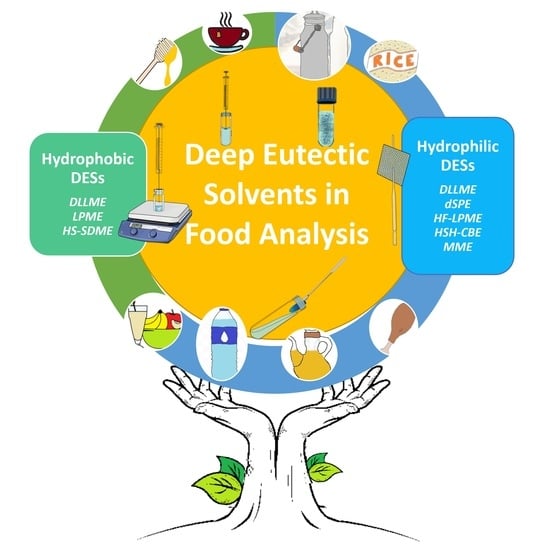

Deep Eutectic Solvents Application in Food Analysis

Abstract

:1. Introduction

2. Application of Hydrophilic Deep Eutectic Solvents

3. Applications of Hydrophobic Deep Eutectic Solvents

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Tang, W.; An, Y.; Row, K.H. Emerging applications of (micro) extraction phase from hydrophilic to hydrophobic deep eutectic solvents: Opportunities and trends. TrAC Trends Anal. Chem. 2021, 136, 116187. [Google Scholar] [CrossRef]

- Gałuszka, A.; Migaszewski, Z.; Namieśnik, J. The 12 principles of green analytical chemistry and the SIGNIFICANCE mnemonic of green analytical practices. TrAC Trends Anal. Chem. 2013, 50, 78–84. [Google Scholar] [CrossRef]

- Feng, J.; Loussala, H.M.; Han, S.; Ji, X.; Li, C.; Sun, M. Recent advances of ionic liquids in sample preparation. TrAC Trends Anal. Chem. 2020, 125, 115833. [Google Scholar] [CrossRef]

- Pacheco-Fernández, I.; Pino, V. Green solvents in analytical chemistry. Curr. Opin. Green Sustain. Chem. 2019, 18, 42–50. [Google Scholar] [CrossRef]

- Carasek, E.; Bernardi, G.; Morelli, D.; Merib, J. Sustainable green solvents for microextraction techniques: Recent developments and applications. J. Chromatogr. A 2021, 1640, 461944. [Google Scholar] [CrossRef] [PubMed]

- Shishov, A.; Pochivalov, A.; Nugbienyo, L.; Andruch, V.; Bulatov, A. Deep eutectic solvents are not only effective extractants. TrAC Trends Anal. Chem. 2020, 129, 115956. [Google Scholar] [CrossRef]

- Abbott, A.P.; Capper, G.; Davies, D.L.; Rasheed, R.K.; Tambyrajah, V. Novel solvent properties of choline chloride/urea mixtures. Chem. Commun. 2003, 1, 70–71. [Google Scholar] [CrossRef] [Green Version]

- Fernández, M.d.l.Á.; Boiteux, J.; Espino, M.; Gomez, F.J.V.; Silva, M.F. Natural deep eutectic solvents-mediated extractions: The way forward for sustainable analytical developments. Anal. Chim. Acta 2018, 1038, 1–10. [Google Scholar] [CrossRef]

- Smith, E.L.; Abbott, A.P.; Ryder, K.S. Deep eutectic solvents (DESs) and their applications. Chem. Rev. 2014, 114, 11060–11082. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Saha, S.K.; Dey, S.; Chakraborty, R. Effect of choline chloride-oxalic acid based deep eutectic solvent on the ultrasonic assisted extraction of polyphenols from Aegle marmelos. J. Mol. Liq. 2019, 287, 110956. [Google Scholar] [CrossRef]

- Habibi, E.; Ghanemi, K.; Fallah-Mehrjardi, M.; Dadolahi-Sohrab, A. A novel digestion method based on a choline chloride–oxalic acid deep eutectic solvent for determining Cu, Fe, and Zn in fish samples. Anal. Chim. Acta 2013, 762, 61–67. [Google Scholar] [CrossRef] [PubMed]

- Altunay, N.; Elik, A.; Gürkan, R. Innovative and practical deep eutectic solvent based vortex assisted microextraction procedure for separation and preconcentration of low levels of arsenic and antimony from sample matrix prior to analysis by hydride generation-atomic absorption spectrometry. Food Chem. 2019, 293, 378–386. [Google Scholar] [CrossRef]

- Karimi, M.; Dadfarnia, S.; Shabani, A.M.H.; Tamaddon, F.; Azadi, D. Deep eutectic liquid organic salt as a new solvent for liquid-phase microextraction and its application in ligandless extraction and preconcentration of lead and cadmium in edible oils. Talanta 2015, 144, 648–654. [Google Scholar] [CrossRef] [PubMed]

- Altunay, N.; Elik, A.; Gürkan, R. Natural deep eutectic solvent-based ultrasound-assisted-microextraction for extraction, pre-concentration and analysis of methylmercury and total mercury in fish and environmental waters by spectrophotometry. Food Addit. Contam. Part. A 2019, 36, 1079–1097. [Google Scholar] [CrossRef]

- Huang, Y.; Feng, F.; Chen, Z.-G.; Wu, T.; Wang, Z.-H. Green and efficient removal of cadmium from rice flour using natural deep eutectic solvents. Food Chem. 2018, 244, 260–265. [Google Scholar] [CrossRef]

- Altunay, N.; Elik, A.; Gürkan, R. A novel, green and safe ultrasound-assisted emulsification liquid phase microextraction based on alcohol-based deep eutectic solvent for determination of patulin in fruit juices by spectrophotometry. J. Food Compos. Anal. 2019, 82, 103256. [Google Scholar] [CrossRef]

- Fan, C.; Cao, X.; Han, T.; Pei, H.; Hu, G.; Wang, W.; Qian, C. Selective microextraction of polycyclic aromatic hydrocarbons using a hydrophobic deep eutectic solvent composed with an iron oxide-based nanoferrofluid. Microchim. Acta 2019, 186, 560. [Google Scholar] [CrossRef]

- Ortega-Zamora, C.; Jiménez-Skrzypek, G.; González-Sálamo, J.; Hernández-Borges, J. Extraction of phthalic acid esters from soft drinks and infusions by dispersive liquid-liquid microextraction based on the solidification of the floating organic drop using a menthol-based natural deep eutectic solvent. J. Chromatogr. A 2021, 1646, 462132. [Google Scholar] [CrossRef]

- Lee, J.; Jung, D.; Park, K. Hydrophobic deep eutectic solvents for the extraction of organic and inorganic analytes from aqueous environments. TrAC Trends Anal. Chem. 2019, 118, 853–868. [Google Scholar] [CrossRef]

- Liu, Y.; Friesen, J.B.; McAlpine, J.B.; Lankin, D.C.; Chen, S.-N.; Pauli, G.F. Natural deep eutectic solvents: Properties, applications, and perspectives. J. Nat. Prod. 2018, 81, 679–690. [Google Scholar] [CrossRef]

- Bajkacz, S.; Rusin, K.; Wolny, A.; Adamek, J.; Erfurt, K.; Chrobok, A. Highly efficient extraction procedures based on natural deep eutectic solvents or ionic liquids for determination of 20-hydroxyecdysone in spinach. Molecules 2020, 25, 4736. [Google Scholar] [CrossRef] [PubMed]

- Altunay, N.; Elik, A.; Gürkan, R. Preparation and application of alcohol based deep eutectic solvents for extraction of curcumin in food samples prior to its spectrophotometric determination. Food Chem. 2020, 310, 125933. [Google Scholar] [CrossRef] [PubMed]

- Sorouraddin, S.M.; Farajzadeh, M.A.; Okhravi, T. Application of deep eutectic solvent as a disperser in reversed-phase dispersive liquid-liquid microextraction for the extraction of Cd(II) and Zn(II) ions from oil samples. J. Food Compos. Anal. 2020, 93, 103590. [Google Scholar] [CrossRef]

- López, R.; D’Amato, R.; Trabalza-Marinucci, M.; Regni, L.; Proetti, P.; Maratta, A.; Cerutti, S.; Pacheco, P. Green and simple extraction of free seleno-amino acids from powdered and lyophilized milk samples with natural deep eutectic solvents. Food Chem. 2020, 326, 126965. [Google Scholar] [CrossRef]

- Doldolova, K.; Bener, M.; Lalikoğlu, M.; Aşçı, Y.S.; Arat, R.; Apak, R. Optimization and modeling of microwave-assisted extraction of curcumin and antioxidant compounds from turmeric by using natural deep eutectic solvents. Food Chem. 2021, 353, 129337. [Google Scholar] [CrossRef]

- Zounr, R.A.; Tuzen, M.; Khuhawar, M.Y. Determination of selenium and arsenic ions in edible mushroom samples by novel chloride–oxalic acid deep eutectic solvent extraction using graphite furnace-atomic absorption spectrometry. J. AOAC Int. 2018, 101, 593–600. [Google Scholar] [CrossRef] [PubMed]

- Panhwar, A.H.; Tuzen, M.; Kazi, T.G. Choline chloride-oxalic acid as a deep eutectic solvent-based innovative digestion method for the determination of selenium and arsenic in fish samples. J. AOAC Int. 2018, 101, 1183–1189. [Google Scholar] [CrossRef]

- Bağda, E.; Altundağ, H.; Soylak, M. Highly simple deep eutectic solvent extraction of manganese in vegetable samples prior to its ICP-OES analysis. Biol. Trace Elem. Res. 2017, 179, 334–339. [Google Scholar] [CrossRef]

- Bajkacz, S.; Adamek, J. Development of a method based on natural deep eutectic solvents for extraction of flavonoids from food samples. Food Anal. Methods 2018, 11, 1330–1344. [Google Scholar] [CrossRef] [Green Version]

- Huang, Y.; Feng, F.; Jiang, J.; Qiao, Y.; Wu, T.; Voglmeir, J.; Chen, Z.-G. Green and efficient extraction of rutin from tartary buckwheat hull by using natural deep eutectic solvents. Food Chem. 2017, 221, 1400–1405. [Google Scholar] [CrossRef]

- Guo, N.; Ping-Kou; Jiang, Y.-W.; Wang, L.-T.; Niu, L.-J.; Liu, Z.-M.; Fu, Y.-J. Natural deep eutectic solvents couple with integrative extraction technique as an effective approach for mulberry anthocyanin extraction. Food Chem. 2019, 296, 78–85. [Google Scholar] [CrossRef] [PubMed]

