The Role of Powertrain Electrification in Achieving Deep Decarbonization in Road Freight Transport

Abstract

:1. Introduction

1.1. Motivation of the Research

1.2. Review of the Existing Literature

1.3. Contribution

1.4. Organization of the Article

2. Methods

2.1. Formulation of the Vehicle Stock Turnover Model for the Road Freight Vehicle Fleet

2.2. Road Freight Vehicles Characteristics

2.3. Road Freight Transport in Japan and Scenarios for Deep Decarbonization

2.4. Main Assumptions and Limitations

3. Results and Discussion

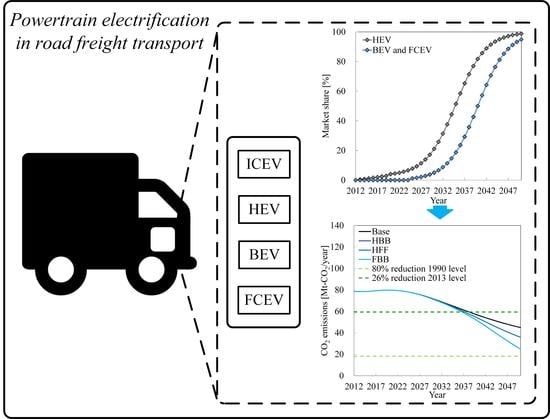

3.1. Powertrain Electrification of the Road Freight Vehicle Stock

3.2. Power Electrification Potential for Decarbonization of Road Freight Transport

3.3. Economic Impact of Powertrain Electrification on the Road Freight Vehicle Fleet

3.4. Policy Implications

3.5. Sensitivity Analysis

4. Conclusions

- Driven by the reduction of the vehicle stock, the improvement of vehicle fuel consumption and the adoption of HEVs, energy consumption and CO2 emissions decrease around 42% between 2012 and 2050 in the Base scenario. In contrast, powertrain electrification can reduce TTW CO2 emissions up to 20.1% in the HBB and HFF scenarios and 44.6% in the FBB scenario, compared with the 2050 baseline value; while maximum WTW CO2 emissions reductions are 17.3%, 13.4% and 32.6% in the HBB, HFF and FBB scenarios. Despite the significant reductions in CO2 emissions, powertrain electrification alone is not enough to achieve any of the CO2 emissions reduction targets in road freight transport.

- Despite aggressive deployment of EDVs, diesel- and gasoline-fueled vehicles account for more than 46% of the vehicle stock and more than 74% of the road freight vehicle fleet TTW energy consumption in all scenarios. This evidences the difficulty of reducing the dependence of fossil fuels in road freight transport. In that sense, considering other measures to reduce CO2 emissions in road freight transport along with powertrain electrification is suggested for future research.

- The net cash flows are positive for all alternative scenarios considering powertrain electrification during the whole time horizon. The HFF scenario has the lowest net cash flows, peaking at 4.6 billion USD/year in 2049 and reaching 4.5 billion USD/year by 2050. Scenarios where BEVs are deployed have the largest net cash flows by 2050, 9.6 and 6.6 Billion USD/year for the HBB and FBB scenarios, respectively.

- Deployment of FCEVs for normal vehicles and BEVs for compact and mini-sized vehicles in the Japanese road freight vehicle fleet is recommended. Since road freight vehicles are concentrated in fewer owners than passenger LDVs, it is recommended to design policies to help road freight vehicle fleet owners investing in EDVs. EDV diffusion in road freight transport can help improving social acceptance of powertrain electrification and developing infrastructure that can benefit EDV diffusion in passenger LDVs. Assessing powertrain electrification in passenger LDVs and road freight vehicles considering the dynamics of technology diffusion is recommended for future work.

