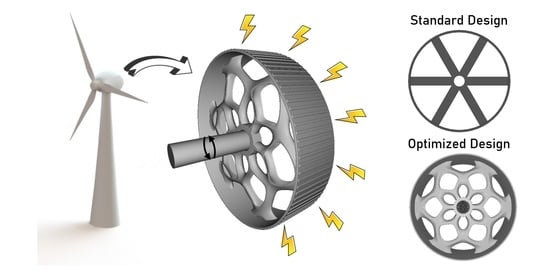

Reducing the Structural Mass of Large Direct Drive Wind Turbine Generators through Triply Periodic Minimal Surfaces Enabled by Hybrid Additive Manufacturing

Abstract

:1. Introduction

2. Materials and Methods

2.1. Implicit Modeling

2.2. Rotor Loading Criteria

2.3. Lattice Optimization and Simulation

2.4. Hybrid Additive Manufacturing

2.5. Experimental Validation

3. Results and Discussion

3.1. Simulation

3.1.1. GA Optimized Minimal Surfaces

3.1.2. Functionally Graded Lattice Optimization

3.2. Manufacturing

3.3. Experimental Validation

4. Conclusions

- A 34% max mass reduction with a Schwartz Primitive TPMS design in a 5 MW PMDD generator rotor structural mass coupling implicit modeling, functionally graded lattice optimization, and FEA through a genetic algorithm

- Implementation of functionally graded lattice optimization for further parameter optimization allows customization of the lattice thickness towards the deflection field. This enabled a design catered towards the weakness of each lattice and further improved mass savings while maintaining deflection criteria.

- Successful manufacturing with hybrid additive manufacturing on a scaled rotor TPMS structure suggesting feasibility of scaling to full size using this technique.

- The Schwartz Primitive design depicted increased strength in the torsional deflection than Gyroid or Diamond designs

- Experimental validation of the TPMS structure FEA model through DIC of a 3D printed Schwartz Primitive rotor model in PLA.

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| TPMS | Triply Periodic Minimal Surface |

| FEA | Finite Element Analysis |

| PMDD | Permanent Magnet Direct Drive |

| AM | Additive Manufacturing |

| FDM | Fused Deposition Modeling |

| DMLS | Direct Metal Laser Sintering |

| GA | Genetic Algorithm |

| DIC | Digital Image Correlation |

| PLA | Polylactic Acid |

References

- US EIA. U.S. Energy Information Administration Annual Energy Outlook 2020; U.S. Department of Energy: Washington, DC, USA, 2020. [Google Scholar]

- Keller, J.; Sheng, S.; Cotrell, J.; Greco, A. Wind Turbine Drivetrain Reliability Collaborative Workshop: A Recap; National Renewable Energy Laboratory, U.S. Department of Energy: Washington, DC, USA, 2016. [Google Scholar]

- Mueller, M.A.; Polinder, H.; McDonald, A.S. Structural mass in direct-drive permanent magnet electrical generators. IET Renew. Power Gener. 2008, 2, 3–15. [Google Scholar]

- McDonald, A. Structural Analysis of Low Speed, High Torque Electrical Generators for Direct Drive Renewable Energy Converters. Ph.D. Thesis, University of Edinburgh, Edinburgh Research Archive, Edinburgh, UK, 2008. [Google Scholar]

- Zavvos, A.; McDonald, A.; Mueller, M. Optimisation tools for large permanent magnet generators for direct drive wind turbines. IET Renew. Power Gener. 2013, 7, 163–171. [Google Scholar] [CrossRef]

- Mueller, M.A.; McDonald, A.S. A lightweight low-speed permanent magnet electrical generator for direct-drive wind turbines. Wind Energy 2009, 12, 768–780. [Google Scholar] [CrossRef]

- Drechsler, M.; Nicholas, J. Distribution of the lattice energy in cubic crystals and its variation with compression or expansion. Solid State Commun. 1967, 5, i. [Google Scholar] [CrossRef]