- Bajkacz, S.; Adamek, J. Evaluation of new natural deep eutectic solvents for the extraction of isoflavones from soy products. Talanta 2017, 168, 329–335. [Google Scholar] [CrossRef] [PubMed]

- Pradanas-González, F.; Álvarez-Rivera, G.; Benito-Peña, E.; Navarro-Villoslada, F.; Cifuentes, A.; Herrero, M.; Moreno-Bondi, M.C. Mycotoxin extraction from edible insects with natural deep eutectic solvents: A green alternative to conventional methods. J. Chromatogr. A 2021, 1648, 462180. [Google Scholar] [CrossRef] [PubMed]

- Aslan Türker, D.; Doğan, M. Application of deep eutectic solvents as a green and biodegradable media for extraction of anthocyanin from black carrots. LWT 2021, 138, 110775. [Google Scholar] [CrossRef]

- Paradiso, V.M.; Squeo, G.; Pasqualone, A.; Caponio, F.; Summo, C. An easy and green tool for olive oils labelling according to the contents of hydroxytyrosol and tyrosol derivatives: Extraction with a natural deep eutectic solvent and direct spectrophotometric analysis. Food Chem. 2019, 291, 1–6. [Google Scholar] [CrossRef]

- Zhao, Z.; Liu, C.; Lian, J.; Liang, N.; Zhao, L. Development of extraction separation technology based on deep eutectic solvent and magnetic nanoparticles for determination of three sex hormones in milk. J. Chromatogr. B 2021, 1166, 122558. [Google Scholar] [CrossRef]

- Piemontese, L.; Perna, F.M.; Logrieco, A.; Capriati, V.; Solfrizzo, M. Deep eutectic solvents as novel and effective extraction media for quantitative determination of ochratoxin A in wheat and derived products. Molecules 2017, 22, 121. [Google Scholar] [CrossRef] [Green Version]

- Elik, A.; Unal, Y.; Altunay, N. Development of a chemometric-assisted deep eutectic solvent-based microextraction procedure for extraction of caffeine in foods and beverages. Food Addit. Contam. Part. A 2019, 36, 1139–1150. [Google Scholar] [CrossRef]

- He, T.; Zhou, T.; Wan, H.; Han, Q.; Ma, Y.; Tan, T.; Wan, Y. One-step deep eutectic solvent strategy for efficient analysis of aflatoxins in edible oils. J. Sci. Food Agric. 2020, 100, 4840–4848. [Google Scholar] [CrossRef]

- Altunay, N.; Unal, Y.; Elik, A. Towards green analysis of curcumin from tea, honey and spices: Extraction by deep eutectic solvent assisted emulsification liquid-liquid microextraction method based on response surface design. Food Addit. Contam. Part. A 2020, 37, 869–881. [Google Scholar] [CrossRef]

- Li, G.; Zhu, T.; Row, K.H. Deep eutectic solvents for the purification of chloromycetin and thiamphenicol from milk. J. Sep. Sci. 2017, 40, 625–634. [Google Scholar] [CrossRef] [PubMed]

- Zounr, R.A.; Tuzen, M.; Khuhawar, M.Y. A simple and green deep eutectic solvent based air assisted liquid phase microextraction for separation, preconcentration and determination of lead in water and food samples by graphite furnace atomic absorption spectrometry. J. Mol. Liq. 2018, 259, 220–226. [Google Scholar] [CrossRef]

- Solaesa, A.G.; Fernandes, J.O.; Sanz, M.T.; Benito-Román, Ó.; Cunha, S.C. Green determination of brominated flame retardants and organochloride pollutants in fish oils by vortex assisted liquid-liquid microextraction and gas chromatography-tandem mass spectrometry. Talanta 2019, 195, 251–257. [Google Scholar] [CrossRef] [PubMed]

- Heidari, H.; Ghanbari-Rad, S.; Habibi, E. Optimization deep eutectic solvent-based ultrasound-assisted liquid-liquid microextraction by using the desirability function approach for extraction and preconcentration of organophosphorus pesticides from fruit juice samples. J. Food Compos. Anal. 2020, 87, 103389. [Google Scholar] [CrossRef]

- Aydin, F.; Yilmaz, E.; Soylak, M. Vortex assisted deep eutectic solvent (DES)-emulsification liquid-liquid microextraction of trace curcumin in food and herbal tea samples. Food Chem. 2018, 243, 442–447. [Google Scholar] [CrossRef]

- Zounr, R.A.; Tuzen, M.; Deligonul, N.; Khuhawar, M.Y. A highly selective and sensitive ultrasonic assisted dispersive liquid phase microextraction based on deep eutectic solvent for determination of cadmium in food and water samples prior to electrothermal atomic absorption spectrometry. Food Chem. 2018, 253, 277–283. [Google Scholar] [CrossRef]

- Haq, H.U.; Balal, M.; Castro-Muñoz, R.; Hussain, Z.; Safi, F.; Ullah, S.; Boczkaj, G. Deep eutectic solvents based assay for extraction and determination of zinc in fish and eel samples using FAAS. J. Mol. Liq. 2021, 333, 115930. [Google Scholar] [CrossRef]

- Borahan, T.; Unutkan, T.; Turan, N.B.; Turak, F.; Bakırdere, S. Determination of lead in milk samples using vortex assisted deep eutectic solvent based liquid phase microextraction-slotted quartz tube-flame atomic absorption spectrometry system. Food Chem. 2019, 299, 125065. [Google Scholar] [CrossRef] [PubMed]

- Tekin, Z.; Unutkan, T.; Erulaş, F.; Bakırdere, E.G.; Bakırdere, S. A green, accurate and sensitive analytical method based on vortex assisted deep eutectic solvent-liquid phase microextraction for the determination of cobalt by slotted quartz tube flame atomic absorption spectrometry. Food Chem. 2020, 310, 125825. [Google Scholar] [CrossRef]

- Zounr, R.A.; Tuzen, M.; Khuhawar, M.Y. Ultrasound assisted deep eutectic solvent based on dispersive liquid liquid microextraction of arsenic speciation in water and environmental samples by electrothermal atomic absorption spectrometry. J. Mol. Liq. 2017, 242, 441–446. [Google Scholar] [CrossRef]

- Panhwar, A.H.; Tuzen, M.; Kazi, T.G. Deep eutectic solvent based advance microextraction method for determination of aluminum in water and food samples: Multivariate study. Talanta 2018, 178, 588–593. [Google Scholar] [CrossRef] [PubMed]

- Sivrikaya, S. A deep eutectic solvent based liquid phase microextraction for the determination of caffeine in Turkish coffee samples by HPLC-UV. Food Addit. Contam. Part. A 2020, 37, 488–495. [Google Scholar] [CrossRef] [PubMed]

- Farajzadeh, M.A.; Shahedi Hojghan, A.; Afshar Mogaddam, M.R. Development of a new temperature-controlled liquid phase microextraction using deep eutectic solvent for extraction and preconcentration of diazinon, metalaxyl, bromopropylate, oxadiazon, and fenazaquin pesticides from fruit juice and vegetable samples. J. Food Compos. Anal. 2018, 66, 90–97. [Google Scholar] [CrossRef]

- Sereshti, H.; Jamshidi, F.; Nouri, N.; Nodeh, H.R. Hyphenated dispersive solid- and liquid-phase microextraction technique based on a hydrophobic deep eutectic solvent: Application for trace analysis of pesticides in fruit juices. J. Sci. Food Agric. 2020, 100, 2534–2543. [Google Scholar] [CrossRef]

- Farajzadeh, M.A.; Sattari Dabbagh, M.; Yadeghari, A. Deep eutectic solvent based gas-assisted dispersive liquid-phase microextraction combined with gas chromatography and flame ionization detection for the determination of some pesticide residues in fruit and vegetable samples. J. Sep. Sci. 2017, 40, 2253–2260. [Google Scholar] [CrossRef] [PubMed]

- Farajzadeh, M.A.; Afshar Mogaddam, M.R.; Aghanassab, M. Deep eutectic solvent-based dispersive liquid–liquid microextraction. Anal. Methods 2016, 8, 2576–2583. [Google Scholar] [CrossRef]

- Bazmandegan-Shamili, A.; Dadfarnia, S.; Shabani, A.M.H.; Moghadam, M.R.; Saeidi, M. Temperature-controlled liquid–liquid microextraction combined with high-performance liquid chromatography for the simultaneous determination of diazinon and fenitrothion in water and fruit juice samples. J. Sep. Sci. 2018, 41, 2411–2418. [Google Scholar] [CrossRef] [PubMed]

- Sang, J.; Li, B.; Huang, Y.; Ma, Q.; Liu, K.; Li, C. Deep eutectic solvent-based extraction coupled with green two-dimensional HPLC-DAD-ESI-MS/MS for the determination of anthocyanins from Lycium ruthenicum Murr. fruit. Anal. Methods 2018, 10, 1247–1257. [Google Scholar] [CrossRef]

- Deng, W.; Yu, L.; Li, X.; Chen, J.; Wang, X.; Deng, Z.; Xiao, Y. Hexafluoroisopropanol-based hydrophobic deep eutectic solvents for dispersive liquid-liquid microextraction of pyrethroids in tea beverages and fruit juices. Food Chem. 2019, 274, 891–899. [Google Scholar] [CrossRef]

- Shishov, A.; Gagarionova, S.; Bulatov, A. Deep eutectic mixture membrane-based microextraction: HPLC-FLD determination of phenols in smoked food samples. Food Chem. 2020, 314, 126097. [Google Scholar] [CrossRef]

- Fasihi, M.; Rajabi, M.; Barfi, B.; Sajjadi, S.M. Deep eutectic-based vortex-assisted/ultrasound-assisted liquid-phase microextractions of chromium species. J. Iran. Chem. Soc. 2020, 17, 1705–1713. [Google Scholar] [CrossRef]

- Panhwar, A.H.; Tuzen, M.; Kazi, T.G. Ultrasonic assisted dispersive liquid-liquid microextraction method based on deep eutectic solvent for speciation, preconcentration and determination of selenium species (IV) and (VI) in water and food samples. Talanta 2017, 175, 352–358. [Google Scholar] [CrossRef] [PubMed]

