnd=1585319547759&adjacent=true&FT=D&DB=EPODOC (accessed on 27 March 2020).

- Ceruti, A.; Liverani, A.; Bombardi, T. Augmented vision and interactive monitoring in 3D printing process. Int. J. Interact. Des. Manuf. (IJIDeM) 2016, 11, 385–395. [Google Scholar] [CrossRef]

- Wake, N.; Bjurlin, M.; Rostami, P.; Chandarana, H.; Huang, W. V12-03 Three Dimensional Printing and Augmented Reality: Enhanced Precision for Robotic Assisted Partial Nephrectomy. J. Urol. 2018, 199, e1237. [Google Scholar] [CrossRef]

- Butt, J.; Ghorabian, M.; Ahmed, A.; Shirvani, H. Finite Element Modelling and Validation of Thermomechanical Behaviour for Layered Aluminium Parts Made by Composite Metal Foil Manufacturing. J. Compos. Sci. 2018, 2, 68. [Google Scholar] [CrossRef] [Green Version]

- Nammi, S.K.; Butt, J.; Mauricette, J.L.; Shirvani, H. Numerical Analysis of Thermal Stresses around Fasteners in Composite Metal Foils. IOP Conf. Ser. Mater. Sci. Eng. 2017, 280, 12016. [Google Scholar] [CrossRef] [Green Version]

- Lindgren, L.-E.; Lundbäck, A.; Fisk, M.; Pederson, R.; Andersson, J. Simulation of additive manufacturing using coupled constitutive and microstructure models. Addit. Manuf. 2016, 12, 144–158. [Google Scholar] [CrossRef]

- Heigel, J.; Michaleris, P.; Reutzel, E. Thermo-mechanical model development and validation of directed energy deposition additive manufacturing of Ti–6Al–4V. Addit. Manuf. 2015, 5, 9–19. [Google Scholar] [CrossRef]

- Brenken, B.; Barocio, E.; Favaloro, A.J.; Kunc, V.; Pipes, R.B. Development and validation of extrusion deposition additive manufacturing process simulations. Addit. Manuf. 2019, 25, 218–226. [Google Scholar] [CrossRef]

- Rodič, B. Industry 4.0 and the New Simulation Modelling Paradigm. Organizacija 2017, 50, 193–207. [Google Scholar] [CrossRef] [Green Version]

- Banks, J.; Carson, J.S.; Nelson, B.L.; Nicol, D.M. Verification and Validation of Simulation Models. Discrete-Event System Simulation, 3rd ed.; Prentice-Hall: Upper Saddle River, NJ, USA, 2001; pp. 367–397. [Google Scholar]

- Liravi, F.; Das, S.; Zhou, C. Separation force analysis and prediction based on cohesive element model for constrained-surface Stereolithography processes. Comput. Des. 2015, 69, 134–142. [Google Scholar] [CrossRef]

- Peyre, P.; Rouchausse, Y.; Defauchy, D.; Régnier, G. Experimental and numerical analysis of the selective laser sintering (SLS) of PA12 and PEKK semi-crystalline polymers. J. Mater. Process. Technol. 2015, 225, 326–336. [Google Scholar] [CrossRef]

- Kovaleva, I.; Kovalev, O.; Smurov, I. Model of Heat and Mass Transfer in Random Packing Layer of Powder Particles in Selective Laser Melting. Phys. Procedia 2014, 56, 400–410. [Google Scholar] [CrossRef] [Green Version]

- Strano, G.; Hao, L.; Everson, R.; Evans, K.E. Surface roughness analysis, modelling and prediction in selective laser melting. J. Mater. Process. Technol. 2013, 213, 589–597. [Google Scholar] [CrossRef]

- Qiu, C.; Panwisawas, C.; Ward, M.; Basoalto, H.C.; Brooks, J.W.; Attallah, M.M. On the role of melt flow into the surface structure and porosity development during selective laser melting. Acta Mater. 2015, 96, 72–79. [Google Scholar] [CrossRef] [Green Version]

- Romano, J.; Ladani, L.; Razmi, J.; Sadowski, M. Temperature distribution and melt geometry in laser and electron-beam melting processes—A comparison among common materials. Addit. Manuf. 2015, 8, 1–11. [Google Scholar] [CrossRef]

