The Oscillatory Spinning Drop Technique. An Innovative Method to Measure Dilational Interfacial Rheological Properties of Brine-Crude Oil Systems in the Presence of Asphaltenes

Abstract

:1. Introduction

1.1. Dilational Interfacial Rheology

1.2. Basic Aspects of the Oscillating Spinning Drop Interfacial Rheology Technique

1.3. Practical Aspects of the Measurement

- At very low frequency (0.025 Hz or lower), the oscillation time is quite long; hence the time is sufficient for surfactant exchanges to occur and surfactant to adsorb. Therefore, surface concentration (i.e., surface tension) gradients are very low, relaxation occurs, and Gibbs-Marangoni effects are negligible. That is probably one of the reasons why dilational modulus becomes very low.

- At a high frequency (much higher than 0.25 Hz), the oscillation time is very short. It doesn’t give sufficient time for surfactant molecules to adsorb when the droplet elongates. This generates an interface that behaves as an elastic body. The dilational modulus becomes very high, reaching the limiting elasticity plateau, where the interface behaves as an “insoluble” monolayer. Among the particularities of these systems, we can mention that the external phase must be transparent or just a little opaque; otherwise, the measurement cannot be performed because the software cannot distinguish the interface in the photographic data. Usually, the external phase is transparent; hence the measurement is straightforward.

2. The Measurement of Simple Surfactant-Oil-Water Systems with the Spinning Drop Interfacial Rheology Technique

- The attainment of a very low elastic modulus E’ at optimum formulation (Figure 3a) has been explained by the occurrence of very fast surfactant exchanges between the bulk and the interface at HLDN = 0 [17,23]. This generates very low interfacial tension gradients and the disappearance of the Gibbs-Marangoni effect.

- The systematic occurrence of a minimum phase angle at HLDN = 0 (Figure 3b). This is probably due to the formation of non-wetting microemulsion lenses around the droplet [10,19,48,49,50], which provides a more elastic response to the interface. More performant SOW systems, i.e., higher solubilization, seem to relate to a lower phase angle [19,21].

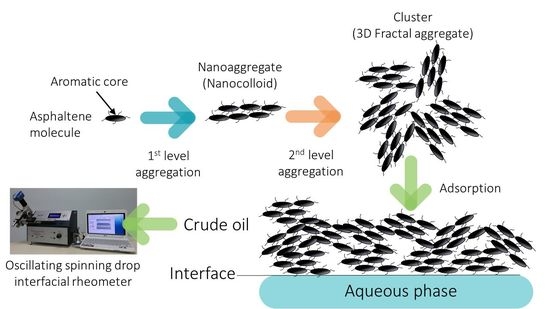

3. The Measurement of Complex Crude Oil/Brine Systems (with Asphaltenes)

3.1. Dynamic Interfacial Tension

3.2. Dynamic Dilational Modulus

3.3. Effect of Asphaltene Concentration on Interfacial Tension and Moduli

3.3.1. Interfacial Tension at Equilibrium

3.3.2. Dilational Modulus at Equilibrium

3.4. Asphaltene Polarity and Diluting Oil Phase Type

4. Dilational Interfacial Rheology in Surfactant-Crude Oil-Brine Complex Systems at Optimum Formulation

4.1. Formulation Aspects to Attain HLDN = 0 in Water-in-Crude Oil Emulsions and Its Relationship with Emulsion Instability

- (a)

- (b)

- (c)

- (d)

- A minimum in interfacial tension and dilational moduli is systematically attained in a formulation scan at optimum formulation. The minimum in the elastic moduli can be explained by the acceleration of surfactant exchanges between the bulk and the interface, which makes Gibbs–Marangoni effects almost negligible.

- The phase angle also presents a minimum at HLDN = 0, which varies according to the surfactant and cosurfactant species. This has been explained by the possible formation of a microemulsion lens around the droplet due to the non-wetting behavior of the bicontinuous middle phase.

- Concomitant minimum emulsion stability is generated at HLDN = 0. This has been explained by the very low elastic modulus attained due to the very fast surfactant exchanges. It could also be since almost all of the surfactant is in the microemulsion middle phase. Hence, there is not enough surfactant available in the excess oil and water phases to stabilize emulsions.

- i.

- ii.

- iii.

4.2. Formulation Scans in Surfactant-Crude Oil-Brine Systems at the Optimum Formulation

5. Conclusions and Perspective

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Reed, R.L.; Healy, R.N. Some physicochemical aspects of microemulsion flooding: A review. In Improved Oil Recovery by Surfactant and Polymer Flooding; Academic Press: Cambridge, MA, USA, 1977; pp. 383–437. [Google Scholar]

- Wade, W.; Morgan, J.C.; Schechter, R.S.; Jacobson, J.K.; Salager, J.-L. Interfacial tension and phase behavior of surfactant systems. Soc. Pet. Eng. J. 1978, 18, 242–252. [Google Scholar] [CrossRef]

- Cayias, J.L.; Schechter, R.S.; Wade, W.H. Measurement of Low Interfacial Tension Via the Spinning Drop Technique. In ACS Symposium Series; American Chemical Society: Washington, DC, USA, 1975; pp. 234–247. [Google Scholar] [CrossRef]

