Thermo-Economic Evaluation of Aqua-Ammonia Solar Absorption Air Conditioning System Integrated with Various Collector Types

Abstract

:1. Introduction

- ✓

- NH3-H2O absorption cycles have been studied under different operating conditions. The selection was made based on the best-operating conditions.

- ✓

- Two different types of solar collectors (ETC and PTC) have been compared while combining them with absorption cycles.

- ✓

- A detailed mathematical model has been performed.

- ✓

- The comparison is performed based on the terms of energy, exergy, design, cost, and thermo-economic. The design technique of modeling has been adopted in this study.

- ✓

- Based on the optimized selection, a case study for 700–800 kW (200–230 TR) cooling load has been performed.

2. Thermal Solar Cooling System Description

- ➢

- Evacuated tube collector (ETC) and/or parabolic trough collector (PTC) for thermal power generation. Water working fluid is the main fluid through the solar part.

- ➢

- A Flash evaporation tank is used to separate steam at lower pressure. This is a vertical flash vessel, with the inlet of high-pressure high-temperature water located at about one-third of the way up to its height. The standard design of flash vessels requires that the diameter of the vessel is chosen so that the steam flows toward the top outlet connection at no more than about 3 m/s. This should ensure that any water droplets could fall through the steam in a contra-flow, to the bottom of the vessel. Adequate height above the inlet is necessary to ensure separation. The separation is also facilitated by having the inlet projecting downward into the vessel. The water connection is sized to minimize the pressure drop from the vessel to the pump inlet to avoid cavitation.

- ➢

- The pumping unit has been used for flow circulation and pressure drop issues.

- ➢

- In the evaporator, low-pressure liquid-vapor mixture refrigerant pure ammonia (NH3), evaporates on the outer surface of the evaporator’s tube bundle. Heat is supplied to the evaporator by water flowing inside the evaporator’s tubes; this chilled water is subsequently used for refrigeration. The refrigerant vapor leaving the evaporator as saturated vapor enters the absorber at low-temperature and low-pressure conditions.

- ➢

- In the absorber, The refrigerant vapor is then absorbed and dissolved by the weak ammonia–water (NH3-H2O) solution coming from the generator. It is worth mentioning that the weak solution is the solution with less amount of refrigerant, i.e., highly concentrated by water. The heat liberated during the absorption process is removed by using cooling water flowing inside the tubes.

- ➢

- The solution pump receives a strong NH3-H2O solution and delivers it at high pressure to the generator via the solution heat exchanger. Note that the solution is a saturated liquid and hence the pump work is very small.

- ➢

- In the generator, the high-pressure solution entering the generator is heated and the ammonia in the solution is vaporized. The heat for this process could be provided by solar energy or a gas burner. The remaining weak NH3-H2O solution exits via the heat exchanger to the absorber through a pressure-reducing solution valve.

- ➢

- A solution heat exchanger (SHX) is included here; as the solution after the pump requires heating and the hot solution leaves the generator would increase the absorber temperature if it were not cooled before entry.

- ➢

- In the condenser, the high-pressure, high-temperature refrigerant vapor leaving the generator is passed to the condenser where it is cooled by cooling water. The refrigerant saturated vapor is condensed to a liquid. This liquid is then flowed through an expansion refrigerant valve and to the evaporator.

3. Methodology, Assumptions and Mathematical Model

3.1. Thermodynamic Model

- (1)

- The system runs in a steady-state condition.

- (2)

- Heat losses to the surroundings are neglected.

3.1.1. ETC Model

3.1.2. PTC Model

3.1.3. Flashing Tank

3.1.4. Pump

3.1.5. Mathmatical Model of the Absorption Cycle

- (1)

- Refrigerant leaving the evaporator is saturated ammonia vapor.

- (2)

- Refrigerant leaving the condenser is saturated ammonia liquid.

- (3)

- No liquid carry over from evaporator.

- (4)

- Refrigerant vapor leaving the generator has the equilibrium temperatures of the weak solution of the generator’s pressure and is salt free.

- (5)

- The solutions leaving the generator and absorber are saturated.

- (6)

- The pumping process is isentropic.

