1. Introduction

According to Energy Information Administration (EIA) [

1], the USA oil and gas production from unconventional reservoirs, which have ultra-low permeability (nano-Darcy (nD) to micro-Darcy (µD)), have been considerably improved since 2007. Even though horizontal drilling and multistage-hydraulic fracturing are necessary to produce with economical rates from such reservoirs [

2,

3,

4,

5], the oil and gas production rates significantly decrease by 90% in the first two to three years of production [

5]. Despite implementing horizontal drilling and multi-stage hydraulic fracturing, unconventional hydrocarbon recovery factors are still low, with 10% in oil reservoirs and 25% in gas reservoirs [

5,

6]. Implementing hydraulic fracturing treatments requires a substantial amount of water, which puts additional stress on local water resources.

One of the USA’s most prominent shale plays is Marcellus, which has been drawing much attention over the last years, and it has become one of the hottest plays in the Appalachian Basin and the USA [

7]. It covers approximately 95,000 sq. miles of the Appalachian Basin [

7] across the US Eastern part. According to EIA [

7], the Marcellus formation is set under six states: Pennsylvania (35.35%), West Virginia (21.33%), New York (20.06%), Ohio (18.19%), Virginia (3.85%), and Maryland (1.09%). The Marcellus shale was deposited during Middle Devonian time in oxygen-inadequate marine environments, making the Marcellus an organic-rich shale formation. The Marcellus formation is well-known as shale gas formation. Additionally, it has 410.3 Trillion cubic feet (Tcf) and 55% of the total recoverable shale gas resources, which can be considered the most recoverable gas resources in the US. However, most of its resources (57%) are still undeveloped [

8].

Figure 1 shows the sweet spots and thermal maturity characteristics in the Marcellus play, wherein most of the play’s eastern area, dry gas wells are located, and liquid-rich wells are mainly in the Marcellus’ western area play. According to Higley, et al. [

9], the Marcellus formation can be geologically divided to six continuous assessment units. The Northern Interior Marcellus Shale Gas AU contains the highest estimated ultimate recovery per well (EUR) of (3.125 billion cubic feet of gas) while the Western Margin Marcellus Shale Gas AU contains the highest potential production area of 43,524 km

2 (10,755,000 acres).

The depth of the Marcellus formation varies between 1219 m and 2591 m (4000 ft and 8500 ft) and its thickness ranges from 15 m to 61 m (50 ft to 200 ft) [

7,

8,

10]. In general, shale formations are well-known for their heterogeneity. Shale properties vary from one zone to another. Typically, the Marcellus shale is black shale, but it may have some mixed-layer limestone and some pyrite depending on the location. The upper section of the Marcellus formation is mainly composed of mixed-layer of clay minerals (9–35%); the formation base is mainly composed of quartz (10–60%,), pyrite (5–13%), and feldspar (0–10%), while the lower section is composed of calcite (3–48%) and dolomite (0–10%) [

11,

12,

13,

14,

15]. However, some of the Marcellus shale rocks, especially the outcrop ones, could have lost their organic carbon substances due to the weathering process, where the color of the rocks turns from black to dark or light gray [

16]. The results of X-ray diffraction (XRD) tests conducted by Gupta and Mishra [

17] and Piane et al. [

18] revealed that Marcellus core samples contain 75% and 80–90% calcite, respectively. Additionally, Crandall, et al. [

19] scanned the Marcellus formation (Tippens 6HS Well) using a computerized tomography (CT) scanner and claimed that the Marcellus reservoir has several calcareous sections, calcite veins, and calcite clasts. They also demonstrated that the formation has more than 40% calcite in some sections. Moreover, the matrix pores in the Marcellus are poorly linked, creating gas trapped in shale that cannot easily move [

20]. Some of the Marcellus’s average general properties were estimated, such as depth (2057 m), thickness (38 m), porosity (8%), and Total Organic Content (TOC) (12% wt.) [

7]. The permeability varies between 10 nD and 10 µD [

8,

10].