- A large asymmetry was found between the vehicle stock distribution by size class and the CO2 emissions; with normal vehicles accounting for more than 61% of the TTW and WTW CO2 emissions in all scenarios, despite representing only 13.3% of the vehicle stock. It is therefore recommended to prioritize normal vehicles when designing measures for powertrain electrification in road freight transport.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| α | Model parameter |

| β | Growth parameter |

| a | Vehicle age |

| a0 | Vehicle median service life |

| AIRIA | Automobile Inspection & Registration Association |

| BEV | Battery electric vehicle |

| ccap | Vehicle capital cost |

| cene | Energy price |

| cOM | Vehicle operating and maintenance cost |

| COP | Conference of Parties |

| CRF | Capital recovery factor |

| E | Road freight vehicle energy consumption |

| EDV | Electric-drive vehicle |

| EF | Fuel CO2 emission factor |

| FCEV | Fuel cell electric vehicle |

| G | Road freight vehicle fleet CO2 emissions |

| GHG | Greenhouse gas |

| GVW | Gross Vehicle Weight |

| HDV | Heavy-duty vehicle |

| HEV | Hybrid electric vehicle |

| ICEV | Internal combustion engine vehicle |

| IEA | International Energy Agency |

| JAMA | Japanese Automobile Manufacturers Association |

| LDV | Light-duty vehicle |

| LEAP | Long-range Energy Alternatives Planning system |

| M | Annual traveled distance |

| MDV | Medium-duty vehicle |

| MLIT | Japan Ministry of Land, Infrastructure, Transport and Tourism |

| N | Vehicle stock |

| OEM | Original equipment manufacturer |

| O&M | Operating and maintenance |

| PHEV | Plug-in hybrid electric vehicle |

| PM | Particulate matter |

| r | Vehicle survival rate |

| R | Vehicle fuel consumption |

| RCO | Relative cost of ownership |

| S | New vehicle sales |

| SMR | Steam methane reforming |

| t | Vehicle type |

| TCO | Total cost of ownership |

| TTW | Tank to wheel |

| v | Vehicle vintage |

| WTW | Well to wheel |

| y | Calendar year |

References

- Sims, R.; Schaeffer, R.; Creutzig, F.; Cruz-Núñez, X.; D’Agosto, M.; Dimitriu, D.; Figueroa Meza, M.J.; Fulton, L.; Kobayashi, S.; Lah, O.; et al. Transport. In Climate Change 2014: Mitigation of Climate Change. Contribution of Working Group III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Edenhofer, O., Pichs-Madruga, R., Sokona, Y., Farahani, E., Kadner, S., Seyboth, K., Adler, A., Baum, I., Brunner, S., Eickemeier, P., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2014; pp. 599–670. [Google Scholar]

- IEA/OECD (Ed.) Energy Technology Perspectives 2017: Catalysing Energy Tehnology Transformations; International Energy Agency and Organization for Economic Cooperation and Development: Paris, France, 2017. [Google Scholar]

- IEA/OECD. The Future of Trucks: Implications for Energy and the Environment; International Energy Agency and Organization for Economic Cooperation and Development: Paris, France, 2017. [Google Scholar]

- Kast, J.; Morrison, G.; Gangloff, J.J.; Vijayagopal, R.; Marcinkoski, J. Designing hydrogen fuel cell electric trucks in a diverse medium and heavy duty market. Res. Transp. Econ. 2018, 70, 139–147. [Google Scholar] [CrossRef]

- ICCT. Overview of the Heavy-Duty Vehicle Market and CO2 Emissions in the European Union; The International Council on Clean Transportation. Available online: http://www.theicct.org/sites/default/files/publications/ICCT_EU-HDV_mkt-analysis_201512.pdf (accessed on 20 February 2020).

