The Effects of Ultrasonic Disintegration as a Function of Waste Activated Sludge Characteristics and Technical Conditions of Conducting the Process—Comprehensive Analysis

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sludge Collection and Analysis

2.2. Experimental Design and Operating Conditions

2.2.1. Ultrasonic Disintegration

2.2.2. Anaerobic Digestion

2.3. Direct and Technological Effects

2.3.1. Indicators of the Direct and Technological Effects

2.4. Statistical Analysis

3. Results and Discussion

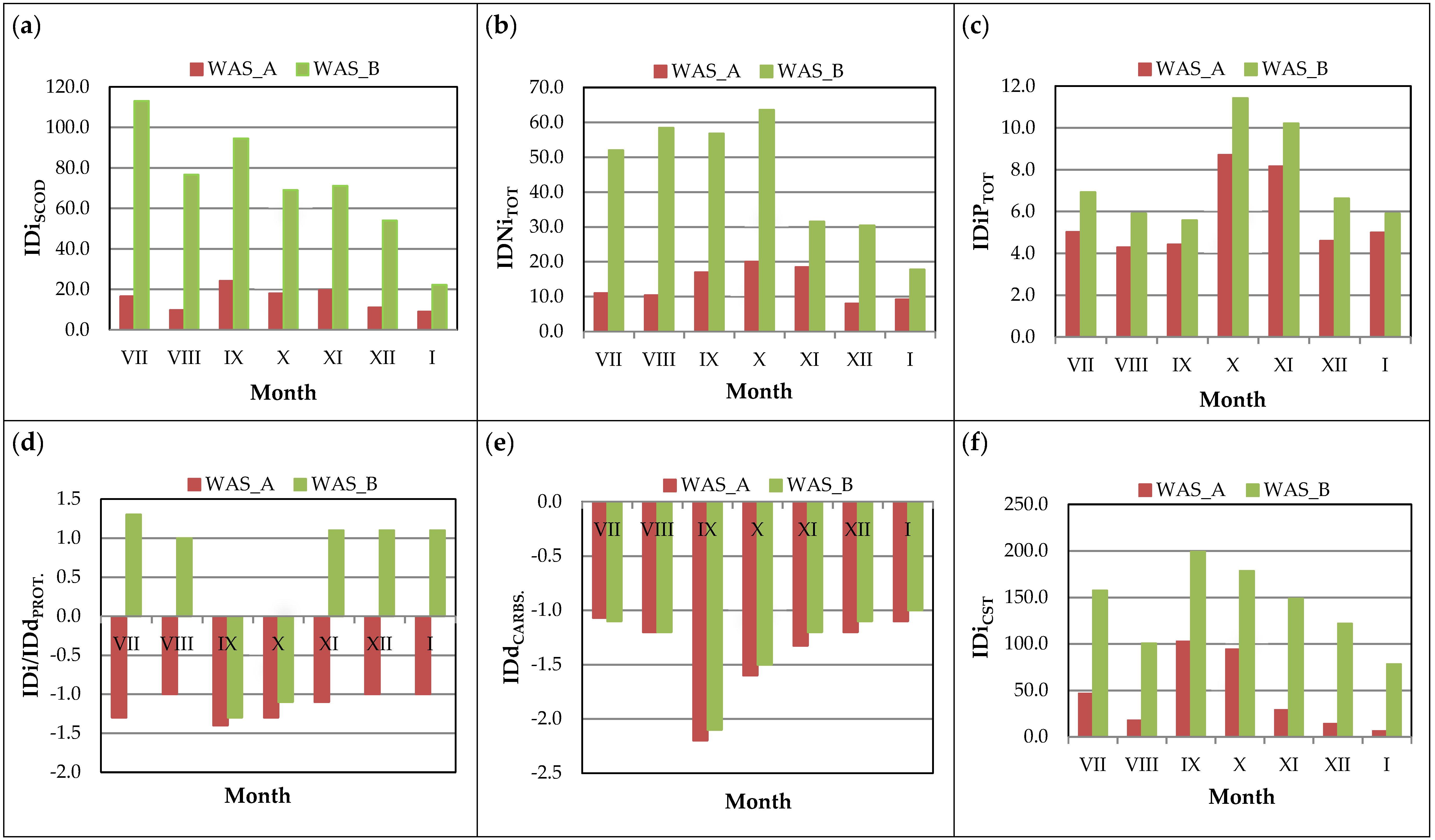

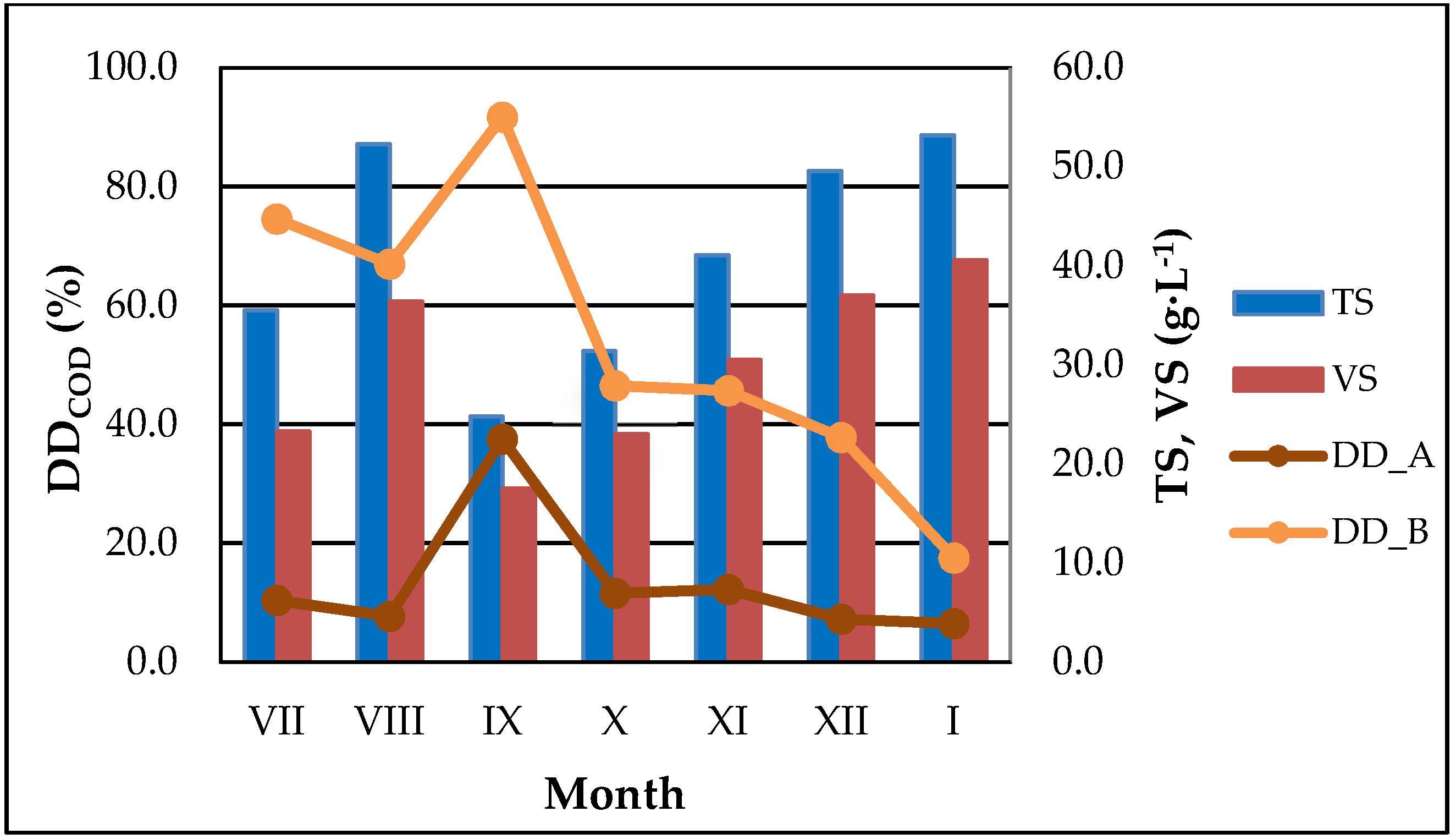

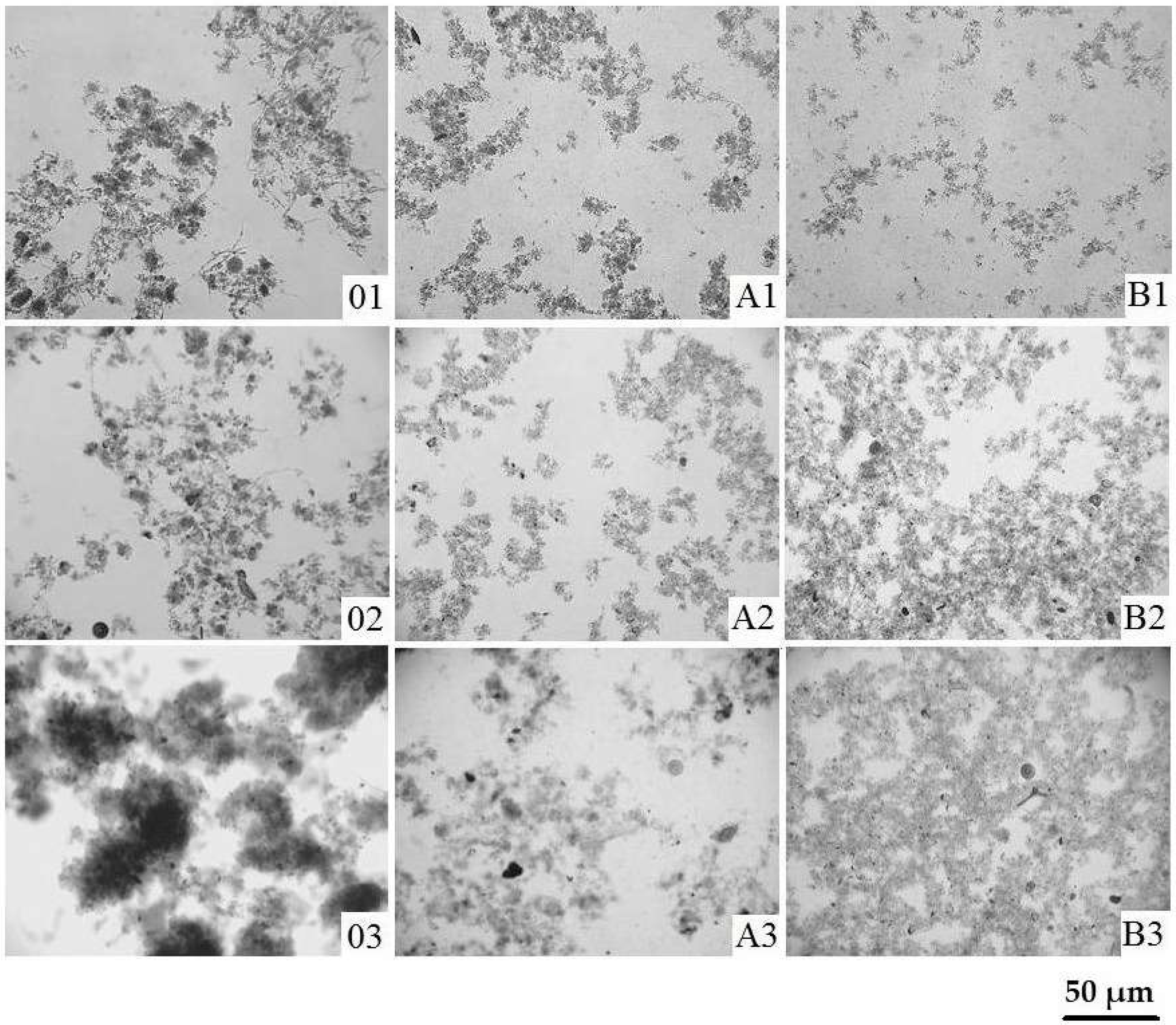

3.1. Direct Effects

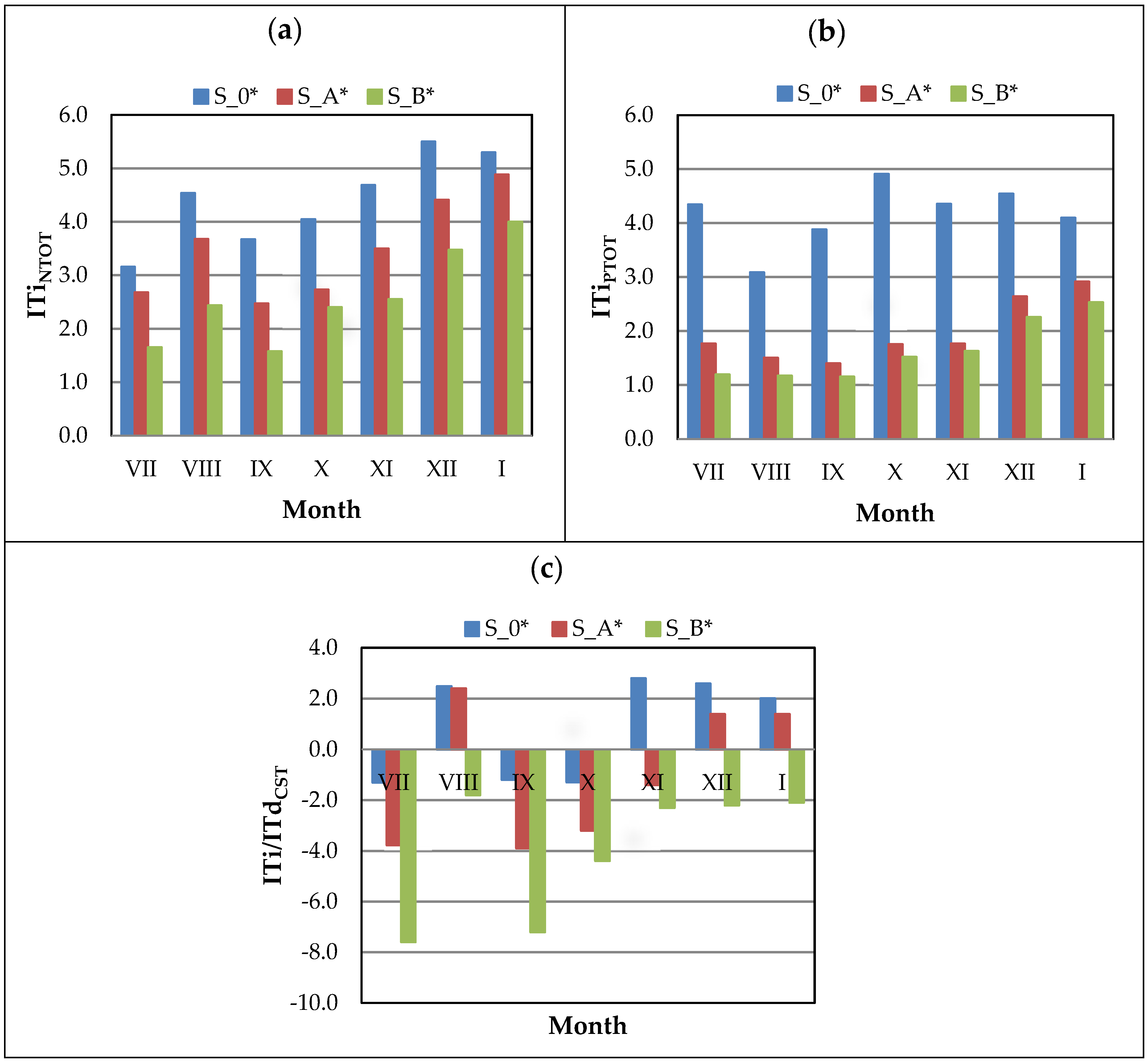

3.2. Technological Effects

3.3. Statistical Analysis

3.3.1. Analysis of Direct Effects

3.3.2. Analysis of Technological Effects

3.3.3. Analysis of Technological Conditions of Process Conducting

4. Conclusions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Variables | WAS_A | WAS_B |

|---|---|---|

| pH | 0.149546 | 0.021015 * |

| SCOD | 0.000456 * | 0.000558 * |

| NTOT | 0.000060 * | 0.000463 * |

| PTOT | 0.000037 * | 0.000010 * |

| Proteins | 0.018871 * | 0.478267 |

| Carbohydrates | 0.000543 * | 0.000457 * |

| CST | 0.010617 * | 0.000000 * |

| T | 0.000540 * | 0.000000 * |

| Variables | pH | SCOD | NTOT | PTOT | Proteins | Carbohydrates | CST |

|---|---|---|---|---|---|---|---|

| pH | 0.00 | −0.37 | −0.17 | −0.35 | −0.30 | −0.05 | −0.01 |