- Riedlbauer, D.; Scharowsky, T.; Singer, R.F.; Steinmann, P.; Körner, C.; Mergheim, J. Macroscopic simulation and experimental measurement of melt pool characteristics in selective electron beam melting of Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2016, 88, 1309–1317. [Google Scholar] [CrossRef] [Green Version]

- Gharbi, M.; Peyre, P.; Gorny, C.; Carin, M.; Morville, S.; Le Masson, P.; Carron, D.; Fabbro, R. Influence of various process conditions on surface finishes induced by the direct metal deposition laser technique on a Ti–6Al–4V alloy. J. Mater. Process. Technol. 2013, 213, 791–800. [Google Scholar] [CrossRef] [Green Version]

- Morville, S.; Carin, M.; Peyre, P.; Gharbi, M.; Carron, D.; Le Masson, P.; Fabbro, R. 2D longitudinal modeling of heat transfer and fluid flow during multilayered direct laser metal deposition process. J. Laser Appl. 2012, 24, 32008. [Google Scholar] [CrossRef]

- Xu, X.; Meteyer, S.; Perry, N.; Zhao, Y.F. Energy consumption model of Binder-jetting additive manufacturing processes. Int. J. Prod. Res. 2014, 53, 1–11. [Google Scholar] [CrossRef]

- Chen, H.; Zhao, Y.F. Process parameters optimization for improving surface quality and manufacturing accuracy of binder jetting additive manufacturing process. Rapid Prototyp. J. 2016, 22, 527–538. [Google Scholar] [CrossRef]

- Boschetto, A.; Giordano, V.; Veniali, F. Surface roughness prediction in fused deposition modelling by neural networks. Int. J. Adv. Manuf. Technol. 2013, 67, 2727–2742. [Google Scholar] [CrossRef]

- Croccolo, D.; De Agostinis, M.; Olmi, G. Experimental characterization and analytical modelling of the mechanical behaviour of fused deposition processed parts made of ABS-M30. Comput. Mater. Sci. 2013, 79, 506–518. [Google Scholar] [CrossRef]

- Sugavaneswaran, M.; Arumaikkannu, G. Modelling for randomly oriented multi material additive manufacturing component and its fabrication. Mater. Des. 2014, 54, 779–785. [Google Scholar] [CrossRef]

- Zhou, W.; Loney, D.; Degertekin, F.L.; Rosen, D.W.; Fedorov, A.G. What controls dynamics of droplet shape evolution upon impingement on a solid surface? AIChE J. 2013, 59, 3071–3082. [Google Scholar] [CrossRef]

- Butt, J.; Ghorabian, M.; Mohaghegh, V.; Shirvani, H. Finite Element Modeling and Mechanical Testing of Metal Composites Made by Composite Metal Foil Manufacturing. J. Manuf. Mater. Process. 2019, 3, 81. [Google Scholar] [CrossRef] [Green Version]

- Kelly, G.S.; Advani, S.; Gillespie, J.W.; Bogetti, T.A. A model to characterize acoustic softening during ultrasonic consolidation. J. Mater. Process. Technol. 2013, 213, 1835–1845. [Google Scholar] [CrossRef]

- Avventuroso, G.; Silvestri, M.; Frazzon, E.M. Additive Manufacturing Plant for Large Scale Production of Medical Devices: A Simulation Study. IFAC-PapersOnLine 2018, 51, 1442–1447. [Google Scholar] [CrossRef]

- LANNER. Metalysis Revolutionise UK Metal Production with Simulation. 2016. Available online: https://www.lanner.com/en-us/insights/news/metalysis-revolutionise-uk-metal-production-with-simulation.html (accessed on 15 March 2020).

- Bahrin, M.A.K.; Othman, M.F.; Azli, N.H.N.; Talib, M.F. Industry 4.0: A Review on Industrial Automation and Robotic. J. Teknol. 2016, 78, 137–143. [Google Scholar] [CrossRef] [Green Version]

- Druehl, C.; Carrillo, J.; Hsuan, J. Technological Innovations: Impacts on Supply Chains. In Contributions to Management Science; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2018; pp. 259–281. [Google Scholar]

- Branch Technology. Available online: https://www.branch.technology/ (accessed on 15 March 2020).

- Stone Spray Project Uses 3D Printer to Build Long-Lasting, Intricate Sandcastles. Available online: https://www.theverge.com/2012/8/5/3220003/stone-spray-project-3d-printer-sandcastles (accessed on 15 March 2020).

- Suspended Depositions. Available online: http://nstrmnt.com/#/suspended-depositions/ (accessed on 15 March 2020).