- Cayias, J.L.; Schechter, R.S.; Wade, W.H. Modeling crude oils for low interfacial tension. Soc. Pet. Eng. J. 1976, 16, 351–357. [Google Scholar] [CrossRef]

- Vonnegut, B. Rotating bubble method for the determination of surface and interfacial tensions. Rev. Sci. Instrum. 1942, 13, 6–9. [Google Scholar] [CrossRef]

- Couper, A.; Newton, R.; Nunn, C. A simple derivation of Vonnegut’s equation for the determination of interfacial tension by the spinning drop technique. Colloid Polym. Sci. 1983, 261, 371–372. [Google Scholar] [CrossRef]

- Zamora, J.M.; Marquez, R.; Forgiarini, A.M.; Langevin, D.; Salager, J.L. Interfacial rheology of low interfacial tension systems using a new oscillating spinning drop method. J. Colloid Interface Sci. 2018, 519, 27–37. [Google Scholar] [CrossRef]

- Cash, R.; Cayias, J.L.; Fournier, G.; McAllister, D.; Shares, T.; Schechter, R.S.; Wade, W.H. The Application Of Low Interfacial Tension Scaling Rules to Binary Hydrocarbon Mixtures. J. Colloid Interface Sci. 1977, 59, 39–44. [Google Scholar] [CrossRef]

- Chiwetelu, C.I.; Hornof, V.; Neale, G.H. The measurement of dynamic interfacial tension by photo-micropendography. J. Colloid Interface Sci. 1988, 125, 586–601. [Google Scholar] [CrossRef]

- Langevin, D. Emulsions, Microemulsions and Foams; Springer: Cham, Switzerland, 2020; ISBN 978-3-030-55681-5. [Google Scholar]

- Edwards, D.A.; Brenner, H.; Wasan, D.T. Interfacial Transport Processes and Rheology; Butterworths-Heinemann: Oxford, UK, 1991; ISBN 0750691859. [Google Scholar]

- Miller, R.; Liggieri, L. Progress in Colloid and Interface Science: Interfacial Rheology; CRC Press: Boca Raton, FL, USA, 2009; p. 699. [Google Scholar]

- Langevin, D. Rheology of adsorbed surfactant monolayers at fluid surfaces. Annu. Rev. Fluid Mech. 2014, 46, 47–65. [Google Scholar] [CrossRef]

- Freer, E.; Svitova, T.; Radke, C.J. The role of Interfacial Rheology in reservoir mixed Wettability. J. Pet. Sci. Eng. 2003, 39, 137. [Google Scholar] [CrossRef]

- Ravera, F.; Loglio, G.; Kovalchuk, V.I. Interfacial dilational rheology by oscillating bubble/drop methods. Curr. Opin. Colloid Interface Sci. 2010, 15, 217–228. [Google Scholar] [CrossRef]

- Nguyen, D.; Balsamo, V. Emulsification of heavy oil in aqueous solutions of poly(vinyl alcohol): A method for reducing apparent viscosity of production fluids. Energy Fuels 2013, 27, 1736–1747. [Google Scholar] [CrossRef]

- Marquez, R.; Forgiarini, A.M.; Langevin, D.; Salager, J.-L. Instability of Emulsions Made with Surfactant–Oil–Water Systems at Optimum Formulation with Ultralow Interfacial Tension. Langmuir 2018, 34, 9252–9263. [Google Scholar] [CrossRef]

- Marquez, R.; Forgiarini, A.M.; Fernández, J.; Langevin, D.; Salager, J.-L. New Interfacial Rheology Characteristics Measured using a Spinning-Drop Rheometer at the Optimum Formulation of a Simple Surfactant–Oil–Water System. J. Surfactants Deterg. 2018, 21, 611–623. [Google Scholar] [CrossRef]

- Marquez, R.; Antón, R.; Vejar, F.; Salager, J.L.; Forgiarini, A.M. New Interfacial Rheology Characteristics Measured Using a Spinning Drop Rheometer at the Optimum Formulation. Part 2. Surfactant–Oil–Water Systems with a High Volume of Middle-Phase Microemulsion. J. Surfactants Deterg. 2019, 22, 177–188. [Google Scholar] [CrossRef]

- Marquez, R.; Forgiarini, A.; Langevin, D.; Salager, J.-L. Breaking of Water-In-Crude Oil Emulsions. Part 9. New Interfacial Rheology Characteristics Measured Using a Spinning Drop Rheometer at Optimum Formulation. Energy Fuels 2019, 33, 8151–8164. [Google Scholar] [CrossRef]

- Marquez, R.; Meza, L.; Alvarado, J.G.; Bullón, J.; Langevin, D.; Forgiarini, A.M.; Salager, J.-L. Interfacial Rheology Measured with a Spinning Drop Interfacial Rheometer: Particularities in More Realistic Surfactant–Oil–Water Systems Close to Optimum Formulation at HLDN = 0. J. Surfactants Deterg. 2021, 24, 587–601. [Google Scholar] [CrossRef]

- Slattery, J.C.; Chen, J.D.; Thomas, C.P.; Fleming, P.D. Spinning drop interfacial viscometer. J. Colloid Interface Sci. 1980, 73, 483–499. [Google Scholar] [CrossRef]