| SCOD | −0.32 | −0.75 ** | −0.56 | 0.19 | 0.42 | 0.68 ** | −0.71 ** |

| NTOT | 0.29 | −0.72 ** | −0.61 | −0.10 | 0.37 | 0.85 * | −0.87 * |

| PTOT | −0.51 | −0.20 | −0.74 | 0.54 | 0.70 | 0.46 | −0.39 |

| Proteins | −0.68 ** | −0.35 | −0.27 | 0.92 * | 0.96 * | 0.57 | −0.48 |

| Carbohydrates | −0.21 | −0.88 * | −0.43 | 0.45 | 0.79 * | 0.98 * | −0.97 * |

| CST | −0.44 | −0.65 ** | −0.60 | 0.47 | 0.66 ** | 0.75 ** | −0.72 ** |

| TS | −0.31 | −0.85 * | −0.54 | 0.37 | 0.70 ** | 0.90 * | −0.94 * |

| VS | −0.43 | −0.83 * | −0.52 | 0.51 | 0.80 * | 0.90 * | −0.92 * |

| ΔT | 0.47 | 0.84 * | 0.53 | −0.52 | −0.80 * | −0.87 * | 0.88 * |

| Variables | pH | SCOD | NTOT | PTOT | Proteins | Carbohydrates | CST |

|---|---|---|---|---|---|---|---|

| pH | 0.21 | 0.44 | 0.60 | −0.16 | −0.36 | −0.07 | −0.24 |

| SCOD | −0.28 | 0.04 | 0.06 | 0.25 | 0.33 | 0.65 ** | −0.79 * |

| NTOT | 0.29 | 0.22 | 0.02 | −0.01 | 0.53 | 0.84 * | −0.58 |

| PTOT | −0.42 | −0.55 | −0.51 | 0.55 | 0.51 | 0.44 | −0.34 |

| Proteins | −0.66 ** | −0.92 * | −0.95 * | 0.95 * | 0.87 * | 0.58 | −0.58 |

| Carbohydrates | −0.21 | −0.31 | −0.47 | 0.56 | 0.88 * | 0.98 * | −0.91 * |

| CST | −0.48 | −0.28 | −0.31 | 0.44 | 0.57 | 0.73 ** | −0.74 ** |

| TS | −0.28 | −0.17 | −0.26 | 0.46 | 0.67 | 0.88 * | −0.91 * |

| VS | −0.40 | −0.32 | −0.40 | 0.60 | 0.75 ** | 0.89 * | −0.94 * |

| ΔT | 0.59 | 0.43 | 0.50 | −0.71 ** | −0.77 * | −0.76 * | 0.94 * |

| Variables | WAS_A | WAS_B |

|---|---|---|

| pH | 0.019198 * | 0.000932 * |

