Tailoring the Local Design of Deep Water Composite Risers to Minimise Structural Weight

Abstract

:1. Introduction

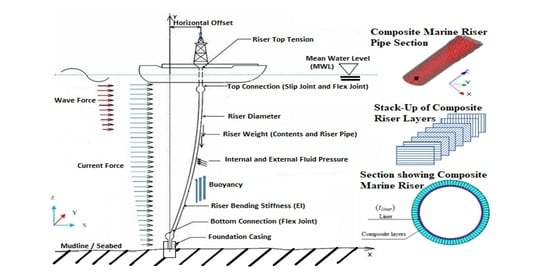

2. Analytical Model

2.1. Stress and Deformation

2.2. Elastic Solution of Stresses

2.3. Constitutive Equation

3. Numerical Model

3.1. The Model Design

3.2. Material Properties

3.3. Stack-Up Sequence

3.4. Design Load Cases

3.5. Design Method

3.6. Stress Plot Criteria

3.7. Finite Element Modelling

3.8. Mesh and Convergence

3.9. Validation

4. Results

4.1. Studies on the Design Models

4.1.1. Result of Conventional Design

4.1.2. Result of Tailored Local Design

4.2. Result of Load Cases

4.2.1. Result of Burst Case

4.2.2. Result of Collapse Case

4.2.3. Result of Tension Case

4.2.4. Result of Tension cum External Pressure Case

4.3. Result of Minimum Weight Study

4.3.1. Effect of Weight per Unit Area

4.3.2. Effect of Matrix Cracking

4.3.3. Result of Structural Weight

4.3.4. Result of Aggregate Thickness

4.3.5. Result of Stack-Up Sequence

4.3.6. Result of CPR Weight Reduction

5. Concluding Remarks

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, H.; Tong, L.; Addo, M.A. Mechanical Analysis of Flexible Riser with Carbon Fiber Composite Tension Armor. J. Compos. Sci. 2020, 5, 3. [Google Scholar] [CrossRef]

- Ochoa, O.; Salama, M. Offshore composites: Transition barriers to an enabling technology. Compos. Sci. Technol. 2005, 65, 2588–2596. [Google Scholar] [CrossRef]

- Savari, A. Failure analysis of composite repaired pipes subjected to internal pressure. J. Reinf. Plast. Compos. 2022, 1–20, ahead-of-print. [Google Scholar] [CrossRef]

- Amaechi, C.V.; Chesterton, C.; Butler, H.O.; Gu, Z.; Odijie, A.C.; Wang, F.; Hou, X.; Ye, J. Finite Element Modelling on the Mechanical Behaviour of Marine Bonded Composite Hose (MBCH) under Burst and Collapse. J. Mar. Sci. Eng. 2022, 10, 151. [Google Scholar] [CrossRef]

- Amaechi, C.V.; Chesterton, C.; Butler, H.O.; Gu, Z.; Odijie, A.C. Numerical Modelling on the Local Design of a Marine Bonded Composite Hose (MBCH) and Its Helix Reinforcement. J. Compos. Sci. 2022, 6, 79. [Google Scholar] [CrossRef]

- Odijie, A.C.; Wang, F.; Ye, J. A review of floating semisubmersible hull systems: Column stabilized unit. Ocean Eng. 2017, 144, 191–202. [Google Scholar] [CrossRef] [Green Version]

- Johnson, D.; Salama, M.; Long, J.; Wang, S. Composite Production Riser—Manufacturing Development and Qualification Testing. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 4–7 May 1998; pp. 113–123. [Google Scholar] [CrossRef]

- Johnson, D.B.; Baldwin, D.D.; Long, J.R. Mechanical Performance of Composite Production Risers. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 3–6 May 1999; pp. 1–10. [Google Scholar] [CrossRef]

- Amaechi, C.V. Novel Design, Hydrodynamics and Mechanics of Marine Hoses in Oil/Gas Applications. Ph.D. Thesis, Lancaster University, Engineering Department, Lancaster, UK, 2021. [Google Scholar]

- Amaechi, C.V.; Chesterton, C.; Butler, H.O.; Wang, F.; Ye, J. Review on the design and mechanics of bonded marine hoses for Catenary Anchor Leg Mooring (CALM) buoys. Ocean Eng. 2021, 242, 110062. [Google Scholar] [CrossRef]

- Amaechi, C.V.; Wang, F.; Ja’E, I.A.; Aboshio, A.; Odijie, A.C.; Ye, J. A literature review on the technologies of bonded hoses for marine applications. Ships Offshore Struct. 2022, 1–32, ahead-of-print. [Google Scholar] [CrossRef]

- Amaechi, C.V.; Chesterton, C.; Butler, H.O.; Wang, F.; Ye, J. An Overview on Bonded Marine Hoses for sustainable fluid transfer and (un)loading operations via Floating Offshore Structures (FOS). J. Mar. Sci. Eng. 2021, 9, 1236. [Google Scholar] [CrossRef]

- Amaechi, C.V.; Wang, F.; Ye, J. Mathematical Modelling of Bonded Marine Hoses for Single Point Mooring (SPM) Systems, with Catenary Anchor Leg Mooring (CALM) Buoy Application—A Review. J. Mar. Sci. Eng. 2021, 9, 1179. [Google Scholar] [CrossRef]

- Pham, D.-C.; Sridhar, N.; Qian, X.; Sobey, A.; Achintha, M.; Shenoi, A. A review on design, manufacture and mechanics of composite risers. Ocean Eng. 2016, 112, 82–96. [Google Scholar] [CrossRef] [Green Version]

- Picard, D.; Hudson, W.; Bouquier, L.; Dupupet, G.; Zivanovic, I. Composite Carbon Thermoplastic Tubes for Deepwater Applications. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 30 April–3 May 2007; pp. 1–9. [Google Scholar] [CrossRef]

- Rasheed, H.; Tassoulas, J. Strength Evaluation of Composite Risers. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 1–4 May 1995; pp. 215–222. [Google Scholar] [CrossRef]

- Carpenter, C. Qualification of Composite Pipe. J. Pet. Technol. 2016, 68, 56–58. [Google Scholar] [CrossRef]

- Wilkins, J. Qualification of Composite Pipe. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 2–5 May 2016; pp. 1–15, Paper Number: OTC-27179-MS. [Google Scholar] [CrossRef]