- Hales, T.C. The Honeycomb Conjecture. Discret. Comput. Geom. 2001, 25, 1–22. [Google Scholar] [CrossRef] [Green Version]

- Almsherqi, Z.A.; Kohlwein, S.D.; Deng, Y. Cubic membranes: A legend beyond the Flatland* of cell membrane organization. J. Cell Biol. 2006, 173, 839–844. [Google Scholar] [CrossRef] [Green Version]

- Maskery, I.; Sturm, L.; Aremu, A.; Panesar, A.; Williams, C.; Tuck, C.; Wildman, R.; Ashcroft, I.; Hague, R. Insights into the mechanical properties of several triply periodic minimal surface lattice structures made by polymer additive manufacturing. Polymer 2018, 152, 62–71. [Google Scholar] [CrossRef]

- Giannitelli, S.; Accoto, D.; Trombetta, M.; Rainer, A. Current trends in the design of scaffolds for computer-aided tissue engineering. Acta Biomater. 2014, 10, 580–594. [Google Scholar] [CrossRef]

- Maconachie, T.; Tino, R.; Lozanovski, B.; Watson, M.; Jones, A.; Pandelidi, C.; Alghamdi, A.; Almalki, A.; Downing, D.; Brandt, M.; et al. The compressive behaviour of ABS gyroid lattice structures manufactured by fused deposition modelling. Int. J. Adv. Manuf. Technol. 2020, 107, 4449–4467. [Google Scholar] [CrossRef]

- Yánez, A.; Herrera, A.; Martel, O.; Monopoli, D.; Afonso, H. Compressive behaviour of gyroid lattice structures for human cancellous bone implant applications. Mater. Sci. Eng. C 2016, 68, 445–448. [Google Scholar] [CrossRef]

- Afshar, M.; Anaraki, A.P.; Montazerian, H.; Kadkhodapour, J. Additive manufacturing and mechanical characterization of graded porosity scaffolds designed based on triply periodic minimal surface architectures. J. Mech. Behav. Biomed. Mater. 2016, 62, 481–494. [Google Scholar] [CrossRef] [PubMed]

- Adam, G.A.; Zimmer, D. Design for Additive Manufacturing—Element transitions and aggregated structures. CIRP J. Manuf. Sci. Technol. 2014, 7, 20–28. [Google Scholar] [CrossRef]

- Ponche, R.; Kerbrat, O.; Mognol, P.; Hascoet, J.Y. A novel methodology of design for Additive Manufacturing applied to Additive Laser Manufacturing process. Robot. Comput. Integr. Manuf. 2014, 30, 389–398. [Google Scholar] [CrossRef] [Green Version]

- Yang, Z.; Yu, Y.; Wei, Y.; Huang, C. Crushing behavior of a thin-walled circular tube with internal gradient grooves fabricated by SLM 3D printing. Thin-Walled Struct. 2017, 111, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Catchpole-Smith, S.; Sélo, R.; Davis, A.; Ashcroft, I.; Tuck, C.; Clare, A. Thermal conductivity of TPMS lattice structures manufactured via laser powder bed fusion. Addit. Manuf. 2019, 30, 100846. [Google Scholar] [CrossRef]

- Snyder, J.C.; Thole, K.A. Tailoring Surface Roughness Using Additive Manufacturing to Improve Internal Cooling. J. Turbomach. 2020, 142. [Google Scholar] [CrossRef]

- Yan, C.; Hao, L.; Hussein, A.; Bubb, S.L.; Young, P.; Raymont, D. Evaluation of light-weight AlSi10Mg periodic cellular lattice structures fabricated via direct metal laser sintering. J. Mater. Process. Technol. 2014, 214, 856–864. [Google Scholar] [CrossRef]