| TS | 0.000013 * | 0.000003 * |

| VS | 0.000009 * | 0.000005 * |

| NTOT | 0.000113 * | 0.000463 * |

| PTOT | 0.023667 * | 0.047379 * |

| CST | 0.191863 | 0.000351 * |

| Variables | pH | TS | VS | NTOT | PTOT | CST | 3 Biogas |

|---|---|---|---|---|---|---|---|

| pH | −0.44 | 0.03 | −0.19 | −0.26 | −0.65 ** | −0.18 | −0.42 |

| TS | −0.53 | 0.98 * | 0.99 * | 0.92 * | 0.57 | 0.74 ** | 0.85 * |

| VS | −0.34 | 0.92 * | 0.99 * | 0.97 * | 0.73 ** | 0.81 * | 0.94 * |

| NTOT | 0.20 | −0.67 ** | −0.75 ** | −0.73 ** | −0.74 ** | −0.64 | −0.79 * |

| PTOT | 0.47 | 0.22 | 0.48 | 0.63 | 0.88 * | 0.59 | 0.74 ** |

| CST | 0.61 | −0.91 * | −0.88 * | −0.75 ** | −0.37 | −0.66 ** | −0.77 * |

| Variables | pH | TS | VS | NTOT | PTOT | CST | Biogas |

|---|---|---|---|---|---|---|---|

| pH | −0.02 | −0.11 | −0.32 | −0.19 | −0.75 ** | −0.31 | −0.43 |

| TS | −0.64 | 0.99 * | 0.93 * | 0.88 * | 0.29 | 0.78 * | 0.76 * |

| VS | −0.63 | 0.97 * | 0.99 * | 0.92 * | 0.50 | 0.87 * | 0.89 * |

| NTOT | −0.16 | −0.26 | −0.51 | −0.49 | −0.94 * | −0.62 | −0.76 * |

| PTOT | 0.17 | 0.15 | 0.41 | 0.31 | 0.91 * | 0.57 | 0.63 |

| CST | 0.28 | −0.81 * | −0.92 * | −0.94 * | −0.72 ** | −0.88 * | −0.93 * |

| Variable | Unit | p Value |

|---|---|---|

| pH | - | 0.233545 |

| SCOD | mg·L−1 | 0.000273 * |

| NTOT | mg·L−1 | 0.000387 * |

| PTOT | mg·L−1 | 0.031615 * |

| Proteins | mg·L−1 | 0.344718 |

| Carbohydrates | mg·L−1 | 0.729555 |

| CST | s | 0.000003 |

| ΔT | °C | 0.000001 * |

