Synthesis of Ammonium-Based ILs with Different Lengths of Aliphatic Chains and Organic Halogen-Free Anions as Corrosion Inhibitors of API X52 Steel

Abstract

:1. Introduction

2. Results and Discussion

2.1. Characterization of ILs

2.2. Rp- and Tafel-Polarization Analysis

2.3. Electrochemical Impedance Spectroscopy (EIS)

2.4. Adsorption Isotherm

2.5. Surface-Morphology Analysis

2.6. Computer-Simulation Analysis

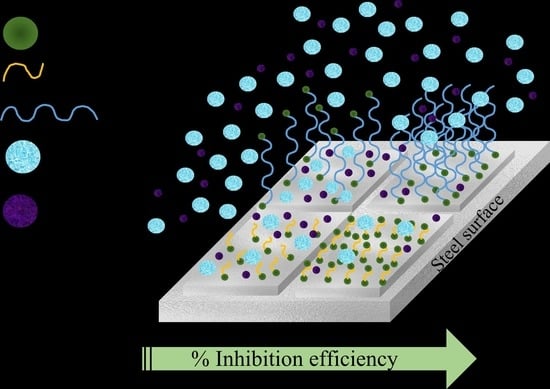

2.7. Inhibition Mechanism

3. Materials and Methods

3.1. Synthesis of ILs

3.2. Materials and Test Solutions

3.3. Electrochemical Techniques

3.4. DFT Calculations

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Heydari, M.; Javidi, M. Corrosion inhibition and adsorption behaviour of an amido-imidazoline derivative on API 5L X52 steel in CO2-saturated solution and synergistic effect of iodide ions. Corros. Sci. 2012, 61, 148–155. [Google Scholar] [CrossRef]

- Chauhan, D.S.; Quraishi, M.A.; Sorour, A.A.; Verma, C. A review on corrosion inhibitors for high-pressure supercritical CO2 environment: Challenges and opportunities. J. Pet. Sci. Eng. 2022, 215, 110695. [Google Scholar] [CrossRef]

- Karimi-Abadeh, H.; Javidi, M. Assessment and influence of temperature, NaCl and H2S on CO2 corrosion behavior of different microstructures of API 5L X52 carbon steel in aqueous environments. J. Nat. Gas Sci. Eng. 2019, 67, 93–107. [Google Scholar] [CrossRef]

- Arellanes-Lozada, P.; Díaz-Jiménez, V.; Hernández-Cocoletzi, H.; Nava, N.; Olivares-Xometl, O.; Likhanova, N.V. Corrosion inhibition properties of iodide ionic liquids for API 5L X52 steel in acid medium. Corros. Sci. 2020, 175, 108888. [Google Scholar] [CrossRef]

- Finšgar, M.; Jackson, J.; Dehghani, A.; Bahlakeh, G.; Ramezanzadeh, B.; Ramezanzadeh, M. Application of corrosion inhibitors for steels in acidic media for the oil and gas industry: A review. Corros. Sci. 2014, 86, 17–41. [Google Scholar] [CrossRef]

- Singh, A.; Ansari, K.R.; Quraishi, M.A.; Banerjee, P. Corrosion inhibition and adsorption of imidazolium based ionic liquid over P110 steel surface in 15% HCl under static and dynamic conditions: Experimental, surface and theoretical analysis. J. Mol. Liq. 2021, 323, 114608. [Google Scholar] [CrossRef]

- Abdallah, Y.M.; Shalabi, K.; Bayoumy, N.M. Eco-Friendly synthesis, biological activity and evaluation of some new pyridopyrimidinone derivatives as corrosion inhibitors for API 5L X52 carbon steel in 5% sulfamic acid medium. J. Mol. Struct. 2018, 1171, 658–671. [Google Scholar] [CrossRef]

- Shuai, Y.; Shuai, J.; Zhang, X. Experimental and numerical investigation of the strain response of a dented API 5L X52 pipeline subjected to continuously increasing internal pressure. J. Nat. Gas Sci. Eng. 2018, 56, 81–92. [Google Scholar] [CrossRef]

- Manrique, E.J.; Mogollon, J.L.; Linares, J.A.; Farrera, M. Basic nitrogen compounds in crude oils: Effect on mineral dissolution during acid stimulation processes. In Proceedings of the SPE International Symposium on Oilfield Chemistry, Houston, TX, USA, 18–21 February 1997; pp. 137–148. [Google Scholar]

- Afshari, F.; Ghomi, E.R.; Dinari, M.; Ramakrishna, S. Recent Advances on the Corrosion Inhibition Behavior of Schiff base Compounds on Mild Steel in Acidic Media. ChemistrySelect 2023, 8, e202203231. [Google Scholar] [CrossRef]

- Dwivedi, D.; Lepková, K.; Becker, T. Carbon steel corrosion: A review of key surface properties and characterization methods. RSC Adv. 2017, 7, 4580–4610. [Google Scholar] [CrossRef]