- Fillous, L.; Cárdenas, A.; Rouvière, J.; Salager, J.-L. Interfacial Mass Transfer versus Formulation in Multiple Phase Anionic Surfactant-Oil-Water Systems. J. Surfactants Deterg. 1999, 2, 303–307. [Google Scholar] [CrossRef]

- Salager, J.-L.; Forgiarini, A.M.; Bullón, J. How to attain ultralow interfacial tension and three-phase behavior with surfactant formulation for enhanced oil recovery: A review. Part 1. Optimum formulation for simple surfactant-oil-water ternary systems. J. Surfactants Deterg. 2013, 16, 449–472. [Google Scholar] [CrossRef]

- Salager, J.-L.; Forgiarini, A.M.; Márquez, L.; Manchego, L.; Bullón, J.; Marquez, L.; Manchego, L.; Bullon, J. How to Attain an Ultralow Interfacial Tension and a Three-Phase Behavior with a Surfactant Formulation for Enhanced Oil Recovery: A Review. Part 2. Performance Improvement Trends from Winsor’s Premise to Currently Proposed Inter- and Intra-Molecular Mixtures. J. Surfactants Deterg. 2013, 16, 631–663. [Google Scholar] [CrossRef] [Green Version]

- Salager, J.-L. Fundamental basis for the action of a chemical dehydrant. Influence of the physical and chemical formulation on the stability of an emulsion. Int. Chem. Eng. 1990, 30, 103–116. [Google Scholar]

- Cash, R.L.; Cayias, J.L.; Fournier, G.R.; Jacobson, J.K.; LeGear, C.A.; Schares, T.; Schechter, R.S.; Wade, W.H. Low interfacial tension variables. In Proceedings of the Detergents in the Changing Scene; American Oil Chemists’ Society: Urbana, IL, USA, 1975. [Google Scholar]

- Shinoda, K.; Arai, H. The effect of phase volume on the phase inversion temperature of emulsions stabilized with nonionic surfactants. J. Colloid Interface Sci. 1967, 25, 429–431. [Google Scholar] [CrossRef]

- Shinoda, K.; Saito, H. The effect of temperature on the phase equilibria and the types of dispersions of the ternary system composed of water, cyclohexane, and nonionic surfactant. J. Colloid Interface Sci. 1968, 26, 70–74. [Google Scholar] [CrossRef]

- Salager, J.-L.; Morgan, J.C.; Schechter, R.S.; Wade, W.H.; Vasquez, E. Optimum formulation of surfactant/water/oil systems for minimum interfacial tension or phase behavior. Soc. Pet. Eng. J. 1979, 19, 107–115. [Google Scholar] [CrossRef]

- Bourrel, M.; Salager, J.L.; Schechter, R.S.; Wade, W.H. A correlation for phase behavior of nonionic surfactants. J. Colloid Interface Sci. 1980, 75, 451–461. [Google Scholar] [CrossRef]

- Antón, R.E.; Garcés, N.; Yajure, A. A correlation for three-phase behavior of cationic surfactant-oil-water systems. J. Dispers. Sci. Technol. 1997, 18, 539–555. [Google Scholar] [CrossRef]

- Miñana-Perez, M.; Graciaa, A.; Lachaise, J.; Salager, J.-L. Solubilization of polar oils with extended surfactants. Colloids Surfaces A Physicochem. Eng. Asp. 1995, 100, 217–224. [Google Scholar] [CrossRef]

- Miñana-Perez, M.; Graciaa, A.; Lachaise, J.; Salager, J.-L. Solubilization of polar oils in microemulsion systems. Trends Colloid Interface Sci. IX 1995, 98, 177–179. [Google Scholar] [CrossRef]

- Salager, J.-L.; Forgiarini, A.; Marquez, R. Extended Surfactants Including an Alkoxylated Central Part Intermediate Producing a Gradual Polarity Transition—A Review of the Properties Used in Applications Such as Enhanced Oil Recovery and Polar Oil Solubilization in Microemulsions. J. Surfactants Deterg. 2019, 22, 935–972. [Google Scholar] [CrossRef]

- Salager, J.-L.; Anton, R.E. Ionic Microemulsions. In Handbook of Microemulsion Science and Technology; Kumar, P., Mittal, K., Eds.; Marcel Dekker: New York, NY, USA, 1999; pp. 247–280. [Google Scholar]

- Salager, J.-L.; Marquez, N.; Graciaa, A.; Lachaise, J. Partitioning of ethoxylated octylphenol surfactants in microemulsion-oil-water systems: Influence of temperature and relation between partitioning coefficient and physicochemical formulation. Langmuir 2000, 16, 5534–5539. [Google Scholar] [CrossRef]

- Salager, J.-L.; Antón, R.E.; Forgiarini, A.; Márquez, L. Formulation of Microemulsions. In Microemulsions: Background, New Concepts, Applications, Perspectives, Stubenrauch Ed.; Wiley: Hoboken, NJ, USA, 2009; pp. 84–121. ISBN 9781444305524. [Google Scholar]

- Salager, J.-L.; Antón, R.E.; Bullón, J.; Forgiarini, A.; Marquez, R. How to Use the Normalized Hydrophilic-Lipophilic Deviation (HLDN) Concept for the Formulation of Equilibrated and Emulsified Surfactant-Oil-Water Systems for Cosmetics and Pharmaceutical Products. Cosmetics 2020, 7, 57. [Google Scholar] [CrossRef]