Since 2007, oil and gas production from unconventional resources (extremely low permeability formations) started to significantly increase [

1]. Economical production from such resources requires drilling horizontally as well as implementing multistage hydraulic fracture treatments [

2,

3,

4,

5,

21,

22]. Wang et al. [

23] stated that more than 90% of gas wells and 70% of oil wells are hydraulically fractured worldwide. Hydrocarbon production rate decreases by 90% in the first 2–3 years even after applying horizontal drilling and multistage hydraulic fracturing [

5]. Additionally, even after conducting horizontal drilling and multistage fracturing, oil and gas recovery factors from unconventional resources are low (10% from oil resources and 25% from gas resources) [

5,

6].

The technique of cryogenic treatments requires injecting extremely cold fluids such as liquid nitrogen (LN

2) into a formation to create fractures in addition to connecting pre-existing fracture networks. Due to the instant difference in the temperatures, a rapid increase in the tensile stress occurs and as a result, new cracks are created [

24]. When injecting LN

2 into reservoirs, it vaporizes at a liquid-to-gas expansion ratio of 1:694 (at atmospheric pressure and 20 °C), which pressurizes the formation, propagates the fractures deeper, and connects pre-existing fractures networks [

25].

Several field studies have investigated the effects of cryogenic treatments on hydrocarbon production rates. McDaniel et al. [

26] stimulated one tight sandstone and four coalbed methane wells by safely injecting LN

2 (−196 to −147 °C) through free-hanging fiberglass pipes without any casing damage and as a result, they gained 43% of gas production increment. Grundmann et al. [

27] cryogenically treated a Devonian shale well in Knott, Kentucky, using LN

2, and as a result, hydrocarbon production improved by 8%. Rassenfoss [

28] reported that production from wells that were fractured using natural gas liquids (NGL) in Texas is 77% higher than hydraulically fractured wells.

Also, the thermal shock concept has been experimentally addressed using different samples including sandstone, granite, shale, and coal. Kim and Kemeny [

29] investigated the thermal shock efficacy on Quartzite, Granite, Diabase, and Cretaceous Volcanic Sediments. They rapidly cooled the core samples after heating them to 100 °C. They claimed that slow heating the core samples heals some of the pre-existing cracks while the rapid cooling creates new cracks inside the samples, which increases their porosity and decreases their compressional and shear velocities.

Cha et al. [

30] investigated the effects of implementing cryogenic treatments on sandstone and concrete blocks using CT scan and acoustic velocity measurements. Their results revealed that conducting cryogenic treatments created new cracks in the block samples that altered the acoustic velocities of the samples. Repeating the cryogenic treatments created more cracks and widened the pre-existing cracks. Additionally, cryogenic treatments resulted in the formation of invisible cracks in the sandstone sample that could be proven by the reduction of the acoustic velocities of the samples.

Alqatahni et al. [

31] applied cryogenic treatments on sandstone, shale, and concrete. They found that the effect of the cryogenic treatments is a function of treatment duration, fluid injection pressure, number of cycling, stress conditions, and rock properties. They also claimed that such treatments enhanced the permeability of the samples (pressure decay tests) and lowered the breakdown pressure of the samples by 40%, all of which are indications of crack creations. Also, Wang et al. [

22] cryogenically treated tight sandstone, Niobrara shale, and concrete samples using liquid nitrogen at an injection pressure of 3.10 MPa. As a result of the cryogenic treatments, the breakdown pressure significantly reduced while the permeability of the samples was enhanced.

Jiang et al. [

32] submerged shale samples from the Longmaxi formation, China, in liquid nitrogen for twenty minutes. Their results illustrated that the compressional velocity of the core samples reduced by up to 16%, the permeability improved by up to 74%, while the compressive strength decreased by up to 34%. Their results proved that cryogenic treatments caused the formation of new cracks inside the core samples.

Elwegaa et al. [

33] heated two samples (a gas shale formation and Eagle Ford formation) to 82 °C for 60 min. Then, they injected cold nitrogen (−18 °C) for 15 min at an injection pressure of 6.89 MPa. Their results showed the thermal shock technique created new fractures and propagated existing ones resulting in changes in the Young’s modulus and Poisson’s ratio of the samples. Khalil and Emadi [

34] investigated the cryogenic treatment effects on shale samples using liquid nitrogen. They stated that cryogenic treatments created new cracks in the core samples, which increased the porosity and permeability of the samples while it reduced the compressional and shear velocities of the core samples.