- Bai, Y.; Bai, Q. Subsea Pipelines and Risers, 1st ed.; Elsevier Science Ltd.: Kidlington, UK, 2005; pp. 3–19. [Google Scholar] [CrossRef]

- Dareing, D.W. Oilwell Drilling Engineering; ASME: New York, NY, USA, 2019. [Google Scholar] [CrossRef]

- Dareing, D.W. Mechanics of Drillstrings and Marine Risers, 1st ed.; ASME Press: New York, NY, USA, 2012. [Google Scholar] [CrossRef]

- Sparks, C.P. Fundamentals of Marine Riser—Basic Principles and Simplified Analyses, 2nd ed.; PennWell: Oklahoma, TN, USA, 2018. [Google Scholar]

- Amaechi, C.V.; Chesterton, C.; Butler, H.O.; Gillet, N.; Wang, C.; Ja’E, I.A.; Reda, A.; Odijie, A.C. Review of Composite Marine Risers for Deep-Water Applications: Design, Development and Mechanics. J. Compos. Sci. 2022, 6, 96. [Google Scholar] [CrossRef]

- Amaechi, C.V. A review of state-of-the-art and meta-science analysis on composite risers for deep seas. Ocean Eng. 2022. under review. [Google Scholar]

- Gillett, N. Design and Development of a Novel Deepwater Composite Riser. BEng Dissertation, Engineering Department, Lancaster University, Lancaster, UK, 2018. [Google Scholar]

- Chesterton, C. A Global and Local Analysis of Offshore Composite Material Reeling Pipeline Hose, with FPSO Mounted Reel Drum. BEng Dissertation, Engineering Department, Lancaster University, Lancaster, UK, 2020. [Google Scholar]

- Amaechi, C.V.; Ye, J. A numerical modeling approach to composite risers for deep waters. In Proceedings of the International Conference on Composite Structures (ICCS20), ICCS20 20th International Conference on Composite Structures, Paris, France, 4–7 September 2017; Published in Structural and Computational Mechanics Book Series. Ferreira, A.J.M., Larbi, W., Deu, J.-F., Tornabene, F., Fantuzzi, N., Eds.; Societa Editrice Esculapio: Bologna, Italy, 2017; pp. 262–263. [Google Scholar]

- Ye, J.; Cai, H.; Liu, L.; Zhai, Z.; Amaechi, C.V.; Wang, Y.; Wan, L.; Yang, D.; Chen, X.; Ye, J. Microscale intrinsic properties of hybrid unidirectional/woven composite laminates: Part I experimental tests. Compos. Struct. 2021, 262, 113369. [Google Scholar] [CrossRef]

- Ward, E.G.; Ochoa, O.; Kim, W.; Gilbert, R.M.; Jain, A.; Miller, C.; Denison, E. A Comparative Risk Analysis of Composite and Steel Production Risers; MMS Project 490, Minerals Management Service (MMS); Texas A&M University: College Station, TX, USA, 2007. Available online: https://www.bsee.gov/sites/bsee.gov/files/tap-technical-assessment-program/490ab.pdf (accessed on 4 March 2022).

- Amaechi, C.V.; Gillett, N.; Odijie, A.C.; Wang, F.; Hou, X.; Ye, J. Local and Global Design of Composite Risers on Truss SPAR Platform in Deep waters, Paper 20005. In Proceedings of the 5th International Conference on Mechanics of Composites, Lisbon, Portugal, 1–4 July 2019; pp. 1–3. Available online: https://eprints.lancs.ac.uk/id/eprint/136431 (accessed on 4 March 2022).

- Sparks, C.; Odru, P.; Metivaud, G.; Le Floc’h, C. Composite Riser Tubes: Defect Tolerance Assessment and Nondestructive Testing. Paper presented at the Offshore Technology Conference, Houston, TX, USA, 4 May 1992; pp. 191–198. [Google Scholar]

- Ochoa, O.O. Composite Riser Experience and Design Guidance; Prepared for MMS as a Guideline for Composite Offshore Engagements. Final Project Report. MMS Project Number 490, Offshore Technology Research Center; Texas A&M University: College Station, TX, USA, 2006; pp. 1–42. Available online: https://www.bsee.gov/sites/bsee.gov/files/tap-technical-assessment-program//490aa.pdf (accessed on 18 March 2022).

- Pham, D.C.; Narayanaswamy, S.; Qian, X.; Zhang, W.; Sobey, A.; Achintha, M.; Shenoi, R.A. Composite riser design and development—A review. In Analysis and Design of Marine Structures V; CRC Press: Boca Raton, FL, USA, 2015; pp. 651–660. Available online: https://eprints.soton.ac.uk/372798/1/DC%2520Pham%2520et%2520al%2520%2520Composite%2520riser%2520design%2520and%2520development%2520%2520A%2520review_2.pdf (accessed on 18 March 2022). [CrossRef]

- Bakaiyan, H.; Hosseini, H.; Ameri, E. Analysis of multi-layered filament-wound composite pipes under combined internal pressure and thermomechanical loading with thermal variations. Compos. Struct. 2009, 88, 532–541. [Google Scholar] [CrossRef]

- Baldwin, D.; Newhouse, N.; Lo, K.; Burden, R. Composite Production Riser Design. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 5–8 May 1997; pp. 1–8. [Google Scholar] [CrossRef]

- Baldwin, D.D.; Johnson, D.B. Rigid Composite Risers: Design for Purpose Using Performance-Based Requirements. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 6–9 May 2002; pp. 1–10. [Google Scholar] [CrossRef]

- Baldwin, D.; Lo, K.; Long, J. Design Verification of a Composite Production Riser. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 4–7 May 1998; pp. 103–112. [Google Scholar] [CrossRef]

- Chen, Y.; Seemann, R.; Krause, D.; Tay, T.-E.; Tan, V. Prototyping and testing of composite riser joints for deepwater application. J. Reinf. Plast. Compos. 2016, 35, 95–110. [Google Scholar] [CrossRef] [Green Version]

- Salama, M.M.; Murali, J.; Baldwin, D.D.; Jahnsen, O.; Meland, T. Design Consideration for Composite Drilling Riser. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 3–6 May 1999; pp. 1–11. [Google Scholar] [CrossRef]

- Salama, M. Lightweight Materials For Deepwater Offshore Structures. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 5–8 May 1986; pp. 297–304. [Google Scholar] [CrossRef]

- Salama, M.M.; Spencer, B.E. Metal Lined Composite Risers in Offshore Applications. U.S. Patent 20040086341A1, 6 May 2004. Available online: https://patentimages.storage.googleapis.com/ce/83/5d/acfffc9dadc312/US20040086341A1.pdf (accessed on 4 March 2022).