Absorber

Solution Heat Exchanger SHX

Generator

Condenser

Evaporator

3.1.5. Availability, Cost, and Performance

4. Results and Comments

4.1. Optimization of NH3-H2O Cycle

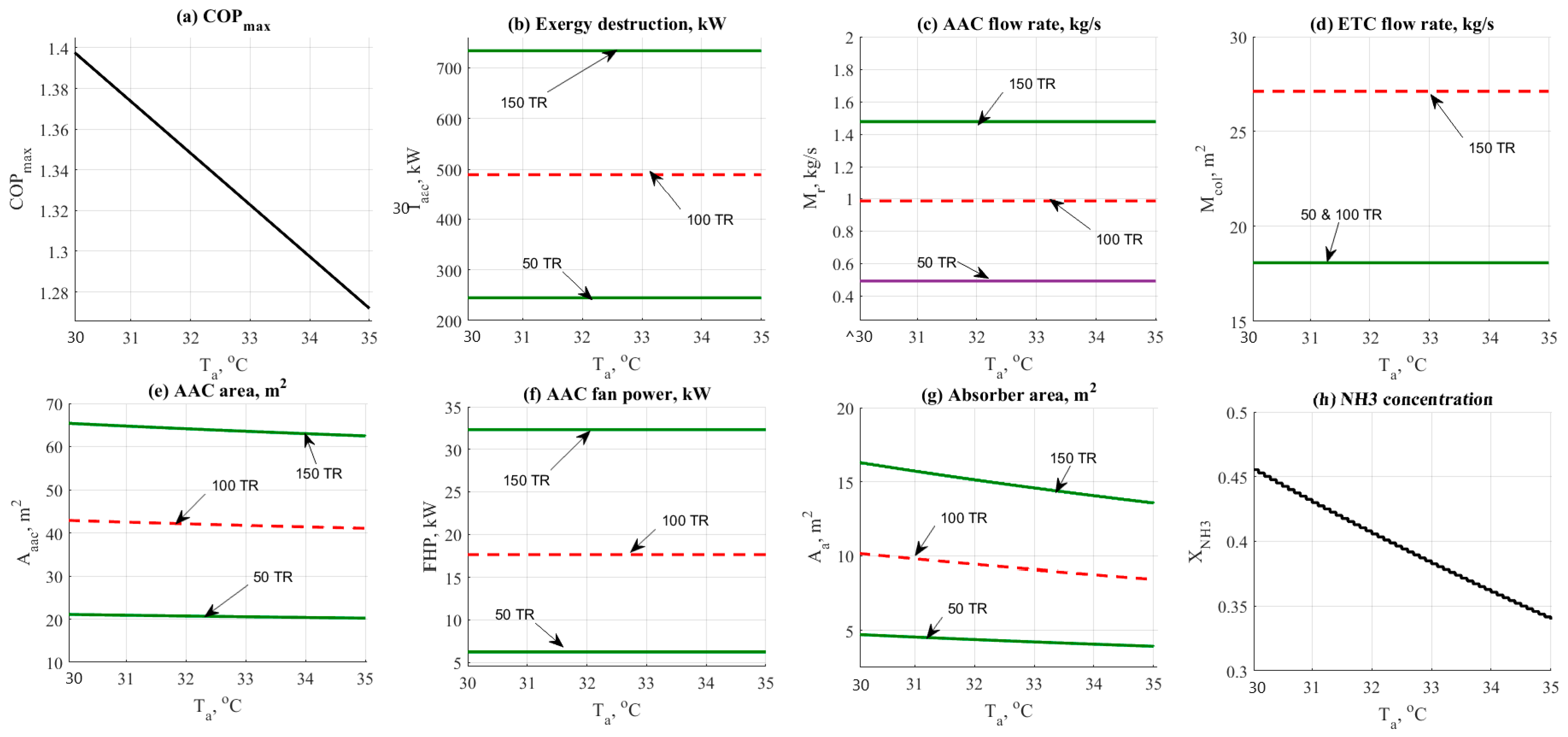

4.1.1. Absorber Temperature Effect

4.1.2. Condenser Temperature Effect

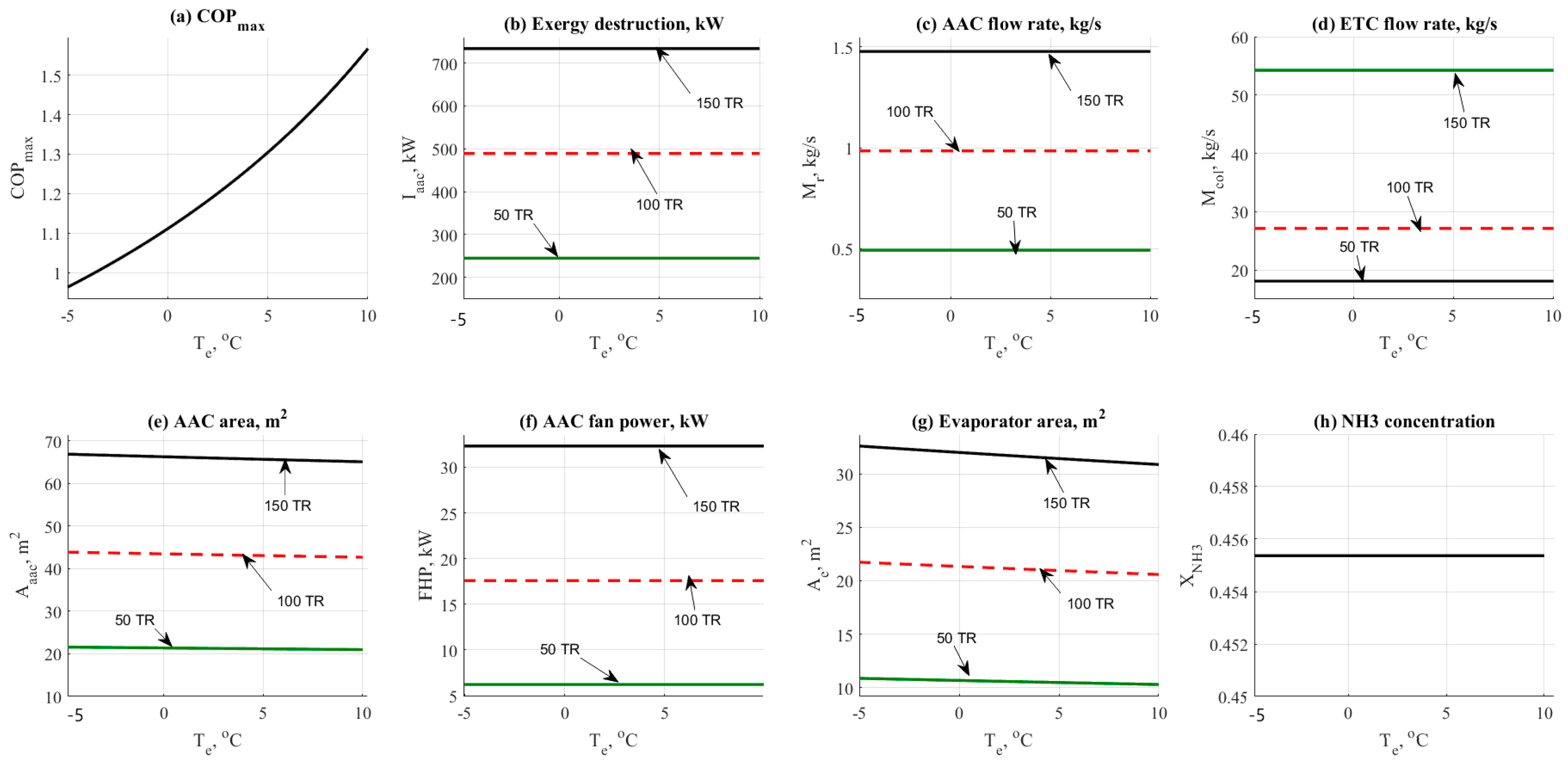

4.1.3. Evaporator Temperature Effect