- Doe, P.; El-Emary, M.; Wade, W.; Schecter, R. The Influence of Surfactant Structure on Low Interfacial Tensions. In Chemistry of Oil Recovery; ACS Symposium Series; American Chemical Society: Washington, DC, USA, 1979; Volume 91, pp. 2–17. ISBN 9780841204775. [Google Scholar]

- Aubry, J.M.; Ontiveros, J.F.; Salager, J.-L.; Nardello-Rataj, V. Use of the normalized hydrophilic-lipophilic-deviation (HLDN) equation for determining the equivalent alkane carbon number (EACN) of oils and the preferred alkane carbon number (PACN) of nonionic surfactants by the fish-tail method (FTM). Adv. Colloid Interface Sci. 2020, 276, 102099. [Google Scholar] [CrossRef] [PubMed]

- Salager, J.-L. A normalized Hydrophilic-Lipophilic Deviation expression HLDN is necessary to avoid confusions close to the optimum formulation of Surfactant-Oil-Water systems. J. Surfactants Deterg. 2021, 24, 731–748. [Google Scholar] [CrossRef]

- Salager, J.-L.; Bullón, J.; Pizzino, A.; Rondón-González, M.; Tolosa, L.; Somasundaran, P. Emulsion formulation engineering for the practitioner. In Encyclopedia of Surface and Colloid Science; Somasundaran, P., Ed.; Taylor & Francis: New York, NY, USA, 2010; Volume 1, pp. 1–6. [Google Scholar]

- Salager, J.-L. Emulsion Phase Inversion Phenomena. In Emulsions and Emulsion Stability; Sjoblom, J., Ed.; CRC Publishing: Boca Raton, FL, USA, 2006; p. 185. [Google Scholar]

- Antón, R.E.; Andérez, J.M.; Bracho, C.; Vejar, F.; Salager, J.-L. Practical Surfactant Mixing Rules Based on the Attainment of Microemulsion–Oil–Water Three-Phase Behavior Systems. Adv. Polym. Sci. 2008, 218, 83. [Google Scholar] [CrossRef]

- Salager, J.-L.; Antón, R.E.; Anderez, J.M.; Aubry, J.-M. Formulation des micro-émulsions par la méthode HLD. Tech. l’Ingénieur 2001, 157, 1–16. [Google Scholar]

- Vera, R.E.; Salazar-Rodríguez, F.; Marquez, R.; Forgiarini, A.M. How the Influence of Different Salts on Interfacial Properties of Surfactant–Oil–Water Systems at Optimum Formulation Matches the Hofmeister Series Ranking. J. Surfactants Deterg. 2020, 23, 603–615. [Google Scholar] [CrossRef]

- Kahlweit, M.; Strey, R.; Busse, G. Microemulsions: A qualitative thermodynamic approach. J. Phys. Chem. 1990, 94, 3881–3894. [Google Scholar] [CrossRef]

- Langevin, D.; Meunier, J. Interfacial tension: Theory and experiment. In Micelles, Membranes, Microemulsions, and Monolayers; Gelbart, W.M., Ben-Shaul, A., Roux, D., Eds.; Springer: New York, NY, USA, 1994; pp. 485–519. ISBN 978-1-4613-8391-8. [Google Scholar]

- Sottmann, T.; Strey, R. Ultralow interfacial tensions in water-n-alkane-surfactant systems. J. Chem. Phys. 1997, 106, 8606–8615. [Google Scholar] [CrossRef]

- Langevin, D.; Argillier, J.F. Interfacial behavior of asphaltenes. Adv. Colloid Interface Sci. 2016, 233, 83–93. [Google Scholar] [CrossRef]

- Schuler, B.; Meyer, G.; Peña, D.; Mullins, O.C.; Gross, L. Unraveling the Molecular Structures of Asphaltenes by Atomic Force Microscopy. J. Am. Chem. Soc. 2015, 137, 9870–9876. [Google Scholar] [CrossRef]

- Carnahan, N.F.; Salager, J.L.; Antón, R.; Dávila, A. Properties of resins extracted from Boscan crude oil and their effect on the stability of asphaltenes in Boscan and Hamaca crude oils. Energy Fuels 1999, 13, 309–314. [Google Scholar] [CrossRef]

- Langevin, D.; Poteau, S.; Hénaut, I.; Argillier, J.F. Crude oil emulsion properties and their application to heavy oil transportation. Oil Gas Sci. Technol. 2004, 59, 511–521. [Google Scholar] [CrossRef]

- Mullins, O.C.; Sabbah, H.; Eyssautier, J.; Pomerantz, A.E.; Barré, L.; Andrews, A.B.; Ruiz-Morales, Y.; Mostowfi, F.; McFarlane, R.; Goual, L. Advances in asphaltene science and the Yen–Mullins model. Energy Fuels 2012, 26, 3986–4003. [Google Scholar] [CrossRef]

- Schuler, B.; Zhang, Y.; Liu, F.; Pomerantz, A.E.; Andrews, A.B.; Gross, L.; Pauchard, V.; Banerjee, S.; Mullins, O.C. Overview of asphaltene nanostructures and thermodynamic applications. Energy Fuels 2020, 34, 15082–15105. [Google Scholar] [CrossRef]