| Variable | Unit | p Value |

|---|---|---|

| pH | - | 0.082577 |

| TS | g·L−1 | 0.884421 |

| VS | g·L−1 | 0.792592 |

| NTOT | mg·L−1 | 0.324162 |

| PTOT | mg·L−1 | 0.942013 |

| CST | s | 0.000801 * |

| Biogas production | cm3 | 0.577505 |

References

- Council Directive 91/271/EEC of 21 May 1991 Concerning Urban Waste−Water Treatment. Available online: https://eur−lex.europa.eu/legal−content/EN/TXT/PDF/?uri=CELEX:31991L0271&from=EN (accessed on 30 May 1991).

- Pilli, S.; Bhunia, P.; Yan, S.; LeBlanc, R.J.; Tyagi, R.D.; Surampalli, R.Y. Ultrasonic pretreatment of sludge: A review. Ultrason. Sonochem. 2011, 18, 1–18. [Google Scholar] [CrossRef] [PubMed]

- Lippert, T.; Bandelin, J.; Musch, A.; Drewes, J.E.; Koch, K. Energy-positive sewage sludge pre-treatment with a novel ultrasonic flatbed reactor at low energy input. Bioresour. Technol. 2018, 264, 298–305. [Google Scholar] [CrossRef] [PubMed]

- Milieu Ltd. Final report for the European Commission, Milieu Ltd, WRc, RPA, DG Environment 2008. Environmental, Economic and Social Impacts of the Use of Sewage Sludge on Land. Final Report, Part II: Project Interim (DGENV.G.4/ETU/2008/0076r.). Available online: http://ec.europa.eu/environment/archives/waste/sludge/pdf/part_ii_report.pdf (accessed on 29 April 2015).

- Simonetti, M.; Rossi, G.; Cabbai, V.; Goi, D. Tests on the effect of ultrasonic treatment on two different activated sludge waste. Environ. Prot. Eng. 2014, 40, 23–34. [Google Scholar]

