1. Introduction

Power LEDs are today the most important components of solid-state lighting sources [

1,

2,

3]. Temperature strongly influences properties of all semiconductor devices, including power LEDs, [

1,

2,

4,

5,

6]. For a single semiconductor device, the value of its junction temperature depends on both the ambient temperature

Ta and the excess Δ

T of the device internal junction temperature, which is caused by the self-heating phenomenon [

7,

8,

9,

10,

11,

12,

13]. Thus, the device temperature rise depends on power dissipated in a considered semiconductor device and on the efficiency of heat removal characterized by thermal parameters. In typically used compact thermal models of semiconductor devices, at the steady state, thermal resistance can be used for this purpose [

14,

15].

The thermal resistance between the p–n junction of a power LED and the ambient is used to describe the total influence of all components included in the heat flow path, e.g., the package of the device, the printed circuit board (PCB), and the heatsink, on the heat transfer efficiency [

4,

16]. Thus, the manner of assembly of a power LED can influence its thermal properties and, consequently, electric and optical properties of this device [

17,

18].

In our previous papers, [

18,

19,

20], we investigated the dependences of the electric, optical, and thermal parameters of power LEDs on cooling conditions. In particular, these papers show that the influence of cooling conditions on mentioned parameters could be noticeable, e.g., self-heating could cause a high decrease in luminance of light emitted by these diodes.

Additionally, in references [

21,

22], it is shown that an increase in the semiconductor device internal temperature causes a visible decrease of its lifetime. Besides, the parameters of mounting process [

17,

23] and the area of soldering pads [

14] also influence the device thermal. Manufacturers of power LEDs are continuously improving the quality of packages for these devices, which are characterized by lower and lower values of junction-to-case thermal resistance

Rthj-c. The value of this parameter depends, e.g., on physical and chemical processes used during the packaging of these devices [

23]. In the assembly of power LEDs, a soldering process is typically used. As previously shown [

17,

24,

25], the composition of the soldering alloy, the type of reflow oven, and the soldering temperature profile in time can influence thermal resistance of a soldering joint between the case of a power LED and the PCB.

Górecki et al in the paper [

7] describe a problem of multipath heat transfer between the device package and the ambient, whereas Górecki and Zarębski in the paper [

14] the influence of selected factors characterizing, e.g., the assembly process of the tested devices on its thermal resistance are analyzed. In order to improve the efficiency of removal of heat generated in power LEDs, a special terminal of these devices is used that makes it possible to conduct only heat between the junction of this device and the PCB. Of course, in order to use such a terminal a special pad (thermal pad) must be situated on the PCB. Górecki and Ptak in the paper [

26] we showed the measurements results illustrating the influence of the area of a thermal pad on thermal resistances of selected power LEDs. In these investigations, we used a custom PCB designed by the authors. Górecki et al in the paper [

18], some results of measurements thermal parameters of power LEDs mounted on the MCPCB with soldered and not soldered thermal pad are presented. These measurements were performed for the tested devices operating with free convection cooling.

This paper, which is an extended version of our paper [

27], illustrates the influence of the use of a thermal pad on thermal, electric and optical properties of selected power LEDs assembled in different types of packages and situated on typical metal core PCBs (MCPCBs) offered by manufacturers of the tested LEDs. The measurement results presented in this paper were performed for power LEDs situated on the cold plate. The temperature of this cold plate was regulated in a wide range of its value. This paper consists of the following parts. First, the employed measurement method is introduced in detail. Next, the tested devices are described. Finally, the obtained results of investigations are presented and discussed.

2. Measurement Method

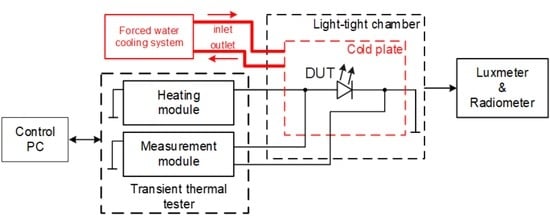

This Section describes the measurement method and the set-up used to obtain characteristics of the tested diodes illustrating an influence of the operating conditions on electric, optical and thermal properties of these devices. All the considered parameters are measured simultaneously with the use of the set-up described below. A view of the considered set-up is shown in

Figure 1a. This set-up consists of a transient thermal tester, a water-cooling system with a cold plate, a light-tight chamber, a luxmeter, and a radiometer. The interior of the light-tight chamber with the cold plate are shown in

Figure 1b [

28]. The cold plate with a tested power LED is placed inside the light-tight chamber. The thermocouple is used to measure the temperature of the cold plate. The block diagram showing the main components of the measurement system is presented in

Figure 2.