Yang et al. [

35] implemented fracturing experiments on tight sandstone samples using water, nitrogen (N

2), liquid carbon dioxide (L-CO

2), and supercritical carbon dioxide (SC-CO

2). Compared to water, they proved that CO

2-based fluids have stronger fracturing capacity and produce more complexity.

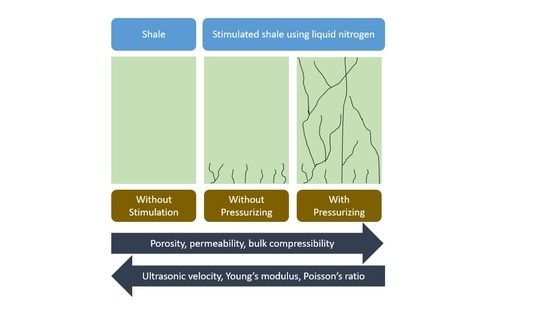

This comprehensive study investigates the effect of implementing and pressurizing cryogenic treatments on the physical (porosity and permeability) and mechanical properties (Young’s modulus, Poisson’s ratio, and bulk compressibility) of Marcellus core samples.

2. Materials and Methods

Ten core samples with a diameter of 3.81 cm and length of 5.08 cm from an outcrop Marcellus shale formation, cut parallel to the bedding, were used in this study. To assure flat edge core samples, the end-faces of all core samples were polished (capped), and the dimensions of the samples were measured using a digital caliper. After completing all the tests (porosity, permeability, and ultrasonic velocities), X-Ray Diffraction (XRD) tests were implemented on the samples to investigate their mineralogical compositions. The technique of computed tomography (CT) scanning is a medical non-destructive diagnostic imaging process that applies X-ray technology as well as mathematical reconstruction algorithms to show cross-sectional images of core samples. More than 20 years ago, the oil and gas industry started to use the CT scan technique [

36]. CT-images can be an excellent method to demonstrate fractures inside samples [

37]. In this research, a CT-scanner was used to detect cracks inside the core samples before and after conducting cryogenic treatments. It has a 7-mA current and 140 kV voltage. A full rotation of the CT scan imaging takes six seconds, which produces eight slices of 1.25 mm spacing between the slices.

Because the pore throats of shale core samples are very tight, implementing the methods of the conventional porosity measurement might lead to erroneous results. Khalil et al. [

38] experimentally investigated the effect of injection pressure on porosity measurements of shale core samples using helium at injection pressures of 0.69, 1.38, 2.07, and 2.76 MPa. They claimed that 1.38 MPa is the optimal injection pressure to measure the porosity of shale core samples without damaging the samples, and increasing the pressure above that does not promise significant changes in the porosity measurements. Hence, the porosities of the core samples were measured using helium at an injection pressure of 1.38 MPa.

Another important parameter to evaluate the efficacy of cryogenic treatments on the core samples is permeability, which was measured using New England Research (NER) AutoLab 1500. NER developed a pressure decay method (complex transient method) to measure the extremely low permeability of unconventional core samples. Rapidly applying confining pressure may create new cracks inside the samples. To avoid crack forming, several researchers recommend applying confining pressure at rates of 0.05 to 0.1 MPa/s [

39,

40,

41,

42,

43,

44]. A rate of 0.017 MPa/s was used in this research to reach 5.17 MPa confining pressure. After that, using helium, a pore pressure of 1.73 MPa was applied into the samples until the downstream and upstream sides reached a pressure equilibrium (up to 48 h), which is a function of the permeability of the core samples. The pore pressure reduced by 0.86 MPa and stayed constant for eight minutes, then it elevated to 2.59 MPa and stayed for another eight minutes, and finally, it went back to 1.73 MPa. The permeability of the core samples was calculated based on the pressure responses of the downstream.