- Shahid, R.; Kazi, T.G.; Afridi, H.I.; Talpur, F.N.; Akhtar, A.; Baig, J.A. Deep-eutectic-solvent-based dispersive and emulsification liquid–liquid microextraction methods for the speciation of selenium in water and determining its total content levels in milk formula and cereals. Anal. Methods 2020, 12, 5186–5194. [Google Scholar] [CrossRef]

- Fasihi, M.; Rajabi, M.; Barfi, B.; Sajjadi, S.M. Efficacious and environmentally friendly deep eutectic solvent-based liquid-phase microextraction for speciation of Cr(III) and Cr(VI) ions in food and water samples. Int. J. Environ. Anal. Chem. 2020, 1–13. [Google Scholar] [CrossRef]

- Deng, W.; Huang, A.; Zheng, Q.; Yu, L.; Li, X.; Hu, H.; Xiao, Y. A density-tunable liquid-phase microextraction system based on deep eutectic solvents for the determination of polycyclic aromatic hydrocarbons in tea, medicinal herbs and liquid foods. Food Chem. 2021, 352, 129331. [Google Scholar] [CrossRef]

- Zahiri, E.; Khandaghi, J.; Farajzadeh, M.A.; Afshar Mogaddam, M.R. Combination of dispersive solid phase extraction with solidification organic drop–dispersive liquid–liquid microextraction based on deep eutectic solvent for extraction of organophosphorous pesticides from edible oil samples. J. Chromatogr. A 2020, 1627, 461390. [Google Scholar] [CrossRef]

- Bian, Y.; Wang, Y.; Yu, J.; Zheng, S.; Qin, F.; Zhao, L. Analysis of six preservatives in beverages using hydrophilic deep eutectic solvent as disperser in dispersive liquid-liquid microextraction based on the solidification of floating organic droplet. J. Pharm. Biomed. Anal. 2021, 195, 113889. [Google Scholar] [CrossRef] [PubMed]

- Abdolhosseini, M.; Shemirani, F.; Yousefi, S.M. Poly (deep eutectic solvents) as a new class of sustainable sorbents for solid phase extraction: Application for preconcentration of Pb (II) from food and water samples. Microchim. Acta 2020, 187, 602. [Google Scholar] [CrossRef]

- Svigelj, R.; Bortolomeazzi, R.; Dossi, N.; Giacomino, A.; Bontempelli, G.; Toniolo, R. An effective gluten extraction method exploiting pure choline chloride-based deep eutectic solvents (ChCl-DESs). Food Anal. Methods 2017, 10, 4079–4085. [Google Scholar] [CrossRef]

- Khezeli, T.; Daneshfar, A.; Sahraei, R. A green ultrasonic-assisted liquid–liquid microextraction based on deep eutectic solvent for the HPLC-UV determination of ferulic, caffeic and cinnamic acid from olive, almond, sesame and cinnamon oil. Talanta 2016, 150, 577–585. [Google Scholar] [CrossRef]

- Shirani, M.; Habibollahi, S.; Akbari, A. Centrifuge-less deep eutectic solvent based magnetic nanofluid-linked air-agitated liquid–liquid microextraction coupled with electrothermal atomic absorption spectrometry for simultaneous determination of cadmium, lead, copper, and arsenic in food sample. Food Chem. 2019, 281, 304–311. [Google Scholar] [CrossRef] [PubMed]

- Mardani, A.; Afshar Mogaddam, M.R.; Farajzadeh, M.A.; Mohebbi, A.; Nemati, M.; Torbati, M. A three-phase solvent extraction system combined with deep eutectic solvent-based dispersive liquid–liquid microextraction for extraction of some organochlorine pesticides in cocoa samples prior to gas chromatography with electron capture detection. J. Sep. Sci. 2020, 43, 3674–3682. [Google Scholar] [CrossRef]

- Tan, T.; Li, Z.; Mao, X.; Wan, Y.; Qiu, H. Deep eutectic solvent-based liquid-phase microextraction for detection of plant growth regulators in edible vegetable oils. Anal. Methods 2016, 8, 3511–3516. [Google Scholar] [CrossRef]

- Benvenutti, L.; del Pilar Sanchez-Camargo, A.; Zielinski, A.A.F.; Ferreira, S.R.S. NADES as potential solvents for anthocyanin and pectin extraction from Myrciaria cauliflora fruit by-product: In silico and experimental approaches for solvent selection. J. Mol. Liq. 2020, 315, 113761. [Google Scholar] [CrossRef]

- Mohd Fuad, F.; Mohd Nadzir, M.; Harun@Kamaruddin, A. Hydrophilic natural deep eutectic solvent: A review on physicochemical properties and extractability of bioactive compounds. J. Mol. Liq. 2021, 339, 116923. [Google Scholar] [CrossRef]

- Gómez, A.V.; Tadini, C.C.; Biswas, A.; Buttrum, M.; Kim, S.; Boddu, V.M.; Cheng, H.N. Microwave-assisted extraction of soluble sugars from banana puree with natural deep eutectic solvents (NADES). LWT 2019, 107, 79–88. [Google Scholar] [CrossRef]

- Chanioti, S.; Tzia, C. Extraction of phenolic compounds from olive pomace by using natural deep eutectic solvents and innovative extraction techniques. Innov. Food Sci. Emerg. Technol. 2018, 48, 228–239. [Google Scholar] [CrossRef]

- Esfahani, H.S.; Khoshsima, A.; Pazuki, G. Choline chloride-based deep eutectic solvents as green extractant for the efficient extraction of 1-butanol or 2-butanol from azeotropic n-heptane + butanol mixtures. J. Mol. Liq. 2020, 313, 113524. [Google Scholar] [CrossRef]

- Craveiro, R.; Aroso, I.; Flammia, V.; Carvalho, T.; Viciosa, M.T.; Dionísio, M.; Barreiros, S.; Reis, R.L.; Duarte, A.R.C.; Paiva, A. Properties and thermal behavior of natural deep eutectic solvents. J. Mol. Liq. 2016, 215, 534–540. [Google Scholar] [CrossRef]

- Gałuszka, A.; Migaszewski, Z.M.; Konieczka, P.; Namieśnik, J. Analytical Eco-Scale for assessing the greenness of analytical procedures. TrAC Trends Anal. Chem. 2012, 37, 61–72. [Google Scholar] [CrossRef]

- Rychen, G.; Aquilina, G.; Azimonti, G.; Bampidis, V.; Bastos, M.d.L.; Bories, G.; Chesson, A.; Cocconcelli, P.S.; Flachowsky, G.; Gropp, J.; et al. Safety and efficacy of L-arginine produced by fermentation with Escherichia coli NITE BP-02186 for all animal species. EFSA J. 2018, 16. [Google Scholar] [CrossRef]

- Mortensen, A.; Aguilar, F.; Crebelli, R.; Di Domenico, A.; Dusemund, B.; Frutos, M.J.; Galtier, P.; Gott, D.; Gundert-Remy, U.; Leblanc, J.; et al. Re-evaluation of glycerol (E 422) as a food additive. EFSA J. 2017, 15, 4720. [Google Scholar] [CrossRef] [Green Version]

- Zhao, B.-Y.; Xu, P.; Yang, F.-X.; Wu, H.; Zong, M.-H.; Lou, W.-Y. Biocompatible deep eutectic solvents based on choline chloride: Characterization and application to the extraction of rutin from sophora japonica. ACS Sustain. Chem. Eng. 2015, 3, 2746–2755. [Google Scholar] [CrossRef]

- Van Osch, D.J.G.P.; Zubeir, L.F.; van den Bruinhorst, A.; Rocha, M.A.A.; Kroon, M.C. Hydrophobic deep eutectic solvents as water-immiscible extractants. Green Chem. 2015, 17, 4518–4521. [Google Scholar] [CrossRef] [Green Version]

- Caldeirão, L.; Fernandes, J.O.; Gonzalez, M.H.; Godoy, H.T.; Cunha, S.C. A novel dispersive liquid-liquid microextraction using a low density deep eutectic solvent-gas chromatography tandem mass spectrometry for the determination of polycyclic aromatic hydrocarbons in soft drinks. J. Chromatogr. A 2021, 1635, 461736. [Google Scholar] [CrossRef] [PubMed]

- Zhu, S.; Zhou, J.; Jia, H.; Zhang, H. Liquid–liquid microextraction of synthetic pigments in beverages using a hydrophobic deep eutectic solvent. Food Chem. 2018, 243, 351–356. [Google Scholar] [CrossRef] [PubMed]

- Ji, Y.; Meng, Z.; Zhao, J.; Zhao, H.; Zhao, L. Eco-friendly ultrasonic assisted liquid–liquid microextraction method based on hydrophobic deep eutectic solvent for the determination of sulfonamides in fruit juices. J. Chromatogr. A 2020, 1609, 460520. [Google Scholar] [CrossRef]

- Arcon, D.P.; Franco, F.C. All-fatty acid hydrophobic deep eutectic solvents towards a simple and efficient microextraction method of toxic industrial dyes. J. Mol. Liq. 2020, 318, 114220. [Google Scholar] [CrossRef]

- Makoś, P.; Słupek, E.; Gębicki, J. Hydrophobic deep eutectic solvents in microextraction techniques–A review. Microchem. J. 2020, 152, 104384. [Google Scholar] [CrossRef]

- Zainal-Abidin, M.H.; Hayyan, M.; Wong, W.F. Hydrophobic deep eutectic solvents: Current progress and future directions. J. Ind. Eng. Chem. 2021, 97, 142–162. [Google Scholar] [CrossRef]

- Cao, J.; Su, E. Hydrophobic deep eutectic solvents: The new generation of green solvents for diversified and colorful applications in green chemistry. J. Clean. Prod. 2021, 314, 127965. [Google Scholar] [CrossRef]

- Florindo, C.; Branco, L.C.; Marrucho, I.M. Quest for green-solvent design: From hydrophilic to hydrophobic (deep) eutectic solvents. ChemSusChem 2019, 12, 1549–1559. [Google Scholar] [CrossRef] [PubMed]

- Gilmore, M.; McCourt, É.N.; Connolly, F.; Nockemann, P.; Swadźba-Kwaśny, M.; Holbrey, J.D. Hydrophobic deep eutectic solvents incorporating trioctylphosphine oxide: Advanced liquid extractants. ACS Sustain. Chem. Eng. 2018, 6, 17323–17332. [Google Scholar] [CrossRef] [Green Version]

- Nunes, R.J.; Saramago, B.; Marrucho, I.M. Surface tension of DL-menthol:octanoic acid eutectic mixtures. J. Chem. Eng. Data 2019, 64, 4915–4923. [Google Scholar] [CrossRef]