Tested devices are heated by the transient thermal tester, which is also used to record their dynamic temperature responses, i.e., the variations of the voltage drop across LED junctions in time. When isothermal characteristics are measured, the tested devices, soldered to an MCPCB, are placed on a cold plate. The temperature of the cold plate is stabilized at a preset temperature value by a thermostat forcing liquid flow through the plate. Taking into account that, in the case of power devices, the temperature regulation time might be unacceptably long, the control system response might be accelerated, as demonstrated in [

29], owing to the use of Peltier thermoelectric modules inserted between the plate and the PCB. However, if non-isothermal measurements are to be taken in the natural convection cooling conditions, the MCPCB is placed horizontally in thermally insulating clamps. For optical measurements, devices on the cold plate or in the clamp are placed inside the light-tight box and the flux density of emitted light is measured by a radiometer. The operation of the entire measurement system is controlled by a PC where all measurement data are stored.

Thermal resistance was measured with the commercial T3Ster

® equipment manufactured by the MicReD division of Mentor Graphics (Budapest, Hungary) [

30]. This equipment is now the industrial standard for device thermal characterization [

15] and it realizes the classical pulse measurement method described e.g. in the papers [

9]. In this method the tested device is excited by rectangular current pulses. The frequency of this signal is very low, and the duty cycle is close to 1. The user can select the values of low measurement current

IL and high heating current

IH. The voltage drop values of tested diodes are measured at the low (

VL) and high (

VH) forward current values.

The device under test was placed on the cold plate, whose temperature value was stabilized by a thermostat. The system for water forced cooling of electronic devices is described in the paper [

31]. In order to assure higher thermal conductance, some silicon thermal paste was applied between the cold plate surface and the metal core printed circuit board (MCPCB) on which the tested diodes were mounted. The cold plate temperature

Ta was regulated during the experiment over the range from 10 °C to 90 °C.

The measurement equipment is dedicated to thermal parameters of typical semiconductor devices, e.g., p–n diodes, but it does not include instruments making it possible to measure optical parameters of power LEDs. Therefore, it is possible to measure with this system only electric thermal resistance defined in the JEDEC standard [

15]. When only electric thermal resistance is measured, the influence of optical power on the results of measurements is neglected.

In order to measure thermal resistance of the considered type of power LEDs, the measurement equipment shown in

Figure 1 was used. The thermal resistance

Rth is measured using the following formula:

where

αT denotes the slope of the thermometric characteristic

VL(

T) describing the dependence of the diode forward voltage

VL on temperature at the forward current equal to

IM;

VLB and

VLE denote the values of the diode forward voltage measured at the current I

M when measurements, respectively, start and end;

IH and

VH denote forward current and forward voltage of the tested diodes during heating process at the steady state, whereas

Popt is the optical power emitted by tested device.

The measurements of the surface optical power density were performed using the HD2302 radiometer [

32] manufactured by Delta Ohm (Caselle di Selvazzano, Italy). The probe of the radiometer was situated at the distance of 17 cm directly above the light source. The optical power emitted by the investigated diodes was measured using the method presented in [

18,

33]. This method is based on the measurements of surface density of power of the emitted light by means of the radiometer, the data provided by the diode manufacturer, and the application of some classic geometrical dependencies.

The junction temperature values of the tested diodes at the steady state were measured using the standard pulse electric method [

34]. Measurements were performed for different values of LED forward current over a wide range of values of cold plate temperature. The values of diode current

ID and voltage

VD as well as their junction temperature

Tj and the surface power density of the emitted radiation

Φe were registered simultaneously.

The electric current-voltage characteristics of the tested LEDs measured at the thermal steady state. The measurements were carried out by measuring thermal resistance. The coordinates of points lying on these characteristics are (VH, IH).

4. Results

Using the measurement method described in

Section 2, selected characteristics illustrating electric, optical, and thermal properties of the tested diodes were obtained for these devices operating with soldered thermal pads and non-soldered thermal pads. The electric properties of the considered devices are described by the non-isothermal current-voltage characteristics. The thermal properties are illustrated by the dependencies of thermal resistance on the diode forward current. Finally, the optical properties of these power LEDs are characterized by dependencies of optical power and luminance on the forward current. Moreover, radiant efficiency of the tested power LEDs was calculated. Selected results of these investigations are shown in

Figure 4,

Figure 5,

Figure 6,

Figure 7,

Figure 8,

Figure 9,

Figure 10,

Figure 11,

Figure 12 and

Figure 13. In these figures, the solid lines denote the measurement results obtained for the diodes with the thermal pad soldered, and the dashed ones - for the diodes operating without the thermal pad soldered.