- Meng, J.; You, J.B.; Hao, H.; Tan, X.; Zhang, X. Primary submicron particles from early stage asphaltene precipitation revealed in situ by total internal reflection fluorescence microscopy in a model oil system. Fuel 2021, 296, 120584. [Google Scholar] [CrossRef]

- Goual, L.; Sedghi, M.; Wang, X.; Zhu, Z. Asphaltene aggregation and impact of alkylphenols. Langmuir 2014, 30, 5394–5403. [Google Scholar] [CrossRef]

- Alvarez, G.; Poteau, S.; Argillier, J.F.; Langevin, D.; Salager, J.L. Heavy oil-water interfacial properties and emulsion stability: Influence of dilution. Energy Fuels 2009, 23, 294–299. [Google Scholar] [CrossRef]

- Alvarado, J.G.; Delgado-Linares, J.G.; Forgiarini, A.M.; Salager, J.-L. Breaking of water-in-crude oil emulsions. Part 8. Demulsifier performance at optimum formulation is significantly inproved by a small aromatic content of the oil. Energy Fuels 2019, 33, 1928–1936. [Google Scholar] [CrossRef]

- Rondón, M.; Pereira, J.C.; Bouriat, P.; Graciaa, A.; Lachaise, J.; Salager, J.-L. Breaking of water-in-crude-oil emulsions. 2. Influence of asphaltene concentration and diluent nature on demulsifier action. Energy Fuels 2008, 22, 702–707. [Google Scholar] [CrossRef]

- Kilpatrick, P.K. Water-in-crude oil emulsion stabilization: Review and unanswered questions. Energy Fuels 2012, 26, 4017–4026. [Google Scholar] [CrossRef]

- Zhang, Y.; Siskin, M.; Gray, M.R.; Walters, C.C.; Rodgers, R.P. Mechanisms of Asphaltene Aggregation: Puzzles and a New Hypothesis. Energy Fuels 2020, 34, 9094–9107. [Google Scholar] [CrossRef]

- Alicke, A.; Simon, S.; Sjöblom, J.; Vermant, J. Assessing the Interfacial Activity of Insoluble Asphaltene Layers: Interfacial Rheology versus Interfacial Tension. Langmuir 2020, 36, 14942–14959. [Google Scholar] [CrossRef]

- Svalova, A.; Walshaw, D.; Lee, C.; Demyanov, V.; Parker, N.G.; Povey, M.J.; Abbott, G.D. Estimating the asphaltene critical nanoaggregation concentration region using ultrasonic measurements and Bayesian inference. Sci. Rep. 2021, 11, 1–11. [Google Scholar] [CrossRef]

- Acevedo, S.; Castillo, J.; Vargas, V.; Castro, A.; Delgado, O.; Cortés, F.B.; Franco, C.A.; Bouyssiere, B. Suppression of Phase Separation as a Hypothesis to Account for Nuclei or Nanoaggregate Formation by Asphaltenes in Toluene. Energy Fuels 2018, 32, 6669–6677. [Google Scholar] [CrossRef]

- Mullins, O.C. The modified yen model. Energy Fuels 2010, 24, 2179–2207. [Google Scholar] [CrossRef]

- Lobato, M.D.; Gámez, F.; Lago, S.; Pedrosa, J.M. The influence of the polarity of fractionated asphaltenes on their Langmuir-film properties. Fuel 2017, 200, 162–170. [Google Scholar] [CrossRef]

- Ashoorian, S.; Javadi, A.; Hosseinpour, N.; Husein, M. Evolution of adsorbed layers of asphaltenes at oil-water interfaces: A novel experimental protocol. J. Colloid Interface Sci. 2021, 594, 80–91. [Google Scholar] [CrossRef]

- Yeung, A.; Dabros, T.; Czarnecki, J.; Masliyah, J. On the Interfacial Properties of micrometre-sized water Droplets in Crude Oil. Proc. R. Soc. A 1999, 455, 3709. [Google Scholar] [CrossRef]

- McLean, J.D.; Kilpatrick, P.K. Effects of asphaltene aggregation in model heptane-toluene mixtures on stability of water-in-oil emulsions. J. Colloid Interface Sci. 1997, 196, 23–34. [Google Scholar] [CrossRef] [PubMed]

- Delgado-Linares, J.G.; Pereira, J.C.; Rondón, M.; Bullón, J.; Salager, J.L. Breaking of Water-in-Crude Oil Emulsions. 6. Estimating the Demulsifier Performance at Optimum Formulation from Both the Required Dose and the Attained Instability. Energy Fuels 2016, 30, 5483–5491. [Google Scholar] [CrossRef]

- Delgado-Linares, J.G.; Alvarado, J.G.; Véjar, F.; Bullón, J.; Forgiarini, A.M.; Salager, J.L. Breaking of Water-in-Crude Oil Emulsions. 7. Demulsifier Performance at Optimum Formulation for Various Extended Surfactant Structures. Energy Fuels 2016, 30, 7065–7071. [Google Scholar] [CrossRef]