- XtreeE, The Large Scale 3D. Available online: https://xtreee.com/en/ (accessed on 15 March 2020).

- MX3D-Bridge. Available online: https://mx3d.com/projects/mx3d-bridge/ (accessed on 15 March 2020).

- AiMaker Autonomous Large Scale 3D Printing. Available online: https://www.ai-build.com/ (accessed on 15 March 2020).

- The 4D Hybrid Main Objective is to Develop a New Concept of Hybrid Additive Manufacturing Based on the Modular Integration of Compact, Low-Cost Modules Including Laser Source, Deposition Head, Sensors and Control. Available online: https://4dhybrid.eu/objectives/ (accessed on 15 March 2020).

- The Promise of Robotic Metal Additive Manufacturing. Available online: https://www.additivemanufacturing.media/articles/the-promise-of-robotic-metal-additive-manufacturing (accessed on 15 March 2020).

- The Hidden Complexities of Wire Arc Additive Manufacturing. Available online: https://www.additivemanufacturing.media/articles/the-hidden-complexities-of-wire-arc-additive-manufacturing (accessed on 15 March 2020).

- Building the Future with Robotic Additive Manufacturing. Available online: https://www.robotics.org/content-detail.cfm/Industrial-Robotics-Industry-Insights/Building-the-Future-with-Robotic-Additive-Manufacturing/content_id/6860 (accessed on 15 March 2020).

- Keating, S.J.; Leland, J.C.; Cai, L.; Oxman, N. Toward site-specific and self-sufficient robotic fabrication on architectural scales. Sci. Robot. 2017, 2, eaam8986. [Google Scholar] [CrossRef]

- WinSun Deploys 3D Printed Isolation Wards for Coronavirus Medical Staff. Available online: https://www.3dprintingmedia.network/winsun-3d-printed-isolation-wards-coronavirus-medical-workers/ (accessed on 15 March 2020).

- 3D Printing is Applied in UK Project to Produce Autonomous Evolving Robots. Available online: https://3dprintingindustry.com/news/3d-printing-is-applied-in-uk-project-to-produce-autonomous-evolving-robots-136278/ (accessed on 15 March 2020).

- Danish Designers Propose Using Roaming 3D-Printing Robots to Repair Environments. Available online: https://www.dezeen.com/2019/08/23/break-the-grid-3d-printing-robots-technology/ (accessed on 15 March 2020).

- Hale, M.F.; Buchanan, E.; Winfield, A.F.; Timmis, J.; Hart, E.; Eiben, A.E.; Angus, M.; Veenstra, F.; Li, W.; Woolley, R.; et al. The ARE Robot Fabricator: How to (Re) produce Robots that Can Evolve in the Real World. In Proceedings of the 2018 Conference on Artificial Life: A Hybrid of the European Conference on Artificial Life (ECAL) and the International Conference on the Synthesis and Simulation of Living Systems (ALIFE), Tokyo, Japan, 23–27 July 2018; MIT Press: Cambridge, MA, USA; pp. 95–102. [Google Scholar]

- Tucker, K.; Bulim, J.; Koch, G.; North, M.M. Internet industry: A perspective review through internet of things and internet of everything. Int. Manag. Rev. 2018, 14, 26. [Google Scholar]

- Bortolini, M.; Ferrari, E.; Gamberi, M.; Pilati, F.; Faccio, M. Assembly system design in the Industry 4.0 era: A general framework. IFAC-PapersOnLine 2017, 50, 5700–5705. [Google Scholar] [CrossRef]

- Butt, J.; Onimowo, D.A.; Gohrabian, M.; Sharma, T.; Shirvani, H. A desktop 3D printer with dual extruders to produce customised electronic circuitry. Front. Mech. Eng. 2018, 13, 528–534. [Google Scholar] [CrossRef]

- Gao, J. Production of Multiple Material Parts Using a Desktop 3D Printer. In Advances in Manufacturing Technology XXXI, Proceedings of the 15th International Conference on Manufacturing Research, Incorporating the 32nd National Conference on Manufacturing Research, 5–7 September 2017, University of Greenwich, UK; IOS Press: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Saleh, E.; Zhang, F.; He, Y.; Vaithilingam, J.; Fernandez, J.L.; Wildman, R.; Ashcroft, I.; Hague, R.; Dickens, P.; Tuck, C. 3D Inkjet Printing of Electronics Using UV Conversion. Adv. Mater. Technol. 2017, 2, 1700134. [Google Scholar] [CrossRef]

- DragonFly LDM Precision Additive Manufacturing System for Electronics. Available online: https://www.nano-di.com/ (accessed on 17 March 2020).