4.1.4. Generator Temperature Effect

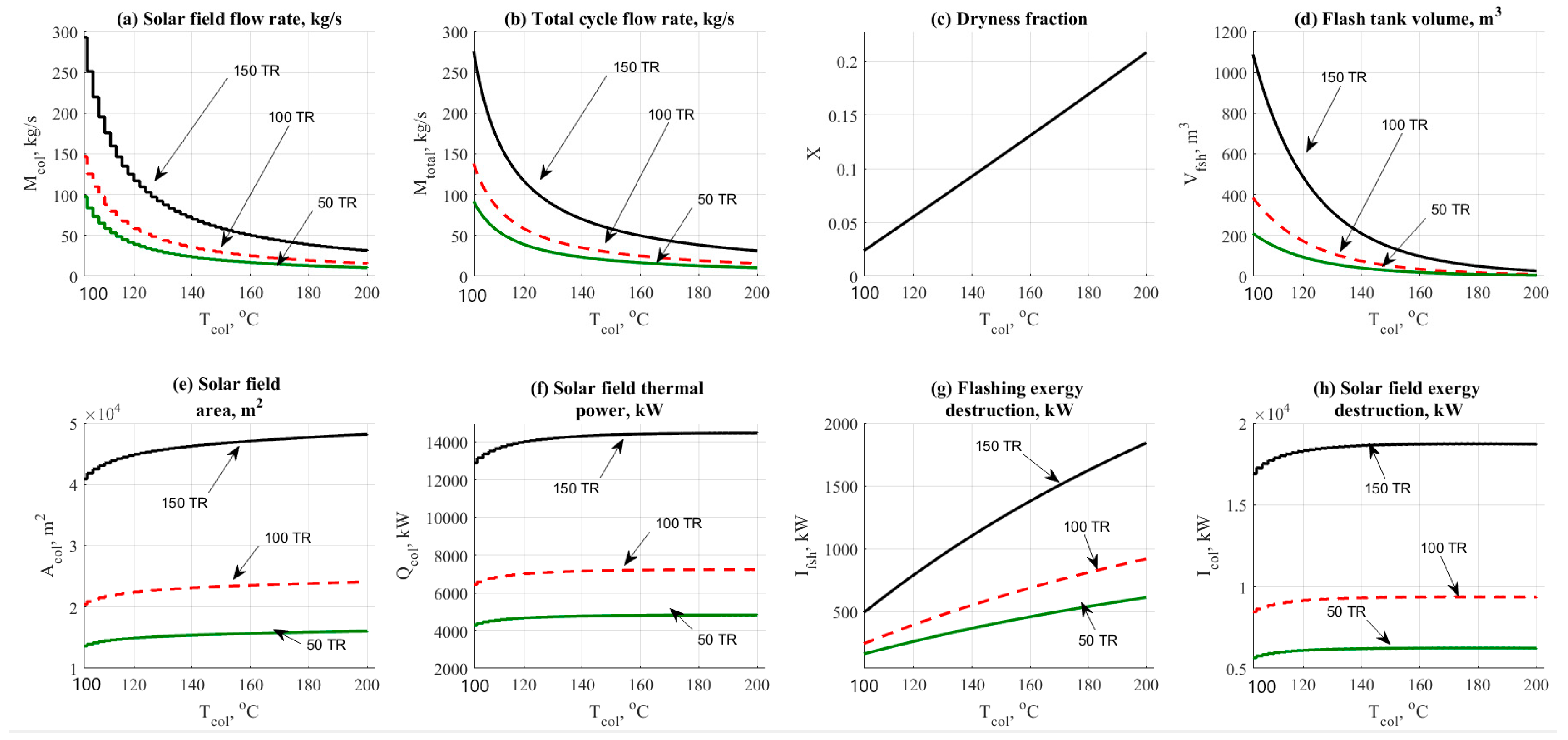

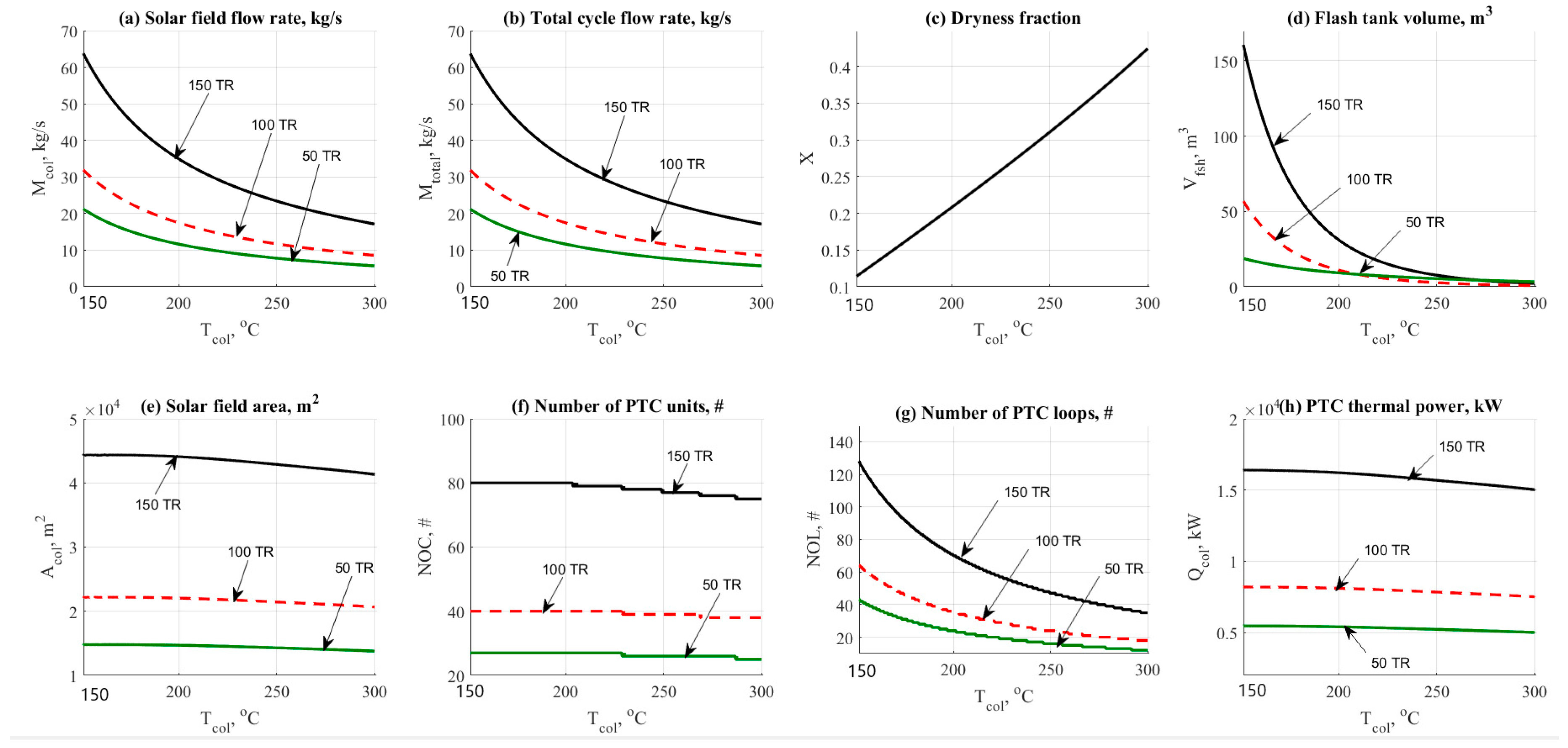

4.1.5. Solar Field Top Temperature Effect

- ➢

- Ta = 35 °C.