- Rondón, M.; Bouriat, P.; Lachaise, J.; Salager, J.L. Breaking of water-in-crude oil emulsions. 1. Physicochemical phenomenology of demulsifier action. Energy Fuels 2006, 20, 1600–1604. [Google Scholar] [CrossRef]

- Bourrel, M.; Passade-Boupat, N. Crude Oil Surface Active Species: Consequences for Enhanced Oil Recovery and Emulsion Stability. Energy Fuels 2018, 32, 2642–2652. [Google Scholar] [CrossRef]

- Jeribi, M.; Almir-Assad, B.; Langevin, D.; Henaut, I.; Argillier, J.F. Adsorption kinetics of asphaltenes at liquid interfaces. J. Colloid Interface Sci. 2002, 256, 268–272. [Google Scholar] [CrossRef]

- Dicharry, C.; Arla, D.; Sinquin, A.; Graciaa, A.; Bouriat, P. Stability of water/crude oil emulsions based on interfacial dilatational rheology. J. Colloid Interface Sci. 2006, 297, 785–791. [Google Scholar] [CrossRef]

- Fan, Y.; Simon, S.; Sjöblom, J. Interfacial shear rheology of asphaltenes at oil-water interface and its relation to emulsion stability: Influence of concentration, solvent aromaticity and nonionic surfactant. Colloids Surf. A Physicochem. Eng. Asp. 2010, 366, 120–128. [Google Scholar] [CrossRef]

- Tao, J.; Shi, P.; Fang, S.; Li, K.; Zhang, H.; Duan, M. Effect of rheology properties of oil/water interface on demulsification of crude oil emulsions. Ind. Eng. Chem. Res. 2015, 54, 4851–4860. [Google Scholar] [CrossRef]

- Sun, T.; Zhang, L.; Wang, Y.; Peng, B.; Zhao, S. Dynamic Dilational Properties of Oil-Water Interfacial Films containing Surface Active Fractions from Crude Oil. J. Dispers. Sci. Technol. 2003, 24, 699. [Google Scholar] [CrossRef]

- Bouriat, P.; El Kerri, N.; Graciaa, A.; Lachaise, J. Properties of a two-dimensional asphaltene network at the water-cyclohexane interface deduced from dynamic tensiometry. Langmuir 2004, 20, 7459–7464. [Google Scholar] [CrossRef]

- Aske, N.; Orr, R.; Sjöblom, J.; Kallevik, H.; Øye, G. Interfacial properties of water—Crude oil systems using the oscillating pendant drop. Correlations to asphaltene solubility by near infrared spectroscopy. J. Dispers. Sci. Technol. 2004, 25, 263–275. [Google Scholar] [CrossRef]

- Spiecker, P.M.; Kilpatrick, P.K. Interfacial Rheology of Petroleum Asphaltenes at the Oil–Water Interface. Langmuir 2004, 20, 4022–4032. [Google Scholar] [CrossRef]

- Yang, X.; Verruto, V.J.; Kilpatrick, P.K. Dynamic asphaltene-resin exchange at the oil/water interface: Time-dependent W/O emulsion stability for asphaltene/resin model oils. Energy Fuels 2007, 21, 1343–1349. [Google Scholar] [CrossRef]

- Quintero, C.G.; Noïk, C.; Dalmazzone, C.; Grossiord, J.L. Formation Kinetics and Viscoelastic Properties of Water/Crude Oil Interfacial Films. Oil Gas Sci. Technol. 2009, 64, 607. [Google Scholar] [CrossRef]

- Krawczyk, M.A.; Wasan, D.T.; Shetty, C.S. Chemical Demulsification of Petroleum Emulsions Using Oil-Soluble Demulsifiers. Ind. Eng. Chem. Res. 1991, 30, 367–375. [Google Scholar] [CrossRef]

- Freer, E.; Yim, K.S.; Fuller, G.G.; Radke, C.J. Interfacial rheology of globular and flexible proteins at the hexadecane/water interface: Comparison of shear and dilatation deformation. J. Phys. Chem. B 2004, 108, 3835–3844. [Google Scholar] [CrossRef]

- Yarranton, H.W.; Urrutia, P.; Sztukowski, D.M. Effect of interfacial rheology on model emulsion coalescence. II. Emulsion coalescence. J. Colloid Interface Sci. 2007, 310, 253–259. [Google Scholar] [CrossRef] [PubMed]

- Angle, C.W.; Hua, Y. Dilational interfacial rheology for increasingly deasphalted bitumens and n-C5 asphaltenes in toluene/NaHCO3 solution. Energy Fuels 2012, 26, 6228–6239. [Google Scholar] [CrossRef]

- Zarkar, S.; Pauchard, V.; Farooq, U.; Couzis, A.; Banerjee, S. Interfacial properties of asphaltenes at toluene-water interfaces. Langmuir 2015, 31, 4878–4886. [Google Scholar] [CrossRef]

- Bauget, F.; Langevin, D.; Lenormand, R. Dynamic surface properties of asphaltenes and resins at the oil—Air interface. J. Colloid Interface Sci. 2001, 239, 501–508. [Google Scholar] [CrossRef]

- Sun, T.; Zhang, L.; Wang, Y.; Zhao, S.; Peng, B.; Li, M.; Yu, J. Influence of demulsifiers of different structures on interfacial dilational properties of an oil-water interface containing surface-active fractions from crude oil. J. Colloid Interface Sci. 2002, 255, 241–247. [Google Scholar] [CrossRef] [PubMed]