Figure 4 presents the non-isothermal current voltage characteristics of the XPLAWT diodes obtained at selected values of temperature of the cold plate

Ta, which is equal to temperature of the MCPCB. As it is visible in the figure, an increase in temperature

Ta shifts the characteristics to the left. This effect is observed as a result of self-heating, which is more visible for the diode operating without the thermal pad. In this case the increase in the diode internal temperature over the cold plate temperature is higher. For both manners of assembly, the differences in the junction temperature and the forward voltage drop increase with current. On the other hand, an increase in junction temperature at a constant value of forward voltage causes approximately exponential increase of the forward current.

In

Figure 4 it is shown that differences in the forward voltage of the diode XPLAWT due to the variation of the device junction temperature

Tj between diodes operating with a thermal pad and without it are equal even to 150 mV at the current of 2 A. In turn, the differences in values of junction temperature at the same value of current exceed even 60 °C. The maximum value of junction temperature of the diode operating without a thermal pad is equal to even 145 °C at

Ta = 90 °C and

ID = 2 A. The temperature coefficient of forward voltage changes with the value of forward current and temperature

Ta. At the forward current equal to 2 A and temperature

Ta = 10 °C, this coefficient is equal to −2.5 mV/K.

Figure 5 presents for different forward current values the measured diode voltage change Δ

VD in response to the variation of the cold plate temperature from 90 °C to 10 °C (Δ

Ta = −80 °C) in the case of MCE diodes operating with the thermal pad and without it. The value of Δ

VD was obtained as the difference of values of forward voltage of the tested LEDs measured at the same value of their forward current and at both above mentioned values of cold pate temperature. As observed, the value of Δ

VD is an increasing function of current

ID. Due to the self-heating phenomenon, the value of the considered voltage change is higher for the diode operating without the thermal pad. The observed differences between values of Δ

VD obtained for both considered mounting methods attain even 60 mV at the current equal to 0.7 A.

Figure 6 illustrates the dependence of the forward voltage of the MCE diode on temperature

Ta at two different forward current values. As observed, an increase in temperature of the cold plate causes a decrease in the diode forward voltage. The observed dependence

VD(Ta) is non-linear. The values of

VD voltage obtained for the diode operating with the thermal pad are lower than for the diode operating without the pad, but the differences between these values decrease with the increase of temperature

Ta and with the decrease in forward current

ID.

Figure 7 illustrates for different cold plate temperature values the influence of the forward current on the junction temperature of the MCE diodes operating in both types of mounting manner considered here. Obviously, an increase in forward current and the cold plate temperature causes an increase in the junction temperature. It is worth observing that the diode operating with the thermal path has even a 25 °C lower value of junction temperature

Tj than the diode of the same type operating without the thermal pad. The influence of the thermal pad on the junction temperature is the most visible for the lowest value of temperature

Ta. It can be also observed that an increase in the value of forward current causes a decrease of the difference between values of temperature

Tj obtained at different values of temperature

Ta. It is a result of a decreasing thermal resistance value of the tested diodes with an increase in the cold plate temperature.

The influence of device mounting manner of the considered diodes on their thermal resistance is illustrated in

Figure 8 and

Figure 9. In

Figure 8, the measured dependences of thermal resistance of the XPLAWT (

Figure 8a) and MCE (

Figure 8b) diodes on their forward current are shown. The measurements were performed at different values of cold plate temperature. It can be easily noticed that owing to the use of the thermal pad the diode thermal resistance of XPLAWT diode is effectively reduced. Differences in the value of this parameter exceed even 40% for the low value of forward current (100 mA). At higher values of current these differences decrease. For the current equal to 2 A, the value of thermal resistance decreases by less than 30%. For the LED operating without the thermal pad, this decrease is smaller, and it does not exceed 25%.