- ➢

- Tc = 43 °C.

- ➢

- Te = 7~10 °C.

- ➢

- Tg = 85~90 °C.

- ➢

- ETC Thigh = 150~200 °C.

- ➢

- PTC Thigh = 250~300 °C.

4.1.6. Cooling Load Effect

4.2. Case Study Results

5. Conclusions

- ▪

- Design aspects, such as solar area and flashing tank volume were found to have a great influence on the cycle cost.

- ▪

- Increasing the cooling load increases the required solar field area and the flow rate of the heat transfer fluid.

- ▪

- Optimization of the operating conditions, such as temperatures, has been performed for two configurations. The following values of operating conditions are considered the best, related to design aspects, COP, exergy destruction rate, and cost:

- ○

- Ta = 35 °C.

- ○

- Tc = 43 °C.

- ○

- Te = 7~10 °C.

- ○

- Tg = 85~90 °C.

- ○

- ETC Thigh = 150~200 °C.

- ○

- PTC Thigh = 250~300 °C.

- ▪

- A case study is presented in a sports arena located in Baghdad, Iraq, for which the needed cooling load was in the range of 700 to 800 kW. PTC/NH3-H2O was recorded the best based on design and hourly costs. The required solar area was in the range of 2000–2500 m2. While the total hourly costs were in the range of USD 11.3–12.6/h which is quite attractive.

- ▪

- PTC/NH3-H2O gives the lowest values related to exergy destruction rates for all units. As expected, the solar filed would harvest a larger amount of exergy destruction rates for two configurations due to the large area and mass flow rate effect. The PTC/NH3-H2O exergy destruction rate results are in the range of 4600–5000 kW.

- ▪

- PTC/NH3-H2O gives the lowest value of flashing tank design aspects such as width, 1.343 m, height, 2.743 m, and volume, 3.883 m3. ETC/NH3-H2O comes next with a total flashing tank equal to ~7.276 m3.

- ▪

- It is quite clear that PTC/NH3-H2O followed by ETC/NH3-H2O have a remarkable result according to the terms of energy, design, and cost. Generally, the PTC system is considered the best choice for the NH3-H2O solar cooling system.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| A | Availability, kW, Area, m2 |

| At | Tube cross-sectional area, m2 |

| Af | Amortization factor, 1/y |

| AAC | Absorption Air Conditioning |

| C | Thermo-economic cost stream, USD/kJ |

| Cp | Specific heat capacity, kJ/kg °C @ constant pressure |

| COP | Coefficient of Performance |

| D | Diameter, m |

| Denv | Collector glass envelope diameter, m |

| E | Exergy stream, kW |

| ETC | Evacuated Tube Collector |

| f | Function |

| FHP | Fan power, kW |

| H, h | Height, m, Enthalpy, kJ/kg |

| Hdish | Dish parabola height, m |

| Is | Solar intensity, W/m2 |

| i | Interest rate, % |

| L | Length, m |

| Lm | Module length, m |

| LMT | Logarithmic Mean Temperature, °C |

| LPC | Levelized Power Cost, USD/kWh |

| LTp | Plant life time, y |

| M | Mass flow rate, kg/s |

| NOT | Number of Tubes |

| NOC | Number of Collectors |

| NOL | Number of Loops |

| P | Power, or Pressure, bar |

| ΔP | Pressure, bar |

| Q | Thermal power, kW |

| RPR | Relative Performance Ratio |

| Re | Raynold’s Number |

| S, s | Entropy, kJ/kg °C |

| SHX | Solution Heat Exchanger |

| T | Temperature, °C |

| U | Overall heat transfer coefficient, W/m2 °C |

| V, Vol | Volume, cm3 |

| v | Velocity, m/s |

| W | Power, Work, kW |

| Wc | Collector width, m |

| X | Concentration percentage, % |

| Z | Hourly cost, USD/h |

| Subscripts | |

| a, abs | Absorber |

| air | Air |

| amb | Ambient |

| a-hex | From absorber to heat exchanger stream |

| c | Condenser |

| c-evp | From condenser to evaporator stream |

| col | Collector |

| cw | Cooling water |

| e | Evaporator |

| etc | Evacuated tube collector |

| e-abs | From evaporator to absorber stream |

| f | Liquid phase |

| fan | Fan |

| fsh | Flashing tank |

| fst | Flashing steam |

| g | Generator, vapor phase |

| g-hex | From generator to heat exchanger stream |

| i | Inlet |

| loop | Loop |

| o | Out |

| p | Pump |

| ptc | Parabolic trough collector |

| pi,o | Pump inlet and outlet |

| q | Heat |

| r | Refrigerant |

| s | Steam |

| st | Steam |

| str | Strong |

| t | Turbine, total |

| w | Water |

| wk | Weak solution |

| Greek | |

| η | Efficiency, % |

| ρ | Density, kg/m3 |

| µ | Dynamic viscosity, Pa.s |

References

- Zeyghami, M.; Goswami, D.Y.; Stefanakos, E. A review of solar thermo-mechanical refrigeration and cooling methods. Renew. Sustain. Energy Rev. 2015, 51, 1428–1445. [Google Scholar] [CrossRef]