- Chen, Y.; Bin Tan, L.; Jaiman, R.K.; Sun, X.; Tay, T.E.; Tan, V.B.C. Global-Local Analysis of a Full-Scale Composite Riser During Vortex-Induced Vibration. In Proceedings of the ASME 2013 32nd International Conference on Ocean, Offshore and Arctic Engineering. Volume 7: CFD and VIV, Nantes, France, 9–14 June 2013. [Google Scholar] [CrossRef]

- Akula, V.M.K. Global-Local Analysis of a Composite Riser. In Proceedings of the ASME 2014 Pressure Vessels and Piping Conference. Volume 3: Design and Analysis, Anaheim, CA, USA, 20–24 July 2014. [Google Scholar] [CrossRef]

- Tan, L.; Chen, Y.; Jaiman, R.K.; Sun, X.; Tan, V.; Tay, T. Coupled fluid–Structure simulations for evaluating a performance of full-scale deepwater composite riser. Ocean Eng. 2015, 94, 19–35. [Google Scholar] [CrossRef]

- Wang, C.; Shankar, K.; Morozov, E.V. Global design and analysis of deep sea FRP composite risers under combined environmental loads. Adv. Compos. Mater. 2017, 26, 79–98. [Google Scholar] [CrossRef]

- Wang, C.; Shankar, K.; Morozov, E.V. Design of deep sea composite risers under combined environmental loads. In Proceedings of the 9th Composites Australia & CRC-ACS conference Diversity in Composites Conference, Leura, Australia, 15–16 March 2012; pp. 1–14. [Google Scholar]

- Wang, C.; Shankar, K.; Morozov, E.V. Local design of composite risers under burst, tension and collapse cases. In Proceedings of the 18th International Conference on Composite Materials (ICCM18), Jeju, Korea, 22 August 2011; pp. 1–6. Available online: http://www.iccm-central.org/Proceedings/ICCM18proceedings/data/2.%20Oral%20Presentation/Aug22%28Monday%29/M04%20Applications%20of%20Composites/M4-1-IF0161.pdf (accessed on 4 March 2022).

- Wang, C.G.; Shankar, K.; Morozov, E.V. Tailoring of Composite Reinforcements for Weight Reduction of Offshore Production Risers. Appl. Mech. Mater. 2011, 66, 1416–1421. [Google Scholar] [CrossRef]

- Calash & MagmaGlobal. Commercial Review of 8 Riser SLOR System: Magma M-Pipe Versus Steel Pipe; CALASH Report; Prepared for MagmaGlobal; Calash & MagmaGlobal: Portsmouth, UK, 2015; pp. 1–16. [Google Scholar]

- MagmaGlobal. Ocyan-Magma CompRisers. 2016. Available online: https://www.magmaglobal.com/risers/ocyan-compriser/ (accessed on 23 May 2021).

- MagmaGlobal. Magma M-Pipe® End Fittings, Monitoring and Bend Test. 2015. Available online: https://www.youtube.com/watch?v=kNoM32UZcgc (accessed on 22 May 2021).

- Salama, M.M.; Johnson, D.B.; Long, J.R. Composite Production Riser—Testing and Qualification. SPE Prod. Facil. 1998, 13, 170–177. [Google Scholar] [CrossRef]

- Beyle, A.I.; Gustafson, C.G.; Kulakov, V.L.; Tarnopol’Skii, Y.M. Composite risers for deep-water offshore technology: Problems and prospects. 1. Metal-composite riser. Polym. Mech. 1997, 33, 403–414. [Google Scholar] [CrossRef]

- Smits, A.; Neto, T.B.; de Boer, H. Thermoplastic Composite Riser Development for Ultradeep Water. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 30 April–3 May 2018; pp. 1–9. [Google Scholar] [CrossRef]

- Van, O.M.; Gioccobi, S.; de Boer, H. Evaluation of the first deployment of a composite downline in deepwater Brazil. In Proceedings of the IBP1852_14, Rio Oil & Gas Conference 2014, Rio De Janeiro, Brazil, 15–18 September 2014. [Google Scholar]

- Van Onna, M.; O’Brien, P. A New Thermoplastic Composite Riser for Deepwater Application. In Proceedings of the Subsea UK Conference; Subsea UK News: Aberdeen, UK, 2011; pp. 1–23. Available online: https://www.subseauk.com/documents/martinvanonnasubsea2011presentation.pdf (accessed on 4 March 2022).

- Van, O.M.; Lyon, J. Installation of World’s 1st Subsesa Thermoplastic Composite Pipe Jumper on Alder 2011. 2017. Available online: https://www.subseauk.com/documents/presentations/martin%20van%20onna%20-%20fields%20of%20the%20future%20-%20airborne.pdf (accessed on 4 March 2022).

- Steuten, B.; van, O.M. Reduce Project and Life Cycle Cost with TCP Flowline. In Proceedings of the Offshore Technology Conference Asia, Kuala Lumpur, Malaysia, 22–25 March 2016; pp. 1–10. [Google Scholar] [CrossRef]

- Ye, J.; Soldatos, K.P. Three-dimensional buckling analysis of laminated composite hollow cylinders and cylindrical panels. Int. J. Solids Struct. 1995, 32, 1949–1962. [Google Scholar] [CrossRef]

- Bhudolia, S.; Fischer, S.; He, P.; Yue, C.Y.; Joshi, S.C.; Yang, J. Design, Manufacturing and Testing of Filament Wound Composite Risers for Marine and Offshore Applications. Mater. Sci. Forum 2015, 813, 337–343. [Google Scholar] [CrossRef]

- Xia, M.; Takayanagi, H.; Kemmochi, K. Analysis of multi-layered filament-wound composite pipes under internal pressure. Compos. Struct. 2001, 53, 483–491. [Google Scholar] [CrossRef]

