Microstructural Features and Ductile-Brittle Transition Behavior in Hot-Rolled Lean Duplex Stainless Steels

Abstract

:1. Introduction

2. Experimental Procedures

3. Results and Discussion

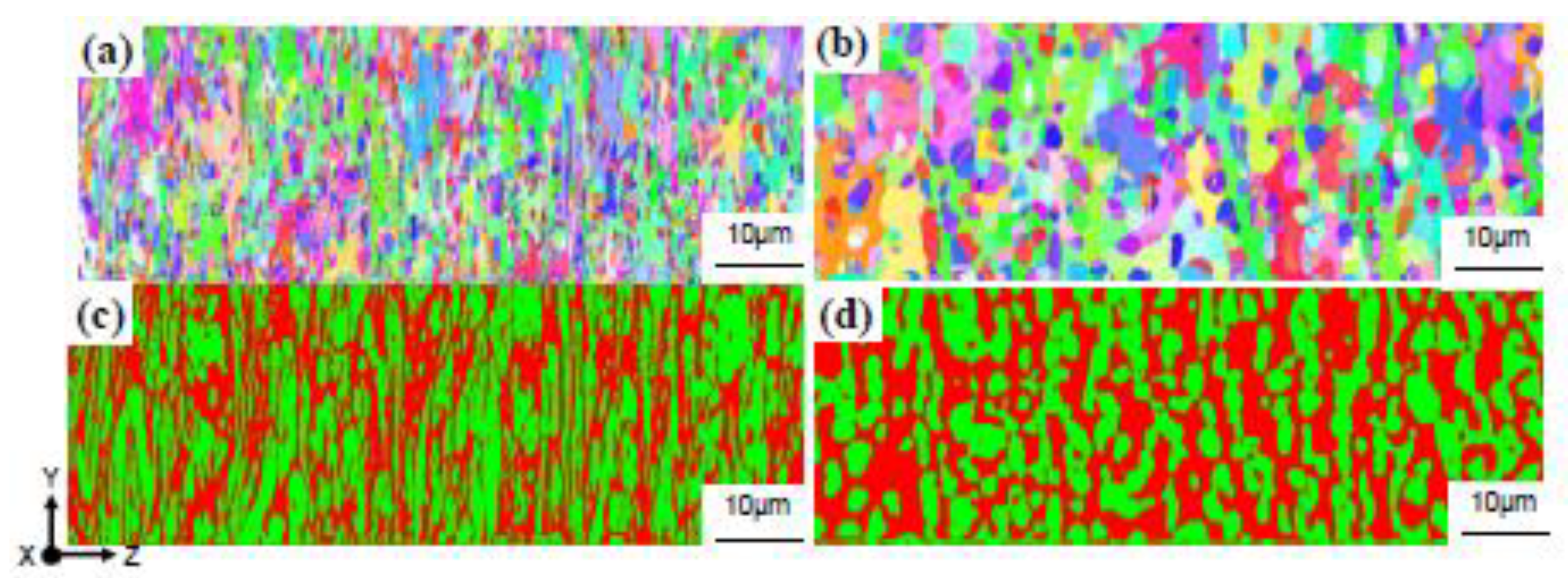

3.1. Microstructural Features

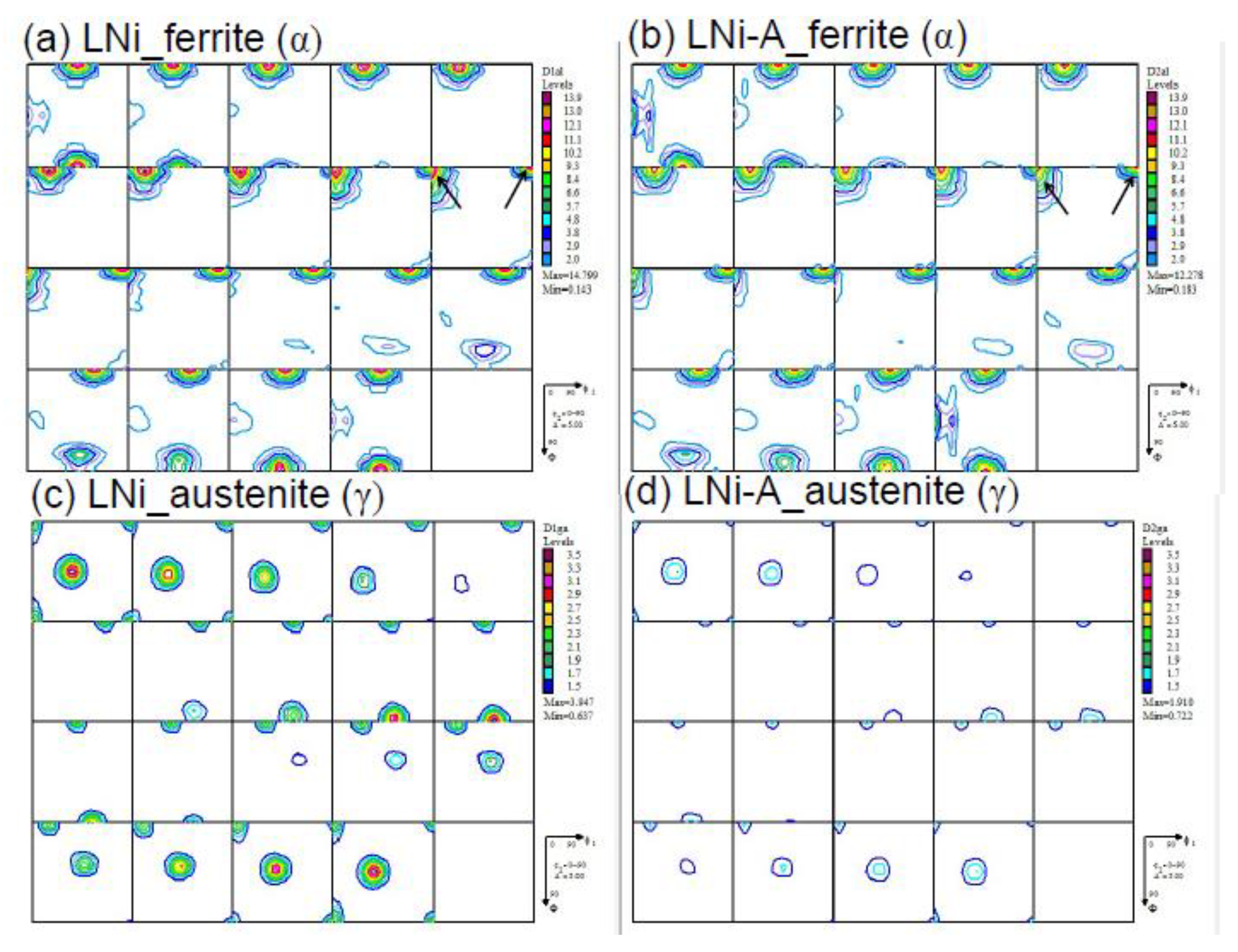

3.2. Characteristics of Texture Determined by Neutron Diffraction

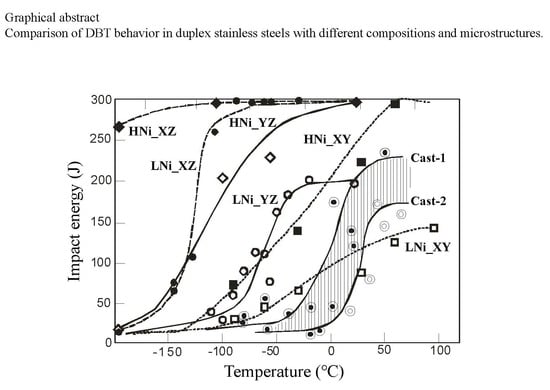

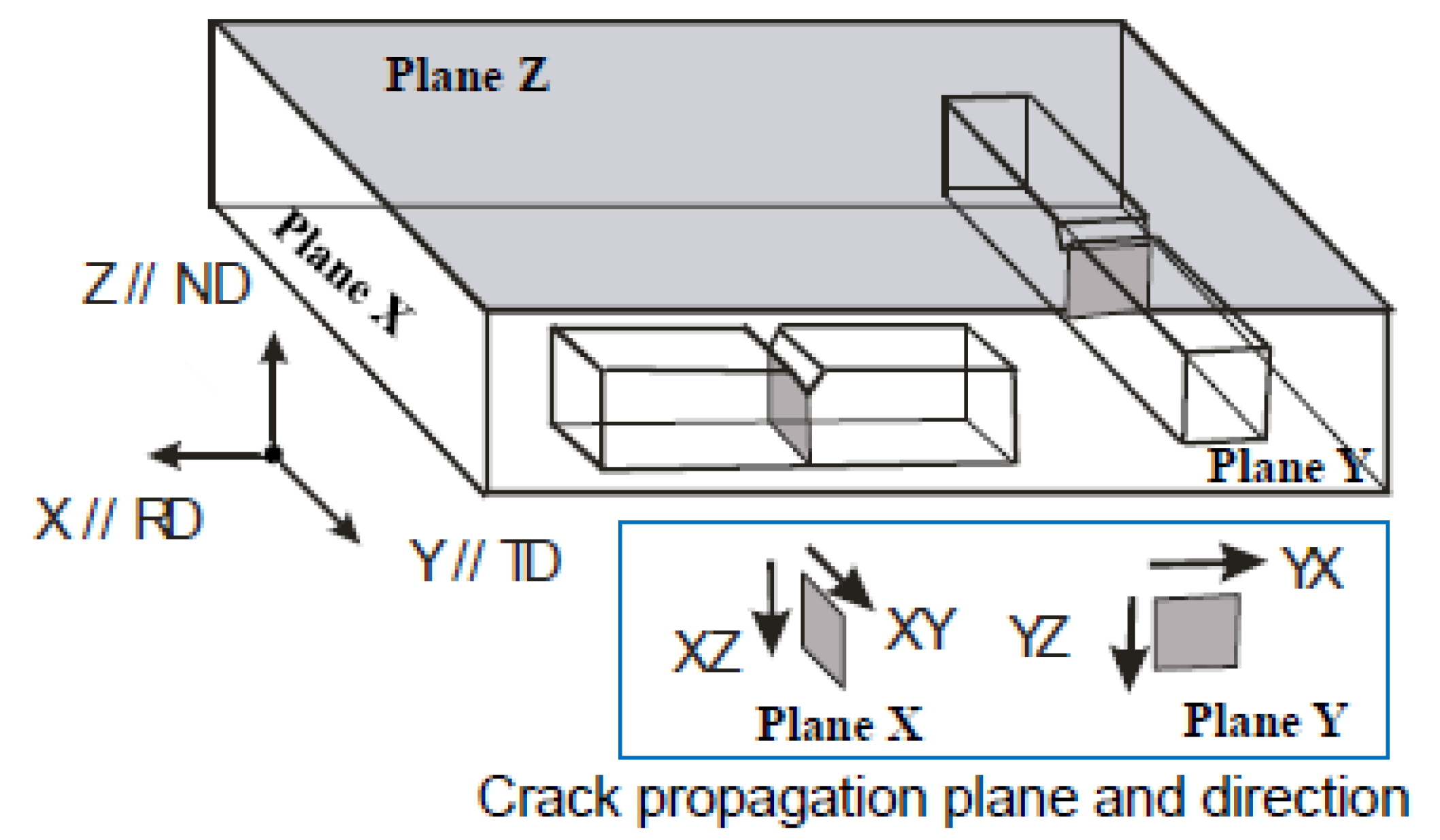

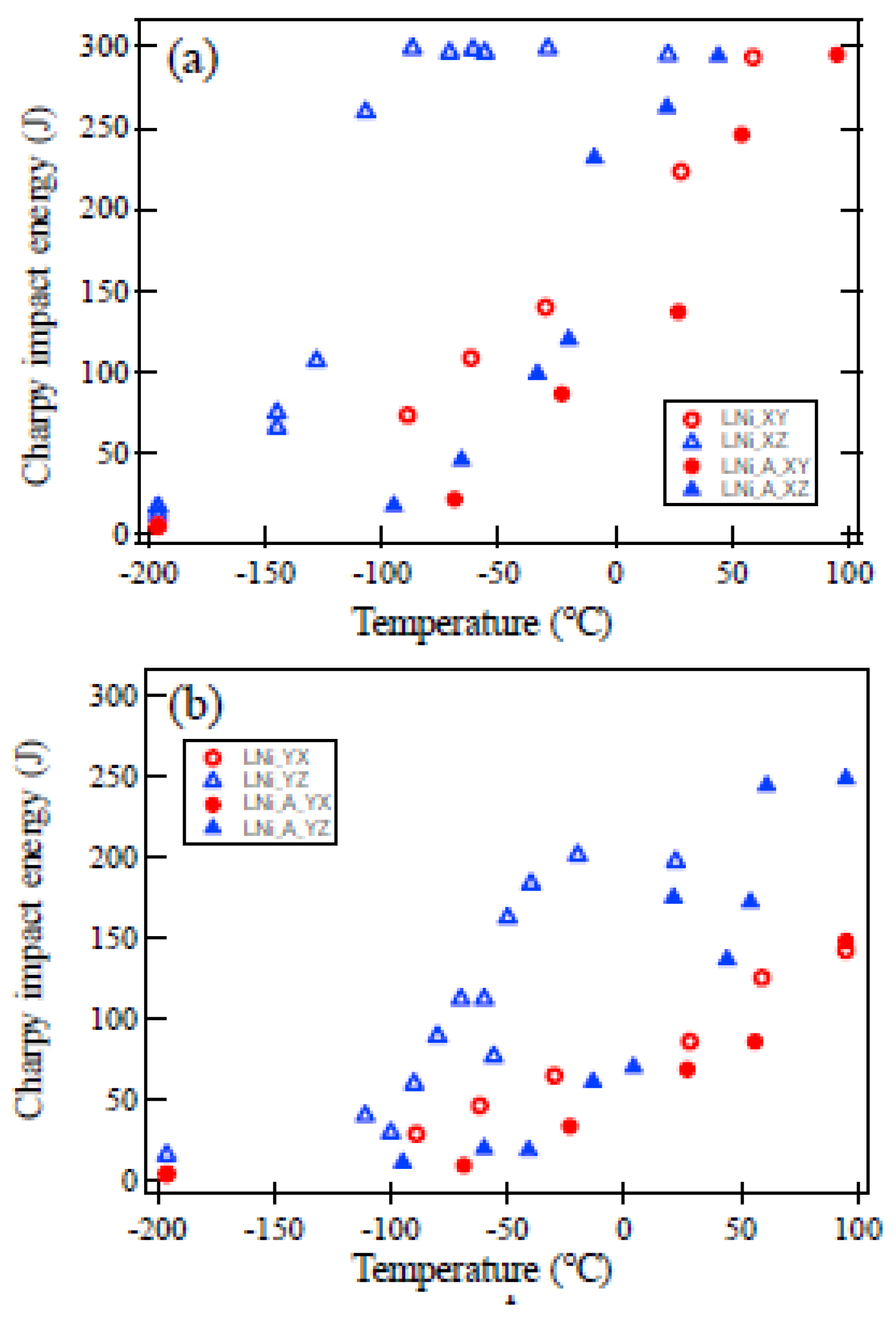