- Verma, C.; Haque, J.; Ebenso, E.E.; Quraishi, M.A. Melamine derivatives as effective corrosion inhibitors for mild steel in acidic solution: Chemical, electrochemical, surface and DFT studies. Results Phys. 2018, 9, 100–112. [Google Scholar] [CrossRef]

- Kobzar, Y.L.; Fatyeyeva, K. Ionic liquids as green and sustainable steel corrosion inhibitors: Recent developments. Chem. Eng. J. 2021, 425, 131480. [Google Scholar] [CrossRef]

- Cherrad, S.; Alrashdi, A.A.; Lee, H.-S.; El aoufir, Y.; Lgaz, H.; Satrani, B.; Ghanmi, M.; Aouane, E.M.; Chaouch, A. Cupressus arizonica fruit essential oil: A novel green inhibitor for acid corrosion of carbon steel. Arabian J. Chem. 2022, 15, 103849. [Google Scholar] [CrossRef]

- Al-Kaisy, G.M.J.; Mutalib, M.I.A.; Rao, T.V.V.L.N.; Senatore, A. Tribological performance of low viscosity halogen-free ammonium based protic ionic liquids with carboxylate anions as neat lubricants. Tribol. Int. 2021, 160, 107058. [Google Scholar] [CrossRef]

- Deyab, M.A. Understanding the anti-corrosion mechanism and performance of ionic liquids in desalination, petroleum, pickling, de-scaling, and acid cleaning applications. J. Mol. Liq. 2020, 309, 113107. [Google Scholar] [CrossRef]

- Gurjar, S.; Sharma, S.K.; Sharma, A.; Ratnani, S. Performance of imidazolium based ionic liquids as corrosion inhibitors in acidic medium: A review. Appl. Surf. Sci. Adv. 2021, 6, 100170. [Google Scholar] [CrossRef]

- Tecuapa-Flores, D.; Guadalupe Hernández, J.; Reyes Domínguez, I.; Turcio-Ortega, D.A.; Cruz-Borbolla, J.; Thangarasu, P. Understanding of benzimidazole based ionic liquid as an efficient corrosion inhibitor for carbon steel: Experimental and theoretical studies. J. Mol. Liq. 2022, 358, 119204. [Google Scholar] [CrossRef]

- Chen, G.; Li, F.; Zhang, C.; Guo, X.; Yang, Z.; Yu, Q.; Yu, B.; Cai, M.; Tian, D. Effect of two halogen-free ionic liquids with different anions on the tribological properties of TC4. J. Mol. Liq. 2021, 343, 117627. [Google Scholar] [CrossRef]

- Zhang, C.; Li, F.; Yang, Z.; Wang, X.; Chen, G.; Lu, Z.; Jia, L.; Yu, Q.; Cai, M. Comparing tribology properties of halogen-free ionic liquid, halogen-containing ionic liquid, and PAO 10 lubricants for steel–Al2024 friction contact at room temperature and high temperature. J. Mol. Liq. 2021, 323, 115041. [Google Scholar] [CrossRef]

- Olivares-Xometl, O.; Lijanova, I.V.; Likhanova, N.V.; Arellanes-Lozada, P.; Hernández-Cocoletzi, H.; Arriola-Morales, J. Theoretical and experimental study of the anion carboxylate in quaternary-ammonium-derived ionic liquids for inhibiting the corrosion of API X60 steel in 1 M H2SO4. J. Mol. Liq. 2020, 318, 114075. [Google Scholar] [CrossRef]

- Kannan, P.; Varghese, A.; Palanisamy, K.; Abousalem, A.S. Probing the effect of newly synthesized phenyltrimethylammonium tetrachloroaluminate ionic liquid as an inhibitor for carbon steel corrosion. Appl. Surf. Sci. Adv. 2021, 6, 100150. [Google Scholar] [CrossRef]

- Montalban, M.G.; Hidalgo, J.M.; Collado-Gonzalez, M.; Diaz Banos, F.G.; Villora, G. Assessing chemical toxicity of ionic liquids on Vibrio fischeri: Correlation with structure and composition. Chemosphere 2016, 155, 405–414. [Google Scholar] [CrossRef]

- Pham, T.P.; Cho, C.W.; Yun, Y.S. Structural effects of ionic liquids on microalgal growth inhibition and microbial degradation. Environ. Sci. Pollut. Res. Int. 2016, 23, 4294–4300. [Google Scholar] [CrossRef]

- Kaczerewska, O.; Leiva-Garcia, R.; Akid, R.; Brycki, B.; Kowalczyk, I.; Pospieszny, T. Heteroatoms and π electrons as favorable factors for efficient corrosion protection. Mater. Corros. 2019, 70, 1099–1110. [Google Scholar] [CrossRef]