- Florindo, C.; Branco, L.C.; Marrucho, I.M. Development of hydrophobic deep eutectic solvents for extraction of pesticides from aqueous environments. Fluid Phase Equilib. 2017, 448, 135–142. [Google Scholar] [CrossRef]

- Ortega-Zamora, C.; González-Sálamo, J.; Hernández-Sánchez, C.; Hernández-Borges, J. Menthol-based deep eutectic solvent dispersive liquid-liquid microextraction: A simple, quick and green approach for the analysis of phthalic acid esters from water and beverage samples. ACS Sustain. Chem. Eng. 2020, 8, 8783–8794. [Google Scholar] [CrossRef]

- Liu, W.; Zong, B.; Wang, X.; Cai, J.; Yu, J. A highly efficient vortex-assisted liquid–liquid microextraction based on natural deep eutectic solvent for the determination of Sudan I in food samples. RSC Adv. 2019, 9, 17432–17439. [Google Scholar] [CrossRef] [Green Version]

- Khare, L.; Karve, T.; Jain, R.; Dandekar, P. Menthol based hydrophobic deep eutectic solvent for extraction and purification of ergosterol using response surface methodology. Food Chem. 2021, 340, 127979. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Lu, Y.; Shi, L.; Yang, D.; Yang, Y. Novel low viscous hydrophobic deep eutectic solvents liquid-liquid microextraction combined with acid base induction for the determination of phthalate esters in the packed milk samples. Microchem. J. 2020, 159, 105332. [Google Scholar] [CrossRef]

- Soltani, S.; Sereshti, H.; Nouri, N. Deep eutectic solvent-based clean-up/vortex-assisted emulsification liquid-liquid microextraction: Application for multi-residue analysis of 16 pesticides in olive oils. Talanta 2021, 225, 121983. [Google Scholar] [CrossRef]

- Ma, S.; Jin, X.; Wei, H.; Liu, Y.; Guo, M. Hydrophobic deep eutectic solvent-based ultrasonic-assisted liquid-liquid micro-extraction combined with HPLC-FLD for diphenylamine determination in fruit. Food Addit. Contam. Part. A 2021, 38, 339–349. [Google Scholar] [CrossRef] [PubMed]

- Torbati, M.; Farajzadeh, M.A.; Mogaddam, M.R.A.; Torbati, M. Deep eutectic solvent based homogeneous liquid–liquid extraction coupled with in-syringe dispersive liquid–liquid microextraction performed in narrow tube; application in extraction and preconcentration of some herbicides from tea. J. Sep. Sci. 2019, 42, 1768–1776. [Google Scholar] [CrossRef] [PubMed]

- Shishov, A.; Gorbunov, A.; Baranovskii, E.; Bulatov, A. Microextraction of sulfonamides from chicken meat samples in three-component deep eutectic solvent. Microchem. J. 2020, 158, 105274. [Google Scholar] [CrossRef]

- Ge, D.; Shan, Z.; Pang, T.; Lu, X.; Wang, B. Preparation of new hydrophobic deep eutectic solvents and their application in dispersive liquid–liquid microextraction of Sudan dyes from food samples. Anal. Bioanal. Chem. 2021, 413, 3873–3880. [Google Scholar] [CrossRef] [PubMed]

- Farajzadeh, M.A.; Abbaspour, M.; Kazemian, R. Synthesis of a green high density deep eutectic solvent and its application in microextraction of seven widely used pesticides from honey. J. Chromatogr. A 2019, 1603, 51–60. [Google Scholar] [CrossRef]

- Shi, Y.; Li, X.; Shang, Y.; Li, T.; Zhang, K.; Fan, J. Effective extraction of fluorescent brightener 52 from foods by in situ formation of hydrophobic deep eutectic solvent. Food Chem. 2020, 311, 125870. [Google Scholar] [CrossRef]

- Faraji, M.; Mahmoodi-Maymand, M.; Dastmalchi, F. Green, fast and simple dispersive liquid-liquid microextraction method by using hydrophobic deep eutectic solvent for analysis of folic acid in fortified flour samples before liquid chromatography determination. Food Chem. 2020, 320, 126486. [Google Scholar] [CrossRef] [PubMed]

- Yu, K.; Yue, M.-E.; Xu, J.; Jiang, T.-F. Determination of fluoroquinolones in milk, honey and water samples by salting out-assisted dispersive liquid-liquid microextraction based on deep eutectic solvent combined with MECC. Food Chem. 2020, 332, 127371. [Google Scholar] [CrossRef]

- Elik, A.; Bingöl, D.; Altunay, N. Ionic hydrophobic deep eutectic solvents in developing air-assisted liquid-phase microextraction based on experimental design: Application to flame atomic absorption spectrometry determination of cobalt in liquid and solid samples. Food Chem. 2021, 350, 129237. [Google Scholar] [CrossRef]

- Faraji, M. Determination of some red dyes in food samples using a hydrophobic deep eutectic solvent-based vortex assisted dispersive liquid-liquid microextraction coupled with high performance liquid chromatography. J. Chromatogr. A 2019, 1591, 15–23. [Google Scholar] [CrossRef]

- Çıtak, D.; Sabancı, D. Response surface methodology and hydrophobic deep eutectic solvent based liquid phase microextraction combination for determination of cadmium in food and water samples. J. Food Meas. Charact. 2021, 15, 1843–1850. [Google Scholar] [CrossRef]

- Khanehzar, H.; Faraji, M.; Nezhadali, A.; Yamini, Y. Combining of modified QuEChERS and dispersive liquid–liquid microextraction as an efficient sample preparation method for extraction of acetamiprid and imidacloprid from pistachio samples. J. Iran. Chem. Soc. 2021, 18, 641–649. [Google Scholar] [CrossRef]

- Erbas, Z.; Soylak, M.; Yilmaz, E.; Dogan, M. Deep eutectic solvent based liquid phase microextraction of nickel at trace level as its diethyldithiocarbamate chelate from environmental samples. Microchem. J. 2019, 145, 745–750. [Google Scholar] [CrossRef]

- Mohebi, A.; Samadi, M.; Tavakoli, H.R.; Parastouei, K. Homogenous liquid–liquid extraction followed by dispersive liquid–liquid microextraction for the extraction of some antibiotics from milk samples before their determination by HPLC. Microchem. J. 2020, 157, 104988. [Google Scholar] [CrossRef]

- Liu, X.; Bian, Y.; Zhao, J.; Wang, Y.; Zhao, L. Menthol-based deep eutectic solvent in dispersive liquid-liquid microextraction followed by solidification of floating organic droplet for the determination of three bisphenols with UPLC-MS/MS. Microchem. J. 2020, 159, 105438. [Google Scholar] [CrossRef]

- Ji, Y.; Zhao, M.; Li, A.; Zhao, L. Hydrophobic deep eutectic solvent-based ultrasonic-assisted dispersive liquid-liquid microextraction for preconcentration and determination of trace cadmium and arsenic in wine samples. Microchem. J. 2021, 164, 105974. [Google Scholar] [CrossRef]

- Ravandi, M.G.; Fat’hi, M.R. Green effervescence assisted dispersive liquid–liquid microextraction based on a hydrophobic deep eutectic solvent for determination of Sunset Yellow and Brilliant Blue FCF in food samples. New J. Chem. 2018, 42, 14901–14908. [Google Scholar] [CrossRef]

- Ali, J.; Tuzen, M.; Kazi, T.G. Green and innovative technique develop for the determination of vanadium in different types of water and food samples by eutectic solvent extraction method. Food Chem. 2020, 306, 125638. [Google Scholar] [CrossRef]

- Habila, M.A.; AlMasoud, N.; Alomar, T.S.; AlOthman, Z.A.; Yilmaz, E.; Soylak, M. Deep eutectic solvent-based microextraction of lead(II) traces from water and aqueous extracts before FAAS measurements. Molecules 2020, 25, 4794. [Google Scholar] [CrossRef]

- Fan, C.; Wang, H.; Liu, Y.; Cao, X. New deep eutectic solvent based superparamagnetic nanofluid for determination of perfluoroalkyl substances in edible oils. Talanta 2021, 228, 122214. [Google Scholar] [CrossRef]

- Triaux, Z.; Petitjean, H.; Marchioni, E.; Boltoeva, M.; Marcic, C. Deep eutectic solvent–based headspace single-drop microextraction for the quantification of terpenes in spices. Anal. Bioanal. Chem. 2020, 412, 933–948. [Google Scholar] [CrossRef]

- Nemati, M.; Farajzadeh, M.A.; Mohebbi, A.; Khodadadeian, F.; Afshar Mogaddam, M.R. Development of a stir bar sorptive extraction method coupled to solidification of floating droplets dispersive liquid–liquid microextraction based on deep eutectic solvents for the extraction of acidic pesticides from tomato samples. J. Sep. Sci. 2020, 43, 1119–1127. [Google Scholar] [CrossRef] [PubMed]

- Memon, Z.M.; Yilmaz, E.; Shah, A.M.; Kazi, T.G.; Devrajani, B.R.; Soylak, M. A green ultrasonic-assisted liquid–liquid microextraction technique based on deep eutectic solvents for flame atomic absorption spectrometer determination of trace level of lead in tobacco and food samples. J. Iran. Chem. Soc. 2019, 16, 687–694. [Google Scholar] [CrossRef]

- Liu, X.; Chen, M.; Meng, Z.; Qian, H.; Zhang, S.; Lu, R.; Gao, H.; Zhou, W. Extraction of benzoylurea pesticides from tea and fruit juices using deep eutectic solvents. J. Chromatogr. B 2020, 1140, 121995. [Google Scholar] [CrossRef]

- Kachangoon, R.; Vichapong, J.; Santaladchaiyakit, Y.; Burakham, R.; Srijaranai, S. An eco-friendly hydrophobic deep eutectic solvent-based dispersive liquid–liquid microextraction for the determination of neonicotinoid insecticide residues in water, soil and egg yolk samples. Molecules 2020, 25, 2785. [Google Scholar] [CrossRef]

- Jouyban, A.; Farajzadeh, M.A.; Afshar Mogaddam, M.R. In matrix formation of deep eutectic solvent used in liquid phase extraction coupled with solidification of organic droplets dispersive liquid-liquid microextraction; application in determination of some pesticides in milk samples. Talanta 2020, 206, 120169. [Google Scholar] [CrossRef]