- Kast, J.; Vijayagopal, R.; Gangloff, J.J.; Marcinkoski, J. Clean commercial transportation: Medium and heavy duty fuel cell electric trucks. Int. J. Hydrog. Energy 2017, 42, 4508–4517. [Google Scholar] [CrossRef] [Green Version]

- Dablanc, L. City distribution, a key element of the urban economy: Guidelines for practitioners. In City Distribution and Urban Freight Transport: Multiple Perspectives; Macharis, C., Melo, S., Eds.; Edward Elgar Publishing: Cheltenham, UK, 2011; pp. 13–36. [Google Scholar]

- WHO. Review of Evidence on Health Aspects of Air Pollution—REVIHAAP Project; First Results; World Health Organization, Regional Office for Europe: Copenhagen, Denmark, 2013. [Google Scholar]

- HEI. Panel on the Health Effects of Traffic-Related Air Pollution. In Special Report 17; Traffic-Related Air Pollution: A Critical Review of the Literature on Emissions, Exposure, and Health Effects; Health Effects Institute: Boston, MA, USA, 2010; Available online: https://www.healtheffects.org/system/files/SR17TrafficReview.pdf (accessed on 4 May 2020).

- WHO. Press Release No 213: IARC: Diesel Engine Exhaust Carcinogenic; World Health Organization: Lyon, France, 2012; Available online: http://www.iarc.fr/en/media-centre/pr/2012/pdfs/pr213_E.pdf (accessed on 30 March 2020).

- OECD/ITF. The Carbon Footprint of Global Trade; Tackling Emissions from International Freight Transport. Organisation for Economic Co-operation and Development and International Transport Forum: Paris, France, 2016. Available online: http://www.itf-oecd.org/sites/default/files/docs/cop-pdf-06.pdf (accessed on 15 April 2020).

- Urban Foresight; EVI; IEA/OECD. EV City Casebook; 50 Big Ideas Shaping the Future of Electric Mobility; Urban Foresight, Electric Vehicles Initiative of the Clean Energy Ministerial and International Energy Agency and Organization for Economic Cooperation and Development: Newcastle, UK, 2014. [Google Scholar]

- ICCT. Transitioning to Zero-Emission Heavy-Duty Freight Vehicles; The International Council on Clean Transportation. Available online: https://www.theicct.org/sites/default/files/publications/Zero-emission-freight-trucks_ICCT-white-paper_26092017_vF.pdf (accessed on 20 April 2020).

- Den Boer, E.; Aarnik, S.; Kleiner, F.; Pagenkopf, J. Zero Emissions Trucks: An Overview of State-of-the-Art Technologies and Their Potential; CE Delft. Available online: https://www.cedelft.eu/publicatie/zero_emission_trucks/1399 (accessed on 7 April 2018).

- IEA/OECD. Global EV Outlook 2019: Scaling Up the Transition to Electric Mobility; International Energy Agency/Organization for Economic Cooperation and Development and Electric Vehicles Initiative of the Clean Energy Ministerial: Paris, France, 2019. [Google Scholar]

- Tryggestad, C.; Sharma, N.; van de Staaij, J.; Keizer, A. New Reality: Electric Trucks and Their Implications on Energy Demand; Energy Insights by McKinsey. Available online: https://www.mckinseyenergyinsights.com/insights/new-reality-electric-trucks-and-their-implications-on-energy-demand (accessed on 21 April 2020).

- BYD. BYD is Leading the Transition to a Zero-Emissions Future with Advanced Electric Trucks, Buses and Forklifts. Available online: https://en.byd.com/news-posts/press-release-byd-is-leading-the-transition-to-a-zero-emissions-future-with-advanced-battery-electric-trucks-buses-and-forklifts/ (accessed on 10 April 2020).

- Isuzu Motors Limited. Isuzu Exhibitions in the 45th Tokyo Motor Show 2017. Available online: http://www.isuzu.co.jp/world/press/2017/9_22tms.html (accessed on 24 April 2020).

- Carey, N. UPS Reserves 125 Tesla Semi-Trucks, Largest Public Pre-Order Yet; Reuters. Available online: https://www.reuters.com/article/us-ups-tesla-orders/ups-reserves-125-tesla-semi-trucks-largest-public-pre-order-yet-idUSKBN1ED1QM (accessed on 17 March 2020).

- Renault. Renault Trucks will Start Selling Electric Trucks in 2019. Available online: http://corporate.renault-trucks.com/en/press-releases/renault-trucks-will-start-selling-electric-trucks-in-2019.html (accessed on 20 April 2020).