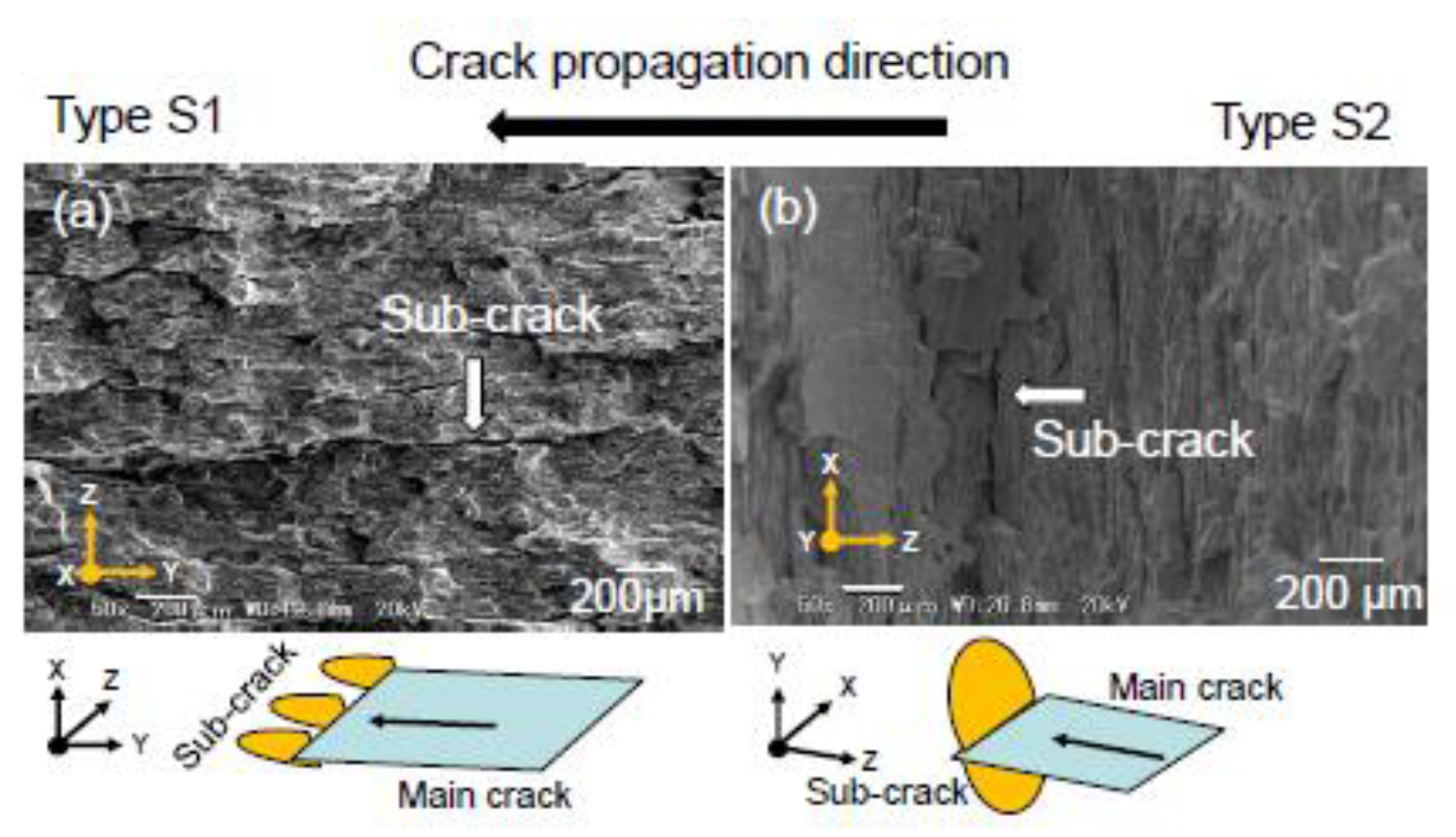

3.3. Influence of Crack Propagation Direction on DBT Behavior

3.4. Effect of Microstructure and Texture on Low Temperature Fracture Behavior

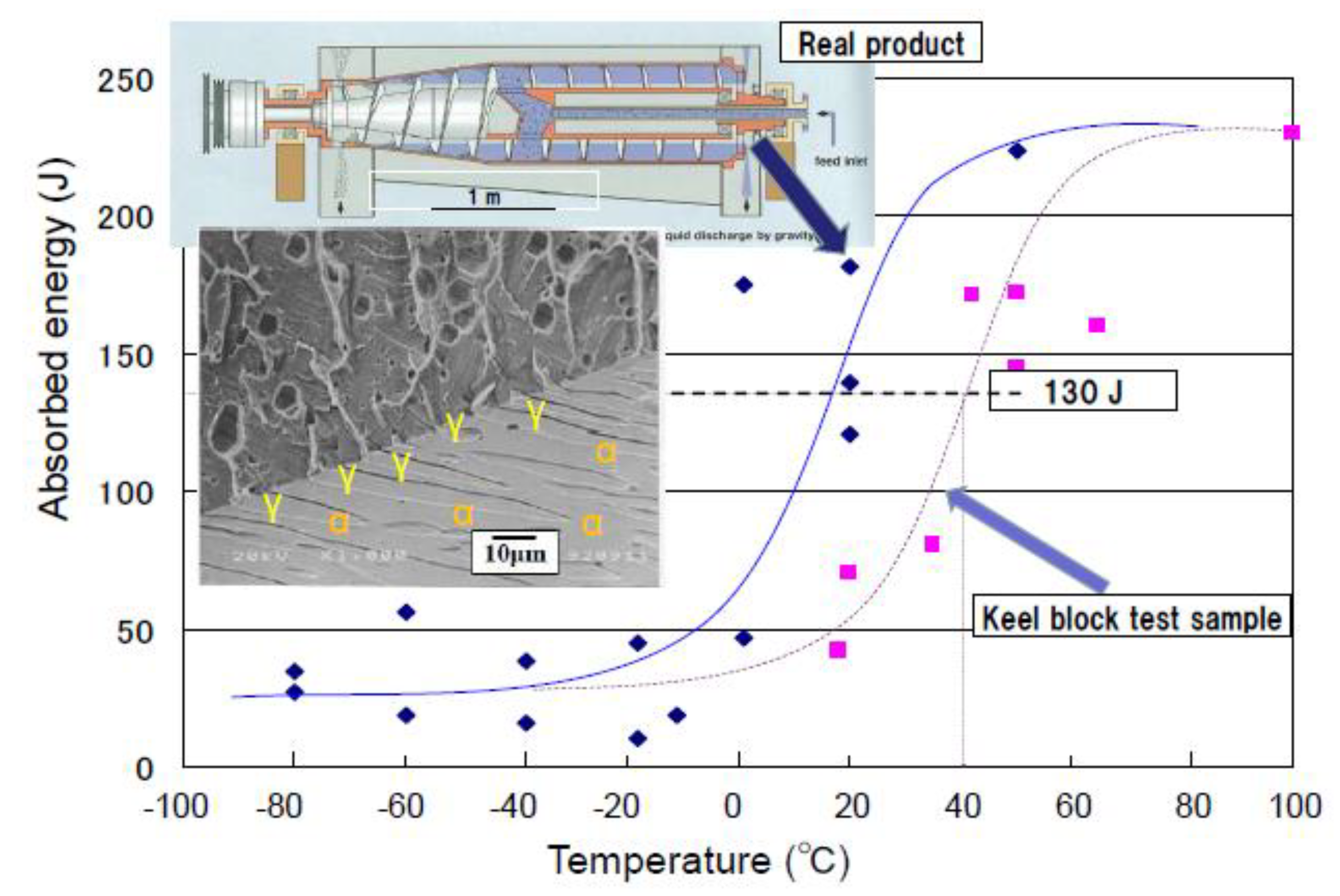

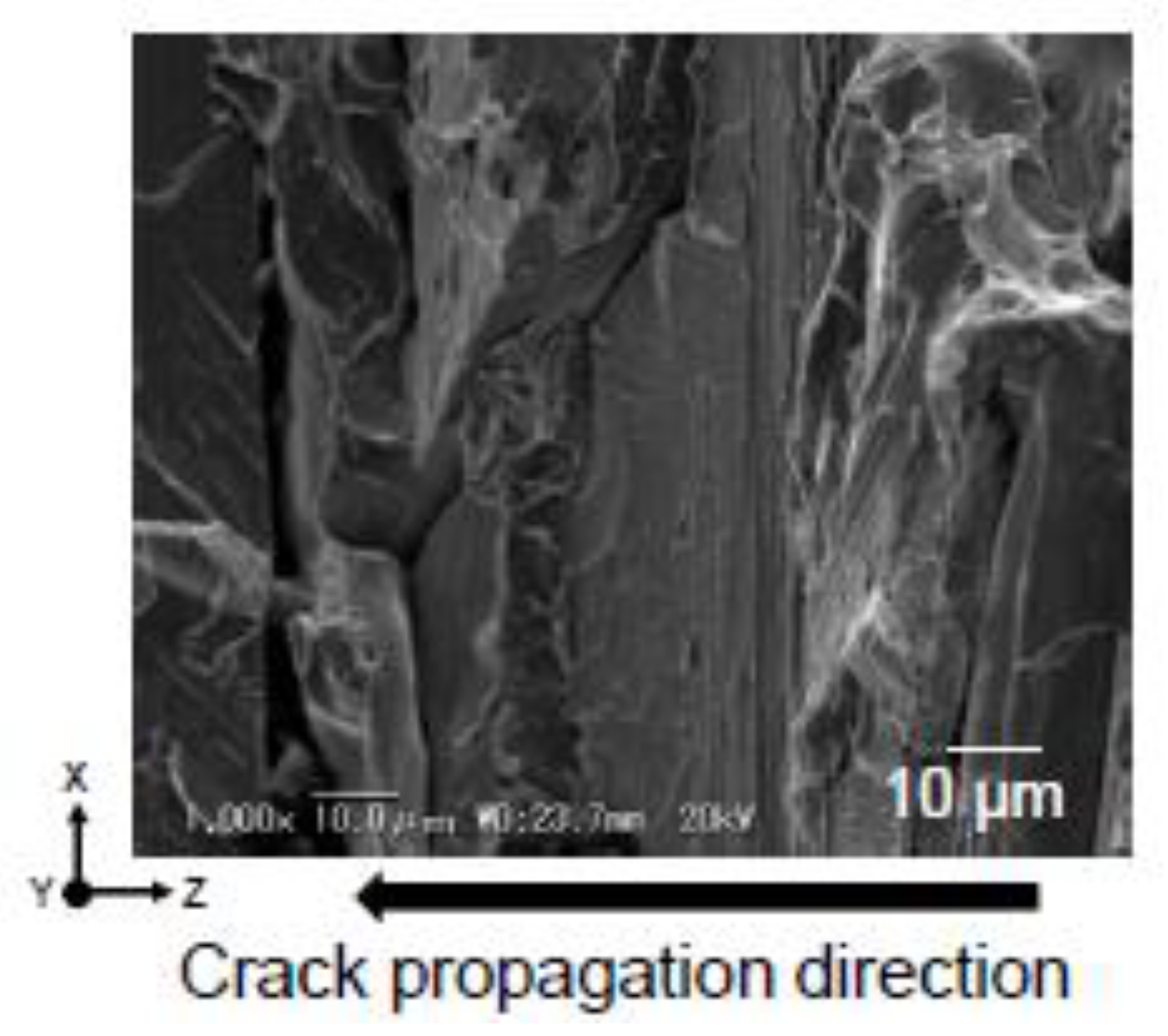

3.5. Role of Ductile γ Phase and Effect of α Grain Size on DBTT

4. Conclusions

- (1)

- The textures of the lean duplex stainless steels consisting of ferrite (α) and austenite (γ) were characterized locally by using EBSD