- Balsamo, V.; Phan, J.; Nguyen, D. Effect of diluents on interfacial properties and sagd emulsion stability: II. Differential scanning calorimetry and light scattering methods. In Proceedings of the SPE Heavy Oil Conference-Canada, Calgary, AB, Canada, 11–13 June 2013; pp. 16–26. [Google Scholar] [CrossRef]

- Varadaraj, R.; Brons, C. Molecular Origins of Crude Oil Interfacial Activity. Part 4: Oil-Water Interface Elasticity and Crude Oil Asphaltene Films. Energy Fuels 2012, 26, 7164. [Google Scholar] [CrossRef]

- McLean, J.D.; Kilpatrick, P.K. Effects of asphaltene solvency on stability of water-in-crude-oil emulsions. J. Colloid Interface Sci. 1997, 189, 242–253. [Google Scholar] [CrossRef] [Green Version]

- Bourrel, M.; Graciaa, A.; Schechter, R.S.; Wade, W.H. The relation of emulsion stability to phase behavior and interfacial tension of surfactant systems. J. Colloid Interface Sci. 1979, 72, 161. [Google Scholar] [CrossRef]

- Milos, F.S.; Wasan, D.T. Emulsion Stability of Surfactants Systems near the Three Phase Region. Colloids Surf. A 1982, 4, 91–96. [Google Scholar] [CrossRef]

- Salager, J.-L.; Loaiza-Maldonado, I.; Minaňa-Perez, M.; Silva, F. Surfactant-Oil-Water Systems Near The Affinity Inversion Part I: Relationship Between Equilibrium Phase Behavior And Emulsion Type And Stability. J. Dispers. Sci. Technol. 1982, 3, 279–292. [Google Scholar] [CrossRef]

- Antón, R.E.; Salager, J.-L. Emulsion instability in the three-phase behavior region of surfactant-alcohoi-oil-brine systems. J. Colloid Interface Sci. 1986, 111, 54–59. [Google Scholar] [CrossRef]

- Goldszal, A.; Bourrel, M. Demulsification of crude oil emulsions: Correlation to microemulsion phase behavior. Ind. Eng. Chem. Res. 2000, 39, 2746–2751. [Google Scholar] [CrossRef]

- Salager, J.L.; Forgiarini, A.M.; Rondón, M.J. How to Attain Ultralow Interfacial Tension and Three-Phase Behavior with a Surfactant Formulation for Enhanced Oil Recovery: A Review—Part 3. Practical Procedures to Optimize the Laboratory Research According to the Current State of the Art in Surfactant. J. Surfactants Deterg. 2017, 20, 3–19. [Google Scholar] [CrossRef]

- Kim, Y.H.; Wasan, D.T. Effect of Demulsifier Partitioning on the Destabilization of Water-in-Oil Emulsions. Ind. Eng. Chem. Res. 1996, 35, 1141–1149. [Google Scholar] [CrossRef]

- Forgiarini, A.M.; Marquez, R.; Salager, J.-L. Formulation improvements in the applications of surfactant-oil-water systems using the HLDN approach with extended surfactant structure. Molecules 2021, 26, 3771. [Google Scholar] [CrossRef] [PubMed]

- Cardenas, A.; Fillous, L.; Rouviere, J.; Salager, J. An experimental method to estimate the mass transfer through the interfacial region of liquid membrane systems. Ciencia 2001, 9, 70–76. [Google Scholar]

- Alvarez, G.; Antón, R.; Marfisi, S.; Márquez, L.; Salager, J.L. Apparent equilibration time required for surfactant-oil-water systems to emulsify into the morphology imposed by the formulation. Part 2: Effect of sec-butanol concentration and initial location. Langmuir 2004, 20, 5179–5181. [Google Scholar] [CrossRef] [PubMed]

- Marfisi, S.; Rodríguez, M.P.; Alvarez, G.; Celis, M.-T.; Forgiarini, A. Complex Emulsion Inversion Pattern associated with the Partitioning of Nonionic Surfactant Mixtures in the presence of alcohol cosurfactant. Langmuir 2005, 21, 6712. [Google Scholar] [CrossRef]

- Salager, J.-L.; Manchego, L.; Márquez, L.; Bullón, J.; Forgiarini, A. Trends to attain a lower interfacial tension in a revisited pure alkyl polyethyleneglycol surfactant–alkane–water ternary system. Basic concepts and straightforward guidelines for improving performance in enhanced oil recovery formulations. J. Surfactants Deterg. 2014, 17, 199–213. [Google Scholar] [CrossRef]

- Berger, P.D.; Hsu, C.; Arendell, J.P. Designing and selecting demulsifiers for optimum field performance on the basis of production fluid characteristics. SPE Prod. Eng. 1988, 3, 522–526. [Google Scholar] [CrossRef]

- Daniel-David, D.; Pezron, I.; Dalmazzone, C.; Noïk, C.; Clausse, D.; Komunjer, L. Elastic Properties of Crude Oil/Water Interface in presence of Polymeric Emulsion Breakers. Colloids Surf. A 2005, 270–271, 257. [Google Scholar] [CrossRef]