- Le, N.T.; Julcour-Lebigue, C.; Delmas, H. An executive review of sludge pretreatment by sonication. J. Environ. Sci. 2015, 37, 139–153. [Google Scholar] [CrossRef] [PubMed]

- Skórkowski, Ł.; Zielewicz, E.; Kawczyński, A.; Gil, B. Assessment of excess sludge ultrasonic, mechanical and hybrid pretreatment in relation to the energy parameters. Water 2018, 10, 551. [Google Scholar] [CrossRef]

- Koch, K.; Lippert, T.; Hauck Sabadini, N.; Drewes, J.E. Tube reactors as a novel ultrasonication system for trouble−free treatment of sludges. Ultrason. Sonochem. 2017, 37, 464–470. [Google Scholar] [CrossRef] [PubMed]

- Gonzalez, A.; Hendriks, A.T.W.M.; van Lier, J.B.; de Kreuk, M. Pre−treatments to enhance the biodegradability of waste activated sludge: Elucidating the rate limiting step. Biotechnol. Adv. 2018, 36, 1431–1469. [Google Scholar] [CrossRef] [PubMed]

- Lizama, A.C.; Figueiras, C.C.; Herrera, R.R.; Pedreguera, A.Z.; Espinoza, J.E.R. Effects of ultrasonic pretreatment on the solubilization and kinetic study of biogas production from anaerobic digestion of waste activated sludge. Int. Biodeterior. Biodegrad. 2017, 123, 1–9. [Google Scholar] [CrossRef]

- Zielewicz, E. Effects of ultrasonic disintegration of excess sewage sludge. Top Curr. Chem. 2016, 374, 149–174. [Google Scholar]

- Cimochowicz–Rybicka, M. Minimization of Sewage Sludge Production—European Trends and Selected Technologies. Available online: https://www.kth.se/polopoly_fs/1.651120!/JPSU18P12.pdf (accessed on 10 October 2018).