- Mitsubishi Fuso Truck and Bus Corporation. The World’s First Mass-Produced All-Electric Compact Truck “eCanter”. Available online: http://www.mitsubishi-fuso.com/content/fuso/jp/truck/ecanter/lp.html (accessed on 13 December 2019). (In Japanese).

- FCB. Switzerland unveils fuel cell powered heavy truck, and first hydroelectric hydrogen station. Fuel Cells Bull. 2016, 2016(12), 14–15. [Google Scholar] [CrossRef]

- Toyota. Toyota Opens a Portal to the Future of Zero Emission Trucking. Available online: https://media.toyota.ca/releases/toyota-opens-a-portal-to-the-future-of-zero-emission-trucking (accessed on 17 April 2020).

- FCB. Ballard, Kenworth fuel cell truck validation moves to next stage. Fuel Cells Bull. 2018, 2018(2), 3. [Google Scholar]

- Nikola Motor Company; Bosch. A World-First: The Powertrain for the Electric Long-Haul Truck. Available online: https://www.bosch-presse.de/pressportal/de/en/a-world-first-the-powertrain-for-the-electric-long-haul-truck-126336.html (accessed on 24 March 2020).

- Askin, A.C.; Barter, G.E.; West, T.H.; Manley, D.K. The heavy-duty vehicle future in the United States: A parametric analysis of technology and policy tradeoffs. Energy Policy 2015, 81, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Y.; Ercan, T.; Tatari, O. Life cycle based multi-criteria optimization for optimal allocation of commercial delivery truck fleet in the United States. Sustain. Prod. Consum. 2016, 8, 18–31. [Google Scholar] [CrossRef]

- Wikström, M.; Hansson, L.; Alvfors, P. Socio-technical experiences from electric vehicle utilisation in commercial fleets. Appl. Energy 2014, 123, 82–93. [Google Scholar] [CrossRef]

- Vora, A.P.; Jin, X.; Hoshing, V.; Saha, T.; Shaver, G.; Varigonda, S.; Wasynczuk, O.; Tyner, W.E. Design-space exploration of series plug-in hybrid electric vehicles for medium-duty truck applications in a total cost-of-ownership framework. Appl. Energy 2017, 202, 662–672. [Google Scholar] [CrossRef]

- Lee, D.-Y.; Thomas, V.M. Parametric modeling approach for economic and environmental life cycle assessment of medium-duty truck electrification. J. Clean. Prod. 2017, 142, 3300–3321. [Google Scholar] [CrossRef] [Green Version]

- Sen, B.; Ercan, T.; Tatari, O. Does a battery-electric truck make a difference?—Life cycle emissions, costs, and externality analysis of alternative fuel-powered Class 8 heavy-duty trucks in the United States. J. Clean. Prod. 2017, 141, 110–121. [Google Scholar] [CrossRef]

- Feng, W.; Figliozzi, M.A. Conventional vs electric commercial vehicle fleets: A case study of economic and technological factors affecting the competitiveness of electric commercial vehicles in the USA. Procedia Soc. Behav. Sci. 2012, 39, 702–711. [Google Scholar] [CrossRef] [Green Version]

- Roeth, M.; Kircher, D.; Smith, J.; Swim, R. Barriers to the Increased Adoption of Fuel Efficiency Technologies in the North American On-Road Freight Sector; Report for the International Council on Clean Transportation (ICCT). Available online: https://www.theicct.org/sites/default/files/publications/ICCT-NACFE-CSS_Barriers_Report_Final_20130722.pdf (accessed on 9 April 2020).

- Schoettle, B.; Sivak, M.; Tunnell, M. A Survey of Fuel Econmy and Fuel Usage by Heavy-Duty Truck Fleets; University of Michigan and American Transportation Reserach Institute. Available online: http://atri-online.org/wp-content/uploads/2016/10/2016.ATRI-UMTRI.FuelEconomyReport.Final_.pdf (accessed on 29 April 2020).