- Jones, R.M. Mechanics of Composite Materials, 2nd ed.; Taylor & Francis: Philadelphia, PA, USA, 1999. [Google Scholar] [CrossRef]

- Kaw, A.K. Mechanics of Composite Materials, 2nd ed.; CRC Press Imprint; Taylor & Francis: Boca Raton, FL, USA, 2005. [Google Scholar] [CrossRef]

- Ye, J. Laminated Composite Plates and Shells: 3D Modelling; Springer: London, UK, 2003. [Google Scholar]

- Ye, J. Structural and Stress Analysis: Theories, Tutorials and Examples Second; CRC Press: New York, NY, USA, 2016. [Google Scholar]

- DNV. Recommended Practice: Composite Risers DNV-RP-F202 October; Det Norske Veritas: Oslo, Norway, 2010; Available online: https://rules.dnv.com/docs/pdf/dnvpm/codes/docs/2010-10/RP-F202.pdf (accessed on 4 March 2022).

- DNV. DNV-OS-C501: Composite Components; Det Norske Veritas: Oslo, Norway, 2013; Available online: https://rules.dnv.com/docs/pdf/dnvpm/codes/docs/2013-11/OS-C501.pdf (accessed on 4 March 2022).

- DNVGL. Recommended Practice: Thermoplastic Composite Pipes—DNVGL-RP-F119 December; Det Norske Veritas & Germanischer Lloyd: Oslo, Norway, 2015; Available online: https://www.dnvgl.com/oilgas/download/dnvgl-st-f119-thermoplastic-composite-pipes.html (accessed on 4 March 2022).

- DNV. Dynamic Risers: Offshore Standard DNV-OS-F201, October; Det Norske Veritas: Oslo, Norway, 2010; Available online: https://rules.dnv.com/docs/pdf/dnvpm/codes/docs/2010-10/Os-F201.pdf (accessed on 4 March 2022).

- ABS. Guide for Building and Classing Subsea Riser Systems, 3rd ed.; American Bureau of Shipping: New York, NY, USA, 2017; Available online: https://ww2.eagle.org/content/dam/eagle/rules-and-guides/current/offshore/123_guide_building_and_classing_subsea_riser_systems_2017/Riser_Guide_e-Mar18.pdf (accessed on 16 May 2021).

- Schuett, C.; Paternoster, A. Full Generic Qualification of Nylon 12 Carbon Fiber Composite for Dynamic Thermoplastic Composite Pipe and Hybrid Flexible Pipe Applications. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 16–19 August 2021. [Google Scholar] [CrossRef]

- Salama, M.M.; Stjern, G.; Storhaug, T.; Spencer, B.; Echtermeyer, A. The First Offshore Field Installation for a Composite Riser Joint. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 6–9 May 2002. [Google Scholar] [CrossRef]

- Bybee, K. The First Offshore Installation of a Composite Riser Joint. J. Pet. Technol. 2003, 55, 72–74. [Google Scholar] [CrossRef]

- Echtermeyer, A.; Steuten, B. Thermoplastic Composite Riser Guidance Note. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 6–9 May 2013; pp. 1–10. [Google Scholar] [CrossRef]

- Hossain, R.; Carey, J.; Mertiny, P. Framework for a Combined Netting Analysis and Tsai-Wu-Based Design Approach for Braided and Filament-Wound Composites. J. Press. Vessel Technol. 2013, 135, 031204. [Google Scholar] [CrossRef]

- Evans, J.T.; Gibson, A.G. Composite angle ply laminates and netting analysis. Proc. R. Soc. A Math. Phys. Eng. Sci. 2002, 458, 3079–3088. [Google Scholar] [CrossRef]

- Tew, B.W. Preliminary Design of Tubular Composite Structures Using Netting Theory and Composite Degradation Factors. J. Press. Vessel Technol. 1995, 117, 390–394. [Google Scholar] [CrossRef]

- DOD. Military Handbook, MIL-HDBK-17-3F: Composite Materials Handbook; Polymer Matrix Composites Materials Usage, Design and Analysis; U.S. Department of Defense (DOD): Arlington, VA, USA, 17 June 2002; Volume 3 of 5, pp. 43–53. Available online: https://www.library.ucdavis.edu/wp-content/uploads/2017/03/HDBK17-3F.pdf (accessed on 4 March 2022).

- Andersen, W.; Anderson, J.; Landriault, L. Full-Scale Testing of Prototype Composite Drilling Riser Joints-Interim Report. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 4–7 May 1998; pp. 147–154. [Google Scholar] [CrossRef]

- Roberts, D.; Hatton, S.A. Development and Qualification of End Fittings for Composite Riser Pipe. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 6–9 May 2013. [Google Scholar] [CrossRef]

- Cederberg, C.A.; Baldwin, D.D.; Bhalla, K.; Tognarelli, M.A. Composite-Reinforced Steel Drilling Riser for Ultra-Deepwater High Pressure Wells. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 6–9 May 2013. [Google Scholar] [CrossRef]

- Pham, D.C.; Su, Z.; Narayanaswamy, S.; Qian, X.; Huang, Z.; Sobey, A.; Shenoi, A. Experimental and numerical studies of large-scaled filament wound T700/X4201 composite risers under bending. In Proceedings of the ECCM17—17th European Conference on Composite Materials, Munich, Germany, 26–30 June 2016; Available online: https://www.researchgate.net/publication/307631336_Experimental_and_numerical_studies_of_large-scaled_filament_wound_T700X4201_composite_risers_under_bending (accessed on 15 February 2022).