- Likhanova, N.V.; Arellanes-Lozada, P.; Olivares-Xometl, O.; Lijanova, I.V.; Arriola-Morales, J.; Mendoza-Hérnandez, J.C.; Corro, G. Ionic Liquids with Carboxylic-Acid-Derived Anions Evaluated as Corrosion Inhibitors under Dynamic Conditions. Int. J. Electrochem. Sci. 2019, 14, 2655–2671. [Google Scholar] [CrossRef]

- Vinutha, M.R.; Venkatesha, T.V. Review on Mechanistic Action of Inhibitors on Steel Corrosion in Acidic Media. Port. Electrochim. Acta 2016, 34, 157–184. [Google Scholar] [CrossRef]

- Likhanova, N.V.; Arellanes-Lozada, P.; Olivares-Xometl, O.; Hernández-Cocoletzi, H.; Lijanova, I.V.; Arriola-Morales, J.; Castellanos-Aguila, J.E. Effect of organic anions on ionic liquids as corrosion inhibitors of steel in sulfuric acid solution. J. Mol. Liq. 2019, 279, 267–278. [Google Scholar] [CrossRef]

- Cabeza, O. Chapter 1—Properties and Green Aspects of Ionic Liquids. In Ionic Liquids in Separation Technology; Pérez De Los Ríos, A., Hernández Fernández, F.J., Eds.; Elsevier: Amsterdam, The Netherlands, 2014; pp. 1–93. [Google Scholar]

- Zhu, L.; Dong, J.; Zeng, Q.; Chao, M.; Gong, K.; Li, W.; Wang, X. A comprehensive study of amino acids based ionic liquids as green lubricants for various contacts. Tribol. Int. 2021, 162, 107137. [Google Scholar] [CrossRef]

- Aslam, R.; Mobin, M.; Huda; Obot, I.M.; Alamri, A.H. Ionic liquids derived from α-amino acid ester salts as potent green corrosion inhibitors for mild steel in 1M HCl. J. Mol. Liq. 2020, 318, 113982. [Google Scholar] [CrossRef]

- Berdimurodov, E.; Kholikov, A.; Akbarov, K.; Guo, L.; Kaya, S.; Katin, K.P.; Kumar-Verma, D.; Rbaa, M.; Dagdag, O.; Haldhar, R. Novel bromide–cucurbit[7]uril supramolecular ionic liquid as a green corrosion inhibitor for the oil and gas industry. J. Electroanal. Chem. 2021, 901, 115794. [Google Scholar] [CrossRef]

- Quraishi, M.A.; Chauhan, D.S.; Ansari, F.A. Development of environmentally benign corrosion inhibitors for organic acid environments for oil-gas industry. J. Mol. Liq. 2021, 329, 115514. [Google Scholar] [CrossRef]

- Verma, C.; Alrefaee, S.H.; Quraishi, M.A.; Ebenso, E.E.; Hussain, C.M. Recent developments in sustainable corrosion inhibition using ionic liquids: A review. J. Mol. Liq. 2021, 321, 114484. [Google Scholar] [CrossRef]

- Olivares-Xometl, O.; Likhanova, N.V.; Domínguez-Aguilar, M.A.; Arce, E.; Dorantes, H.; Arellanes-Lozada, P. Synthesis and corrosion inhibition of α-amino acids alkylamides for mild steel in acidic environment. Mater. Chem. Phys. 2008, 110, 344–351. [Google Scholar] [CrossRef]

- Verma, C.; Quraishi, M.A.; Ebenso, E.E. Microwave and ultrasound irradiations for the synthesis of environmentally sustainable corrosion inhibitors: An overview. Sustainable Chem. Pharm. 2018, 10, 134–147. [Google Scholar] [CrossRef]

- Zehra, S.; Mobin, M.; Aslam, R.; Lgaz, H.; Chung, I.-M. Assessment of biodegradable glycine and glutamic acid based ionic liquids as mild steel corrosion inhibitors in acid solution: An experimental and theoretical approach. J. Mol. Struct. 2021, 1240, 130505. [Google Scholar] [CrossRef]

- Ganjoo, R.; Sharma, S.; Thakur, A.; Assad, H.; Kumar-Sharma, P.; Dagdag, O.; Berisha, A.; Seydou, M.; Ebenso, E.E.; Kumar, A. Experimental and theoretical study of Sodium Cocoyl Glycinate as corrosion inhibitor for mild steel in hydrochloric acid medium. J. Mol. Liq. 2022, 364, 119988. [Google Scholar] [CrossRef]

- Liao, L.L.; Mo, S.; Luo, H.Q.; Feng, Y.J.; Yin, H.Y.; Li, N.B. Relationship between inhibition performance of melamine derivatives and molecular structure for mild steel in acid solution. Corros. Sci. 2017, 124, 167–177. [Google Scholar] [CrossRef]

