Instantaneous Self-Powered Sensing System Based on Planar-Structured Rotary Triboelectric Nanogenerator

Abstract

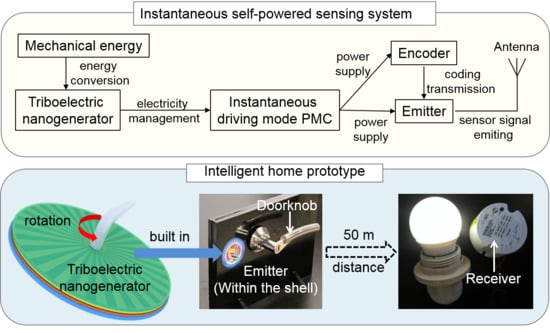

:1. Introduction

2. Design

2.1. The Design Considerations for the Instantaneous Self-Powered Sensing System

2.2. Design of the High-Power Generator for Instantaneous Driving

3. Results and Discussion

3.1. Electrical Outputs of Generators

3.2. Comparison of the Two Generators in Increasing Their Power

3.3. Performance of the Instantaneous Driving Mode Power Management Circuit

3.4. Demonstration of an Instantaneous Self-Powered Sensing Application

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Environmental Energy Harvesting Technology | Advantages | Disadvantages | Applications in Self-Powered Sensing System |

|---|---|---|---|

| Triboelectric nanogenerator based | high power; great advantage in low-frequency mechanical energy harvesting; low cost; lightweight; flexibility | energy loss induced by friction damping; difficulty in power management circuit design | environmental monitoring [28]; self-powered pressure sensor [29]; data acquisition/transmission [11] |

| Electromagnetic generator based | high power; great advantage in high-frequency mechanical energy harvesting | bulky; hard to integrate with electronics | vibration monitoring [30]; traffic monitoring [31] |

| Piezoelectric nanogenerator based | high output voltage; light weight; high integration level | fragile; low power | data transmission [6]; self-powered pressure sensor [32] |

| Thermoelectric generator based | thermal energy harvesting; flexibility; wearable | low power; not applicable in mechanical energy harvesting | health monitoring [33] |

Appendix B

Appendix C

Appendix D

References

- Wu, X.; Freese, D.; Cabrera, A.; Kitch, W.A. Electric vehicles’ energy consumption measurement and estimation. Transp. Res. Part D Transp. Environ. 2015, 34, 52–67. [Google Scholar] [CrossRef]

- Barré, A.; Deguilhem, B.; Grolleau, S.; Gérard, M.; Suard, F.; Riu, D. A review on lithium-ion battery ageing mechanisms and estimations for automotive applications. J. Power Sources 2013, 241, 680–689. [Google Scholar] [CrossRef] [Green Version]

- Atalay, S.; Sheikh, M.; Mariani, A.; Merla, Y.; Bower, E.; Widanage, W.D. Theory of battery ageing in a lithium-ion battery: Capacity fade, nonlinear ageing and lifetime prediction. J. Power Sources 2020, 478, 229026. [Google Scholar] [CrossRef]

- Luo, J.; Wang, Z.L. Recent progress of triboelectric nanogenerators: From fundamental theory to practical applications. EcoMat 2020, 2, e12059. [Google Scholar] [CrossRef]

- Torah, R.; Glynne-Jones, P.; Tudor, M.; O’Donnell, T.; Roy, S.; Beeby, S. Self-powered autonomous wireless sensor node using vibration energy harvesting. Meas. Sci. Technol. 2008, 19, 125202. [Google Scholar] [CrossRef]

- Ferrari, M.; Ferrari, V.; Guizzetti, M.; Marioli, D. An autonomous battery-less sensor module powered by piezoelectric energy harvesting with RF transmission of multiple measurement signals. Smart Mater. Struct. 2009, 18, 085023. [Google Scholar] [CrossRef]

- Leonov, V.; Torfs, T.; Fiorini, P.; Hoof, C.V. Thermoelectric Converters of Human Warmth for Self-Powered Wireless Sensor Nodes. IEEE Sens. J. 2007, 5, 650–657. [Google Scholar] [CrossRef]

- Zhu, G.; Zhou, Y.S.; Peng, B.; Meng, X.S.; Jing, Q.; Chen, J.; Wang, Z.L. A shape adaptive thin film based approach for 50% high efficiency energy generation through micro grating sliding electrification. Adv. Mater. 2014, 26, 3788–3796. [Google Scholar] [CrossRef]