- Zhao, H.; Burke, A.; Zhu, L. Analysis of Class 8 Hybrid-Electric Truck Technologies Using Diesel, LNG, Electricity, and Hydrogen, as the Fuel for Various Applications. In Proceedings of the EVS27 International Battery, Hybrid and Fuel Cell Electric Vehicle Symposium; Institute of Electrical and Electronics Engineers: Barcelona, Spain, 2013; p. 17. [Google Scholar]

- Lee, D.Y.; Thomas, V.M.; Brown, M.A. Electric urban delivery trucks: Energy use, greenhouse gas emissions, and cost-effectiveness. Environ. Sci. Technol. 2013, 47, 8022–8030. [Google Scholar] [CrossRef] [PubMed]

- Lajunen, A. Fuel economy analysis of conventional and hybrid heavy vehicle combinations over real-world operating routes. Transp. Res. Part D Transp. Environ. 2014, 31, 70–84. [Google Scholar] [CrossRef]

- Gao, Z.; Smith, D.E.; Stuart Daw, C.; Dean Edwards, K.; Kaul, B.C.; Domingo, N.; Parks, J.E.; Jones, P.T. The evaluation of developing vehicle technologies on the fuel economy of long-haul trucks. Energy Convers. Manag. 2015, 106, 766–781. [Google Scholar] [CrossRef] [Green Version]

- Lebeau, P.; Macharis, C.; Van Mierlo, J.; Lebeau, K. Electrifying light commercial vehicles for city logistics? A total cost of ownership analysis. Eur. J. Transp. Infrastruct. Res. 2015, 15, 551–569. [Google Scholar]

- Zhao, Y.; Onat, N.C.; Kucukvar, M.; Tatari, O. Carbon and energy footprints of electric delivery trucks: A hybrid multi-regional input-output life cycle assessment. Transp. Res. Part D Transp. Environ. 2016, 47, 195–207. [Google Scholar] [CrossRef]

- Zhao, Y.; Tatari, O. Carbon and energy footprints of refuse collection trucks: A hybrid life cycle evaluation. Sustain. Prod. Consum. 2017, 12, 180–192. [Google Scholar] [CrossRef]

- Zhou, T.; Roorda, M.J.; MacLean, H.L.; Luk, J. Life cycle GHG emissions and lifetime costs of medium-duty diesel and battery electric trucks in Toronto, Canada. Transp. Res. Part D 2017, 55, 91–98. [Google Scholar] [CrossRef]

- Davis, B.A.; Figliozzi, M.A. A methodology to evaluate the competitiveness of electric delivery trucks. Transp. Res. Part E Logist. Transp. Rev. 2013, 49, 8–23. [Google Scholar] [CrossRef]

- Christensen, L.; Klauenberg, J.; Kveiborg, O.; Rudolph, C. Suitability of commercial transport for a shift to electric mobility with Denmark and Germany as use cases. Res. Transp. Econ. 2017, 64, 48–60. [Google Scholar] [CrossRef] [Green Version]

- Li, W.; Dai, Y.; Ma, L.; Hao, H.; Lu, H.; Albinson, R.; Li, Z. Oil-saving pathways until 2030 for road freight transportation in China based on a cost-optimization model. Energy 2015, 86, 369–384. [Google Scholar] [CrossRef]

- Oshiro, K.; Masui, T. Diffusion of low emission vehicles and their impact on CO2 emission reduction in Japan. Energy Policy 2015, 81, 215–225. [Google Scholar] [CrossRef]

- Fridstrøm, L. From innovation to penetration: Calculating the energy transition time lag for motor vehicles. Energy Policy 2017, 108, 487–502. [Google Scholar] [CrossRef]

- Mulholland, E.; Teter, J.; Cazzola, P.; McDonald, Z.; Ó Gallachóir, B.P. The long haul towards decarbonising road freight—A global assessment to 2050. Appl. Energy 2018, 216, 678–693. [Google Scholar] [CrossRef]

- MLIT. Road Transport Vehicle Law Enforcement Act, Ordinance of the Ministry No 74, August 16 of 1951; Last modification in December 28 of 2016; Ministry of Land, Infrastructure,Transport and Tourism: Tokyo, Japan, 1951. (In Japanese)

- MLIT. Vehicle Fuel Consumption List (March 2018); Ministry of Land, Infrastructure, Transport and Tourism: Tokyo, Japan, 2018. (In Japanese)

- SEI. LEAP User Guide; Heaps, C., Ed.; Stockholm Environment Institute—SEI: Somerville, MA, USA, 2018; Available online: https://www.energycommunity.org/Help/leap.htm (accessed on 1 March 2020).