- How the IoT Will Fit in Additive Manufacturing. Available online: https://www.makepartsfast.com/how-the-iot-will-fit-in-additive-manufacturing/ (accessed on 17 March 2020).

- Press Releases News about EOS and 3D Printing. Available online: https://www.eos.info/press/eos-promotes-integration-of-3d-printing-into-internet-of-things (accessed on 17 March 2020).

- Wang, Y.; Lin, Y.; Zhong, R.Y.; Xu, X. IoT-enabled cloud-based additive manufacturing platform to support rapid product development. Int. J. Prod. Res. 2018, 57, 3975–3991. [Google Scholar] [CrossRef]

- Qin, J.; Liu, Y.; Grosvenor, R. A Framework of Energy Consumption Modelling for Additive Manufacturing Using Internet of Things. Procedia CIRP 2017, 63, 307–312. [Google Scholar] [CrossRef]

- Gf, B.; Rv, A. An IoT-Based Solution for Control and Monitoring of Additive Manufacturing Processes. J. Powder Met. Min. 2017, 6, 2. [Google Scholar] [CrossRef]

- Wu, X.; Zhu, X.; Wu, G.; Ding, W. Data mining with big data. IEEE Trans. Knowl. Data Eng. 2013, 26, 97–107. [Google Scholar] [CrossRef]

- Doug, L. 3D Data Management: Controlling Data Volume. Velocity, and Variety. In Application Delivery Strategies; META Group: Stamford, CO, USA, 2001. [Google Scholar]

- Kaisler, S.; Armour, F.; Espinosa, J.A.; Money, W. Big Data: Issues and Challenges Moving Forward. In Proceedings of the 2013 46th Hawaii International Conference on System Sciences, Wailea, HI, USA, 7–10 January 2013; pp. 995–1004. [Google Scholar]

- Oguntimilehin, A.; Ademola, E.O. A review of big data management, benefits and challenges. Rev. Big Data Manag. Benefits Chall. 2014, 5, 1–7. [Google Scholar]

- The 42 V’s of Big Data and Data Science. Available online: https://www.elderresearch.com/blog/42-v-of-big-data (accessed on 17 March 2020).

- Raghupathi, W.; Raghupathi, V. Big data analytics in healthcare: Promise and potential. Health Inf. Sci. Syst. 2014, 2, 3. [Google Scholar] [CrossRef]

- Lee, J.; Bagheri, B.; Kao, H.-A. A Cyber-Physical Systems architecture for Industry 4.0-based manufacturing systems. Manuf. Lett. 2015, 3, 18–23. [Google Scholar] [CrossRef]

- Mies, D.; Marsden, W.; Warde, S. Overview of Additive Manufacturing Informatics: “A Digital Thread”. Integr. Mater. Manuf. Innov. 2016, 5, 114–142. [Google Scholar] [CrossRef] [Green Version]

- Knapp, G.; Mukherjee, T.; Zuback, J.; Wei, H.; Palmer, T.; De, A.; Debroy, T. Building blocks for a digital twin of additive manufacturing. Acta Mater. 2017, 135, 390–399. [Google Scholar] [CrossRef]

- Beyer, C.; Figueroa, D. Design and Analysis of Lattice Structures for Additive Manufacturing. J. Manuf. Sci. Eng. 2016, 138, 121014. [Google Scholar] [CrossRef]

- Maconachie, T.; Leary, M.; Lozanovski, B.; Zhang, X.; Qian, M.; Faruque, O.; Brandt, M.; Zhang, X. SLM lattice structures: Properties, performance, applications and challenges. Mater. Des. 2019, 183, 108137. [Google Scholar] [CrossRef]

- Strantza, M.; Vafadari, R.; De Baere, D.; Vrancken, B.; Van Paepegem, W.; Vandendael, I.; Terryn, H.; Guillaume, P.; Van Hemelrijck, D. Fatigue of Ti6Al4V Structural Health Monitoring Systems Produced by Selective Laser Melting. Materials 2016, 9, 106. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ceruti, A.; Marzocca, P.; Liverani, A.; Bil, C. Maintenance in aeronautics in an Industry 4.0 context: The role of Augmented Reality and Additive Manufacturing. J. Comput. Des. Eng. 2019, 6, 516–526. [Google Scholar] [CrossRef]