- Mukherjee, S.; Kushnick, A.P. Effect of demulsifiers on interfacial properties governing crude oil demulsification. Prepr. Symp. 1988, 33, 205–210. [Google Scholar] [CrossRef]

- Tambe, D.; Paulis, J.; Sharma, M.M. Factors Controlling the Stability of Colloid-Stabilized Emulsions. J. Colloid Interface Sci. 1995, 171, 463. [Google Scholar] [CrossRef]

- Bouriat, P.; Rondón, M.; Lachaise, J.; Salager, J.L. Correlation between interfacial tension bump and optimal crude oil dehydration. Energy Fuels 2009, 23, 3998–4002. [Google Scholar] [CrossRef]

- Kim, Y.H.; Wasan, D.T.; Breen, P.J. A study of dynamic interfacial mechanisms for demulsification of water-in-oil emulsions. Colloids Surf. A Physicochem. Eng. Asp. 1995, 95, 235–247. [Google Scholar] [CrossRef]

- Marquez, R.; Salager, J.-L.; Langevin, D.; Forgiarini, A.M. Using the oscillatory spinning drop interfacial rheology technique as a tool to select demulsifiers according to their emulsion breaking performance at optimum formulation (HLDN = 0). In Proceedings of the 21st International Conference Petrophase, Online Conference, USA, 7 June 2021. [Google Scholar]

- Molaei, M.; Crocker, J.C. Interfacial microrheology and tensiometry in a miniature, 3-d printed Langmuir trough. J. Colloid Interface Sci. 2020, 560, 407–415. [Google Scholar] [CrossRef]

- Kale, S.K.; Cope, A.J.; Goggin, D.M.; Samaniuk, J.R. A miniaturized radial Langmuir trough for simultaneous dilatational deformation and interfacial microscopy. J. Colloid Interface Sci. 2021, 582, 1085–1098. [Google Scholar] [CrossRef] [PubMed]

- Koteich Khatib, S.; Bullón, J.; Vivas, J.; Bahsas, A.; Rosales-Oballos, Y.; Marquez, R.; Forgiarini, A.; Salager, J.L. Synthesis, Characterization, Evaluation of Interfacial Properties and Antibacterial Activities of Dicarboxylate Anacardic Acid Derivatives from Cashew Nut Shell Liquid of Anacardium occidentale L. J. Surfactants Deterg. 2020, 23, 503–512. [Google Scholar] [CrossRef]

| System | Interfacial Tension (mN/m) | Droplet Volume (µL) | Recommended Rotational Speed Interval (rpm) 1 | Approximate Equilibration Time |

|---|---|---|---|---|

| Surfactant-air-water | 10–40 | 20–25 | 7000–10,000 | 30 min–a few hours |

| Oil-water (with asphaltenes) | 10–40 | 20–25 | 7000–10,000 | 1 h–several hours |

| SOW with high tension | 2–10 | 10–20 | 6000–10,000 | 20 min–2 h |

| SOW system with low tension | 0.1–2 | 5–10 | 4000–6000 | 20 min–2 h |

| SOW system with ultralow tension | 0.0001–0.1 | 0.5–5 | 3000–4000 | 1 min–1 h |

| Variable | Property | Description | Reference |

|---|---|---|---|

| Time | Dynamic interfacial tension | Reduction of dynamic interfacial tension over time until equilibrium | [7,14,59,76,77,78,79] |

| Dynamic interfacial modulus | Increase in the modulus over time | [7,14,77,80,81,82,83,84,85] | |

| Asphaltene concentration | Interfacial tension | Reduction of interfacial tension with the concentration of asphaltenes up to saturation of the interface | [7,59,78,86] |

| Dilational modulus | Increase of dilational modulus with the asphaltene concentration up to a maximum between 1000 and 10,000 ppm of asphaltenes | [7,16,59,82,87,88,89] | |

| Oil phase nature | Elastic modulus E’ | E’ increase when the oil phase is less polar | [7,16,78,88] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marquez, R.; Bullon, J.; Forgiarini, A.; Salager, J.-L. The Oscillatory Spinning Drop Technique. An Innovative Method to Measure Dilational Interfacial Rheological Properties of Brine-Crude Oil Systems in the Presence of Asphaltenes. Colloids Interfaces 2021, 5, 42. https://0-doi-org.brum.beds.ac.uk/10.3390/colloids5030042

Marquez R, Bullon J, Forgiarini A, Salager J-L. The Oscillatory Spinning Drop Technique. An Innovative Method to Measure Dilational Interfacial Rheological Properties of Brine-Crude Oil Systems in the Presence of Asphaltenes. Colloids and Interfaces. 2021; 5(3):42. https://0-doi-org.brum.beds.ac.uk/10.3390/colloids5030042

Chicago/Turabian StyleMarquez, Ronald, Johnny Bullon, Ana Forgiarini, and Jean-Louis Salager. 2021. "The Oscillatory Spinning Drop Technique. An Innovative Method to Measure Dilational Interfacial Rheological Properties of Brine-Crude Oil Systems in the Presence of Asphaltenes" Colloids and Interfaces 5, no. 3: 42. https://0-doi-org.brum.beds.ac.uk/10.3390/colloids5030042