Additionally, NER AutoLab 1500 was used to measure the ultrasonic velocity of the core samples at two confining pressure cycles. At the ramp-up cycle (first cycle), an increment of 5.17 MPa confining pressures increased from 5.17 MPa to the Marcellus average reservoir pressure of 29.33 MPa. The same confining pressures were used, but in the opposite direction at the ramp-down cycle (second cycle). At each confining pressure, one compressional wave and two orthogonally shear waves were captured. By determining the arrival time of each wave, the compressional and shear velocities of the core samples can be calculated. The Young’s modulus and Poisson’s ratio can be calculated using Equations (1) and (2) [

45,

46,

47,

48,

49].

where

is the dynamic Young’s modulus in Pascal,

is the rock density in kg/m

3,

is the shear velocity in m/s,

is the compressional velocity in m/s, and

is the dynamic Poisson’s ratio (dimensionless). Moreover, the core samples bulk compressibility (

), which is the change in the core samples bulk volume due to applying confining pressure, can be calculated using Equation (3).

Figure 2 illustrates the setup of the cryogenic treatment that contains a Vertical Gas-Liquid Cylinder (VGL) to inject LN

2 at 0.14 MPa, a nitrogen gas cylinder to pressurize the samples, a regulator to control the gas injection pressure, a core holder to contain the samples, a laboratory oven to apply the Marcellus average reservoir temperature of 66 °C, a cryogenic pressure transducer to record the core holder pressure, a T-type thermocouple to record the core holder temperature, pressure and temperature meters to record the pressure and temperature during the tests, cryogenic valves to open and close the setup, and relief-valves to relieve any extra pressure in the setup. All fittings, valves, tubing, thermocouples, and pressure transducers were capable to withstand cryogenic temperature (−177 °C) for safety purposes. It is worth noting that the maximum safe injection pressure that could be applied to the setup was 4.14 MPa due to the pressure limitation of the cryogenic pressure transducer.

Polytetrafluoroethylene (PTFE) Teflon (heat-shrinking sleeve) was applied on ten Marcellus core samples to prevent the samples from breaking apart during cryogenic treatments and to avoid oil contaminations during permeability and velocity tests. The temperature operating range of PTFE sleeves is between 260 °C and −270 °C. After heating the core samples to 66 °C, the average reservoir temperature, sixty cubic centimeters of LN

2 (as low as −177 °C) were injected into the setup including the core samples, thermal shock process, at 0.14 MPa. Then, using nitrogen, nine samples were pressurized at 1.38, 2.76, and 4.14 MPa (each pressure was applied on three core samples) while the tenth was not pressurized at all. During each cryogenic treatment, the temperature and pressure of the setup were recorded using a T-type thermocouple and a cryogenic pressure transducer.

Figure 3 demonstrates the real-time pressure and temperature responses at the 4.14 MPa injection pressure. When LN

2 was injected into the setup, the temperature rapidly decreased to −177 °C. Within 138 min, the setup temperature increased again to 66 °C using the laboratory oven, and as a result, the pressure was supposed to increase as well. However, the pressure was approximately maintained at injection pressures of 1.38, 2.76, and 4.14 MPa by automatically opening the cryogenic pressure-relief valves.

3. Results and Discussion

The core samples mineralogical compositions were determined using X-ray diffraction (XRD) tests.

Figure 4 shows the average core samples mineralogical compositions as 69.8% calcite, 28.5% quartz, 1.2% dolomite, and 0.5% pyrite. The XRD test did not demonstrate any response at a diffraction angle lower than 20°2θ (

Figure 5) revealing the absence of clay minerals. Since the samples were from the outcrop, the clay minerals had been most likely weathered away.

Injecting cryogenic fluids into the core samples creates time-dependent tensile stress due to the thermal stress [

49] that results in crack initiation inside the samples [

24,

27]. Then, the temperature of the cryogenic fluids starts to increase when contacting the warm core samples, which turns these fluids into a gaseous phase with an expansion ratio of 1:694 [

31]. This expansion increases the pressure, and as a result, the cracks propagate deeper into the samples.

Regardless of the magnitude of the cryogenic treatment pressure, the CT-scan and ultrasonic measurement results demonstrated that conducting such treatments on the samples resulted in the forming of new cracks in every core sample.