- Chen, X.; Ji, Q.; Wei, J.; Tan, H.; Yu, J.; Zhang, P.; Laude, V.; Kadic, M. Light-weight shell-lattice metamaterials for mechanical shock absorption. Int. J. Mech. Sci. 2020, 169, 105288. [Google Scholar] [CrossRef]

- Gümrük, R.; Mines, R. Compressive behaviour of stainless steel micro-lattice structures. Int. J. Mech. Sci. 2013, 68, 125–139. [Google Scholar] [CrossRef]

- Vyatskikh, A.; Delalande, S.; Kudo, A.; Zhang, X.; Portela, C.M.; Greer, J.R. Additive manufacturing of 3D nano-architected metals. Nat. Commun. 2018, 9, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Dong, G.; Tang, Y.; Li, D.; Zhao, Y.F. Design and optimization of solid lattice hybrid structures fabricated by additive manufacturing. Addit. Manuf. 2020, 33, 101116. [Google Scholar] [CrossRef]

- Panesar, A.; Abdi, M.; Hickman, D.; Ashcroft, I. Strategies for functionally graded lattice structures derived using topology optimisation for Additive Manufacturing. Addit. Manuf. 2018, 19, 81–94. [Google Scholar] [CrossRef]

- Haertel, J.H.; Nellis, G.F. A fully developed flow thermofluid model for topology optimization of 3D-printed air-cooled heat exchangers. Appl. Therm. Eng. 2017, 119, 10–24. [Google Scholar] [CrossRef] [Green Version]

- Awd, M.; Tenkamp, J.; Hirtler, M.; Siddique, S.; Bambach, M.; Walther, F. Comparison of Microstructure and Mechanical Properties of Scalmalloy® Produced by Selective Laser Melting and Laser Metal Deposition. Materials 2018, 11, 17. [Google Scholar] [CrossRef] [Green Version]

- Gokuldoss, P.K.; Kolla, S.; Eckert, J. Additive Manufacturing Processes: Selective Laser Melting, Electron Beam Melting and Binder Jetting—Selection Guidelines. Materials 2017, 10, 672. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Milad, S.Y.; Latifi Rostami, S.; Kolahdooz, A. Optimization of geometrical parameters in a specific composite lattice structure using neural networks and ABC algorithm. J. Mech. Sci. Technol. 2016, 30, 1763–1771. [Google Scholar]

- Chen, J.; Yang, R.; Ma, R.; Li, J. Design optimization of wind turbine tower with lattice-tubular hybrid structure using particle swarm algorithm. Struct. Des. Tall Spec. Build. 2016, 25, 743–758. [Google Scholar] [CrossRef]

- Bendsøe, M.P.; Kikuchi, N. Generating optimal topologies in structural design using a homogenization method. Comput. Methods Appl. Mech. Eng. 1988, 71, 197–224. [Google Scholar] [CrossRef]

- Bendsøe, M.P. Optimal shape design as a material distribution problem. Struct. Optim. 1989, 1, 193–202. [Google Scholar] [CrossRef]

- Sigmund, O. A 99 line topology optimization code written in Matlab. Struct. Multidiscip. Optim. 2014, 21, 120–127. [Google Scholar] [CrossRef]

- Plocher, J.; Panesar, A. Review on design and structural optimisation in additive manufacturing: Towards next-generation lightweight structures. Mater. Des. 2019, 183, 108164. [Google Scholar] [CrossRef]

- Daynes, S.; Feih, S.; Lu, W.F.; Wei, J. Design concepts for generating optimised lattice structures aligned with strain trajectories. Comput. Methods Appl. Mech. Eng. 2019, 354, 689–705. [Google Scholar] [CrossRef]

- Sethuraman, L.; Dykes, K. GeneratorSE: A Sizing Tool for Variable-Speed Wind Turbine Generators; Technical report NREL/TP -5000-66462; National Renewable Energy Laboratory: Golden, CO, USA, 2017. Available online: https://www.nrel.gov/docs/fy17osti/66462.pdf (accessed on 1 October 2020).