- González Palencia, J.C.; Araki, M.; Shiga, S. Energy consumption and CO2 emissions reduction potential of electric-drive vehicle diffusion in a road freight vehicle fleet. Energy Procedia 2017, 142, 2936–2941. [Google Scholar] [CrossRef]

- González Palencia, J.C.; Sakamaki, T.; Araki, M.; Shiga, S. Impact of powertrain electrification, vehicle size reduction and lightweight materials substitution on energy use, CO2 emissions and cost of a passenger light-duty vehicle fleet. Energy 2015, 93, 1489–1504. [Google Scholar] [CrossRef]

- Teoh, T.; Kunze, O.; Teo, C.C.; Wong, Y.D. Decarbonisation of urban freight transport using electric vehicles and opportunity charging. Sustainability 2018, 10, 3258. [Google Scholar] [CrossRef] [Green Version]

- González Palencia, J.C.; Araki, M.; Shiga, S. CO2 emissions reduction potential of powertrain electrification, lightweight materials use and vehicle size reduction in a passenger light-duty vehicle fleet. In Proceedings of the International Conference on Power Engineering-15 (ICOPE-15); Japan Society of Mechanical Engineers (JSME), American Society of Mechanical Engineers (ASME) and Chinese Society of Power Engineering (CSPE): Yokohama, Japan, 2015; p. 12. [Google Scholar]

- MLIT. Vehicle Fuel Consumption List (March 2013); Ministry of Land, Infrastructure, Transport and Tourism: Tokyo, Japan, 2013. (In Japanese)

- Talebian, H.; Herrera, O.E.; Tran, M.; Mérida, W. Electrification of road freight transport: Policy implications in British Columbia. Energy Policy 2018, 115, 109–118. [Google Scholar] [CrossRef]

- Pagerit, S.; Sharer, P.; Rousseau, A. Fuel Economy Sensitivity to Vehicle Mass for Advanced Vehicle Powertrains. In Proceedings of the SAE World Congress & Exhibition, SAE paper 2006-01-0665; Society of Automotive Engineers: Detroit, MI, USA, 2006. [Google Scholar]

- Contestabile, M.; Offer, G.J.; Slade, R.; Jaeger, F.; Thoennes, M. Battery electric vehicles, hydrogen fuel cells and biofuels. Which will be the winner? Energy Environ. Sci. 2011, 4, 3754–3772. [Google Scholar] [CrossRef]

- DOE. DOE Hydrogen and Fuel Cells Program Record # 14012; Department of Energy United States of America: Washington, DC, USA, 2013. Available online: http://energy.gov/sites/prod/files/14012_fuel_cell_system_cost_2013.pdf (accessed on 10 February 2020).

- Van Vliet, O.P.R.; Kruithof, T.; Turkenburg, W.C.; Faaij, A.P.C. Techno-economic comparison of series hybrid, plug-in hybrid, fuel cell and regular cars. J. Power Sources 2010, 195, 6570–6585. [Google Scholar] [CrossRef]

- Van Vliet, O.; Brouwer, A.S.; Kuramochi, T.; van den Broek, M.; Faaij, A. Energy use, cost and CO2 emissions of electric cars. J. Power Sources 2011, 196, 2298–2310. [Google Scholar] [CrossRef] [Green Version]

- MLIT. Results of the Basic Survey on Motor Vehicle Inspection and Maintenance for the 2004 Fiscal Year (in Japanese); Ministry of Land, Infrastructure, Transport and Tourism: Tokyo, Japan, 2004. Available online: http://www.mlit.go.jp/jidosha/iinkai/seibi/6houkokusyo.pdf (accessed on 16 March 2020).