Figure 6 shows CT scan images of the sample M6 parallel to the sample beddings prior to and after implementing the cryogenic treatment. The top part of

Figure 6B shows a fracture that did not exist before the treatment. Also,

Figure 7A shows CT scan images of the sample M20 that is perpendicular to the bedding before the cryogenic treatment while

Figure 7B shows a CT-scan image after the treatment depicting the existence of a crack. Additionally, the core samples were wiped with toluene to better observe the fractures. Whenever a sample has a fracture, the toluene on the fracture face evaporated lastly, showing the fracture shape (

Figure 8). One core sample (M12), cryogenically treated at 4.14 MPa, was fractured into two halves (

Figure 9).

As previously shown, conducting cryogenic treatments on the samples resulted in the formation of new fractures inside the samples leading to porosity and permeability enhancements.

Figure 10 and

Figure 11 demonstrate a direct relationship between the magnitude of the cryogenic treatment pressurizing and the enhancement of the core samples porosity and permeability. Implementing the cryogenic treatment results in applying high tensile strength on the core samples leading to the initiation of new fractures inside the samples. Then, liquid nitrogen rapidly heats up and turns to a gaseous phase, which increases the pressure inside the created cracks, and as a result, the cracks propagate deeper inside the sample. Hence, increasing the cryogenic treatment pressure results in longer and deeper cracks inside the core samples.

Table 1 demonstrates that the average initial porosities of the sample groups A, B, C, and D were 13.71%, 8.88%, 9.64%, and 8.04%, respectively, and the core samples initial permeabilities were 49.50, 12.93, 13.41, and 9.37 nano-Darcy (nD), respectively. As a result of forming new cracks in the samples due to the cryogenic treatment implementation, the results revealed that the core samples gained extra pore volume of 0.42%, 2.22%, 3.03%, and 4.00% when the samples were cryogenically treated at 0.14, 1.38, 2.76, and 4.14 MPa, respectively. The initial permeability of the core samples is matrix permeability because the CT scan results did not detect any fracture inside the samples and the initial permeability of the core samples was very low (15.7 nD). However, conducting cryogenic treatments on the samples formed new cracks providing new permeable channels inside the core samples and as a result, helium travels fast resulting in significant permeability increments of 21, 439, 1315, and 14,030 folds of increase over the initial permeability at the treatment pressures of 0.14, 1.38, 2.76, and 4.14 MPa, respectively.

It is worth noting that the volumes of the created fractures were significantly smaller than the core samples bulk volume. Hence, the porosity enhancement was not nearly as noticeable as the permeability enhancement. The permeabilities of the core samples after implementing the cryogenic treatments were substantially higher than the initial permeability. Most likely, the permeability of the core samples after conducting such treatments represents the fracture permeability.

Increasing the confining pressure on the core samples increases the compressional and shear velocities [

50,

51] due to compaction on the core samples and the reduction of the pore volume in the samples.

Figure 12 and

Figure 13 illustrate a direct relationship between the confining pressure and both the compressional and shear velocities. Since ultrasonic velocity travels faster through the matrix and slower through pore spaces, the creation of new cracks must result in reductions in such velocities (at the same testing conditions). The results revealed that pressurizing the samples at higher injection pressure after implementing cryogenic treatments caused greater reductions in compressional and shear velocities verifying the forming of new cracks inside the samples. The alterations in the compressional and shear velocities are much lower than the permeability alteration because the extra pore volume due to the crack creation is small comparing to the bulk volume of the core samples, while it significantly affected the results of the core samples permeability.

Figure 12,

Figure 13,

Figure 14 and

Figure 15 demonstrate that conducting cryogenic treatments at 0.14, 1.38, 2.76, and 4.14 MPa caused a reduction in core samples compressional velocities by 0.38%, 0.56%, 0.75%, and 0.95%, while it decreased the shear velocities by 0.36%, 0.66%, 0.70%, and 0.75%, respectively. It is worth noting that the highest decreases in the velocities were observed at the highest treatment pressure (4.14 MPa) owing to the creation of longer and wider cracks leading to the highest porosity and permeability enhancements.