- Francis, J.; Bian, L. Deep Learning for Distortion Prediction in Laser-Based Additive Manufacturing using Big Data. Manuf. Lett. 2019, 20, 10–14. [Google Scholar] [CrossRef]

- Majeed, A.; Lv, J.; Peng, T. A framework for big data driven process analysis and optimization for additive manufacturing. Rapid Prototyp. J. 2019, 25, 308–321. [Google Scholar] [CrossRef]

- Lee, S.; Peng, J.; Shin, D.; Choi, Y.S. Data analytics approach for melt-pool geometries in metal additive manufacturing. Sci. Technol. Adv. Mater. 2019, 20, 972–978. [Google Scholar] [CrossRef] [Green Version]

- Mellow, G. The NIST Definition of Cloud Computing; NIST Special Publication: Gaithersburg, MD, USA, 2013.

- Varghese, B.; Buyya, R. Next generation cloud computing: New trends and research directions. Futur. Gener. Comput. Syst. 2018, 79, 849–861. [Google Scholar] [CrossRef] [Green Version]

- Ghorbel, A.; Ghorbel, M.; Jmaiel, M. Privacy in cloud computing environments: A survey and research challenges. J. Supercomput. 2017, 73, 2763–2800. [Google Scholar] [CrossRef]

- Singh, A.; Chatterjee, K. Cloud security issues and challenges: A survey. J. Netw. Comput. Appl. 2017, 79, 88–115. [Google Scholar] [CrossRef]

- Oracle Cloud Boosts GE Additive’s Fast-Growing 3D Printer Business. Available online: https://blogs.oracle.com/modernfinance/oracle-erp-scm-cloud-ge-additive-3d-printing (accessed on 19 March 2020).

- Easy 3D Printer Management. Available online: https://www.3dprinteros.com/ (accessed on 19 March 2020).

- Stratasys Introduces Work Order Management Software for 3D Printing Shops as Industry Adoption of 3D Printing Booms. Available online: https://investors.stratasys.com/news-events/press-releases/detail/512/stratasys-introduces-work-order-management-software-for-3d (accessed on 19 March 2020).

- Rudolph, J.-P.; Emmelmann, C. A Cloud-based Platform for Automated Order Processing in Additive Manufacturing. Procedia CIRP 2017, 63, 412–417. [Google Scholar] [CrossRef]

- Henzel, R.; Herzwurm, G. Cloud Manufacturing: A state-of-the-art survey of current issues. Procedia CIRP 2018, 72, 947–952. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, L.; Wang, X.V. Cloud manufacturing: Latest advancements and future trends. Procedia Manuf. 2018, 25, 62–73. [Google Scholar] [CrossRef]

- Baumann, F.; Roller, D. Additive Manufacturing, Cloud-Based 3D Printing and Associated Services—Overview. J. Manuf. Mater. Process. 2017, 1, 15. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Blache, R.; Xu, X. Design for Additive Manufacturing in the Cloud Platform. Volume 4 Bio Sustain. Manuf. 2017. [Google Scholar] [CrossRef]

- Haseltalab, V.; Yaman, U. A Cloud Manufacturing Application for Additive Manufacturing Methods. In Proceedings of the 2019 IEEE International Conference on Mechatronics (ICM), Ilmenau, Germany, 18–20 March 2019; Volume 1, pp. 287–292. [Google Scholar]

- Mehrpouya, M.; Dehghanghadikolaei, A.; Fotovvati, B.; Vosooghnia, A.; Emamian, S.S.; Gisario, A. The Potential of Additive Manufacturing in the Smart Factory Industrial 4.0: A Review. Appl. Sci. 2019, 9, 3865. [Google Scholar] [CrossRef] [Green Version]

- Singhal, A. Data Warehousing and Data Mining Techniques for Cyber Security; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2007; Volume 31. [Google Scholar]

- What is Cyber Security? Available online: https://www.ncsc.gov.uk/section/about-ncsc/what-is-cyber-security (accessed on 19 March 2020).