- Scendo, M.; Uznanska, J. The Effect of Ionic Liquids on the Corrosion Inhibition of Copper in Acidic Chloride Solutions. Int. J. Corros. 2011, 2011, 718626. [Google Scholar] [CrossRef]

- Subasree, N.; Selvi, J.A. Imidazolium based ionic liquid derivatives; synthesis and evaluation of inhibitory effect on mild steel corrosion in hydrochloric acid solution. Heliyon 2020, 6, e03498. [Google Scholar] [CrossRef]

- Ansari, F.A.; Quraishi, M.A. Inhibitive Performance of Gemini Surfactants as Corrosion Inhibitors for Mild Steel in Formic Acid. Port. Electrochim. Acta 2010, 28, 321–335. [Google Scholar]

- Hajjaji, F.E.L.; Salim, R.; Ech-chihbi, E.; Titi, A.; Messali, M.; Kaya, S.; Ibrahimi, B.E.; Taleb, M. New imidazolium ionic liquids as ecofriendly corrosion inhibitors for mild steel in hydrochloric acid (1 M): Experimental and theoretical approach. J. Taiwan Inst. Chem. Eng. 2021, 123, 346–362. [Google Scholar] [CrossRef]

- Khamaysa, O.M.A.; Selatnia, I.; Lgaz, H.; Sid, A.; Lee, H.-S.; Zeghache, H.; Benahmed, M.; Ali, I.H.; Mosset, P. Hydrazone-Based green corrosion inhibitors for API grade carbon steel in HCl: Insights from electrochemical, XPS, and computational studies. Colloids Surf. A 2021, 626, 127047. [Google Scholar] [CrossRef]

- Corrales-Luna, M.; Le-Manh, T.; Romero-Romo, M.; Palomar-Pardavé, M.; Arce-Estrada, E.-M. 1-Ethyl 3-methylimidazolium thiocyanate ionic liquid as corrosion inhibitor of API 5L X52 steel in H2SO4 and HCl media. Corros. Sci. 2019, 153, 85–99. [Google Scholar] [CrossRef]

- Aslam, R.; Mobin, M.; Huda; Shoeb, M.; Murmu, M.; Banerjee, P. Proline nitrate ionic liquid as high temperature acid corrosion inhibitor for mild steel: Experimental and molecular-level insights. J. Ind. Eng. Chem. 2021, 100, 333–350. [Google Scholar] [CrossRef]

- Abd-El-Lateef, H.M.; Shalabi, K.; Abdelhamid, A.A. One-Pot synthesis of novel triphenyl hexyl imidazole derivatives catalyzed by ionic liquid for acid corrosion inhibition of C1018 steel: Experimental and computational perspectives. J. Mol. Liq. 2021, 334, 116081. [Google Scholar] [CrossRef]

- Kamali-Ardakani, E.; Kowsari, E.; Ehsani, A. Imidazolium-Derived polymeric ionic liquid as a green inhibitor for corrosion inhibition of mild steel in 1.0 M HCl: Experimental and computational study. Colloids Surf. A 2020, 586, 124195. [Google Scholar] [CrossRef]

- Kannan, P.; Varghese, A.; Palanisamy, K.; Abousalem, A.S. Evaluating prolonged corrosion inhibition performance of benzyltributylammonium tetrachloroaluminate ionic liquid using electrochemical analysis and Monte Carlo simulation. J. Mol. Liq. 2020, 297, 111855. [Google Scholar] [CrossRef]

- Elabbasy, H.M.; Gadow, H.S. Study the effect of expired tenoxicam on the inhibition of carbon steel corrosion in a solution of hydrochloric acid. J. Mol. Liq. 2021, 321, 114918. [Google Scholar] [CrossRef]

- Farag, Z.R.; Moustapha, M.E.; Anouar, E.-H.; Abd-El-Hafeez, G.M. The inhibition tendencies of novel hydrazide derivatives on the corrosion behavior of mild steel in hydrochloric acid solution. J. Mater. Res. Technol. 2022, 16, 1422–1434. [Google Scholar] [CrossRef]

- Ontiveros-Rosales, M.; Espinoza-Vázquez, A.; Rodríguez Gómez, F.J.; Valdez-Rodríguez, S.; Miralrio, A.; Acosta-Garcia, B.A.; Castro, M. Imidazolate of 1-butyl-3-ethyl imidazole as corrosion inhibitor on API 5L X52 steel in NaCl saturated with CO2. J. Mol. Liq. 2022, 363, 119826. [Google Scholar] [CrossRef]

- Deyab, M.A.; Zaky, M.T.; Nessim, M.I. Inhibition of acid corrosion of carbon steel using four imidazolium tetrafluoroborates ionic liquids. J. Mol. Liq. 2017, 229, 396–404. [Google Scholar] [CrossRef]