- Farajzadeh, M.A.; Abbaspour, M.; Kazemian, R.; Afshar Mogaddam, M.R. Preparation of a new three-component deep eutectic solvent and its use as an extraction solvent in dispersive liquid–liquid microextraction of pesticides in green tea and herbal distillates. J. Sci. Food Agric. 2020, 100, 1904–1912. [Google Scholar] [CrossRef] [PubMed]

- Farajzadeh, M.A.; Sohrabi, H.; Mohebbi, A.; Mogaddam, M.R.A. Combination of a modified quick, easy, cheap, efficient, rugged, and safe extraction method with a deep eutectic solvent based microwave-assisted dispersive liquid–liquid microextraction: Application in extraction and preconcentration of multiclass pestic. J. Sep. Sci. 2019, 42, 1273–1280. [Google Scholar] [CrossRef]

- Van Osch, D.J.G.P.; Dietz, C.H.J.T.; van Spronsen, J.; Kroon, M.C.; Gallucci, F.; van Sint Annaland, M.; Tuinier, R. A search for natural hydrophobic deep eutectic solvents based on natural components. ACS Sustain. Chem. Eng. 2019, 7, 2933–2942. [Google Scholar] [CrossRef]

| DES (Molar Ratio) (Volume) | Analytes | Sample | Sample Preparation | Extraction Technique | Separation and Detection Technique | LODs | Recovery % (RSD %) | Comments | Reference |

|---|---|---|---|---|---|---|---|---|---|

| NADES | |||||||||

| ChCl:oxalic acid (1:1) (-) | 17 polyphenols | Aegle marmelos (Bael/woodapple) (500 mg) | Samples were frozen, freeze-dried and pulverized | UAE | HPLC-DAD | - | - (-) | DES was mixed with 25% of water (v/v). | [10] |

| ChCl:oxalic acid (1:2) (2500 μL) | Cu, Fe and Zn | Muscle, liver and gills fish tissues (100 mg) | Samples were freeze-dried, ground to fine powders and sieved through a 125 mesh | An acid digestion method with HNO3 1 M | FAAS | 6–53 μg/L | 95–100% (-) | The reproducibility of the method was validated by analysing all samples in different laboratories by ICP-OES. For comparison, a CAD was used for the determination of analytes in all samples. | [11] |

| ChCl:oxalic acid (1:3) (700 μL) | As and Sb | Waste, mineral, well, tap, and river water, honey and rice (125 mL) | Water samples were filtered. Rice samples were dried, ground and homogenized | VA-DLLME | HG-AAS | 0.0075–0.0156 μg/L | 94–104% (1–3%) | 7 DESs were evaluated. An extraction with MeOH:H2O (1:1, v/v) was done to ensure the reliability of analysis results. THF was used as an emulsifying agent. | [12] |

| ChCl:urea (1:2) (160 μL) | Pb and Cd | Sesame, soybean, olive, sunflower and corn oils (28,000 mg) | Samples were used without any sample pretreatment steps | VA-DLLME | ETAAS | 0.0002–0.008 μg/kg | 95–104% (-) | The quality assurance/quality control procedure was performed to ensure the obtained results. | [13] |

| BeHCl:sorbitol (1:3) (600 μL) | MeHg and total Hg | Fish (tuna, salmon, trout, mackerel, whiting and anchovy), seafood (shrimp) and lake, dam, well and waste water (2.5 mL) | Edible parts of fish were homogenised, oven-dried and frozen. Water samples were filtered and concentrated by evaporation | UA-DLLME | UV-Vis | 0.25–0.92 μg/L | 90–104% (2–5%) | Different pretreatment for each Hg species. NADES phase contained 10% water (v/v). ACN was used as aprotic solvent. NADES acts as a reactive pH-controlled zwitterionic surfactant. | [14] |

| ChCl:L-(+)-tartaric acid:water (1:1:2) (2000 μL) | Cd | Rice flour (300 mg) | Samples were dried | UAE | GFAAS | - | - (-) | 20 NADESs were evaluated. The regeneration of Cd-contaminated NADESs was explored. After the UAE, a conventional acid microwave extraction was performed. | [15] |

| Lactic acid:levulinic acid (1:1) (1500 μL) | 20-hydroxyecdysone | Spinach (100 mg) | Samples were dried and ground | VA-DLLME | UHPLC-UV | 170 μg/kg | 88–93% (3–9%) | DES contained 30% of water. The recovery of the analyte was higher with NADES-SLE than IL-SLE procedure. | [21] |

| BeHCl:glycerol (1:3) (500 μL) | Curcumin | Cinnamon tea, anti-parasite herbal tea, herbal tea, mixed herbal tea, tumeric, curry, cinnamon and sesame (1.5 mL) | Samples were ground, homogenized and extracted with MeOH | VA-DLLME | UV-Vis | 1.5 μg/L | 90–108% (2–4%) | 8 alcohol-based DESs were prepared. | [22] |

| Glycolic acid:mandelic acid (2:1) (750 μL) | Cd(II) and Zn(II) | Fish oil, butter and margarine (7 mL) | Samples were diluted with ethyl acetate | RP-DLLME | FAAS | 0.12–0.18 μg/L | 89–104% (3–10%) | 3% (v/v) HNO3 solution was used as extraction solvent. | [23] |

| Lactic acid:glucose (5:1) (3090 μL) | 3 Se-amino acids | Milk (940 mg) | Samples were lyophilized and powdered | UAE | LC-ICP-MS | 7.37–9.64 μg/kg | 86–109% (<7%) | The DES was mixed with 18% water (v/v). The extraction with NADES has less penalty points of AES than other techniques. | [24] |

| Sucrose:lactic acid:water (1:5:7) for extract curcuminoids and fructose:lactic acid:water (1:5:5) for antioxidant extraction (-) | Curcuminoids and antioxidants | Turmeric (-) | Sample was ground | MAE | HPLC-DAD to quantify the curcumin | - | 37–41% (-) (AR) | 5 NADESs were evaluated and 4 of them showed better results than the ones obtained with MeOH:H2O (4:1, v/v). FCCD was used for optimization. CUPRAC method was used to determine the antioxidant capacity. | [25] |

| ChCl:oxalic acid (1:2) (2500 μL) | Se and As | Mushroom (100 mg) | Samples were dried at 105 °C for 24 h | An acid digestion method with HNO3 1.5 M | GFAAS | 0.32–0.50 μg/L | 96–100% (-) | There are no significant differences between the extraction with DES and the conventional wet acid digestion method. | [26] |

| ChCl:oxalic acid (1:2) (2000 μL) | Se and As | Fish and canned fish (80 mg) | - | An acid digestion method with HNO3 1 M | ETAAS | 0.46–0.75 μg/kg | 94–99% (-) | - | [27] |

| ChCl:tartaric acid ChCl:oxalic acid ChCl:citric acid (1:1) (1000 μL) | Mn | Basil herb, spinach, dill and cucumber barks (830 mg for tartaric and oxalic acid-based DESs and 1250 mg for citric acid-based DES) | Samples were dried, crushed and gridded to fine particles | Samples were extracted with DES for 2 h at 95 °C, centrifugated, filtrated and diluted | ICP-OES | 0.34, 0.50 and 1.23 μg/L (oxalic, tartaric, citric acids, respectively) | 82–114% (-) | All three DESs showed good results as extractants. | [28] |

| AcetylChCl:lactic acid (2:1) (600 μL) | 8 flavonoids | Cranberry, fruits of Lycium barbarum L., grape, plum, orange peel, onion, broccoli, mustard, rosemary and black pepper (200 mg) | Samples were dried, milled and stored in paper bags at ambient temperature for 4–5 months | VA-DLLME | UHPLC-UV | 150 μg/kg | 70–94% (-) | Better recovery values were obtained when adding 30% (v/v) of water to the DES. Chrysin was used as IS. The extraction method was compared with an UAE method. Optimization was done with a CCD. | [29] |

| ChCl:glycerol (1:1) (1000 μL) | Rutin | Tartary buckwheat hull (40 mg) | The sample was ground to powder | UA-DLLME | HPLC-UV | - | - (-) | 13 NADESs were studied. The toxicities of the NADESs were evaluated with two Gram-positive and two Gram-negative bacteria. Closed bottle test was used to determine the biodegradability of the NADESs. | [30] |

| ChCl:citric acid:glucose (1:1:1) (100000 μL) | Anthocyanins | Mulberry (5000 mg) | - | HSH-CBE | HPLC-UV | - | - (-) | PBD and BBD were carried out to determine optimum extraction conditions. HSH-CBE was compared with other extraction methods. DES was mixed with 30% (v/v) of water. | [31] |

| ChCl:citric acid (1:1) (600 μL) | 4 isoflavones | Soybeans, flour, pasta, breakfast cereals, cutlets, tripe, soy drink, soy nuts, soy cubes and dietary supplements (200 mg) | Samples were grounded and dried. In the case of the dietary supplements, the contents of 10–20 capsules were pooled | UA-DLLME | UHPLC-UV | 60–140 μg/kg | 65–99% (-) | 30% (w/w) water in NADES was used. CCD were used to determine the optimum conditions. | [32] |

| ChCl:urea (1:2) (1000 μL) | 6 mycotoxins | Cricket flour, silkworm pupae and black cricket powder (150 mg) | Samples were homogenized | VA-DLLME | UHPLC-MS/MS | 10–110 μg/kg | 49–104% (1–13%) | FFD was used to determine the optimum conditions. DES was supplemented with 15% of Milli-Q water. 3-hydroxy-5-methylphenyl-2,4-dihydroxybenzoate was used as IS. | [33] |

| ChCl:citric acid (1:1) (-) | Anthocyanins | Black carrot (-) | - | UAE | - | - | - (-) | Five DESs were prepared. DESs were added to samples with a sample/DES ratio of 1:4. The biodegradability of the tested DESs were >80% after 28 days. | [34] |

| Glucose:lactic acid:water (1:3:3) (5000 μL) | Phenolic compounds | Extra virgin olive oil (1000 mg) | Purified olive oil was obtained after an omics approach | LLE | HPLC-DAD | - | - (-) | - | [35] |

| ChCl:urea (1:2) (40 µL) | 3 sex hormones | Milk (20 mL) | Samples were mixed with TCA (a protein coagulant), centrifuged and the supernatant was diluted | VA-DLLME | HPLC-DAD | 1.0–1.3 μg/L | 80–116% (3–14%) | MMWCNTs were used as sorbent in mSPE. The DES with the analytes is adsorbed on the surface of MMWCNTs. | [36] |