- nTopology. nTopology Introduces nTop Platform 2.0. Available online: https://ntopology.com (accessed on 12 September 2020).

- Smith, M. ABAQUS/Standard User’s Manual; Version 6.9; Dassault Systèmes Simulia Corp: Johnston, RI, USA, 2009. [Google Scholar]

- GE Additive. Arcam EBS Spectra L. 2020. Available online: https://www.ge.com/additive/additive-manufacturing/machines/arcam-ebm-spectra-l (accessed on 12 September 2020).

- GE Additive. GE Additive creates world’s largest laser-powder 3D printer. Met. Powder Rep. 2017, 72, 367. [Google Scholar] [CrossRef]

- Art Castings of Colorado. Rotor Casts ACC. 2020. Available online: https://www.artcastings.com (accessed on 12 September 2020).

- DZ Turner. Digital Image Correlation Engine (DICe) Reference Manual, Sandia Report; SAND2015-10606 O; U.S. Department of Energy: Washington, DC, USA, 2015.

- Hayes, A.C.; Sethuraman, L.; Fingersh, L.J.; Dykes, K. Additive Manufacturing: A New Paradigm for the Next Generation of High-Power-Density Direct-Drive Electric Generators. In Proceedings of the ASME Power Conference, Lake Buena Vista, FL, USA, 24 June 2018; Volume 2. [Google Scholar] [CrossRef] [Green Version]

- Sivarupan, T.; Upadhyay, M.; Ali, Y.; El Mansori, M.; Dargusch, M.S. Reduced consumption of materials and hazardous chemicals for energy efficient production of metal parts through 3D printing of sand molds. J. Clean. Prod. 2019, 224, 411–420. [Google Scholar] [CrossRef]

- Lamichhane, T.; Sethuraman, L.; Dalagan, A.; Wang, H.; Keller, J.; Paranthaman, M. Additive manufacturing of soft magnets for electrical machines—A review. Mater. Today Phys. 2020, 15, 100255. [Google Scholar] [CrossRef]

| AM Method | Possible Part Dimensions (m) | Cost ($) | Part Resolution (m) | Estimated Print Time (hrs) | Schwartz P Scaled Rotor Weight (mT) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.03 MW | 1 MW | 3 MW | 5 MW | 0.03 MW | 1 MW | 3 MW | 5 MW | ||||

| DMLS [39] | 0–0.5 | $$$ | 100 | 16 | — | — | — | 0.01 | 2.48 | 12.93 | 27.72 |

| Investment Casting Wax Printed Part [41] | 0–3 | $$ | 500 | 6 weeks | 6 weeks | — | — | ||||

| Powder Binder Jetting Sand Casting [44] | 3–10 | $ | 1000 | — | — | 80.9 | 105 | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hayes, A.C.; Whiting, G.L. Reducing the Structural Mass of Large Direct Drive Wind Turbine Generators through Triply Periodic Minimal Surfaces Enabled by Hybrid Additive Manufacturing. Clean Technol. 2021, 3, 227-242. https://0-doi-org.brum.beds.ac.uk/10.3390/cleantechnol3010013

Hayes AC, Whiting GL. Reducing the Structural Mass of Large Direct Drive Wind Turbine Generators through Triply Periodic Minimal Surfaces Enabled by Hybrid Additive Manufacturing. Clean Technologies. 2021; 3(1):227-242. https://0-doi-org.brum.beds.ac.uk/10.3390/cleantechnol3010013

Chicago/Turabian StyleHayes, Austin C., and Gregory L. Whiting. 2021. "Reducing the Structural Mass of Large Direct Drive Wind Turbine Generators through Triply Periodic Minimal Surfaces Enabled by Hybrid Additive Manufacturing" Clean Technologies 3, no. 1: 227-242. https://0-doi-org.brum.beds.ac.uk/10.3390/cleantechnol3010013