- Migahed, M.A.; El-Rabiei, M.M.; Nady, H.; Elgendy, A.; Zaki, E.G.; Abdou, M.I.; Noamy, E.S. Novel Ionic Liquid Compound Act as Sweet Corrosion Inhibitors for X-65 Carbon Tubing Steel: Experimental and Theoretical Studies. J. Bio- Tribo-Corros. 2017, 3, 31. [Google Scholar] [CrossRef]

- Ayawei, N.; Ebelegi, A.N.; Wankasi, D. Modelling and Interpretation of Adsorption Isotherms. J. Chem. 2017, 2017, 3039817. [Google Scholar] [CrossRef]

- Dehghani, A.; Bahlakeh, G.; Ramezanzadeh, B.; Ramezanzadeh, M. Potential role of a novel green eco-friendly inhibitor in corrosion inhibition of mild steel in HCl solution: Detailed macro/micro-scale experimental and computational explorations. Constr. Build. Mater. 2020, 245, 118464. [Google Scholar] [CrossRef]

- El-Azzouzi, M.; Aouniti, A.; El-Massaoudi, M.; Radi, S.; Hammouti, B.; Quraishi, M.A.; Bendaif, H.; El-Ouadi, Y. Inhibition effect of 1,1´-(pyridine-2,6-dihylbis(methylene))bis(5- methyl-1-H-pyrazole-3-carboxylic acid) on the corrosion of mild steel in 1 M HCl. Part A: Experimental study. Int. J. Corros. Scale Inhib. 2017, 6, 463–475. [Google Scholar]

- Cao, S.; Liu, D.; Ding, H.; Wang, J.; Lu, H.; Gui, J. Task-Specific ionic liquids as corrosion inhibitors on carbon steel in 0.5 M HCl solution: An experimental and theoretical study. Corros. Sci. 2019, 153, 301–313. [Google Scholar] [CrossRef]

- Mathammal, R.; Jayamani, N.; Geetha, N. Molecular Structure, NMR, HOMO, LUMO, and Vibrational Analysis of O-Anisic Acid and Anisic Acid Based on DFT Calculations. J. Spectrosc. 2013, 2013, 171735. [Google Scholar] [CrossRef]

- Kaya, S.; Tüzün, B.; Kaya, C.; Obot, I.B. Determination of corrosion inhibition effects of amino acids: Quantum chemical and molecular dynamic simulation study. J. Taiwan Inst. Chem. Eng. 2016, 58, 528–535. [Google Scholar] [CrossRef]

- Rees, R.J.; Lane, G.H.; Hollenkamp, A.F.; Best, A.S. Predicting properties of new ionic liquids: Density functional theory and experimental studies of tetra-alkylammonium salts of (thio)carboxylate anions, RCO2−, RCOS− and RCS2−. Phys. Chem. Chem. Phys. 2011, 13, 10729–10740. [Google Scholar] [CrossRef]

- Díaz-Jiménez, V.; Arellanes-Lozada, P.; Likhanova, N.V.; Olivares-Xometl, O.; Chigo-Anota, E.; Lijanova, I.V.; Gómez-Sánchez, G.; Verpoort, F. Investigation of Sulfonium-Iodide-Based Ionic Liquids to Inhibit Corrosion of API 5L X52 Steel in Different Flow Regimes in Acid Medium. ACS Omega 2022, 7, 42975–42993. [Google Scholar] [CrossRef]

- Haque, J.; Srivastava, V.; Verma, C.; Lgaz, H.; Salghi, R.; Quraishi, M.A. N-Methyl-N,N,N-trioctylammonium chloride as a novel and green corrosion inhibitor for mild steel in an acid chloride medium: Electrochemical, DFT and MD studies. New J. Chem. 2017, 41, 13647–13662. [Google Scholar] [CrossRef]

- Verma, C.; Obot, I.B.; Bahadur, I.; Sherif, E.-S.M.; Ebenso, E.E. Choline based ionic liquids as sustainable corrosion inhibitors on mild steel surface in acidic medium: Gravimetric, electrochemical, surface morphology, DFT and Monte Carlo simulation studies. Appl. Surf. Sci. 2018, 457, 134–149. [Google Scholar] [CrossRef]

- Arellanes-Lozada, P.; Hernández-Cocoletzi, H.; Lijanova, I.V.; Olivares-Cuapa, J.C.; Olivares-Cuapa, J.M.; Calvillo-Muñoz, E.Y.; Likhanova, N.V. Effect of sulfonate anions on the performance of triethylmethylammonium-derived ionic liquids as corrosion inhibitors. J. Adhes. Sci. Technol. 2023, 1–25. [Google Scholar] [CrossRef]

- Lourenço, T.C.; Barros, L.M.S.; Anchieta, C.G.; Nepel, T.C.M.; Júlio, J.P.O.; Dias, L.G.; Filho, R.M.; Doubek, G.; Da Silva, J.L.F. Tuning aprotic solvent properties with long alkyl chain ionic liquid for lithium-based electrolytes. J. Mater. Chem. A 2022, 10, 11684–11701. [Google Scholar] [CrossRef]