| ChCl:urea (1:2) (20000 μL) | Ochratoxin A | Durum wheat, bread crumbs, biscuits and bran (4000 mg) | Samples were grounded | SLE | HPLC-FD | 0.09 μg/kg | 42–88% (2–11%) | The DES contained 40% (w/w) of water. Samples were purified/concentrated with IMA columns. | [37] |

| ChCl:urea (1:2) (565.1 μL) | Caffeine | Cola, energy drink, ice tea, instant coffee, espresso, dry coffee, chocolate and ice cream (2 mL) | Beverages were degassed, diluted, sonicated and filtered. Food samples were ground, sieved, sonicated with boiling water and filtered | UA-DLLME | UV-Vis | 7.5 μg/L | 93–107% (1–2%) | CCD was used to determine the optimum conditions. | [38] |

| ChCl:malonic acid (1:2) (30 μL) | 4 aflatoxins | Corn, soybean, peanut and rapessed oils (5000 mg) | Samples were diluted with n-hexane (1:9, v/v) | UA-DLLME | HPLC-FD | 0.0005–0.003 μg/kg | 72–113% (1–9%) | - | [39] |

| ChCl:maltose (1:3) (762.5 μL) | Curcumin | Tea, honey and spices (5 mL) | Samples were mixed with water, sonicated and filtered | VA-DLLME | UV-Vis | 0.1 μg/L | 94–103% (1–3%) | THF was used as emulsifier solvent. | [40] |

| ChCl:glycerol (1:2) (2000 μL) | 2 antibiotics | Milk (0.5 mL) | Sample was deproteinized with ACN (1% NH3) | DLLME | LC-MS/MS | - | 83–87% (-) | The DES was mixed with chloroform (2:1, v/v). DES was also used to modify MIPs which were used as a sorbent in SPE. Recovery values in SPE were higher than in the DLLME procedure. | [41] |

| Non NADES | |||||||||

| ChCl:phenol (1:4) (600 μL) | Pb(II) | Black and green tea, cumin, cow and chicken meat, linseed, canned fish, potato, and lake, waste, river and sea water (30 mL) | Water samples were filtered and food samples were digested with microwave system | AA-DLLME | GFAAS | 0.0006 μg/L | 97–99% (2–3%) | THF was used as a demulsifying solvent. 4-(2-thiazolylazo) resorcinol (0.1%, w/v) was used as a complexing reagent. | [42] |

| ChCl:phenol (1:2) (180 μL) | 5 PBDEs and 3 OCPs | Fish oil (300 mg) | - | VA-DLLME | GC-MS/MS | 0.2–0.7 μg/kg | 64–110% (0–7%) | FBDE-126 and TPP were used as ISs. The greenness of the procedure was assessed using the AES. DES was mixed with EtOH 1:1 (v/v) to improve reproducibility. | [43] |

| ChCl:phenol (1:2) (408 μL) | 2 OPPs | Red grape and sour cherry juices (10 mL) | Samples were filtered | UA-DLLME | HPLC-UV | 0.070–0.096 μg/L | 87–117% (4–10%) | THF was used as an emulsifier agent. | [44] |

| ChCl:phenol (1:4) (400 μL) | Curcumin | Herbal tea, turmeric drug, turmeric powder and root herbal tea (10 mL) | Herbal tea samples were extracted with boiling demineralized water and HNO3 was used for stabilizing the solutions. Solid samples were powdered and extracted with MeOH | VA-DLLME | UV-vis | 2.86 μg/L | 96–102% (1–6%) | HPLC-DAD was used to check the accuracy of the developed method. Different molar ratios of DES composition were studied. THF was used as an emulsifier agent. | [45] |

| ChCl:phenol (1:4) (500 μL) | Cd | Bean stew, black tea, chicken shawarma, canned corn, corn, canned mushroom, cheese, mushroom, fish tissue, tomato, meat, canned fish, rice and spinach, drinking, tap, and waste water, and ice tea (50 mL) | Solid food samples were digested by a microwave system. Water samples were filtered | UA-DLLME | ETAAS | 0.000023 μg/L | 98–100% for liquid samples and 99% for reference materials used in solid samples (-) | Azo was used as a complexing agent for Cd. THF was used as an emulsifying agent. The optimization was assessed using a factorial design. The proposed technique was compared with other reported methods. | [46] |

| ChCl:phenol (1:2) (600 μL) | Zn | Fish and eel (10 mL) | Samples were digested with HNO3:H2O:H2O2 (1:3:2 mL ratio) and diluted | UA-DLLME | FAAS | 0.041 μg/kg | 93–101% (2–5%) | 8-hydroxy quinoline was used as a chelating agent. THF was used as an emulsifier agent. | [47] |

| ChCl:phenol (1:2) (500 μL) | Pb | Milk (8 mL) | - | VA-DLLME | SQT-FAAS | 8.7 μg/L | 102–103% (1–6%) | Detection power was improved by 48 times using this method with respect to conventional FAAS system. THF was used as an emulsifying agent. | [48] |

| ChCl:phenol (1:2) (600 μL) | Co | Linden tea (10 mL) | Linden samples were boiled in water and filtered | VA-DLLME | SQT-FAAS | 2.0 μg/L | 97–100% (3–5%) | THF was used as an emulsifier agent. | [49] |

| ChCl:phenol (1:3) (1000 μL) | As(III) and As(V) | Edible mushrooms, sediment, green tea, black tea, rice, soil, cigarette, and lake, river, tap and mineral water (25 mL) | Water samples were filtered. Food and environmental samples were digested with HNO3 (65%, w/w) | UA-DLLME | ETAAS | 0.01 μg/L | 96–99% (3–4%) for water samples and 98% (-) for reference materials of mushroom and fish tissue | DDTC was used as a chelating agent. THF was used as dispersive solvent. As(V) was reduced to As(III), and total arsenic was determined. | [50] |

| ChCl:phenol (1:4) (500 μL) | Al(III) | Drinking, river, mineral, sea and spring water, rice, cultivated mushroom and chicken meat (25 mL) | Food samples were used after a microwave digestion | UA-DLLME | ETAAS | 0.032 μg/L | 97–100% (2–4%) | THF was used as extraction solvent. PBD was used to determine the optimum conditions. | [51] |

| ChCl:phenol (1:3) (400 μL) | Caffeine | Coffee (5 mL) | Coffee was grounded and mixed with water. The mixture was heated and centrifuged | VA-DLLME | HPLC-UV | 120 μg/L | 91–101% (-) | THF was used as emulsifier solvent. | [52] |

| ChCl:4-chlorophenol (2:1) (142 µL) | 5 pesticides | Apple, grape and sour cherry juices, and fresh beer, cucumber, potato and tomato (5 mL) | All juices were diluted with water at a ratio 1:3. Vegetables were squeezed, centrifuged and the supernatants were diluted 1:5 | DLLME | GC-FID | 0.13–0.31 μg/L | 86–99% (3–7%) | Diazinon was detected in the tomato samples. Temperature was a key factor in this method. | [53] |

| ChCl:4-chlorophenol (1:2) (145 μL) | 7 pesticides | Apple, pineapple, cherry, peach, and red and green grape juices (10 mL) | Only peach juice was diluted with water (1:1, v/v) | DLLME | GC-ECD | 0.006–0.038 μg/L | 71–115% (-) | dSPME with mGO functionalized was used before DLLME step. ACN was used as disperser. | [54] |

| ChCl:4-chlorophenol (1:2) (190 μL) | 9 pesticides | Apple, onion, cucumber, tomato and grape juice (5 mL) | Fruits were squeezed and diluted, while grape juice was used without dilution | GA-DLLME | GC-FID | 0.24–1.4 μg/L | 86–107% (-) | - | [55] |

| ChCl:4-chlorophenol (1:2) (132 μL) | 6 pesticides | Grape, apple and orange juices, lettuce, carrot, onion, cucumber, tomato and garlic (5 mL) | Orange juice was centrifuged and filtered, and all fruit juices were diluted. Vegetables were crushed, centrifuged and supernatant was diluted | DLLME | GC-FID | 0.46–3.1 μg/L | 87–101% (4–7%) | ACN was used as a disperser solvent. | [56] |

| ChCl:4-chlorophenol (1:2.5) (200 μL) | 2 OPPs | Fresh juice of apple, peach and orange, and tap and well water (6 mL) | Juice samples were centrifuged, filtered and diluted. Water samples were diluted | TC-DLLME | HPLC-UV | 0.15–0.30 μg/L | 96–105% (-) | This method can be applied in saline samples with an ionic strength up to 0.5 M. | [57] |

| ChCl:1,2-propanediol (1:2) (15000 μL) | 7 anthocyanins | Lycium ruthenicum Murr. fruit (1000 mg) | Samples were dried, ground and sieved | UA-SLE | Off-line heart-cutting 2D HPLC-DAD/MS | 36 μg/L | - (-) | DES contained 10% (v/v) water. Extraction optimization was done using BBD. | [58] |

| HFIP:L-carnitine (2:1) (150 mg) | 5 pyrethroids | Black, green and oolong teas, and apple, red grape and purple grape juices (5 mL) | Samples were centrifuged and the supernatant was filtered | VA-DLLME | HPLC-DAD | 0.06–0.17 μg/L | 85–109% (1–8%) | ACN was used as dispersion solvent. L-carnitine-based DESs provided higher EF than betaine-based DESs. | [59] |

| ChCl:phenol (-) (-) | 6 phenols | Smoked sausage and smoked fish (200 mg) | Samples were homogenized and store one month before use them | MME | HPLC-FD | 0.3–1.0 μg/kg | 70–80% (-) | GC-MS was used as a reference procedure. In situ DES formation between analytes (HBDs) and ChCl (HBA) supported in a hydrophilic porous membrane. | [60] |

| ChCl:phenol (1:2) (350 μL) | Cr(III) and Cr(VI) | Tap and river water, mushroom and soybean (10 mL) | Food samples were extracted with HCl and filtered | UA-DLLME | FAAS | 0.4 μg/L | 92–106% (2–4%) | PAN was used as a chelating agent. THF was used as an aprotic solvent. UA-LPME was superior than VA-LPME. Cr(VI) was reduced to Cr(III) with L-ascorbic. | [61] |

| ChCl:phenol (1:3) (500 μL) | Se(IV) and Se (VI) | Tap and mineral water, ice tea, cow milk, mixed fruit juice, orange juice, grape fruit, sheep milk, yogurt, honey, egg, canned fish and eddible mushroom (25 mL) | Water samples were filtered. Food samples were digested with H2O2 and HNO3 | UA-DLLME | ETAAS | 0.0046 μg/L | 96–99% (1–4%) | THF was used as aprotic solvent. 3,3-DAB was used as complexing agent. | [62] |