and quantitatively evaluated by the TOF neutron diffraction, the results of which were analyzed using MAUD software. As results, intense {100}<110> component in α was confirmed and the γ volume fraction was precisely determined with satisfactory texture-correction.

- (2)

- The connectivity of elongated grains and the preferred <100> orientation in the α phase along the normal direction of a steel plate play a critical role on the anisotropic DBT behavior of these duplex stainless steels.

- (3)

- The DBT temperature (DBTT) obtained by V-notch Charpy impact tests is strongly affected by the direction of crack propagation; the cases of crack propagation in the normal direction shows lower DBTT accompanying sub-cracks, so called “delamination toughening”.

- (4)

- In the same crack propagating direction, a higher Ni bearing steel shows a lower DBTT compared with a lower Ni bearing, i.e., lean steel.

- (5)

- The dispersed γ grains hinder the propagation of α cleavage fracture, leading to lower DBTT.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gunn, R.N. (Ed.) Duplex Stainless Steel; Woodhead Publishing: Cambridge, UK, 1997. [Google Scholar]

- Hayden, H.W.; Floreen, S. The influence of martensite and ferrite on the properties of two-phase stainless steels having microduplex structures. Metall. Trans. 1970, 1, 1955–1959. [Google Scholar] [CrossRef]

- Tamura, I.; Tomota, Y.; Akao, A.; Yamaoka, Y.; Ozawa, M.; Kanatani, S. On the strength and ductility of two-phase iron alloys. Trans. ISIJ 1973, 13, 283–292. [Google Scholar] [CrossRef]

- Tomota, Y.; Kuroki, K.; Mori, T.; Tamura, I. Tensile deformation of two-ductile-phase alloys-flow curves of α-γ Fe-Cr-Ni alloys. Mater. Sci. Eng. 1976, 24, 85–94. [Google Scholar] [CrossRef]

- Harjo, S.; Tomota, Y.; Lukas, P.; Vrana, M.; Neov, D.; Mikula, P.; Ono, M. In situ Neutron diffraction during tensile deformation for α-γ Fe-Cr-Ni alloys. Acta Mater. 2001, 49, 2471–2479. [Google Scholar] [CrossRef]