- Assenine, M.A.; Haddad, B.; Paolone, A.; Brandán, S.A.; Villemin, D.; Boumediene, M.; Rahmouni, M.; Bresson, S. Experimental and DFT studies on structure, spectroscopic and thermal properties of N-Methyl-N,N,N-trioctylammonium chloride ionic liquid. J. Mol. Struct. 2021, 1230, 129625. [Google Scholar] [CrossRef]

- Znini, M.; Ansari, A.; Costa, J.; Senhaji, O.; Paolini, J.; Majidi, L. Experimental, Quantum Chemical and Molecular Dynamic Simulations Studies on the Corrosion Inhibition of C38 Steel in 1M HCl by Anethum graveolens Essential Oil. Anal. Bioanal. Electrochem. 2019, 11, 1426–1451. [Google Scholar]

- Jadaa, R.J.; Abd, A.N.; Khadom, A.A. Polyacrylamide as a corrosion inhibitor for mild steel in 2 M phosphoric acid: Experimental and theoretical studies. Chem. Pap. 2021, 75, 5375–5386. [Google Scholar] [CrossRef]

- Gómora-Herrera, D.; Lijanova, I.V.; Olivares-Xometl, O.; Toscano, A.; Likhanova, N.V. Synthesis of the symmetrical methylene diesters from carboxylic ionic liquids. Can. J. Chem. 2017, 95, 744–750. [Google Scholar] [CrossRef]

- Preparing, Cleaning, and Evaluating Corrosion Test Specimens. ASTMG1-03-(2011); ASTM International: West Conshohocken, PA, USA, 2011.

- Conducting Potentiodynamic Polarization Resistance Measurements. ASTMG59-97-(2002); ASTMG59-97-(2002). ASTM International: West Conshohocken, PA, USA, 2002.

- Conventions Applicable to Electrochemical Measurements in Corrosion Testing. ASTMG3-89-(1999); ASTM International: West Conshohocken, PA, USA, 1999.

- Verification of Algorithm and Equipment for Electrochemical Impedance Measurements. ASTMG106-89-(1999); ASTM International: West Conshohocken, PA, USA, 1999.

- Frisch, M.J.; Nakatsuji, H.; Ehara, M.; Toyota, K.; Fukuda, R.; Hasegawa, J.; Ishida, M.; Nakajima, T.; Honda, Y.; Kitao, O.; et al. Gaussian 09, Revision D.01; Gaussian, Inc.: Wallingford, CT, USA, 2013. [Google Scholar]

| Abbreviation | Name | Chemical Structure | Yield (%) |

|---|---|---|---|

| [THDA+][−MC] | Methyl-carbonate of N,N,N-trimethyl-hexadecan-1-ammonium |  | 98.7 |

| [THDA+][−AB] | Butyrate of N,N,N-trimethyl-hexadecan-1-ammonium |  | 51.5 |

| [THDA+][−AI] | 3-Carboxybut-3-enoate of N,N,N-trimethyl-hexadecan-1-ammonium |  | 51.1 |

| [THDA+][−2,2-DSA] | 3-Carboxy-2,2-dimethylpropanoate of N,N,N-trimethyl-hexadecan-1-ammonium |  | 54.3 |

| [THDA+][−AA] | 2-Amine-benzoate of N,N,N-trimethyl-hexadecan-1-ammonium |  | 52.7 |

| [THDA+][−AH] | Hexanoate of N,N,N-trimethy-l-hexadecan-1-ammonium |  | 51.7 |

| [THDA+][−AAD] | Pentanoate 5-carboxy of N,N,N-trimethyl-hexadecan-1-ammonium |  | 38.0 |

| [THDA+][−AD] | Dodecanoate of N,N,N-trimethy-l-hexadecan-1-ammonium |  | 45.8 |

| [THDA+][−A2D] | 11-Carboxyundecanoate of N,N,N-trimethyl-hexadecan-1-ammonium |  | 42.7 |

| [TXMA+][−AI] | 3-Carboxybut-3-enoate of N,N,N-trihexyl-N-methyl-ammonium |  | 96.1 |

| [TXMA+][−2,2-DSA] | 3-Carboxy-2,2-dimethylpropanoate of N,N,N-trihexyl-N-methyl-ammonium |  | 96.0 |

| [TXMA+][−AA] | 2-Amine-benzoate of N,N,N-trihexyl-N-methyl-ammonium |  | 95.7 |

| [TPMA+][−AI] | 3-Carboxybut-3-enoate of N,N,N-tripentyl-N-methyl-ammonium |  | 81.0 |