| ChCl:phenol (1:3) (500 μL) | Se(IV) and Se(VI) | Infant formula milk, infant cereal, tap and mineral water (200 mg) | Milk and cereal samples were digested in a microwave with HNO3 and H2O2 (2:1, v/v). All samples were filtered | UA-DLLME and VA-DLLME | GFAAS | 0.029 (UA-DLLME) and 0.036 (VA-DLLME) μg/L | 98–99% (UA-DLLME) and 96–98% (VA-DLLME) (-) | Na2S2O3 was used to reduce Se(VI) to Se(IV). UA-DLLME required less time and showed better LOD, RSD and EF than VA-DLLME. THF was used as an aprotic solvent. | [63] |

| ChCl:phenyl-EtOH (1:2) (250 μL) | Cr(III) and Cr(VI) | Tap, river and mineral water, and rice and sausage (10 mL) | Food samples were digested with HCl and all samples were filtered | AA-DLLME | FAAS | 0.4 μg/L | 86–105% (1–2%) | PAN was used as a complexing agent. | [64] |

| ChCl:HFIP (1:2) (60 μL for solid samples and 160 μL for liquid samples) | 6 PAHs | Milkvetch, ginseng, honeysuckle, Maojian tea and Anji white tea (500 mg). Jazmine tea beverage, natural mineral water, white grape and litchi juices, and honey (5 mL) | Solid samples were ground into powder and sieved, liquid samples were centrifugated and filtered, and honey was diluted | DT-DLLME | HPLC-FD | 0.00005–0.0042 μg/L | 88–114% (0–10%) | ACN was used as emulsifier and density regulator. Depending on the amount of emulsifier, the DES-rich phase could appear in the bottom or in the top phase. Rhodamine B was added as an indicator of the DES-rich phase. | [65] |

| ChCl:3,3-dimethyl butyric acid (1:1) (15 μL) | 4 OPPs | Sunflower, sesame, olive, canola and corn oil (2.5 mL) | - | DLLME-SFO | GC-NPD | 0.06–0.24 μg/L | 84–100% (2–8%) | dSPE is used before DLLME-SFO for a better performance in edible oil samples easily. PSA was selected as the sorbent in dSPE. | [66] |

| TBABr:acetic acid (1:2) (200 μL) | 6 preservatives | Functional, tea and carbonated drinks (4 mL) | - | DLLME-SFO | HPLC-DAD | 20–50 μg/L | 78–101% (0–4%) | 1-decanol was used as extractant. NaCl was added. BBD was used to determine the optimum conditions. | [67] |

| TBABr:acrylic acid (1:2) (10 mg) | Pb(II) | Tap and mineral water, onion, celery, carrot and tomato (50 mL) | Vegetables were dried at 100 °C and digested with HNO3 and H2O2 | dSPE | FAAS | 2.0 μg/L | 92–106% (1–5%) | DES was polymerized under solventless condition. Sorbent can be reused 16 times without significant decrease in the recovery. Results were compared with the obtained using ICP-MS. | [68] |

| ChCl:ethylene glycol (1:2) (3500 μL) | Gliadin | Heat-untreated (flour) and heat-treated (crackers and biscuits) gluten-free food (350 mg) | Food samples were milled to fine powder | VA-SLE | ELISA | - | 78–113% (3–13%) | The extraction capacity of the DESs was compared with the one of the EtOH-water medium. ChCl:urea DES provided better results, but DES with ethylene glycol provided the best performance in terms of recovery. | [69] |

| ChCl:ethylene glycol (1:2) (50 μL) | Ferulic, caffeic and cinnamic acids | Olive, almond, sesame and cinnamon oils (2 mL) | Samples were diluted with n-hexane (1:1, v/v) | UA-DLLME | HPLC-UV | 0.39–0.63 μg/L | 95–105% (2–5%) | Extraction optimization was done using BBD. | [70] |

| ChCl:thiacetamide (1:2) (40 μL) | Cd, Pb, Cu and As | Walnut, rice, tomato paste, spinach, orange juice, black tea, and tap and river water (48 mL) | Black tea sample was mixed with HNO3 1:1 and heated, and food samples were mixed with HNO3 (65%) and H2O2 (30%) and heated. All samples were filtered | AA-DLLME | ETAAS | 0.003–0.0042 μg/L | 94–101% (2–3%) | The extraction solvent was a magnetic nanofluid (a mixture of mCNTs and DES). | [71] |

| DEAC:pivalic acid (1:2) (80 μL) | 4 OCPs | Cocoa powder and cocoa beans (1000 mg) | Cocoa bean samples were crushed | DLLME | GC-ECD | 0.011–0.031 μg/kg | 84–99% (3–8%) | ACN was used as an extraction solvent and as a dispersive solvent in DLLME. | [72] |

| Tetramethylammonium chloride:ethylene glycol (1:3) (30 μL) | 3 plant growth regulators | Safflower, olive, camellia, colza and soybean oils (1 mL) | Samples were diluted with n-hexane (10% oil and 90% n-hexane) | UA-DLLME | HPLC-UV | 1200–7500 μg/L | 73–108% (0–9%) | - | [73] |

| DES (Molar Ratio) (Volume) | Analytes | Sample | Sample Preparation | Extraction Technique | Separation and Detection Technique | LODs | Recovery% (RSD%) | Comments | Reference |

|---|---|---|---|---|---|---|---|---|---|

| NADES | |||||||||

| Menthol:borneol:camphor (5:1:4) (80 mg) | 14 PAHs | Coffee (8 mL) | Samples were roasted in four different conditions | Nanoferrofluid | HPLC-FD | 0.00031–0.0059 μg/L | 91–121% (1–11%) | NADES modified Fe3O4 mNPs presented excellent microextraction performance. | [17] |

| L-menthol:acetic acid (1:1) (100 µL) | 9 PAEs | Green tea, tonic, lime and lemon drink (20 mL), and camomile, pennyroyal mint and linden teas (15 mL) | Infusions were prepared with hot Milli-Q water. All samples were previously degasified | DLLME-SFO | HPLC-UV | 1.05–15.33 µg/L | 71–125% (1–22%) | DHP and DNOP were used as ISs. | [18] |

| Camphor:hexanoic acid (1:1) (175 μL) | 15 PAHs | Herbal ready-to-drink beverages (10 mL) | - | UA-DLLME | GC-MS/MS | 0.01 μg/L | 69–125% (1–17%) | CCD was applied to evaluate the main factors affecting the process. ACN was used as dispersive solvent. | [85] |

| L-menthol:acetic acid (1:1) (100 μL) | 9 PAEs | Tap and mineral water and sparkling apple juice (20 mL) | Water samples were applied without any previous treatment, while the soft drink was degassed | DLLME | HPLC-UV | 1.08–6.90 μg/L | 71–120% (1–20%) | DHP and DNOP were used as ISs. | [96] |

| ChCl:sesamol (1:3) (800 μL) | Sudan I | Chili oil, chili sauce and duck egg yolk (200 mg) | Chili sauce and duck egg yolk were extracted with n-hexane | VA-DLLME | HPLC-UV | 20 μg/kg | 93–118% (-) | - | [97] |

| DL-menthol:pyruvic acid (1:2) (20000 μL) | Ergosterol | Mushroom (1000 mg) | Mushrooms were washed, shredded, lyophilized and pulverized without peeling off the skin | UA-SLE | HPLC-VWD | - | - (-) | 39 HDESs were evaluated. DES can be reused for up to six extraction cycles. CCD was selected for optimization. | [98] |

| Menthol:lauric acid (1:1) (400 μL) | 7 PAEs | Milk (5 mL) | Sample was centrifuged with ACN, MgSO4 and NaAc. The supernatant was also centrifuged in the same conditions. The final supernatant was diluted | VA-DLLME | HPLC-UV | 1.06–4.55 μg/L | 84–107% (2–4%) | NaOH and HCl were used as emulsifier and phase separation agent, respectively. | [99] |

| Thymol:vanillin (1:1) (200 μL) | 16 pesticides | Olive oil (500 mg) | Samples were vortexed with n-hexane and extracted with ACN. Then, the hydrophilic ChCl:urea DES was added and vortexed | VA-DLLME | GC-μECD | 0.01–0.08 μg/kg | 63–119% (2–7%) | A hydrophilic DES was used in the sample pretreatment to reduce the matrix effect of olive oils. | [100] |

| Menthol:octanoic acid (1:4) (500 μL) | Diphenylamine | Apple, pear and orange (1000 mg) | Samples were homogenised | UA-DLLME | HPLC-FD | 0.05 μg/L | 96–108% (1–4%) | - | [101] |

| ChCl:butyric acid (1:2) (180 μL) | 6 herbicides | Tea (5000 mg) | Samples were used without any pretreatment | HLLE-DLLME | GC-MS | 0.0026–0.0084 μg/kg | 70–89% (-) | NaCl was used as a separation agent. A hydrophilic DES (ChCl:phenol) was used as a disperser solvent. ACN was used as demulsifier agent. | [102] |

| Non NADES | |||||||||

| TBACl:2,3-butanediol (1:3) (500 μL) | Patulin | Apple, orange, peach, apricot, grape, kiwi, cherry and mango juices (3 mL) | Samples were diluted, extracted with ACN, centrifuged and the supernatant was mixed with PSA and MgSO4 | UA-DLLME | UV-Vis | 2.2 μg/L | 90–107% (2–4%) | Acetone was used as emulsifier solvent. | [16] |

| N4444Cl:octanoic acid (1:2) (100 μL) | 8 synthetic pigments | Carbonated drinks, tea beverage, fruit juices, and lactobacillus beverages (10 mL) | Carbonated drinks and tea beverage were used directly. Fuit juices and lactobacillus beverages were diluted 10 times and centrifuged to use the supernatant | VA-DLLME | HPLC-DAD | 0.016–1.120 μg/L | 75–103% (1–5%) | 4 DESs were evaluated. | [86] |

| TOMAC:2-octanol (1:2) (800 μL) | 3 sulfonamides | Apple, grape, peach and pear juices, and black tea (5 mL) | Samples were filtered and sealed | UA-DLLME | HPLC-UV | 20–50 μg/L | 81–104% (0–9%) | 5 DESs were evaluated. | [87] |