- Tytła, M.; Zielewicz, E. The impact of temporal variability of excess sludge characteristics on the effects obtained in the process of its ultrasonic disintegration. Environ. Technol. 2018, 39, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Müller, J. Mechanischer Klärschlammaufschluß, Schriftenereihe “Berichte aus der Verfahrenstechnik”. Ph.D. Thesis, der Fakultät für Maschinenbau und Elektrotechnik der, Universität Braunschweig. Shaker Verlag, Aachen, Germany, 1996. [Google Scholar]

- Wang, F.; Wang, Y.; Ji, M. Mechanisms and kinetics models for ultrasonic waste activated sludge disintegration. J. Hazard. Mater. 2005, 123, 145–150. [Google Scholar] [CrossRef] [PubMed]

- Tiehm, A.; Nickel, K.; Zellhorn, M.; Neis, U. Ultrasound waste activated sludge disintegration for improving anaerobic stabilization. Water Res. 2001, 35, 2003–2009. [Google Scholar] [CrossRef]

- Feng, X.; Lei, H.Y.; Deng, J.C.; Yu, Q.; Li, H. Physical and chemical characteristics of waste activated sludge treated ultrasonically. Chem. Eng. Process. 2009, 48, 187–194. [Google Scholar] [CrossRef]

- Erden, G.; Filibeli, A. Ultrasonic pre−treatment of biological sludge: Consequences for disintegration, anaerobic biodegradability, and filterability. J. Chem. Technol. Biotechnol. 2010, 85, 145–150. [Google Scholar] [CrossRef]

- Cho, S.K.; Shin, H.S.; Kim, D.H. Waste activated sludge hydrolysis during ultrasonication: Two-step disintegration. Bioresour. Technol. 2012, 121, 480–483. [Google Scholar] [CrossRef] [PubMed]

- Ruiz-Hernando, M.; Martinez−Elorza, G.; Labanda, J.; Llorens, J. Dewaterability of sewage sludge by ultrasonic, thermal and chemical treatments. Chem. Eng. J. 2013, 230, 102–110. [Google Scholar] [CrossRef] [Green Version]

- Tomczak-Wandzel, R.; Ofverstrom, S.; Dauknys, R.; Medrzycka, K. Effect of disintegration pretreatment of sewage sludge for enhanced anaerobic digestion. In The 8th International Conference “Environmental Engineering”: Selected Papers, Vilnius, Lithuania, 19−20 May 2011; Čygas, D., Froehner, K.D., Eds.; Vilnius Gediminas Technical University: Vilnius, Lithuania, 2011; pp. 679–683. [Google Scholar]

- Zielewicz, E.; Tytła, M. Effects of ultrasonic disintegration of excess sludge obtained in disintegrators of different constructions. Environ. Technol. 2015, 36, 2210–2216. [Google Scholar]

- Zielewicz, E. Effects of ultrasonic disintegration of excess sewage sludge. Appl. Acoust. 2016, 103, 182–189. [Google Scholar] [CrossRef]

- Tytła, M.; Zielewicz, E. The effect of ultrasonic disintegration process conditions on the physicochemical characteristics of excess sludge. Arch. Environ. Prot. 2016, 42, 19–26. [Google Scholar] [CrossRef] [Green Version]

- Karapanagiotis, N.K.; Rudd, T.; Sterritt, R.M.; Lester, J.N. Extraction and characterisation of extracellular polymers in digested sewage sludge. J. Chem. Technol. Biotechnol. 1989, 44, 107–120. [Google Scholar] [CrossRef]

- Raszka, A.; Surmacz−Górska, J.; Żabczyński, S. Extracellular polymeric substances in the nitrifying activated sludge. ACEE 2010, 3, 115–119. [Google Scholar]

- Polish Committee for Standardization. Characterization of Sludge−Determination of pH−Value; PN−EN 12176:2004; Polish Committee for Standardization: Warszawa, Poland, 2004. [Google Scholar]

- Polish Committee for Standardization. Characteristics of Sewage Sludge, Determination of Dry Residue and Water Content; PN−EN 12880:2004; Polish Committee for Standardization: Warszawa, Poland, 2004. [Google Scholar]

- Polish Committee for Standardization. Characteristics of Sewage Sludge, Determination of Loss on Ignition of Dry Matter; PN−EN 12879:2004; Polish Committee for Standardization: Warszawa, Poland, 2004. [Google Scholar]

- International Organization for Standardization. Water Quality–Determination of the Chemical Oxygen Demand Index (ST−COD)−Small−Scale Sealed Tube Method; ISO 15705:2002; International Organization for Standardization: Geneva, Switzerland, 2002. [Google Scholar]

- International Organization for Standardization. Water Quality–Determination of Nitrogen—Part 1: Method using Oxidative Digestion with Peroxodisulfate; ISO 11905−1:1997; International Organization for Standardization: Geneva, Switzerland, 1997. [Google Scholar]

- International Organization for Standardization. Water Quality–Determination of Phosphorus–Ammonium Molybdate Spectrometric Method; ISO 6878:2004; International Organization for Standardization: Geneva, Switzerland, 2004. [Google Scholar]

- Lowry, O.; Rosebrough, N.; Farr, A.L.; Randall, R. Protein measurement with the Folin phenol reagent. J. Biol. Chem. 1951, 193, 265–275. [Google Scholar] [PubMed]

- Dubois, M.; Gilles, K.A.; Hamilton, J.K.; Reber, P.A.; Smith, F. Colorimetric method for determination of sugars and related substances. Anal. Chem. 1956, 28, 350–356. [Google Scholar] [CrossRef]

- Polish Committee for Standardization. Characterization of Sludges–Filtration Properties—Part 3: Capillary Suction Time (CST); PN−EN 14701–1:2007; Polish Committee for Standardization: Warszawa, Poland, 2004. [Google Scholar]

- Neis, U.; Nickel, K.; Tiehm, A. Enhancement of anaerobic sludge digestion by ultrasonic disintegration. Water Sci. Technol. 2000, 42, 73–80. [Google Scholar] [CrossRef]