- Huang, Z.; Zhang, W.; Qian, X.; Su, Z.; Pham, D.-C.; Sridhar, N. Fatigue behaviour and life prediction of filament wound CFRP pipes based on coupon tests. Mar. Struct. 2020, 72, 102756. [Google Scholar] [CrossRef]

- Huang, Z.; Qian, X.; Su, Z.; Pham, D.C.; Sridhar, N. Experimental investigation and damage simulation of large-scaled filament wound composite pipes. Compos. Part B Eng. 2020, 184, 107639. [Google Scholar] [CrossRef]

- Sparks, C.; Odru, P.; Bono, H.; Metivaud, G. Mechanical Testing Of High-Performance Composite Tubes For TLP Production Risers. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 2–5 May 1988; pp. 467–472. [Google Scholar] [CrossRef]

- Tamarelle, P.; Sparks, C. High-Performance Composite Tubes for Offshore Applications. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 27–30 April 1987; pp. 255–260. [Google Scholar] [CrossRef]

- Amaechi, C.V.; Gillett, N.; Odijie, A.C.; Hou, X.; Ye, J. Composite risers for deep waters using a numerical modelling approach. Compos. Struct. 2019, 210, 486–499. [Google Scholar] [CrossRef] [Green Version]

- Amaechi, C.V. Local tailored design of deep water composite risers subjected to burst, collapse and tension loads. Ocean Eng. 2022, in press. [Google Scholar] [CrossRef]

- Wang, C.; Shankar, K.; Morozov, E.V. Design of composite risers for minimum weight. Publisher: World Academy of Science, Engineering and Technology. Int. J. Mech. Mechatron. Eng. 2012, 6, 2627–2636. Available online: https://publications.waset.org/4236/pdf (accessed on 17 March 2022).

- Wang, C.; Sun, M.; Shankar, K.; Xing, S.; Zhang, L. CFD Simulation of Vortex Induced Vibration for FRP Composite Riser with Different Modeling Methods. Appl. Sci. 2018, 8, 684. [Google Scholar] [CrossRef] [Green Version]

- Singh, M.; Ahmad, S. Local Stress Analysis of Composite Production Riser Under Random Sea. In Proceedings of the ASME 2014 33rd International Conference on Ocean, Offshore and Arctic Engineering. Volume 4B: Structures, Safety and Reliability, San Francisco, CA, USA, 8–13 June 2014. [Google Scholar] [CrossRef]

- Singh, M.; Ahmad, S. Bursting Capacity and Debonding of Ultra Deep Composite Production Riser: A Safety Assessment. In Proceedings of the ASME 2014 33rd International Conference on Ocean, Offshore and Arctic Engineering. Volume 6A: Pipeline and Riser Technology, San Francisco, CA, USA, 8–13 June 2014. [Google Scholar] [CrossRef]

- Singh, M.; Ahmad, S. Probabilistic Analysis and Risk Assessment of Deep Water Composite Production Riser Against Fatigue Limit State. In Proceedings of the ASME 2015 34th International Conference on Ocean, Offshore and Arctic Engineering. Volume 3: Structures, Safety and Reliability, St. John’s, NL, Canada, 31 May–5 June 2015. [Google Scholar] [CrossRef]

- Ragheb, H.; Goodridge, M.; Pham, D.; Sobey, A. Extreme response based reliability analysis of composite risers for applications in deepwater. Mar. Struct. 2021, 78, 103015. [Google Scholar] [CrossRef]

- Ragheb, H.; Sobey, A. Effects of extensible modelling on composite riser mechanical responses. Ocean Eng. 2021, 220, 108426. [Google Scholar] [CrossRef]

- Amaechi, C.V.; Wang, F.; Hou, X.; Ye, J. Strength of submarine hoses in Chinese-lantern configuration from hydrodynamic loads on CALM buoy. Ocean Eng. 2019, 171, 429–442. [Google Scholar] [CrossRef] [Green Version]

- Sonmez, F.O.; 2017. Optimum Design of Composite Structures: A Literature Survey. J. Reinf. Plast. Compos. 2017, 36, 3–39. [Google Scholar] [CrossRef]

- Da Silva, R.F.; Teófilo, F.A.F.; Parente, E., Jr.; de Melo, A.M.C.; de Holanda, Á.S. Optimization of composite catenary risers. Marine Struct. 2013, 33, 1–20. [Google Scholar] [CrossRef]

- Ghiasi, H.; Fayazbakhsh, K.; Pasini, D.; Lessard, L. Optimum stacking sequence design of composite materials Part II: Variable stiffness design. Compos. Struct. 2010, 93, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Ghiasi, H.; Pasini, D.; Lessard, L. Optimum stacking sequence design of composite materials Part I: Constant stiffness design. Compos. Struct. 2009, 90, 1–11. [Google Scholar] [CrossRef]

- Harte, A.; McNamara, J.; Roddy, I. Evaluation of optimisation techniques in the design of composite pipelines. J. Mater. Process. Technol. 2001, 118, 478–484. [Google Scholar] [CrossRef]

- Harte, A.; McNamara, J.; Roddy, I. Application of optimisation methods to the design of high performance composite pipelines. J. Mater. Process. Technol. 2003, 142, 58–64. [Google Scholar] [CrossRef]

- Teófilo, A.F.F.; Parente, E., Jr.; de Melo, A.M.C.; de Holanda, Á.S.; da Silva, R.F. Premilinary Design of Composite Catenary Risers Using Optimization Techniques. Mecánica Computacional, XXIX. 2010, pp. 7927–7948. Available online: https://repositorio.ufc.br/bitstream/riufc/5474/1/2010_eve_amcmelo.pdf (accessed on 18 March 2022).

- Wang, C.; Shankar, K.; A Ashraf, M.; Morozov, E.V.; Ray, T. Surrogate-assisted optimisation design of composite riser. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2016, 230, 18–34. [Google Scholar] [CrossRef]

- Wang, C.; Shankar, K.; Morozov, E.V. Tailored design of top-tensioned composite risers for deep-water applications using three different approaches. Adv. Mech. Eng. 2017, 9, 1–18. [Google Scholar] [CrossRef] [Green Version]

- Hatton, S. Carbon fibre—A riser system enabler. Offshore Eng. 2012, 37, 42–43. Available online: http://www.oedigital.com/engineering/item/696-carbon-fibre—a-riser-system-enabler (accessed on 4 March 2022).

- Jha, V.; Finch, D.; Dodds, N.; Latto, J. Optimized Hybrid Composite Flexible Pipe for Ultra-Deepwater Applications. In Proceedings of the ASME 2015 34th International Conference on Ocean, Offshore and Arctic Engineering. Volume 5A: Pipeline and Riser Technology, St. John’s, NL, Canada, 31 May–5 June 2015. [Google Scholar] [CrossRef]

- Kim, W.K. Composite Production Riser Assessment. Ph.D. Thesis, Department of Mechanical Engineering, Texas A & M University, College Station, TX, USA, 2007. Available online: https://core.ac.uk/download/pdf/4272879.pdf (accessed on 18 March 2022).