| TBABr:malonic acid:hexanoic acid (1:1:1) (2000 mg) | 2 sulfonamides | Chicken meat (1000 mg) | Samples were homogenized and liophilized | DLLME | HPLC-UV | 3–7 μg/kg | 86–109% (8%) | The DES decomposes when aqueous phase is injected, and the hexanoic acid is responsible for the extraction of the analytes. | [103] |

| BTEAB:eugenol (1:2) (75 mg) | 3 sudan dyes | Chili sauce, chili powder and ketchup (8 mL) | Samples were mixed with MeOH, ultrasonicated, centrifuged and diluted | VA-DLLME | HPLC-DAD | 0.5–1 μg/L | 90–119% (0–7%) | 0.5% NaCl (w/v) was added. | [104] |

| Menthol:dichloroacetic acid (1:2) (30 μL) | 7 pesticides | Honey (5000 mg) | Samples were diluted with water, and acetone was used as an extraction solvent | DLLME | GC-FID | 0.32–1.2 μg/kg | 90–109% (1–8%) | Acetone was also used as a dispersive solvent. A cloudy state was formed after dispersion of the DES into the aqueous solution. | [105] |

| 2-ethylhexyl 4-hydroxybenzoate:FWA52 (1:1) (-) | FWA52 | Noodles, fish balls, mushroom and paper cups (1000 mg) | Samples were broken into powder | VA-DLLME | FD | 0.045 μg/L | 82–113% (5–10%) | FWA52 acts as an analyte and HBA, so the HDES was formed during the extraction of FWA52. | [106] |

| TOMAC: amylalcohol (4:1) (150 μL) | Folic acid | Wheat flour (5000 mg) | - | VA-DLLME | HPLC-UV | 1.0 μg/kg | 92–100% (2–6%) | 3 DESs were prepared. The selected DES was mixed with MeOH. | [107] |

| N8881Br:decanoic acid (1:2) (200 μL) | 6 fluoroquinolones | Milk, yogurt, honey, tap water and river water (5 mL) | (NH4)2SO4 was used to make the milk and yogurt demulsification and the honey extraction processes | SO-DLLME-BE | MECC-UV | 6–10 μg/L | 88–115% (1–7%) | HCl was added in the BE. | [108] |

| THACl:oleic acid (1:1) (200 μL) | Co | Biscuit, bitter chocolate wafers, white chocolate, corn, wheat, herbal tea, spinach, mint, tap, waste, river, and well water, chocolate milk, cow milk and red wine (5 mL) | All samples except water samples were mixed with H2O2:HNO3 (1:3, v/v) and a MWA digestion was performed | AA-DLLME | FAAS | 0.04 μg/L | 94–105% (2–4%) | CCD combined with RSM was used for optimization. 6 ionic HDESs were evaluated. The analytical method is based on the complex formation of Co(II) with dithizone. | [109] |

| BTEAC:thymol (1:2) (300 μL) | 5 red dyes | Carbonated drink beverage, jelly and chocolate dragee (40 mL) | The carbonated drink was diluted and solid samples were dissolved | VA-DLLME | HPLC-UV | 0.01–0.08 μg/L | 94–101% (2–6%) | - | [110] |

| P666(14)Cl:pivalic acid (1:4) (200 μL) | Cd(II) | Waste, snow, rain, and tap water, cheese and milk (12 mL) | A wet digestion was applied with HNO3:H2O2 (3:1, v/v) | DLLME | FAAS | 1.6 μg/L | 95–99% (2–4%) | The BBD was used to determine the optimum conditions. | [111] |

| TOMAC:amyl alcohol (1:4) (100 μL) | 2 pesticides | Pistachio (5000 mg) | Sample was milled and homogenized | QuEChERS-DLLME | HPLC-UV | 1.5–3.0 μg/kg | 96–99% (2–7%) | The QuEChERS step allowed a better extraction and clean-up. | [112] |

| TBACl:decanoic acid (1:3) (100 μL) | Ni(II) | Waste, sea, mineral and well water, onion, parsley and cigarette (30 mL) | - | UA-DLLME | FAAS | 0.13 μg/L | 97–105% (-) | THF was used as self-aggregation agent. | [113] |

| PChCl:dichloroacetic acid:dodecanoic acid (1:1:1) (55 μL) | 4 antibiotics | Milk (7 mL) | ACN acted as proteins precipitation | SI-HLLE-DLLME | HPLC-DAD | 2.0–2.8 μg/L | 87–106% (5–6%) | AES tool was used for the assessment of the greenness of the proposed method. | [114] |

| Menthol:undecanol (1:2) (300 μL) | 3 bisphenols | Canned fruits (500 mg) | Samples were homogenized and freeze-dried | DLLME-SFO | UHPLC-MS/MS | 1.5–3.0 μg/kg | 79–101% (1–5%) | ACN was used as dispersion solvent. | [115] |

| TOMAC:DL-lactic acid (1:3) (400 μL) | Cd and As | Sorghum wine (5 mL) | Dried sea snake, seahorse and petrel were added to sorghum wine and keep for 6 months | UA-DLLME | FAAS | 0.08–0.30 μg/L | 91–104% (3–8%) | 8 DESs were compared. MeOH was used as dispersion solvent. | [116] |

| Aliquat 336:decanoic acid (1:2) (600 μL) | 2 food dyes | Fruity pastel, smarties, ice cream, candy and jelly (8 mL) | Samples were dissolved in water, centrifuged and the supernatant was diluted | EA-DLLME | UV-Vis | 2.0–2.9 μg/L | 98–103% (-) | DES was mixed with acetic acid. CO2 was produced in an effervescent reaction (acetic acid and NaHCO3) and was used as the dispersive force for DES. | [117] |

| ZnCl2:acetamide (1:2) (350 μL) | V | Sea, waste, canal, mineral, tap and drinking water (25 mL). Apple, banana, tomato, spinach and cultivated mushroom (1000 mg) | - | The solutions were heated until become turbid and then were centrifuged | GFAAS | 0.01 μg/kg 0.01 μg/L | 96–100% (1–3%) | Triton X-114 was used to enhanced phase transfer ratio. A factorial design and CCD were applied in the optimization process. | [118] |

| FeCl3:phenol (1:5) (150 μL) | Pb(II) | Tap, lake and river water (10 mL), salted peanuts, chickpeas, roasted yellow corn, pistachios and almonds (2 mL) | Water samples were filtered. Food samples were digested with HNO3 | VA-DLLME | FAAS | 0.008 μg/L | 92–101% (-) | α-benzoin oxime was used to enhance the ability of the DES to coordinate Pb(II). | [119] |

| ChCl:1-(o-tolyl)biguanide (1:1) (20 μL) | 5 PFASs | Olive, sesame, sunflower, seed, corn, camellia seed, soybean, blended and vegetable oils (7000 mg) | Samples were homogenized and microextracted at 40 °C | Superparamagnetic nanofluid | UHPLC-MS | 0.0003–0.0016 μg/kg | 90–109% (5–8%) | The DES system based superparamagnetic nanofluid can retrieved by an external magnetic field without additional centrifugation. | [120] |

| TBABr:dodecanol (1:2) (1.5 μL) | 67 terpenes | Cinnamon, cumin, fennel, clove, thyme and nutmeg (50 mg) | Spices were used as fine-grained powders, seeds and in small pieces | HS-SDME | GC-MS | 141–25,920 μg/kg | - (-) | Extraction time and temperature significantly affect the extraction. | [121] |

| ChCl:butyric acid (1:2) (58 μL) | 5 acidic pesticides | Tomato (50 mL) | Samples were cut, crushed, filtering the produced juice and diluted | SBME-DLLME-SFO | GC-MS | 0.007–0.014 μg/L | 86–99% (3–5%) | 15% (w/v) of NaCl was added. A hydrophilic DES (ChCl:ethylene glicol) was used as elution/dispersive solvent. | [122] |

| TBACl:decanoic acid (3:1) (100 μL) | Pb(II) | Tobacco, onion and parsley (30 mL) | Samples were digested with HNO3 and filtered | UA-DLLME | FAAS | 4.4 μg/L | 94–105% (4%) | THF was used as an emulsifier agent. PBD was used to determine the optimum conditions. | [123] |

| P666(14)Cl:tetradecyl alcohol (1:3) (10 mg) | 5 benzoylurea pesticides | Green tea, oolong tea, grapefruit water and lemon water (8 mL) | Samples were filtered | UA-DLLME | HPLC-UV | 0.30–0.60 μg/L | 77–101% (0–7%) | - | [124] |

| TBABr:decanoic acid (1:3) (100 μL) | 4 neonicotinoid insecticides | Water, soil and egg yolk (10 mL) | Water samples were filtered. Soil samples were air-dried, ground, sifted and extracted with anhydrous Na2SO4 and anhydrous NaAc. Egg samples were mixed with anhydrous Na2SO4 and 1% (v/v) acetic acid in ACN | DLLME | HPLC-UV | 1–3 μg/L | 60–114% (<10%) | ACN and SDS were used as disperser solvents. | [125] |

| ChCl:decanoic acid (1:2) (63 μL) | 7 pesticides | Milk (5 mL) | - | DLLME-SFO | GC-FID | 0.9–3.9 μg/L | 64–89% (3–6%) | ChCl:ethylene glycol was used as extraction/disperser solvent. | [126] |

| Dichloroacetic acid:L-menthol:n-butanol (4:1:1) (100 μL) | 10 pesticides | Green tea, and rose water, lemon balm, mint, and pussy willow distillates (50 mL) | The green tea was added to boiling water, centrifuged and filtrated | DLLME | GC-FID | 0.11–0.23 μg/L | 86–112% (1–7%) | MeOH was used as disperser solvent. | [127] |

| Dichloroacetic acid:butanol:menthol (2:1:1) (85 μL) | 10 pesticides | Tomato (10,000 mg) | Samples were chopped, squeezed and homogenized | MWA-DLLME | GC-FID | 0.42–0.74 μg/kg | 85–103% (-) | ACN was used as a dispersive solvent. | [128] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ortega-Zamora, C.; González-Sálamo, J.; Hernández-Borges, J. Deep Eutectic Solvents Application in Food Analysis. Molecules 2021, 26, 6846. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules26226846

Ortega-Zamora C, González-Sálamo J, Hernández-Borges J. Deep Eutectic Solvents Application in Food Analysis. Molecules. 2021; 26(22):6846. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules26226846

Chicago/Turabian StyleOrtega-Zamora, Cecilia, Javier González-Sálamo, and Javier Hernández-Borges. 2021. "Deep Eutectic Solvents Application in Food Analysis" Molecules 26, no. 22: 6846. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules26226846