- Crosby, M.; Pattanayak, P.; Verma, S.; Kalyanaraman, V. Blockchain technology: Beyond bitcoin. Appl. Innov. 2016, 2, 71. [Google Scholar]

- Zheng, Z.; Xie, S.; Dai, H.; Chen, X.; Wang, H. An Overview of Blockchain Technology: Architecture, Consensus, and Future Trends. In Proceedings of the 2017 IEEE International Congress on Big Data (BigData Congress), Honolulu, HI, USA, 25–30 June 2017; pp. 557–564. [Google Scholar] [CrossRef]

- Sikorski, J.J.; Haughton, J.; Kraft, M. Blockchain technology in the chemical industry: Machine-to-machine electricity market. Appl. Energy 2017, 195, 234–246. [Google Scholar] [CrossRef]

- Conteh, N.Y.; Schmick, P.J. Cybersecurity: Risks, vulnerabilities and countermeasures to prevent social engineering attacks. Int. J. Adv. Comput. Res. 2016, 6, 31–38. [Google Scholar] [CrossRef]

- Nurse, J.R.C.; Creese, S.; Goldsmith, M.; Lamberts, K. Trustworthy and effective communication of cybersecurity risks: A review. In Proceedings of the 2011 1st Workshop on Socio-Technical Aspects in Security and Trust (STAST), Milan, Italy, 8 September 2011; pp. 60–68. [Google Scholar] [CrossRef] [Green Version]

- Hutchins, M.J.; Bhinge, R.; Micali, M.K.; Robinson, S.L.; Sutherland, J.W.; Dornfeld, D. Framework for Identifying Cybersecurity Risks in Manufacturing. Procedia Manuf. 2015, 1, 47–63. [Google Scholar] [CrossRef] [Green Version]

- Facebook Security Breach Exposes Accounts of 50 Million Users. Available online: https://www.nytimes.com/2018/09/28/technology/facebook-hack-data-breach.html (accessed on 24 March 2020).

- Fresh Cambridge Analytica Leak Shows Global Manipulation is Out of Control. Available online: https://www.theguardian.com/uk-news/2020/jan/04/cambridge-analytica-data-leak-global-election-manipulation (accessed on 24 March 2020).

- Global Cybersecurity Risks in the Manufacturing Industry. Available online: https://www.willistowerswatson.com/en-US/Insights/2019/07/decode-cyber-brief-global-cybersecurity-risks-in-the-manufacturing-industry#footnote (accessed on 24 March 2020).

- The ISO/IEC 27000 Family of Information Security Standards. Available online: https://www.itgovernance.co.uk/iso27000-family (accessed on 24 March 2020).

- The European Digital Strategy. Available online: https://ec.europa.eu/digital-single-market/en/content/european-digital-strategy (accessed on 24 March 2020).

- Turner, H.; White, J.; Camelio, J.A.; Williams, C.; Amos, B.; Parker, R. Bad Parts: Are Our Manufacturing Systems at Risk of Silent Cyberattacks? IEEE Secur. Priv. Mag. 2015, 13, 40–47. [Google Scholar] [CrossRef]

- Moore, S.; Armstrong, P.; McDonald, T.; Yampolskiy, M. Vulnerability analysis of desktop 3D printer software. 2016 Resilience Week (RWS) 2016, 46–51. [Google Scholar] [CrossRef]

- Sturm, L.D.; Williams, C.B.; Camelio, J.A.; White, J.; Parker, R. Cyber-physical vulnerabilities in additive manufacturing systems: A case study attack on the STL file with human subjects. J. Manuf. Syst. 2017, 44, 154–164. [Google Scholar] [CrossRef]

- Zeltmann, S.E.; Gupta, N.; Tsoutsos, N.G.; Maniatakos, M.; Rajendran, J.; Karri, R. Manufacturing and Security Challenges in 3D Printing. JOM 2016, 68, 1872–1881. [Google Scholar] [CrossRef]

- Padmanabhan, A.; Zhang, J. Cybersecurity risks and mitigation strategies in additive manufacturing. Prog. Addit. Manuf. 2018, 3, 87–93. [Google Scholar] [CrossRef]

- Chhetri, S.R.; Canedo, A.; Al Faruque, M.A. Kcad: Kinetic cyber-attack detection method for cyber-physical additive manufacturing systems. In Proceedings of the 2016 IEEE/ACM International Conference on Computer-Aided Design (ICCAD), Austin, TX, USA, 7–10 November 2016; pp. 1–8. [Google Scholar]

- Straub, J. Identifying positioning-based attacks against 3D printed objects and the 3D printing process. Pattern Recognit. Track. XXVIII 2017, 10203, 1020304. [Google Scholar] [CrossRef]