- Sun, X.S.; Chen, Y.; Tan, V.B.C.; Jaiman, R.K.; Tay, T.-E. Homogenization and Stress Analysis of Multilayered Composite Offshore Production Risers. J. Appl. Mech. 2013, 81, 031003. [Google Scholar] [CrossRef]

- Sun, X.S.; Tan, V.B.C.; Chen, Y.; Tan, L.B.; Jaiman, R.K.; Tay, T.E. Stress analysis of multi-layered hollow anisotropic composite cylindrical structures using the homogenization method. Acta Mech. 2013, 225, 1649–1672. [Google Scholar] [CrossRef]

- Bhavya, S.; Kumar, P.R.; Kalam, A. Failure analysis of a composite cylinder. IOSR J. Mech. Civil Eng. 2012, 3, 1–7. Available online: https://www.iosrjournals.org/iosr-jmce/papers/vol3-issue3/A0330107.pdf (accessed on 4 March 2022). [CrossRef]

- Wang, C. Tailored Design of Composite Risers for Deep Water Applications. Ph.D. Thesis, School of Engineering and Information Technology, The University of New South Wales, Canberra, Australia, 2013. Available online: http://unsworks.unsw.edu.au/fapi/datastream/unsworks:11345/SOURCE01?view=true (accessed on 15 February 2022).

- ANSYS. ANSYS Composite PrepPost User’s Guide Release 18.2; ANSYS Inc.: Canonsburg, PA, USA, 2017. [Google Scholar]

- ANSYS. ANSYS Meshing User’s Guide, Release 18.2; ANSYS Inc.: Canonsburg, PA, USA, 2017. [Google Scholar]

- Sun, C.T.; Li, S. Three-dimensional effective elastic constant for thick laminates. J. Compos. Mater. 1988, 22, 629–639. [Google Scholar] [CrossRef]

- Toray. T700S Data Sheet, Santa Ana, CA, USA. 2008. Available online: https://www.toraycma.com/file_viewer.php?id=4459%0A (accessed on 12 April 2018).

- Hartman, D.; Greenwood, M.E.; Miller, D.M. High Strength Glass Fibers 2006 Repri; AGY: Aiken, SC, USA, 1996; Available online: https://www.agy.com/wp-content/uploads/2014/03/High_Strength_Glass_Fibers-Technical.pdf (accessed on 4 March 2022).

- MatWeb.AS4 PEEK Plus Carbon Fiber Reinforced Unidirectional—MatWeb Material Property Data. MatWeb Material Property Data. 2018. Available online: http://www.matweb.com/search/datasheet.aspx?matguid=1e8a25336d7645d8a24cdbd10ed2dd29&ckck=1 (accessed on 12 April 2018).

- MatWeb. Solvay 934 Epoxy-S2 Glass Fiber Reinforced Unidirectional—MatWeb Material Property Data. MatWeb Material Property Data. 2021. Available online: http://www.matweb.com/search/datasheettext.aspx?matguid=0e86c9201a2d45f7bb61f85b28a3e681 (accessed on 17 March 2018).

- Da Silva, R.F.; Da Rocha, I.B.C.M.; Parente, E., Jr.; De Melo, A.M.C. Optimum Design of Composite Risers Using A Genetic Algorithm. In Proceedings of the 10th World Congress on Computational Mechanics, Sao Paulo, Brazil, 8–13 July 2012; Available online: http://pdf.blucher.com.br.s3-sa-east-1.amazonaws.com/mechanicalengineeringproceedings/10wccm/18916.pdf (accessed on 4 March 2022).

- Meniconi, L.; Reid, S.; Soden, P. Preliminary design of composite riser stress joints. Compos. Part A Appl. Sci. Manuf. 2001, 32, 597–605. [Google Scholar] [CrossRef]

- Ja’E, I.A.; Ali, M.O.A.; Yenduri, A.; Nizamani, Z.; Nakayama, A. Optimisation of mooring line parameters for offshore floating structures: A review paper. Ocean Eng. 2022, 247, 110644. [Google Scholar] [CrossRef]

- Singh, M.; Ahmad, S. Fatigue Life Calculation of Deep Water Composite Production Risers by Rain Flow Cycle Counting Method. In Proceedings of the ASME 2015 34th International Conference on Ocean, Offshore and Arctic Engineering. Volume 5B: Pipeline and Riser Technology, St. John’s, NL, Canada, 31 May–5 June 2015. [Google Scholar] [CrossRef]

- Singh, M.; Ahmad, S.; Jain, A.K. S-N Curve Model for Assessing Cumulative Fatigue Damage of Deep-Water Composite Riser. In Proceedings of the ASME 2020 39th International Conference on Ocean, Offshore and Arctic Engineering. Volume 1: Offshore Technology, Online, 3–7 August 2020. [Google Scholar] [CrossRef]

- Khan, R.A.; Ahmad, S. Nonlinear Dynamic and Bilinear Fatigue Performance of Composite Marine Risers in Deep Offshore Fields. In Proceedings of the ASME 2020 39th International Conference on Ocean, Offshore and Arctic Engineering. Volume 2A: Structures, Safety, and Reliability, Online, 3–7 August 2020. [Google Scholar] [CrossRef]

- Khan, R.A.; Ahmad, S. Bilinear Fatigue Performance of Composite Marine Risers in Deep Offshore Fields Due to Vortex Induced Vibrations. In Proceedings of the ASME 2021 40th International Conference on Ocean, Offshore and Arctic Engineering. Volume 2: Structures, Safety, and Reliability, Online, 21–30 June 2021. [Google Scholar] [CrossRef]