- Hassan, H.; Mohamad, A. A review on solar-powered closed physisorption cooling systems. Renew. Sustain. Energy Rev. 2012, 16, 2516–2538. [Google Scholar] [CrossRef]

- Baniyounes, A.M.; Ghadi, Y.Y.; Rasul, M.G.; Khan, M.M.K. An overview of solar assisted air conditioning in Queensland’s sub-tropical regions, Australia. Renew. Sustain. Energy Rev. 2013, 26, 781–804. [Google Scholar] [CrossRef]

- Al-Alili, A.; Hwang, Y.; Radermacher, R. Review of solar thermal air conditioning technologies. Int. J. Refrig. 2014, 39, 4–22. [Google Scholar] [CrossRef]

- Baniyounes, A.M.; Liu, G.; Rasul, M.; Khan, M. Comparison study of solar cooling technologies for an institutional building in subtropical Queensland, Australia. Renew. Sustain. Energy Rev. 2013, 23, 421–430. [Google Scholar] [CrossRef]

- Kurem, E.; Horuz, I. A comparison between ammonia-water and water-lithium bromide solutions in absorption heat transformers. Int. Commun. Heat Mass Transf. 2001, 28, 427–438. [Google Scholar] [CrossRef]

- Said, S.; Spindler, K.; El-Shaarawi, M.; Siddiqui, M.; Schmid, F.; Bierling, B.; Khan, M. Design, construction and operation of a solar powered ammonia–water absorption refrigeration system in Saudi Arabia. Int. J. Refrig. 2016, 62, 222–231. [Google Scholar] [CrossRef]

- Calise, F.; Libertini, L.; Vicidomini, M. Design and optimization of a novel solar cooling system for combined cycle power plants. J. Clean. Prod. 2017, 161, 1385–1403. [Google Scholar] [CrossRef]

- Neyer, D.; Ostheimer, M.; Hauer, N.; Halmdienst, C.; Pink, W. Application of an adapted single-/half-effect NH3/H2O absorption chiller in tri-generation and solar cooling systems. Sol. Energy 2018, 173, 715–727. [Google Scholar] [CrossRef]

- Aman, J.; Ting, D.-K.; Henshaw, P. Residential solar air conditioning: Energy and exergy analyses of an ammonia–water absorption cooling system. Appl. Therm. Eng. 2014, 62, 424–432. [Google Scholar] [CrossRef] [Green Version]

- Bellos, E.; Tzivanidis, C.; Antonopoulos, K.A. Exergetic, energetic and financial evaluation of a solar driven absorption cooling system with various collector types. Appl. Therm. Eng. 2016, 102, 749–759. [Google Scholar] [CrossRef]

- Fong, K.; Chow, T.; Lee, C.; Lin, Z.; Chan, L. Comparative study of different solar cooling systems for buildings in subtropical city. Sol. Energy 2010, 84, 227–244. [Google Scholar] [CrossRef]

- Al-Falahi, A.; Alobaid, F.; Epple, B. A New Design of an Integrated Solar Absorption Cooling System Driven by an Evacuated Tube Collector: A Case Study for Baghdad, Iraq. Appl. Sci. 2020, 10, 3622. [Google Scholar] [CrossRef]

- Galindo-Luna, Y.R.; Franco, W.R.G.; Carrasco, U.D.; Romero, R.; Jiménez-García, J.C. Integration of the Experimental Results of a Parabolic Trough Collector (PTC) Solar Plant to an Absorption Air-Conditioning System. Appl. Sci. 2018, 8, 2163. [Google Scholar] [CrossRef] [Green Version]

- Cabrera, F.; Fernández-García, A.; Silva, R.; Pérez-García, M. Use of parabolic trough solar collectors for solar refrigeration and air-conditioning applications. Renew. Sustain. Energy Rev. 2013, 20, 103–118. [Google Scholar] [CrossRef]

- Jakob, U.; Eicker, U.; Schneider, D.; Taki, A.; Cook, M. Simulation and experimental investigation into diffusion absorption cooling machines for air-conditioning applications. Appl. Therm. Eng. 2008, 28, 1138–1150. [Google Scholar] [CrossRef] [Green Version]

- Qu, M.; Yin, H.; Archer, D.H. A solar thermal cooling and heating system for a building: Experimental and model based performance analysis and design. Sol. Energy 2010, 84, 166–182. [Google Scholar] [CrossRef]

- Tzivanidis, C.; Bellos, E. The use of parabolic trough collectors for solar cooling–A case study for Athens climate. Case Stud. Therm. Eng. 2016, 8, 403–413. [Google Scholar] [CrossRef] [Green Version]

- Molero-Villar, N.; Cejudo-López, J.; Domínguez-Muñoz, F.; Carrillo-Andrés, A. A comparison of solar absorption system configurations. Sol. Energy 2012, 86, 242–252. [Google Scholar] [CrossRef]