- Floreen, S.; Hayden, H.W. The influence of austenite and ferrite on the mechanical properties of two-phase stainless steels having microduplex structures. Trans. ASM 1968, 61, 489–499. [Google Scholar]

- Kuroda, T.; Ikeuchi, K.; Takahashi, M.; Kitagawa, Y. Formation of cleavage facet in brittle fracture for duplex stainless steel weldment. J. Soc. Mater. Sci. Jpn. 2005, 54, 935–939. [Google Scholar] [CrossRef] [Green Version]

- Kuroda, T.; Ikeuchi, K.; Kitagawa, Y. Three-dimensional reconstruction of fracture surface of duplex stainless steel using stereo matching. J. Soc. Mater. Sci. Jpn. 2002, 51, 188–2002. [Google Scholar] [CrossRef]

- Kawaguchi, Y.; Yamanaka, S. Non-destructive evaluation of thermal aging of cast duplex stainless steel using thermoelectric power measurement. J. Jpn. Inst. Metals 2002, 66, 377–383. [Google Scholar] [CrossRef] [Green Version]

- Yabe, Y.; Hangai, F.; Kurihara, I.; Tomota, Y. Microstructural dependence of mechanical properties in α/γ stainless cast steel. CAMP-ISIJ 1992, 5, 2093. [Google Scholar]

- Takahashi, O.; Yabe, M.; Shibui, Y.; Tomota, Y. Ductile to brittle transition behavior in cast duplex stainless steels. Tetsu-to-Hagané 2014, 100, 1150–1157. [Google Scholar] [CrossRef] [Green Version]

- Takahashi, O. Microstructure and Properties of Two-Phase Cast Alloys. Ph.D. Thesis, Ibaraki University, Mito, Japan, 2014. [Google Scholar]

- Moriai, A.; Torii, S.; Suzuki, H.; Harjo, S.; Morii, Y.; Arai, M.; Tomota, Y.; Suzuki, T.; Akiniwa, Y.; Kimura, H.; et al. Development of engineering diffratometer at J-PARC. Phys. B 2006, 385–386, 1043–1045. [Google Scholar] [CrossRef]

- Harjo, S.; Ito, T.; Aizawa, Y.; Arima, H.; Abe, J.; Moriai, A.; Iwahashi, T.; Kamiyama, T. Current status of engineering materials diffractometer at J-PARC. Mater. Sci. Forum 2011, 681, 443–448. [Google Scholar] [CrossRef]

- Xu, P.G.; Tomota, Y.; Arakaki, Y.; Harjo, S.; Sueyoshi, H. Evaluation of austenite volume fraction in TRIP steel using neutron diffraction. Mater. Charact. 2017, 127, 104–110. [Google Scholar] [CrossRef]

- Tomota, Y.; Sekido, N.; Xu, P.G.; Kawasakai, T.; Harjo, S.; Tanaka, M.; Shinohara, T.; Su, Y.H.; Taniyama, A. Comparison of the measurements of austenite volume fraction by various methods for Mn-Si-C steel. Tetsu-to-Hagane 2017, 103, 573–581. [Google Scholar] [CrossRef] [Green Version]

- Lutterotti, L.; Matthies, S.; Wenk, H.R.; Schultz, A.; Richardson, J. Combined texture and structure analysis of deformed limestone from time-of-flight neutron diffraction spectrum. J. Appl. Phys. 1997, 81, 594–600. [Google Scholar] [CrossRef]

- Xu, P.G.; Harjo, S.; Ojima, M.; Suzuki, H.; Ito, T.; Gong, W.; Vogel, S.C.; Inoue, J.; Tomata, Y.; Aizawa, K.; et al. High stereographic resolution texture and residual stress evaluation using time-of-flight neutron diffraction. J. Appl. Crystal. 2018, 51, 746–760. [Google Scholar] [CrossRef] [PubMed]

- Matsuda, S.; Inoue, T.; Ogasawara, M. The fracture of tempered martensite. Trans. JIM 1968, 9, 343–348. [Google Scholar] [CrossRef] [Green Version]

- Inoue, T.; Matsuda, S.; Aoki, L. The fracture of a low carbon tempered martensite. Mater. Trans. JIM 1970, 11, 36–43. [Google Scholar] [CrossRef] [Green Version]

- Matsuda, S.; Inoue, Y.; Mimura, H.; Okamura, Y. Fracture toughness and effective grain size in low-alloyed high strength steels. In Proceedings of the International Conference on Toward Improved Ductility and Toughness, Kyoto, Japan, 25–26 October 1971; pp. 47–66. [Google Scholar]

- Gilbert, G.; Hahn, G.H.; Reid, C.N.; Wilcox, B.A. Twin-induced grain boundary cracking in b.c.c. metals. Acta Metall. 1964, 12, 754–755. [Google Scholar] [CrossRef]

- Kurdjumov, G.V.; Sachs, G. Über den mechanismus der stahlhärtung. Z. Phys. 1930, 64, 325–343. [Google Scholar] [CrossRef]