The mechanical properties of the samples are functions of the compressional and shear velocities as shown in Equations (1)–(3). Thus, changes in ultrasonic velocities cause changes in the core samples dynamic mechanical properties (Young’s modulus, Poisson’s ratio, and bulk compressibility). Additionally, the results demonstrated that conducting cryogenic treatments on the samples reduces both Young’s modulus and Poisson’s ratio.

There were small reductions in the compressional (0.95%) and shear velocities (0.75%) after conducting the cryogenic treatment since the volume of the created fractures were significantly smaller than the core samples bulk volume. As a result of the reductions in ultrasonic velocities, the Young’s modulus and Poisson’s ratio got altered.

Figure 16 and

Figure 18 illustrate that implementing cryogenic treatments at injection pressures of 0.14, 1.38, 2.76, and 4.14 MPa reduced the core samples Young’s modulus by 0.73%, 1.25%, 1.41%, and 1.60%, respectively. The results of Poisson’s ratio were sensitive to the magnitude of the change in both compressional and shear velocities. Since dynamic Poisson’s ratio is a function of measured compressional and shear velocities (Equation ((2)), any change in the compressional and shear velocities results in a change in Poisson’s ratio as well. If the changes in the velocities are close, the change in Poisson’s ratio is insignificant. Otherwise, depending on which change is dominant, Poisson’s ratio may increase or decrease.

Figure 17 and

Figure 19 demonstrate that the Poisson’s ratio increased by 0.37% at the treatment pressure of 1.38 MPa, it dropped by 0.51% at the treatment pressure of 4.14 MPa, and there was an insignificant reduction (0.04% and 0.03%) at treatment pressures of 0.14 and 2.76 MPa.

The bulk compressibility of the samples represents the change in the bulk volume due to the increase in the applied pressure on the core samples (Equation (3)).

Figure 20 illustrates that increasing the confining pressure reduced the core samples bulk compressibility due to the reduction of the pore volume resulting from squeezing the pore spaces. The results also revealed that conducting cryogenic treatments on the samples increased the core samples bulk compressibility due to the creation of the new cracks inside the samples.

Figure 21 demonstrates that the core samples bulk compressibility improved by 0.78%, 1.04%, 1.83%, and 2.33% when they were stimulated at pressures of 0.14, 1.38, 2.76, and 4.14 MPa, respectively. It is worth noting that the highest increase in the bulk compressibility transpired at 4.14 MPa treatment pressure at which the longest and widest cracks were created.

4. Conclusions

This is one of the first research efforts that investigated the efficacy of pressurizing cryogenic treatments on the core samples porosity, permeability, and mechanical properties of shale core samples (Marcellus formation). Ten core samples have been cryogenically treated in this study. The cryogenic treatment comprised of two parts: thermal shock (injecting LN2) and pressurizing the injected LN2 with N2. The thermal shock technique was applied on one core sample (M4) at the LN2 injection of approximately 0.14 MPa (without pressurizing it), while the other nine core samples were thermally shocked using LN2, and then pressurized with N2 at 1.38, 2.76, and 4.14 MPa (three core samples at each pressure).

The results of the CT-scan, porosity, permeability, and bulk compressibility of the samples proved that fractures were formed in all core samples. The results revealed that conducting the cryogenic treatment on the samples (without pressurizing) increased the porosity and bulk compressibility of the samples by 0.42% and 0.78%, respectively, while the permeability increased by 21 folds over the initial (matrix) permeability. Also, the results illustrated that increasing the cryogenic treatment pressure caused a further increase in the mentioned properties owing to the creation of longer and wider cracks. At 4.14 MPa injection pressure, for example, the porosity and bulk compressibility increased by 4.00% and 2.33%, respectively, and the permeability increased by 14,030 folds of increase over the initial (matrix) permeability.

The compressional and shear velocities have an inverse relationship with the success of cryogenic treatments. Implementing the cryogenic treatment without pressurizing resulted in decreasing the compressional and shear velocities by 0.38 and 0.36%, respectively. Furthermore, when LN2 was injected and then pressurized, the reductions in the compressional and shear velocities were 0.95% and 0.75%, respectively. Like the ultrasonic velocities, Young’s modulus of the core sample decreased after completing the cryogenic treatment.