- Hastie, J.C.; Guz, I.A.; Kashtalyan, M. Structural integrity of deepwater composite pipes under combined thermal and mechanical loading. Procedia Struct. Integr. 2020, 28, 850–863. [Google Scholar] [CrossRef]

| Particulars | Value | Unit |

|---|---|---|

| Material | Composites | - |

| Number of Layers | 17, 18, and 21 | - |

| Failure Criteria | Max. Stress | - |

| Innermost Layer | Liner | - |

| Outer Diameter | 0.305 | m |

| Length of Riser Section | 3.000 | m |

| Ocean Depth | 2030.000 | m |

| Surface Area | 7.661 | m2 |

| Parameter/Description | Fibre Volume Fraction | Density (kg/m3) | E1 (GPa) | E2 = E3 (GPa) | G12 = G13 (GPa) | G23 (GPa) | (GPa) | (GPa) | (GPa) | (GPa) | τ12 (GPa) | ʋ12 = ʋ13 | ʋ23 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (APC2) IM7/PEEK | 0.55 | 1320.0 | 172.00 | 8.30 | 5.50 | 2.80 | 2900 | 1300 | 48.3 | 152.0 | 68.0 | 0.27 | 0.48 |

| (V2021) Carbon fibre/Epoxy | 0.55 | 1580.0 | 10.32 | 10.32 | 7.97 | 3.70 | 4900 | 1470 | 69.0 | 146.0 | 98.0 | 0.27 | 0.50 |

| (APC2) P75/PEEK | 0.55 | 1773.0 | 280.00 | 6.70 | 3.43 | 1.87 | 668 | 364 | 24.8 | 136.0 | 68.0 | 0.30 | 0.69 |

| (T700) Carbon fibre/Epoxy | 0.58 | 1580.0 | 230.00 | 20.90 | 27.60 | 2.70 | 4900 | 1470 | 69.0 | 146.0 | 98.0 | 0.20 | 0.27 |

| (APC2) AS4/PEEK | 0.58 | 1561.0 | 131.00 | 8.70 | 5.00 | 2.78 | 1648 | 864 | 62.4 | 156.8 | 125.6 | 0.28 | 0.48 |

| (S-2) Glass fibre/Epoxy | 0.55 | 2464.0 | 87.93 | 16.00 | 9.00 | 2.81 | 4890 | 1586 | 55.0 | 148.0 | 70.0 | 0.26 | 0.28 |

| (938) P75/Epoxy | 0.55 | 1776.0 | 310.00 | 6.60 | 4.10 | 2.12 | 720 | 328 | 22.4 | 55.2 | 176.0 | 0.29 | 0.70 |

| (938) AS4/Epoxy | 0.60 | 1530.0 | 135.40 | 9.37 | 4.96 | 3.20 | 1732 | 1256 | 49.4 | 167.2 | 71.2 | 0.32 | 0.46 |

| Parameter/Description | Poisson’s Ratio, ʋ | Elongation at Break (%) | Ultimate Stress (MPa) | Yield Stress (MPa) | Elastic Modulus (MPa) | Density (kg/m3) |

|---|---|---|---|---|---|---|

| (Victrex) PEEK | 0.400 | 45.00 | 125.0 | 110.0 | 4.0 | 1300.0 |

| HDPE | 0.460 | 10.00 | 43.0 | 1350.0 | 565.0 | 995.0 |

| (Nylon PA) PA12 | 0.400 | 10.00 | 54.0 | 1500.0 | 540.0 | 1010.0 |

| PVDF | 0.400 | 10.00 | 54.0 | 1540.0 | 550.0 | 1780.0 |

| (X80) Steel | 0.300 | 5.90 | 950.0 | 880.0 | 207.0 | 7850.0 |

| (1953T1) Aluminium alloy | 0.300 | 7.50 | 540.0 | 480.0 | 71.0 | 2780.0 |

| (Ti6Al4V) Titanium alloy | 0.342 | 14.00 | 950.0 | 880.0 | 113.8 | 4430.0 |

| Liner Material | Liner Thickness (mm) | Fibre | Matrix | Lay-Up | Lamina Thickness (mm) | ||

|---|---|---|---|---|---|---|---|

| 0° | ±53.5° | 90° | |||||

| Titanium | 9 | AS4 | PEEK | [903,(±53.5)5,05] | 1.84 | 1.48 | 0.6 |

| Titanium | 9 | IM7 | PEEK | [903,(±53.5)5,05] | 1.84 | 1.48 | 0.6 |

| Titanium | 9 | P75 | PEEK | [903,(±53.5)5,05] | 1.84 | 1.48 | 0.6 |

| Titanium | 9 | AS4 | Epoxy | [903,(±53.5)5,05] | 1.84 | 1.48 | 0.6 |

| Titanium | 9 | IM7 | Epoxy | [903,(±53.5)5,05] | 1.84 | 1.48 | 0.6 |

| Titanium | 9 | P75 | Epoxy | [903,(±53.5)5,05] | 1.84 | 1.48 | 0.6 |

| Design Loads | Parameters | Detailed Information of Load |

|---|---|---|

| Design Load 01 | Tension Load | Using 2.25 as factor of load and the max. tensions |

| Design Load 02 | Internal Pressure (Burst) + effect of load at ends | Using the int. pres. at 155.25 MPa is utilised |

| Design Load 03 | External Pressure (Collapse) | Using the ext. pres. at 60.00 MPa is utilised |

| Design Load 04 | Combined—Tension cum Internal Pressure | Using the int. pres. at 155.25 MPa for the tensions |

| Design Load 05 | Combined—Tension cum External Pressure | Using 2.25 as factor of load for 19.50 MPa ext. pres. |

| Ply/Layer | Name of Layer | Inclination Angle/Orientation (°) | Thickness (mm) |

|---|---|---|---|

| 00 | The Liner | 2.00 | |

| 1, 3, 5, 7, 9, 11, 13, 15, 17, 19, 21 | Hoop Layers | 90 | 1.62 |

| 2, 4, 6, 8, 10, 12, 14, 16, 18, 20 | Axial Layers | 0 | 1.58 |

| Design | Configuration | [04,(±53.5)5,904] | [903,(±53.5)5,05] | ||

|---|---|---|---|---|---|

| Ply/Layer | Name of Layer | Inclination Angle/Orientation (°) | Thickness (mm) | Inclination Angle/Orientation (°) | Thickness (mm) |