- Zhu, G.; Chen, J.; Zhang, T.; Jing, Q.; Wang, Z.L. Radial-arrayed rotary electrification for high performance triboelectric generator. Nat. Commun. 2014, 5, 3426. [Google Scholar] [CrossRef]

- Wang, Z.L. Toward self-powered sensor networks. Nano Today 2010, 5, 512–514. [Google Scholar] [CrossRef]

- Luo, J.; Gao, W.; Wang, Z.L. The Triboelectric Nanogenerator as an Innovative Technology toward Intelligent Sports. Adv. Mater. 2021, 33, 2004178. [Google Scholar] [CrossRef]

- Meng, X.S.; Wang, Z.L.; Zhu, G. Triboelectric-Potential-Regulated Charge Transport through p-n Junctions for Area-Scalable Conversion of Mechanical Energy. Adv. Mater. 2016, 28, 668–676. [Google Scholar] [CrossRef]

- Qian, J.; Jing, X. Wind-driven hybridized triboelectric-electromagnetic nanogenerator and solar cell as a sustainable power unit for self-powered natural disaster monitoring sensor networks. Nano Energy 2018, 52, 78–87. [Google Scholar] [CrossRef]

- Dong, W.; Wang, L.; Yu, G.; Mei, Z. Design of wireless automatic fire alarm system. Procedia Eng. 2016, 135, 413–417. [Google Scholar] [CrossRef] [Green Version]

- Pu, X.; Li, L.; Song, H.; Du, C.; Zhao, Z.; Jiang, C.; Cao, G.; Hu, W.; Wang, Z.L. A self-charging power unit by integration of a textile triboelectric nanogenerator and a flexible lithium-ion battery for wearable electronics. Adv. Mater. 2015, 27, 2472–2478. [Google Scholar] [CrossRef] [PubMed]

- Zhu, G.; Peng, B.; Chen, J.; Jing, Q.; Wang, Z.L. Triboelectric nanogenerators as a new energy technology: From fundamentals, devices, to applications. Nano Energy 2015, 14, 126–138. [Google Scholar] [CrossRef] [Green Version]

- Han, C.; Zhang, C.; Tang, W.; Li, X.; Wang, Z.L. High power triboelectric nanogenerator based on printed circuit board (PCB) technology. Nano Res. 2015, 8, 722–730. [Google Scholar] [CrossRef]

- Sari, I.; Balkan, T.; Kulah, H. An electromagnetic micro power generator for wideband environmental vibrations. Sens. Actuators A Phys. 2008, 145, 405–413. [Google Scholar] [CrossRef]

- Wang, Z.L. On Maxwell’s displacement current for energy and sensors: The origin of nanogenerators. Mater. Today 2017, 20, 74–82. [Google Scholar] [CrossRef]

- Bhatia, D.; Jo, S.H.; Ryu, Y.; Kim, Y.; Kim, D.H.; Park, H.S. Wearable triboelectric nanogenerator based exercise system for upper limb rehabilitation post neurological injuries. Nano Energy 2021, 80, 105508. [Google Scholar] [CrossRef]

- Zhang, W.; Gu, G.; Qin, H.; Li, S.; Shang, W.; Wang, T.; Zhang, B.; Cui, P.; Guo, J.; Yang, F.; et al. Measuring the actual voltage of a triboelectric nanogenerator using the non-grounded method. Nano Energy 2020, 77, 105108. [Google Scholar] [CrossRef]

- Niu, S.; Wang, Z.L. Theoretical systems of triboelectric nanogenerators. Nano Energy 2015, 14, 161–192. [Google Scholar] [CrossRef] [Green Version]

- Li, H.; Su, L.; Kuang, S.; Pan, C.; Zhu, G.; Wang, Z.L. Significant enhancement of triboelectric charge density by fluorinated surface modification in nanoscale for converting mechanical energy. Adv. Funct. Mater. 2015, 25, 5691–5697. [Google Scholar] [CrossRef]

- Luo, J.; Wang, Z.; Xu, L.; Wang, A.C.; Han, K.; Jiang, T.; Lai, Q.; Bai, Y.; Tang, W.; Fan, F.R.; et al. Flexible and durable wood-based triboelectric nanogenerators for self-powered sensing in athletic big data analytics. Nat. Commun. 2019, 10, 5147. [Google Scholar] [CrossRef] [Green Version]