| [TPMA+][−2,2-DSA] | 3-Carboxy-2,2-dimethylpropanoate of N,N,N-tripentyl-N-methyl-ammonium |  | 85.6 |

| [TPMA+][−AA] | 2-Amine-benzoate of N,N,N-tripentyl-N-methyl-ammonium |  | 98.0 |

| IL | Rp (Ω cm2) | IERp (%) | Ecorr (mV) | βa (mV dec−1) | βc (mV dec−1) | icorr (μA cm−2) | IETafel (%) |

|---|---|---|---|---|---|---|---|

| Blank | 243 ± 9 | −478 ± 1 | 89 ± 1 | 113 ± 2 | 82 ± 0.7 | - | |

| [THDA+][−MC] | 619 ± 33 | 60.5 ± 4.0 | −463 ± 7 | 106 ± 16 | 159 ± 13 | 40 ± 0.1 | 51.2 ± 0.4 |

| [THDA+][−AB] | 442 ± 0 | 45.1 ± 0 | −478 ± 9 | 112 ± 9 | 144 ± 19 | 39 ± 0.4 | 52.4 ± 0.6 |

| [THDA+][−AI] | 1263 ± 26 | 80.9 ± 0.5 | −482 ± 2 | 99 ± 6 | 214 ± 8 | 17 ± 0.8 | 79.2 ± 1 |

| [THDA+][−2,2-DSA] | 1013 ± 27 | 75.9 ± 1.9 | −473 ± 2 | 98 ± 5 | 227 ± 3 | 23 ± 0.4 | 71.9 ± 0.5 |

| [THDA+][−AA] | 1397 ± 36 | 81.6 ± 2.3 | −485 ± 2 | 81 ± 3 | 105 ± 8 | 13 ± 0.6 | 84.1 ± 0.7 |

| [THDA+][−AH] | 630 ± 31 | 61.4 ± 1.9 | −476 ± 8 | 106 ± 15 | 137 ± 4 | 35 ± 0.4 | 57.3 ± 0.6 |

| [THDA+][−AAD] | 962 ± 32 | 74.7 ± 1.8 | −486 ± 3 | 100 ± 1 | 223 ± 12 | 23 ± 0.6 | 71.9 ± 0.8 |

| [THDA+][−AD] | 1203 ± 37 | 79.8 ± 1.9 | −481 ± 0 | 81 ± 5 | 231 ± 15 | 18 ± 0.2 | 78 ± 0.3 |

| [THDA+][−A2D] | 841 ± 29 | 71.0 ± 1.8 | −474 ± 0 | 93 ± 2 | 224 ± 3 | 27 ± 0.1 | 67.1 ± 0.3 |

| [TXMA+][−AI] | 684 ± 39 | 63.9 ± 6.8 | −480 ± 2 | 84 ± 8 | 110 ± 21 | 32 ± 0.5 | 60.9 ± 0.7 |

| [TXMA+][−2,2-DSA] | 646 ± 33 | 62.1 ± 4.0 | −479 ± 4 | 88 ± 8 | 125 ± 7 | 34 ± 0.3 | 58.5 ± 0.5 |

| [TXMA+][−AA] | 794 ± 6 | 69.4 ± 0.2 | −480 ± 3 | 83 ± 3 | 117 ± 10 | 26 ± 0.3 | 68.2 ± 0.5 |

| [TPMA+][−AI] | 522 ± 29 | 53.1 ± 3.3 | −476 ± 6 | 75 ± 6 | 126 ± 2 | 35 ± 0.1 | 57.3 ± 0.4 |

| [TPMA+][−2,2-DSA] | 424 ± 15 | 38.6 ± 2.5 | −477 ± 0 | 89 ± 16 | 125 ± 18 | 52 ± 0.8 | 36.5 ± 1.1 |

| [TPMA+][−AA] | 287 ± 0.7 | 15.3 ± 0.2 | −477 ± 5 | 86 ± 12 | 134 ± 19 | 65 ± 1.4 | 20.7 ± 1.8 |

| IL | Concentration (ppm) | Ecorr (mV) | βa (mV dec−1) | βc (mV dec−1) | icorr (μA/cm−2) | IE (%) |