| 00 | The Liner | 0.0 | 2.00 | 0.0 | 9.00 |

| 01 | Axial Layers | 0.0 | 1.58 | 0.0 | 1.84 |

| 02 | 0.0 | 1.58 | 0.0 | 1.84 | |

| 03 | 0.0 | 1.58 | 0.0 | 1.84 | |

| 04 | 0.0 | 1.58 | 0.0 | 1.84 | |

| 05 | Angled Layers (or Off-axis Layers) | 53.5 | 1.88 | 53.5 | 1.48 |

| 06 | −53.5 | 1.88 | −53.5 | 1.48 | |

| 07 | 53.5 | 1.88 | 53.5 | 1.48 | |

| 08 | −53.5 | 1.88 | −53.5 | 1.48 | |

| 09 | 53.5 | 1.88 | 53.5 | 1.48 | |

| 10 | −53.5 | 1.88 | −53.5 | 1.48 | |

| 11 | 53.5 | 1.88 | 53.5 | 1.48 | |

| 12 | −53.5 | 1.88 | −53.5 | 1.48 | |

| 13 | 53.5 | 1.88 | 53.5 | 1.48 | |

| 14 | −53.5 | 1.88 | −53.5 | 1.48 | |

| 15 | Hoop Layers | 90.0 | 1.62 | 90.0 | 1.60 |

| 16 | 90.0 | 1.62 | 90.0 | 1.60 | |

| 17 | 90.0 | 1.62 | 90.0 | 1.60 | |

| 18 | 90.0 | 1.62 | 90.0 | 1.60 | |

| Particulars | Value | Unit |

|---|---|---|

| Maximum Riser Deformation | 3.37 | mm |

| Ultimate Stress of Titanium Alloy | 950.00 | MPa |

| Yield Stress of Titanium Alloy | 880.00 | MPa |

| Titanium Liner’s Equivalent Stress | 550.00 | MPa |

| Particulars | Value | Unit |

|---|---|---|

| Riser’s Maximum Deformation | 1.34 | mm |

| Ultimate Stress of Titanium Alloy | 950.00 | MPa |

| Yield Stress of Titanium Alloy | 880.00 | MPa |

| Titanium Liner’s Equivalent Stress | 525.00 | MPa |

| Particulars | Value | Unit |

|---|---|---|

| Riser’s Maximum Deformation | 7.78 | mm |

| Ultimate Stress of Titanium Alloy | 950.00 | MPa |

| Yield Stress of Titanium Alloy | 880.00 | MPa |

| Titanium Liner’s Equivalent Stress | 162.00 | MPa |

| Particulars | Value | Unit |

|---|---|---|

| Riser’s Maximum Deformation | 11.80 | mm |

| Ultimate Stress of Titanium Alloy | 950.00 | MPa |

| Yield Stress of Titanium Alloy | 880.00 | MPa |

| Titanium Liner’s Equivalent Stress | 253.00 | MPa |

| Design Case | Liner Material | Fibre | Matrix | Lay-Up | Lamina Thickness (mm) | ||

|---|---|---|---|---|---|---|---|

| 0° | ±53.5° | 90° | |||||

| Case 1 | Titanium | AS4 | PEEK | [05,(±53.5)5,905] | 2.49 | 1.7 | 0.6 |

| Case 2 | Titanium | AS4 | PEEK | [903,(±53.5)5,05] | 2.49 | 1.7 | 1.84 |

| Case 3 | Titanium | AS4 | PEEK | [903,(±53.5)5,05] | 2.49 | 1.7 | 3.25 |

| Case 4 | Titanium | AS4 | PEEK | [05,(±53.5)5,905] | 2.49 | 1.7 | 1.7 |

| Case 5 | Titanium | AS4 | PEEK | [905,(±53.5)5,05] | 2.49 | 1.7 | 1.84 |

| Case 6 | Titanium | AS4 | PEEK | [(±53.5)5,05,905] | 1.15 | 1.7 | 1.84 |

| Case 7 | Titanium | AS4 | PEEK | [06,(±53.5)5,904] | 2.49 | 1.7 | 0.6 |

| Case 8 | Titanium | AS4 | PEEK | [905,(±53.5)5,05] | 2.49 | 1.7 | 0.6 |

| Case 9 | Titanium | AS4 | PEEK | [905,(±53.5)5,05] | 1.15 | 1.7 | 1.84 |

| Case 10 | Titanium | AS4 | PEEK | [(±53.5)5,905,05] | 1.15 | 1.7 | 1.84 |

| Case 11 | Titanium | AS4 | PEEK | [(±53.5)5,905,05] | 1.15 | 1.7 | 3.25 |

| Case 12 | Titanium | AS4 | PEEK | [06,(±53.5)5,904] | 2.49 | 1.7 | 1.7 |

| Depth (m) | Thickness (mm) | Weight (kg/m) |

|---|---|---|

| 0–1000 | 155 | 23 |

| 1000–1600 | 162 | 24 |

| 1600–2000 | 170 | 25 |

| ~2000 (approx. range) | 160 |

| Design | Configuration | OD, Outer Diameter | OD Increase | Riser Weight | Weight Saving |

|---|---|---|---|---|---|

| Steel TTR | [90/(0/90)4] | 273–275 | - | 160 | - |

| Preliminary | [54,(±54.7)10,884] | 314.6 | 13% | 73 | 54% |

| Second | [04,(±53.5)5,904] | 315.2 | 13.5% | 70 | 57% |

| Final | [33,(±62)10,885] | 316.6 | 14% | 54 | 66% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amaechi, C.V.; Gillet, N.; Ja’e, I.A.; Wang, C. Tailoring the Local Design of Deep Water Composite Risers to Minimise Structural Weight. J. Compos. Sci. 2022, 6, 103. https://0-doi-org.brum.beds.ac.uk/10.3390/jcs6040103

Amaechi CV, Gillet N, Ja’e IA, Wang C. Tailoring the Local Design of Deep Water Composite Risers to Minimise Structural Weight. Journal of Composites Science. 2022; 6(4):103. https://0-doi-org.brum.beds.ac.uk/10.3390/jcs6040103

Chicago/Turabian StyleAmaechi, Chiemela Victor, Nathaniel Gillet, Idris Ahmed Ja’e, and Chunguang Wang. 2022. "Tailoring the Local Design of Deep Water Composite Risers to Minimise Structural Weight" Journal of Composites Science 6, no. 4: 103. https://0-doi-org.brum.beds.ac.uk/10.3390/jcs6040103