- Straub, J. An approach to detecting deliberately introduced defects and micro-defects in 3D printed objects. Pattern Recognit. Track. XXVIII 2017, 10203, 102030. [Google Scholar] [CrossRef]

- Straub, J. Physical security and cyber security issues and human error prevention for 3D printed objects: Detecting the use of an incorrect printing material. Dimens. Opt. Metrol. Insp. Pract. Appl. VI 2017, 10220, 102200. [Google Scholar] [CrossRef]

- Stock, T.; Seliger, G. Opportunities of Sustainable Manufacturing in Industry 4.0. Procedia CIRP 2016, 40, 536–541. [Google Scholar] [CrossRef] [Green Version]

- Shafiq, S.I.; Sanin, C.; Szczerbicki, E.; Toro, C. Virtual Engineering Object/Virtual Engineering Process: A specialized form of Cyber Physical System for Industrie 4.0. Procedia Comput. Sci. 2015, 60, 1146–1155. [Google Scholar] [CrossRef] [Green Version]

- Industry 4.0: The Fourth Industrial Revolution—Guide to Industrie 4.0. Available online: https://www.i-scoop.eu/industry-4-0/ (accessed on 27 March 2020).

- Simulation for Industry 4.0; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2019.

- Moving Into the 3rd Dimension of Vertical Integration. Available online: https://www.nurun.com/en/global/perspective/the-future-of-retail/moving-into-the-3rd-dimension-of-vertical-integration (accessed on 27 March 2020).

- GE Exists to Bring Real Progress and Possibility to Every Corner of the Planet. Available online: https://www.ge.com/uk/b2b/digital/predix (accessed on 27 March 2020).

- Horizontal and Vertical System Integration (PLM). Available online: https://penta3d.com/solution_category?ctg=Horizontal-and-vertical-system-integration (accessed on 27 March 2020).

- ThingWorx Platform Product Brief. Available online: https://www.ptc.com/en/resources/iiot/product-brief/thingworx-platform (accessed on 27 March 2020).

- Manage the Data for the Entire Additive Manufacturing Process. Available online: https://www.plm.automation.siemens.com/global/en/products/collaboration/additive-manufacturing-data-process-management.html (accessed on 27 March 2020).

- Almada-Lobo, F. The Industry 4.0 revolution and the future of Manufacturing Execution Systems (MES). J. Innov. Manag. 2016, 3, 16–21. [Google Scholar] [CrossRef]

- Chen, Y. Integrated and Intelligent Manufacturing: Perspectives and Enablers. Engineering 2017, 3, 588–595. [Google Scholar] [CrossRef]

- Kim, D.B.; Witherell, P.; Lipman, R.; Feng, S.C. Streamlining the additive manufacturing digital spectrum: A systems approach. Addit. Manuf. 2015, 5, 20–30. [Google Scholar] [CrossRef]

- Security Maturity Model. Available online: https://www.iiconsortium.org/ (accessed on 21 April 2020).

- 3D Opportunity and the Digital Thread. Available online: https://www2.deloitte.com/uk/en/insights/focus/3d-opportunity/3d-printing-digital-thread-in-manufacturing.html (accessed on 21 April 2020).

- 3D Printing Community Responds to COVID-19 and Coronavirus Resources. Available online: https://3dprintingindustry.com/news/3d-printing-community-responds-to-covid-19-and-coronavirus-resources-169143/ (accessed on 21 April 2020).

- Debroy, T.; Zhang, W.; Turner, J.; Babu, S.S. Building digital twins of 3D printing machines. Scr. Mater. 2017, 135, 119–124. [Google Scholar] [CrossRef]

- Mukherjee, T.; Debroy, T. A digital twin for rapid qualification of 3D printed metallic components. Appl. Mater. Today 2019, 14, 59–65. [Google Scholar] [CrossRef]

| AM Categories | Investigative Simulation Focus |

|---|---|

| Vat Photopolymerization | Uniformity, resolution, and stitching capability of a scanning-projection stereolithography method compared to experiments [74]. Development of an optimization model for separation force analysis in constrained surface stereolithography to enhance fabrication performance [75]. |

| Powder Bed Fusion | Determination of optimum process conditions for SLS (Selective Laser Sintering) by analyzing and comparing thermal profiles and subsequent fusion depths [76]. Thermal modeling of particles in a granular porous medium for SLS with a new morphology calculation method has been conducted [77]. |