- Said, S.A.; El-Shaarawi, M.A.; Siddiqui, M.U. Alternative designs for a 24-h operating solar-powered absorption refrigeration technology. Int. J. Refrig. 2012, 35, 1967–1977. [Google Scholar] [CrossRef]

- Abdelhay, A.; Fath, H.; Nada, S. Solar driven polygeneration system for power, desalination and cooling. Energy 2020, 198, 117341. [Google Scholar] [CrossRef]

- Leiva-Illanes, R.; Escobar, R.; Cardemil, J.M.; Alarcón-Padilla, D.-C. Comparison of the levelized cost and thermoeconomic methodologies–Cost allocation in a solar polygeneration plant to produce power, desalted water, cooling and process heat. Energy Convers. Manag. 2018, 168, 215–229. [Google Scholar] [CrossRef]

- Al-Falahi, A.; Alobaid, F.; Epple, B. Design and Thermo-Economic Comparisons of an Absorption Air Conditioning System Based on Parabolic Trough and Evacuated Tube Solar Collectors. Energies 2020, 13, 3198. [Google Scholar] [CrossRef]

- Salehi, S.; Yari, M.; Rosen, M. Exergoeconomic comparison of solar-assisted absorption heat pumps, solar heaters and gas boiler systems for district heating in Sarein Town, Iran. Appl. Therm. Eng. 2019, 153, 409–425. [Google Scholar] [CrossRef]

- Marc, O.; Sinama, F.; Praene, J.-P.; Lucas, F.; Castaing-Lasvignottes, J. Dynamic modeling and experimental validation elements of a 30 kW LiBr/H2O single effect absorption chiller for solar application. Appl. Therm. Eng. 2015, 90, 980–993. [Google Scholar] [CrossRef]

- Zhai, X.; Li, Y.; Cheng, X.; Wang, R. Experimental Investigation on a Solar-powered Absorption Radiant Cooling System. Energy Procedia 2015, 70, 552–559. [Google Scholar] [CrossRef] [Green Version]

- López-Villada, J.; Ayoua, D.S.; Bruno, J.C.; Coronas, A. Modelling, simulation and analysis of solar absorption power-cooling systems. Int. J. Refrig. 2014, 39, 125–136. [Google Scholar] [CrossRef]

- Available online: https://webbook.nist.gov/chemistry/name-ser/ (accessed on 3 February 2020).

- Vakiloroaya, V.; Ha, Q.; Skibniewski, M.J. Modeling and experimental validation of a solar-assisted direct expansion air conditioning system. Energy Build. 2013, 66, 524–536. [Google Scholar] [CrossRef] [Green Version]

- Carles Bruno, J.; Ló pez-Villada, J.; Letelier, E.; Romera, S.; Coronas, A. Modelling and Optimisation of Solar Organic Rankine Cycle Engines for Reverse Osmosis Desalination; Elsevier: Amsterdam, The Netherlands, 2008. [Google Scholar]

- Nafey, A.S.; Sharaf, M.A.; García-Rodríguez, L. A New Visual Library for Design and Simulation of Solar Desalination Systems (SDS); Elsevier: Amsterdam, The Netherlands, 2010. [Google Scholar]

- Eldean, M.A.S.; Soliman, A.M. A new visual library for modeling and simulation of renewable energy desalination systems (REDS). Desalin. Water Treat. 2013, 51, 6905–6920. [Google Scholar] [CrossRef]

- Singh, R.; Kumar, D.R. Theoritical Analysis of Nh3-H2o Refrigeration System Coupled with Diesel Engine: A Thermodynamic Study. IOSR J. Mech. Civ. Eng. 2014, 11, 29–36. [Google Scholar] [CrossRef]

- Vanderzee, E.C.; King, D.L. The enthalpies of solution and formation of ammonia. J. Chem. Thermodyn. 1972, 4, 675–683. [Google Scholar] [CrossRef]

- Ge, Y.; Tassou, S.; Chaer, I. Modelling and performance evaluation of a low-temperature ammonia-water absorption refrigeration system. Int. J. Low-Carbon Technol. 2009, 4, 68–77. [Google Scholar] [CrossRef] [Green Version]

- Shankar Ganesh, N.; Srinivas, T. Evaluation of thermodynamic properties of ammonia/water mixture up to 100bar for power application systems. J. Mech. Eng. Res. 2011, 3, 25–39. [Google Scholar]

- Li, K.W. Applied Thermodynamics: Availability Method and Energy Conversion; CRC Press: Boca Raton, FL, USA, 1995. [Google Scholar]

- Sharaf, M.A. Design and Simulation of Solar Desalination Systems. Ph.D. Thesis, Suez Canal University, Ismailia Governorate, Egypt, 2011. [Google Scholar]