- AIRIA. 2012 Vehicle stock. Automobile Inspection & Registration Association: Tokyo, Japan, 2012. Available online: http://www.airia.or.jp/publish/file/e49tph00000004t7-att/e49tph00000004te.pdf (accessed on 9 April 2020). (In Japanese).

- MOE. The Strategy to Promote Environmentally Friendly Vehicles; Ministry of Environment: Tokyo, Japan, 2010. Available online: http://www.env.go.jp/air/report/h22-02/index.html (accessed on 18 February 2020). (In Japanese)

- Nishimura, E. Assessing the Fuel Use and Greenhouse Gas Emissions of Future Light-Duty Vehicles in Japan. Master’s Thesis, Engineering System Division, Massachussetts Institute of Technology, Cambridge, MA, USA, 2011. [Google Scholar]

- JAMA. The Motor Industry of Japan 2013; Japanese Automobile Manufacturers Association: Tokyo, Japan, 2013; Available online: http://www.jama-english.jp/publications/MIJ2013.pdf (accessed on 23 March 2020).

- AIRIA. New Vehicle Registration by Year; Light-Duty Vehicle Fleet; Automobile Inspection & Registration Association: Tokyo, Japan, 2012. (In Japanese) [Google Scholar]

- NeV. Electric Vehicle Stock Statistics (Estimate); Next Generation Vehicle Promotion Center: Tokyo, Japan, 2016; Available online: http://www.cev-pc.or.jp/tokei/hanbai.html (accessed on 28 January 2016). (In Japanese)

- JAMA. The Motor Industry of Japan 2018; Japanese Automobile Manufacturers Association: Tokyo, Japan, 2018; Available online: http://www.jama-english.jp/publications/MIJ2018.pdf (accessed on 10 March 2020).

- Grübler, A. Technology and Global Change; Cambridge University Press: Cambridge, UK, 2003. [Google Scholar]

- Hollinshead, M.J.; Eastman, C.D.; Etsell, T.H. Forecasting performance and market penetration of fuel cells in transportation. Fuel Cells Bull. 2005, 2005, 10–17. [Google Scholar] [CrossRef]

- Acar, C.; Dincer, I. Review and evaluation of hydrogen production options for better environment. J. Clean. Prod. 2019, 218, 835–849. [Google Scholar] [CrossRef]

- Bandivadekar, A.; Bodek, K.; Cheah, L.; Evans, C.; Groode, T.; Heywood, J.; Kasseris, E.; Kromer, M.; Weiss, M. On the Road in 2035: Reducing Transportation’s Petroleum Consumption and GHG Emissions; Massachusetts Institute of Technology: Cambridge, MA, USA, 2008. [Google Scholar]

- Akerlind, I.B.; Bastani, P.; Berry, I.; Bhatt, K.; Chao, A.; Chow, E.; Karplus, V.; Keith, D.; Khusid, M.; Nishimura, E.; et al. On the Road toward 2050: Potential for Substantial Reductions in Light-Duty Vehicle Energy Use and Greenhouse Gas Emissions; Heywood, J., MacKenzie, D., Eds.; Massachusetts Institute of Technology: Cambridge, MA, USA, 2015. [Google Scholar]

- EDMC; IEEJ. EDMC Handbook of Energy & Economic Statistics 2019; The Energy Data and Modelling Center, The Institute of Energy Economic, The Energy Conservation Center: Tokyo, Japan, 2019. (In Japanese) [Google Scholar]

- IEA/OECD (Ed.) Energy Technology Perspectives 2012; Pathways to a Clean Energy System; Energy Technology Perspectives; International Energy Agency and Organization for Economic Cooperation and Development: Paris, France, 2012. [Google Scholar]