- German Institute for Standardisation. German Standard Methods for the Examination of Water, Waste Water and Sludge; Sludge and Sediments (Group S); Determination of the Amenability to Anaerobic Digestion (S 8); DIN 38414−8:1985−06; German Institute for Standardization: Berlin, Germany, 1985. [Google Scholar]

- Gündüz, Ç. Ultrasonic Disintegration of Sewage Sludge. Master’s Thesis, Dokuz Eylül University, Izmir, Turkey, 2009. [Google Scholar]

- Zhang, P.; Zhang, G.; Wang, W. Ultrasonic treatment of biological sludge: Floc disintegration, cell lysis and inactivation. Biores. Technol. 2007, 98, 207–210. [Google Scholar] [CrossRef] [PubMed]

- Sahinkaya, S. Disintegration of municipal waste activated sludge by simultaneous combination of acid and ultrasonic pretreatment. Process Saf. Environ. Prot. 2015, 93, 201–205. [Google Scholar] [CrossRef]

- Show, K.Y.; Mao, T.; Lee, D.J. Optimization of sludge disruption by sonication. Water Res. 2007, 41, 4741–4747. [Google Scholar] [CrossRef] [PubMed]

- Zhou, J.; Zheng, G.; Zhang, X.; Zhou, L. Influences of extracellular polymeric substances on the dewaterability of sewage sludge during bioleaching. PLoS ONE 2014, 9, e102688. [Google Scholar] [CrossRef] [PubMed]

- Houghton, J.I.; Quarmby, J.; Stephenson, T. Municipal wastewater sludge dewaterability and the presence of microbial extracellular polymer. Water Sci. Technol. 2011, 44, 373–379. [Google Scholar] [CrossRef]

- Vesilind, P.A.; Davis, H.A. Using the CST device for characterizing sludge dewaterability. Water Sci. Technol. 1988, 20, 203–205. [Google Scholar] [CrossRef]

- Tomczak-Wandzel, R.; Mędrzycka, K.; Cimochowicz-Rybicka, M. Wpływ dezintegracji ultradźwiękowej na przebieg fermentacji metanowej. Available online: https://mostwiedzy.pl/pl/publication/wplyw-dezintegracji-ultradzwiekowej-na-przebieg-fermentacji-metanowej-the-effect-of-ultrasonic-disin,110542-1 (accessed on 18 October 2018).

- Braguglia, C.M.; Gianico, A.; Mininni, G. Comparison between ozone and ultrasound disintegration on sludge anaerobic digestion. J. Environ. Manag. 2012, 95, S139–S143. [Google Scholar] [CrossRef] [PubMed]

- Xu, H.; He, P.; Yu, G.; Shao, L. Effect of ultrasonic pretreatment on anaerobic digestion and its sludge dewaterability. J. Environ. Sci. 2011, 23, 1472–1478. [Google Scholar] [CrossRef]

- Martínez, E.; Rosas, J.; Morán, A.; Gómez, X. Effect of ultrasound pretreatment on sludge digestion and dewatering characteristics: Application of particle size analysis. Water 2015, 7, 6483–6495. [Google Scholar] [CrossRef]

- Cimochowicz-Rybicka, M.; Rybicki, S. Application of respirometric tests for assessment of methanogenic bacteria activity in wastewater sludge processing. J. Ecol. Eng. 2013, 14, 44–52. [Google Scholar] [CrossRef]

- Salihu, A.; Alam, M.D. Pretreatment methods of organic wastes for biogas production. J. Appl. Sci. 2016, 16, 124–137. [Google Scholar] [CrossRef]

| Parameter 1 | Unit | Value |

|---|---|---|

| Population equivalent (PE) | - | 155,009 |

| Average flow (Q) | m3·d–1 | 31,913 |

| Hydraulic retention time (HRT) of sludge in anaerobic digester | d | 33 |

| Parameter | Methods/Devices | Reference | Type of Effects |

|---|---|---|---|

| pH | Electrometric method; Multi HQ40D (Hach Lange) | PN-EN 12176:2004 [27] | Direct; Technological |

| TS | Weight method (at 105 °C) | PN–EN 12880:2004 [28] | Technological; |

| VS | Weight method (at 550 °C) | PN–EN 12879:2004 [29] | Technological |

| SCOD0; SCODUD | Potassium dichromate method; measurement tests LCI 400, LCK 014 (Hach Lange); UV–VIS DR 5000 | ISO 15705:2002 [30] | Direct |

| NTOT | Potassium oxidation method measurement tests LCK 238 (Hach Lange); UV–VIS DR 5000 | ISO 11905-1:1997 [31] | Direct, Technological |

| PTOT | Ammonium molybdate method; measurement tests LCK 350 (Hach Lange); UV–VIS DR 5000 | ISO 6878:2004 [32] | Direct, Technological |

| Proteins | Folina—Ciocalteau reagent; UV–VIS DR 5000 | Lowry et al., 1951 [33] | Direct |

| Carbohydrates | Phenol-Sulphuric acid reaction method; UV–VIS DR 5000 | Dubois et al., 1956 [34] | Direct |

| CST | Quantity measurement; Capillary suction timer (Envolab) | PN–EN 14701–1:2007 [35] | Direct, Technological |

| ΔT | Quantity measurement; Digi—Sense (Cole—Parmer) | - | Direct |

| Flocs disruption | Optical microscopy; Optical microscope (MOTIC BA400) | - | Direct |