- Qin, H.; Cheng, G.; Zi, Y.; Gu, G.; Zhang, B.; Shang, W.; Yang, F.; Yang, J.; Du, Z.; Wang, Z.L. High Energy Storage Efficiency Triboelectric Nanogenerators with Unidirectional Switches and Passive Power Management Circuits. Adv. Funct. Mater. 2018, 28, 1805216. [Google Scholar] [CrossRef]

- Shang, W.; Gu, G.; Zhang, W.; Luo, H.; Wang, T.; Zhang, B.; Guo, J.; Cui, P.; Yang, F.; Cheng, G.; et al. Rotational Pulsed Triboelectric Nanogenerators Integrated with Synchronously Triggered Mechanical Switches for High Efficiency Self-Powered Systems. Nano Energy 2021, 82, 105725. [Google Scholar] [CrossRef]

- Qin, H.; Gu, G.; Shang, W.; Luo, H.; Zhang, W.; Cui, P.; Zhang, B.; Guo, J.; Cheng, G.; Du, Z. A universal and passive power management circuit with high efficiency for pulsed triboelectric nanogenerator. Nano Energy 2020, 68, 104372. [Google Scholar] [CrossRef]

- Zhao, Z.F.; Pu, X.; Du, C.; Li, L.; Jiang, C.; Hu, W.; Wang, Z.L. Freestanding Flag-Type Triboelectric Nanogenerator for Harvesting High-Altitude Wind Energy from Arbitrary Directions. ACS Nano 2016, 10, 1780–1787. [Google Scholar] [CrossRef]

- Wang, H.L.; Kuang, S.Y.; Li, H.Y.; Wang, Z.L.; Zhu, G. Large-Area Integrated Triboelectric Sensor Array for Wireless Static and Dynamic Pressure Detection and Mapping. Small 2020, 16, 1906352. [Google Scholar] [CrossRef]

- Galchev, T.V.; Mccullagh, J.; Peterson, R.L.; Najafi, K. Harvesting traffic-induced vibrations for structural health monitoring of bridges. J. Micromechanics Microengineering 2011, 21, 104005. [Google Scholar] [CrossRef] [Green Version]

- Askari, H.; Asadi, E.; Saadatnia, Z.; Khajepour, A.; Khamesee, M.B.; Zu, J. A hybridized electromagnetic-triboelectric self-powered sensor for traffic monitoring: Concept, modelling, and optimization. Nano Energy 2017, 32, 105–116. [Google Scholar] [CrossRef]

- Fuh, Y.K.; Wang, B.S.; Tsai, C.Y. Self-Powered Pressure Sensor with fully encapsulated 3D printed wavy substrate and highly-aligned piezoelectric fibers array. Sci. Rep. 2017, 7, 6759. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yuan, J.; Zhu, R. A fully self-powered wearable monitoring system with systematically optimized flexible thermoelectric generator. Appl. Energy 2020, 271, 115250. [Google Scholar] [CrossRef]

| Routes | Planar-Structured Rotary TENG | Electromagnetic Generator |

|---|---|---|

| integration | increase grid number | increase turn number of coil |

| size | increase size in radial dimension | increase size in radial dimension |

| material | increase surface charge density of electrification layers | increase magnetic field intensity of the magnet |

| rotation speed | increase rotation speed | increase rotation speed |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuang, S.; Suo, X.; Song, P.; Luo, J. Instantaneous Self-Powered Sensing System Based on Planar-Structured Rotary Triboelectric Nanogenerator. Sensors 2021, 21, 3741. https://0-doi-org.brum.beds.ac.uk/10.3390/s21113741

Kuang S, Suo X, Song P, Luo J. Instantaneous Self-Powered Sensing System Based on Planar-Structured Rotary Triboelectric Nanogenerator. Sensors. 2021; 21(11):3741. https://0-doi-org.brum.beds.ac.uk/10.3390/s21113741

Chicago/Turabian StyleKuang, Shuangyang, Xiaochen Suo, Peiyi Song, and Jianjun Luo. 2021. "Instantaneous Self-Powered Sensing System Based on Planar-Structured Rotary Triboelectric Nanogenerator" Sensors 21, no. 11: 3741. https://0-doi-org.brum.beds.ac.uk/10.3390/s21113741