- Ameyama, K.; Murakami, K.; Maki, T.; Tamura, I. Formation process of microduplex structure (α + γ) two phase stainless steel. J. Jpn. Inst. Metals 1985, 49, 1045–1053. [Google Scholar] [CrossRef] [Green Version]

- Ameyama, K.; Maki, T.; Tamura, I. Morphology and crystallographic features of intragranular γ phase in (α + γ) two phase stainless steel. J. Jpn. Inst. Metals 1986, 50, 10–19. [Google Scholar] [CrossRef] [Green Version]

- Ameyama, K.; Maki, T.; Tamura, I. Morphology and crystallography of the precipitation of austenite at ferrite grain boundaries in two-phase stainless steel. J. Jpn. Inst. Metals 1986, 50, 602–611. [Google Scholar] [CrossRef]

- Gerberich, W.W.; Chen, Y.T.; Atteridge, D.G.; Johnson, T. Plastic flow of Fe-binary alloys-II application of the description to the ductile-brittle transition. Acta Metall. 1981, 29, 1187–1201. [Google Scholar] [CrossRef]

- Maeno, K.; Tanaka, M.; Yoshimura, N.; Shirahata, H.; Ushioda, K.; Higashida, K. Change in dislocation mobility with Ni content in ferritic steels and its effect on brittle-to-ductile transition. Tetsu-to-Hagané 2012, 98, 667–674. [Google Scholar] [CrossRef] [Green Version]

- Kimura, Y.; Inoue, T.; Yin, F.X.; Tsuzaki, K. Delamination toughening of ultrafine grain structure steels processed through tempforming at elevated temperatures. ISIJ Int. 2010, 50, 152–161. [Google Scholar] [CrossRef] [Green Version]

- Kimura, Y.; Inoue, T. Influence of warm tempforming on microstructure and mechanical properties in an ultrahigh-strength medium-carbon low-alloy steel. Metall. Mater. Trans. A 2013, 44, 560–576. [Google Scholar] [CrossRef]

- Kimura, Y.; Inoue, T. Influence of carbon content on toughening in ultrafine grain structure steels. Tetsu-to-Hagané 2014, 100, 1104–1105. [Google Scholar] [CrossRef] [Green Version]

- Hanamura, T.; Yin, F.X.; Nagai, K. Ductile-brittle transition temperature of ultrafine ferrite/cementite microstructure in a low carbon steel controlled by effective grain size. ISIJ Int. 2004, 44, 610–617. [Google Scholar] [CrossRef]

- Japan Institute for Metals. Steel (Textbook of Advanced Metal Science Series); Japan Institute for Metals: Sendai, Japan, 1985; p. 64. [Google Scholar]

- Morris, J.W., Jr. On the ductile-brittle transition in lath martensitic steel. ISIJ Int. 2011, 51, 1569–1575. [Google Scholar] [CrossRef] [Green Version]

- Morris, J.W., Jr. Comments on the microstructure and properties of ultrafine grained steel. ISIJ Int. 2011, 48, 1063–1071. [Google Scholar] [CrossRef] [Green Version]

| Steel | C | Si | Mn | P | S | Cr | Ni | Mo | Cu | N |

|---|---|---|---|---|---|---|---|---|---|---|

| LNi | 0.023 | 0.71 | 4.92 | 0.022 | 0.001 | 21.4 | 1.57 | 0.41 | 0.22 | 0.23 |

| HNi | 0.019 | 0.41 | 0.78 | 0.027 | <0.001 | 24.9 | 6.59 | 3.18 | - | 0.17 |

| Steel\Notch Plane and Direction | XZ | YZ | XY | YX |

|---|---|---|---|---|

| LNi | −130 | −65 | −25 | −5 |

| LNi-A | −20 | +30 | +25 | +35 |

| HNi | ≤196 | −105 | −95 | −55 |

| HNi-A | −150 | −105 | −115 | −65 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Takahashi, O.; Shibui, Y.; Xu, P.G.; Harjo, S.; Suzuki, T.; Tomota, Y. Microstructural Features and Ductile-Brittle Transition Behavior in Hot-Rolled Lean Duplex Stainless Steels. Quantum Beam Sci. 2020, 4, 16. https://0-doi-org.brum.beds.ac.uk/10.3390/qubs4010016

Takahashi O, Shibui Y, Xu PG, Harjo S, Suzuki T, Tomota Y. Microstructural Features and Ductile-Brittle Transition Behavior in Hot-Rolled Lean Duplex Stainless Steels. Quantum Beam Science. 2020; 4(1):16. https://0-doi-org.brum.beds.ac.uk/10.3390/qubs4010016

Chicago/Turabian StyleTakahashi, O., Y. Shibui, P.G. Xu, S. Harjo, T. Suzuki, and Y. Tomota. 2020. "Microstructural Features and Ductile-Brittle Transition Behavior in Hot-Rolled Lean Duplex Stainless Steels" Quantum Beam Science 4, no. 1: 16. https://0-doi-org.brum.beds.ac.uk/10.3390/qubs4010016