| Investigation of surface roughness and morphology by modifying sloping angles in SLM (Selective Laser Melting) [78]. Study of surface structure and porosity by varying scanning speed, powder layer thickness, and laser power in SLM [79]. | |

| Modeling the thermal effects on melt pool and microstructure by changing laser power and scan speed in EBM (Electron Beam Melting) [80]. Models for the lifetime, width, and depth of molten powder material pools in EBM by varying beam powers, scan speeds, and line energies in experiments and simulations [81]. | |

| Direct Energy Deposition | Investigating the effects of melt pool formation, layer thickness, and powder/laser interaction on surface finish in DMD (Direct Metal Deposition) [82]. Investigating the effects of laser power, scanning speed, and powder feed rate on surface finish, melt pool, and dilution ratio in DLMD (Direct Laser Metal Deposition) [83]. |

| Binder Jetting (BJ) | Investigating the effects of energy consumption on part geometry and printing parameters in BJ [84]. Determination of optimal BJ process parameters to reduce shrinkage rate and improve surface roughness [85]. |

| Material Extrusion | Modeling the effects of layer thickness, orientation, raster angle, raster width, and air gap angle on surface quality through a feed-forward neural network for FDM printed parts [86]. Investigating the effects of build direction and number of contours on tensile strength and stiffness of FDM parts [87]. |

| Material Jetting | Modeling and fabrication of randomly oriented multi-material in Polyjet 3D Printing [88]. Parametric simulations and experiments for the desired droplet shape post-impact by introducing a shape coefficient in material jetting [89]. |

| Sheet Lamination | Developing transient thermal models to accurately predict the heating time for the proper joining of metal sheets [90]. Developing a thermo-mechanical finite element model to study the effects of thermal and acoustic softening on yield stress in UAM (Ultrasonic Additive Manufacturing) [91]. |

| # | Process | Organization | Description |

|---|---|---|---|

| 1 | Cellular Fabrication (C-Fab™) | Branch Technology | This patented process allows the production of large structures using polymer [96]. |

| 2 | Stone Spray | Institute for Advanced Architecture of Catalonia in Spain | Organic material (soil/sand mixture) and eco-friendly liquid binder are sprayed through a robot to build solid architectures [97]. |

| 3 | Suspended Depositions | NSTRMNT | The system works by injecting and suspending light-curing resin in a gelatinous medium using a robotic arm that can move in 3D vector-based tool paths [98]. |

| 4 | XtreeE Systems | XtreeE | Robotic arm fitted with a concrete extruder to create complex geometric structures as tall as 14 m [99]. |

| 5 | Multi-axis 3D Printing | MX3D Metal | Industrial robots fitted with purpose-built tools and control software to build a stainless-steel bridge in Amsterdam [100]. |

| 6 | AiMaker™ | Ai Build | A robotic, AI-powered 3D printing tool head, which can be attached to any robotic arm to manufacture large-scale architectural pieces from plastic [101]. |

| 7 | 4D Hybrid | University of Applied Sciences and Arts of Southern Switzerland (SUPSI) | Modular integration of compact, low-cost modules including laser source, deposition head, sensors, and control has resulted in the development of a new hybrid additive manufacturing system that can be used in different phases of a product’s lifecycle [102]. |

| 8 | Directed energy deposition (DED) metal AM system | Addere | A robot-based laser system that manufactures metal parts using weld wire [103]. |

| 9 | Lincoln Electric’s wire arc-additive manufacturing process | Lincoln Electric | The robot builds metal parts using metal wire by welding layers together using a torch and a multi-axis, rotating turntable that holds the build plate [104]. |

| 10 | ADDere | Midwest Engineered Systems Inc. | A six-axis articulated robot drives the process, combining hot wire deposition and a laser to build metal parts layer by layer on an existing substrate [105]. |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Butt, J. Exploring the Interrelationship between Additive Manufacturing and Industry 4.0. Designs 2020, 4, 13. https://0-doi-org.brum.beds.ac.uk/10.3390/designs4020013

Butt J. Exploring the Interrelationship between Additive Manufacturing and Industry 4.0. Designs. 2020; 4(2):13. https://0-doi-org.brum.beds.ac.uk/10.3390/designs4020013

Chicago/Turabian StyleButt, Javaid. 2020. "Exploring the Interrelationship between Additive Manufacturing and Industry 4.0" Designs 4, no. 2: 13. https://0-doi-org.brum.beds.ac.uk/10.3390/designs4020013