- Sharaf, M.A.; Nafey, A.S.; García-Rodríguez, L. Author’s Personal Copy Thermo-Economic Analysis of Solar Thermal Power Cycles Assisted MED-VC (Multi Effect Distillation-Vapor Compression) Desalination Processes; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Sharaf, M.; Nafey, A.; Desalination, L.G.-R. Exergy and Thermo-Economic Analyses of A Combined Solar Organic Cycle with Multi Effect Distillation (MED) Desalination Process; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Castro, M.M.; Song, T.W.; Pinto, J.M. Minimization of operational costs in cooling water systems. Chem. Eng. Res. Des. 2000, 78, 192–201. [Google Scholar] [CrossRef]

| Unit Process | Assigned Data | Calculated Data |

|---|---|---|

| Absorption air-conditioning cycle (AAC): (ETC/PTC)/NH3-H2O |

| Solar Field:

|

| Notes: |

| |

| Solar radiation, W/m2 | 500 | |

| Tamb, °C | 25 | |

| Ta, Te, Tg, Tc, Tcol, °C | 30, 10, 90, 40, 175 | 30, 10, 90, 40, 250 |

| Load, TR | 200 | |

| Target cooled air, °C | 20 | |

| Interest rate, % | 5 | |

| Load factor, % | 95 | |

| Plant life time, yr | 20 | |

| Electric cost, $/kWh | 0.065 | |

| Fans efficiency, % | 80~85 | |

| Pumps efficiency, % | 75 | |

| Configuration: | ETC/NH3-H2O | PTC/NH3-H2O |

| Solar field: | ||

| Total solar field area, m2 | 1.188e4 | 1.102e4 |

| Solar thermal power, kW | 3612 | 4051 |

| Inlet temperature, °C | 91.82 | 92.04 |

| Mass flow rate, kg/s | 10.17 | 8.727 |

| Inlet exergy, kW | 5646 | 4217 |

| Exergy destruction, kW | 4683 | 5143 |

| Flash tank: | ||

| Height/Width, m | 3.381/1.655 | 2.743/1.343 |

| Volume, m3 | 7.276 | 3.883 |

| Total flow rate, kg/s | 10.17 | 8.727 |

| Water content, kg/s | 8.551 | 6.91 |

| Dryness fraction | 0.1595 | 0.208 |

| Exergy destruction, kW | 391.1 | 515.6 |

| AAC unit: | ||

| Qa, kW | 1251 | 1153 |

| Aa, m2 | 23.37 | 21.3 |

| Mstr, kg/s | 1.428 | 1.428 |

| Mwk, kg/s | 0.778 | 0.778 |

| Xhex-NH3 | 0.4554 | 0.4554 |

| Ahex, m2 | 7.837 | 6.73 |

| Qg, kW | 1407 | 1256 |

| Ag, m2 | 5.123 | 4.574 |

| Driving steam flow, kg/s | 2.07 | 1.848 |

| Qc, kW | 694.9 | 694.9 |

| Ac, m2 | 9.1 | 9.1 |

| Mr, kg/s | 0.6505 | 0.6505 |

| Qe, kW | 703.4 | 703.4 |

| Ae, m2 | 41.15 | 41.15 |

| FHP, kW | 70.64 | 70.64 |

| Mair, kg/s | 119.5~120 | 119.5~120 |

| COP/COPmax | 0.5/1.559 | 0.5/1.559 |

| RPR | 0.3206 | 0.3591 |

| Exergy destruction, kW | 1010 | 977.3 |

| Fan exergy destruction, kW | 164 | 164 |

| Pump unit: | ||

| Wp, kW | 12.63 | 18.97~19 |

| Exergy destruction, kW | 64.7 | 62.25 |

| Cost and Thermo-economics: | ||

| Zcol, USD/h | 11.75 | 10.93 |

| Zfsh, USD/h | 0.11 | 0.06 |

| Zaac, USD/h | 0.0487 | 0.04716 |

| Zp+f, USD/h | 0.256 | 0.2652 |

| Ztot, USD/h | 12.16 | 11.3 |

| LPC, USD/h | 0.089 | 0.0744 |

| cp, USD/GJ | 0.144 | 0.1554 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Falahi, A.; Alobaid, F.; Epple, B. Thermo-Economic Evaluation of Aqua-Ammonia Solar Absorption Air Conditioning System Integrated with Various Collector Types. Entropy 2020, 22, 1165. https://0-doi-org.brum.beds.ac.uk/10.3390/e22101165

Al-Falahi A, Alobaid F, Epple B. Thermo-Economic Evaluation of Aqua-Ammonia Solar Absorption Air Conditioning System Integrated with Various Collector Types. Entropy. 2020; 22(10):1165. https://0-doi-org.brum.beds.ac.uk/10.3390/e22101165

Chicago/Turabian StyleAl-Falahi, Adil, Falah Alobaid, and Bernd Epple. 2020. "Thermo-Economic Evaluation of Aqua-Ammonia Solar Absorption Air Conditioning System Integrated with Various Collector Types" Entropy 22, no. 10: 1165. https://0-doi-org.brum.beds.ac.uk/10.3390/e22101165