| Biogas production | Quantitative measurement; MULTITEC 540 gauge (Sewerin) | - | Technological |

| Biogas composition | Qualitative measurement; CH4 and CO2 (% vol.), H2S (ppm); MULTITEC 540 gauge (Sewerin) | - | - |

| Parameter | Symbol | Unit | WK-2010 | Ultrasonic Washer |

|---|---|---|---|---|

| Power | P | W | 650 | 90 |

| Frequency | f | kHz | 25 | 25 |

| Number of emitters | - | - | 1 | 1 |

| Emitter surface area | AE | cm2 | 78.5 | 19.6 |

| Emitter diameter | dE | cm | 10 | 5 |

| Emitter position | hE | cm | 1 1 | built |

| Chamber dimensions | idc × dc | cm | 14 × 7 2 | 15 × 13.7 × 20 3 |

| Chamber volume | VC | mL | 1000 | 2000 |

| Parameter | Unit | WAS_NUD | WAS_A | WAS_B |

|---|---|---|---|---|

| Mean; CV | ||||

| pH | - | 7.0 (2.0%) | 6.9 (2.2%) | 6.8 (2.7%) |

| TS | g·L−1 | 41.1 (26.9%) | - | - |

| VS | g·L−1 | 29.8 (29.2%) | - | - |

| SCOD0 /SCODUD | mg·L−1 | 66.8 (22.8%) | 1061.7 (34.8%) | 4573.4 (39.2%) |

| NTOT | mg·L−1 | 10.9 (16.3%) | 139.9 (23.8%) | 470.4 (37.5%) |

| PTOT1 | mg·L−1 | 25.1 (31.4%) | 135.6 (22.5%) | 177.0 (18.7%) |

| Proteins | mg·L−1 | 888.9 (24.9%) | 784.0 (35.1%) | 927.5 (29.2%) |

| Carbohydrates | mg·L−1 | 598.4 (35.6%) | 480.7 (47.5%) | 507.0 (46.9%) |

| CST | s | 9.0 (24.8%) | 343.1 (70.0%) | 1175.1 (10.2%) |

| ΔT | °C | - | 14.0 (39.7%) | 34.0 (29.5%) |

| Parameter | Unit | Inoculum | S_0 | S_0* | S_A | S_A* | S_B | S_B* |

|---|---|---|---|---|---|---|---|---|

| Mean; CV (%) | ||||||||

| pH | - | 7.4 ± (1.7%) | 7.5 (1.4%) | 7.5 (1.1%) | 7.3 (1.7%) | 7.6 (1.2%) | 7.3 (1.6%) | 7.6 (1.3%) |

| TS | g·L−1 | 26.2 (15.1%) | 36.8 (19.8) | 30.2 (21.3%) | 37.5 (19.0%) | 29.2 (20.6%) | 38.7 (17.9%) | 28.6 (19.4%) |

| VS | g·L−1 | 15.9 (14.3%) | 25.2 (20.2%) | 18.7.1 (21.6%) | 26.7 (20.5%) | 18.2 (21.8%) | 27.4 (18.8%) | 17.7 (20.3%) |

| NTOT | mg·L−1 | 728.1 (11.3%) | 210.6 (7.1%) | 925.6 (18.5%) | 277.0 (7.5%) | 951.8 (19.4) | 436.6 (21.9%) | 1064.6 (16.8%) |

| PTOT | mg·L−1 | 116 (44.5%) | 68.7 (52.6) | 288.6 (54.7%) | 130.4 (37%) | 270.1 (60.3%) | 145.8 (35.7%) | 258.8 (64.1%) |

| CST | s | 186.4 (26.6%) | 42.6 (30.6%) | 78.6 (63.8%) | 352.4 (55.9%) | 215.3 (43.8%) | 1068.3 (10.7%) | 342.7 (42.2%) |

| Total biogas production | cm3 | - | - | 2014.0 (32.4%) | - | 2276.0 (34.0%) | - | 2411.0 (29.0%) |

| CH4 | %vol. | - | - | 65.6 (5.7%) | - | 66.0 (5.1%) | - | 67.9 (4.6%) |

| CO2 | %vol. | - | - | 25.9 (16.6%) | - | 25.6 (15.8%) | - | 25.9 (12.1%) |

| H2S | ppm | - | - | <1.0 | - | <1.0 | - | <1.0 |

© 2018 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tytła, M. The Effects of Ultrasonic Disintegration as a Function of Waste Activated Sludge Characteristics and Technical Conditions of Conducting the Process—Comprehensive Analysis. Int. J. Environ. Res. Public Health 2018, 15, 2311. https://0-doi-org.brum.beds.ac.uk/10.3390/ijerph15102311

Tytła M. The Effects of Ultrasonic Disintegration as a Function of Waste Activated Sludge Characteristics and Technical Conditions of Conducting the Process—Comprehensive Analysis. International Journal of Environmental Research and Public Health. 2018; 15(10):2311. https://0-doi-org.brum.beds.ac.uk/10.3390/ijerph15102311

Chicago/Turabian StyleTytła, Malwina. 2018. "The Effects of Ultrasonic Disintegration as a Function of Waste Activated Sludge Characteristics and Technical Conditions of Conducting the Process—Comprehensive Analysis" International Journal of Environmental Research and Public Health 15, no. 10: 2311. https://0-doi-org.brum.beds.ac.uk/10.3390/ijerph15102311