|---|---|---|---|---|---|---|

| Blank | 0 | −478 ± 1 | 89 ± 1 | 113 ± 2 | 82 ± 0.7 | - |

| [THDA+][−AI] | 25 | −495 ± 1 | 130 ± 23 | 253 ± 6 | 29 ± 0.3 | 64.6 ± 0.5 |

| 50 | −499 ± 1 | 116 ± 3 | 240 ± 9 | 27 ± 0.1 | 67.1 ± 0.3 | |

| 75 | −492 ± 1 | 102 ± 1 | 223 ± 3 | 24 ± 0.2 | 70.7 ± 0.3 | |

| 100 | −482 ± 2 | 99 ± 6 | 214 ± 8 | 17 ± 0.8 | 79.2 ± 1 | |

| 200 | −466 ± 7 | 78 ± 3 | 193 ± 6 | 18 ± 0.1 | 78.0 ± 0.2 | |

| [THDA+][−AA] | 25 | −491 ± 1 | 83 ± 1 | 98 ± 1 | 17 ± 0.2 | 79.3 ± 0.3 |

| 50 | −483 ± 5 | 80 ± 9 | 115 ± 8 | 14 ± 0.1 | 82.9 ± 0.2 | |

| 75 | −483 ± 1 | 78 ± 2 | 111 ± 5 | 13 ± 0.3 | 84.1 ± 0.4 | |

| 100 | −484 ± 2 | 81 ± 3 | 105 ± 8 | 13 ± 0.6 | 84.1 ± 0.7 | |

| 200 | −466 ± 7 | 78 ± 3 | 112 ± 6 | 18 ± 0 | 78 ± 0.2 | |

| [THDA+][−AD] | 25 | −487 ± 1 | 93 ± 3 | 178 ± 18 | 22 ± 0.1 | 73.1 ± 0.3 |

| 50 | −489 ± 1 | 103 ± 3 | 187 ± 14 | 21 ± 0 | 74.4 ± 0.2 | |

| 75 | −482 ± 0 | 89 ± 1 | 207 ± 19 | 19 ± 0.1 | 76.8 ± 0.2 | |

| 100 | −481 ± 0 | 81 ± 5 | 231 ± 15 | 18 ± 0.2 | 78 ± 0.3 | |

| 200 | −468 ± 5 | 76 ± 6 | 198 ± 8 | 18 ± 0.6 | 78 ± 0.8 |

| Concentration | Rs (Ω cm2) | Y (μΩ−1 sncm−2) | n | Rct (Ω cm2) | IEEIS |

|---|---|---|---|---|---|

| − | 17 ± 0.2 | 53 ± 2.2 | 0.90 | 134 ± 3.4 | − |

| 25 | 3 ± 0 | 31 ± 5.1 | 0.88 | 889 ± 7.7 | 85.0 ± 1.0 |

| 50 | 3 ± 0.1 | 35 ± 2.7 | 0.86 | 1290 ± 15.3 | 89.7 ± 0.9 |

| 75 | 2 ± 0.1 | 32 ± 1.3 | 0.87 | 1149 ± 37.6 | 88.4 ± 1.2 |

| 100 | 3 ± 0.1 | 35 ± 11.9 | 0.86 | 1319 ± 88.6 | 89.9 ± 1.8 |

| IL | Optimized Structure | MEP |

|---|---|---|

| [THDA+][−AA] |  |  |

| [THDA+][−AI] |  |  |

| [THDA+][−AD] |  |  |

| IL | HOMO | LUMO |

|---|---|---|

| [THDA+][−AA] |  |  |

| [THDA+][−AI] |  |  |

| [THDA+][−AD] |  |  |

| IL | EHOMO (eV) | ELUMO (eV) | ΔGL-H (eV) | μ (D) |

|---|---|---|---|---|

| [THDA+][−AA] | −8.67 | −5.37 | 3.31 | 15.39 |

| [THDA+][−AI] | −9.96 | −5.51 | 4.45 | 14.33 |

| [THDA+][−AD] | −10.10 | −3.63 | 6.46 | 14.37 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cornejo Robles, E.; Olivares-Xometl, O.; Likhanova, N.V.; Arellanes-Lozada, P.; Lijanova, I.V.; Díaz-Jiménez, V. Synthesis of Ammonium-Based ILs with Different Lengths of Aliphatic Chains and Organic Halogen-Free Anions as Corrosion Inhibitors of API X52 Steel. Int. J. Mol. Sci. 2023, 24, 7613. https://0-doi-org.brum.beds.ac.uk/10.3390/ijms24087613

Cornejo Robles E, Olivares-Xometl O, Likhanova NV, Arellanes-Lozada P, Lijanova IV, Díaz-Jiménez V. Synthesis of Ammonium-Based ILs with Different Lengths of Aliphatic Chains and Organic Halogen-Free Anions as Corrosion Inhibitors of API X52 Steel. International Journal of Molecular Sciences. 2023; 24(8):7613. https://0-doi-org.brum.beds.ac.uk/10.3390/ijms24087613

Chicago/Turabian StyleCornejo Robles, Emiliano, Octavio Olivares-Xometl, Natalya V. Likhanova, Paulina Arellanes-Lozada, Irina V. Lijanova, and Víctor Díaz-Jiménez. 2023. "Synthesis of Ammonium-Based ILs with Different Lengths of Aliphatic Chains and Organic Halogen-Free Anions as Corrosion Inhibitors of API X52 Steel" International Journal of Molecular Sciences 24, no. 8: 7613. https://0-doi-org.brum.beds.ac.uk/10.3390/ijms24087613