- IEA/OECD (Ed.) CO2 Emissions from Fuel Combustion Highlights 2013; International Energy Agency and Organization for Economic Cooperation and Development: Paris, France, 2013. [Google Scholar]

- Berraho, D. Options for the Japanese Electricity Mix by 2050. Master’s Thesis, School of Industrial Engineering and Management, Division of Energy and Climate Studies, KTH Royal Institute of technology, Stockholm, Sweden, 2012. [Google Scholar]

- IEA/OECD. World Energy Outlook 2012; International Energy Agency and Organization for Economic Cooperation and Development: Paris, France, 2012. [Google Scholar]

- Delucchi, M.A.; Yang, C.; Burke, A.F.; Ogden, J.M.; Kurani, K.; Kessler, J.; Sperling, D. An assessment of electric vehicles: Technology, infrastructure requirements, greenhouse-gas emissions, petroleum use, material use, lifetime cost, consumer acceptance and policy. Phil. Trans. R. Soc. A 2014, 372, 20120325. [Google Scholar] [CrossRef] [Green Version]

- Hao, H.; Wang, H.; Ouyang, M. Fuel consumption and life cycle GHG emissions by China’s on-road trucks: Future trends through 2050 and evaluation of mitigation measures. Energy Policy 2012, 43, 244–251. [Google Scholar] [CrossRef]

- GIO; NIES. Japan’s GHG Emissions Data (FY1990-2016, Final Figures); Greenhouse Gas Inventory Office of Japan, National Institute of Environmental Studies: Tsukuba, Japan, 2018. Available online: http://www-gio.nies.go.jp/aboutghg/nir/nir-e.html (accessed on 12 February 2020).

| Author | Year | EDV | Stock Turnover | Effects Assessed | |||

|---|---|---|---|---|---|---|---|

| HEV | BEV | FCEV | CO2 Emissions | Cost | |||

| Davis | 2013 | ✓ | ✓ | ||||

| Wikström | 2015 | ✓ | |||||

| Zhao | 2016 | ✓ | ✓ | ✓ | ✓ | ||

| Christensen | 2017 | ✓ | |||||

| Askin | 2015 | ✓ | ✓ | ✓ | ✓ | ||

| Li | 2015 | ✓ | ✓ | ✓ | ✓ | ||

| Oshiro | 2015 | ✓ | ✓ | ✓ | ✓ | ||

| Fridstrøm | 2017 | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Mulholland | 2018 | ✓ | ✓ | ✓ | ✓ | ||

| Talebian | 2018 | ✓ | ✓ | ✓ | ✓ | ||

| This study | 2020 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Size Class | Powertrain | ||||

|---|---|---|---|---|---|

| Scenario | ICEV | HEV | BEV | FCEV | |

| Base | Normal | △ | △ | ||

| Compact | △ | △ | |||

| Mini | △ | △ | |||

| HBB | Normal | ○ | |||

| Compact | ○ | ||||

| Mini | ○ | ||||

| HFF | Normal | ○ | |||

| Compact | ○ | ||||

| Mini | ○ | ||||

| FBB | Normal | ○ | |||

| Compact | ○ | ||||

| Mini | ○ |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

González Palencia, J.C.; Nguyen, V.T.; Araki, M.; Shiga, S. The Role of Powertrain Electrification in Achieving Deep Decarbonization in Road Freight Transport. Energies 2020, 13, 2459. https://0-doi-org.brum.beds.ac.uk/10.3390/en13102459

González Palencia JC, Nguyen VT, Araki M, Shiga S. The Role of Powertrain Electrification in Achieving Deep Decarbonization in Road Freight Transport. Energies. 2020; 13(10):2459. https://0-doi-org.brum.beds.ac.uk/10.3390/en13102459

Chicago/Turabian StyleGonzález Palencia, Juan C., Van Tuan Nguyen, Mikiya Araki, and Seiichi Shiga. 2020. "The Role of Powertrain Electrification in Achieving Deep Decarbonization in Road Freight Transport" Energies 13, no. 10: 2459. https://0-doi-org.brum.beds.ac.uk/10.3390/en13102459