In practice, the results shown in

Figure 8a mean that for the forward current equal to 2 A an excess of the device internal temperature above the ambient temperature is equal to about 90 °C for the LED with the thermal pad and above 130 °C for the LED without the thermal pad, thus demonstrating its importance for the thermal performance of the device. It is also worth noticing that there are no visible differences between the results of measurements obtained for different cold plate temperature values. This proves that in the considered case the value of thermal resistance results mainly from efficiency of heat conduction between the diode junction and the cold plate. The influence of convection and radiation on the thermal resistance value

Rth is negligibly small. The rate of heat removal through the cold plate is very high, and it does not depend on the velocity of cooling liquid.

It is visible in

Figure 8b that for the MCE diode a strong influence of the cold plate temperature on thermal resistance is observed. In the considered range of temperature variations, the thermal resistance can change by over 30%, and for higher

Ta values, thermal resistance

Rth is reduced. For the considered diode operating with the thermal pad, an increasing function describes the dependence

Rth(ID) for low values of current

ID. The influence of this current

ID is very weak for the diode operating with the thermal pad, whereas it is very strong for the diode operating without the thermal pad.

Figure 9 presents the dependence of thermal resistance of the MCE diode on the the cold plate temperature. Looking at

Figure 9, it is visible that there exists a certain minimum of the thermal resistance

Rth at the cold plate temperature value

Ta equal to about 50 °C. It is also easy to observe that for the diode operating without the thermal pad the changes in thermal resistance are much bigger than for the diode operating with the pad.

The last part of the presented experimental results illustrates the influence of the thermal pad on the optical parameters of tested power LEDs. The measured surface power density of light emitted by the XPLAWT diode presented in

Figure 10 is an increasing function of the diode forward current

ID. The increase of the cold plate temperature reduces the emitted light power. Moreover, it is also visible that owing to the use of the thermal pad it is possible to obtain higher values of power density. These differences become more apparent with the increased diode current and exceed even 10%.

Figure 11 shows dependences of a change in the surface power density of the emitted light Δ

Φe on forward current for the MCE diode. This change was measured while changing temperature of the cold plate over the range from 10 °C to 90 °C. This change is an increasing function on the diode forward current, and at

ID = 0.7 A, it attains even 0.7 W/m

2. The changes in the value of

Φe obtained for both the considered kinds of mounting the tested power LEDs do not visibly differ between each other, and they are comparable with the measurement error.

In turn,

Figure 12 illustrates the dependence of the surface power density of the emitted light on temperature of the cold plate at selected values of forward current. The considered dependence

Φe(Ta) is a decreasing function. The slope of this dependences is much higher for the higher of the considered values of the diode forward current. This slope is equal to even −0.225 %/K for

ID = 0.7 A, whereas for

ID = 0.1 A, this slope is practically equal to zero.

The computed dependences of the efficiency

ηopt of the conversion of electrical energy into light in the tested LEDs is shown in

Figure 13a for the diode XPLAWT and in

Figure 13b for the diode MCE. This efficiency is equal to the quotient of the optical power

Popt and the product of the diode current

ID, and the diode forward voltage drop across its junction

VD. The computed efficiency

ηopt, in all cases has a distinct maximum. This maximum is observed at the current equal to about 30 mA for the diode without the thermal pad and around 100 mA for the diode with the thermal pad. Interestingly enough, at lower current values, a higher efficiency of conversion is observed for the diode without the thermal pad. However, within this range of currents, the power of the emitted radiation is relatively small, and junction temperature of the diode is nearly to the cold plate temperature.

Within the range of forward current values typical for the investigated diodes, the use of the thermal pad makes it possible to achieve higher efficiency ηopt and a higher power value of the emitted radiation. The change of the cold plate temperature does not influence in an essential way the relationship between the efficiency values computed for both manners of the diode mounting, since an increase of the cold plate temperature by 80 °C causes the decrease of efficiency by only several percent. It is interesting that the relationship between the characteristics obtained for the MCE diodes operating in different mounting conditions and the cold plate temperature are much different for the XPLAWT diode. Additionally, for the diode with the soldered thermal pad important differences in values of the efficiency ηopt obtained for different Ta values are noticeable. These differences exceed even 7%. For both diodes the maximum value of the efficiency is observed at the ID current in the range from 20 to 50 mA.

In order to compare the influence of thermal pad on properties of the considered power LEDs, some values of parameters of these diodes are collected in

Table 2.

The change in forward voltage ΔVD at maximal value of forward current considered here and the change of the cold plate temperature from 10 °C to 90 °C has much smaller values for the diode XPLAWT, but the highest value of ΔVD voltage is observed for the MCE diode without soldered thermal pads. The value of thermal resistance Rth measured for the above mentioned values of forward current ID is much smaller for the tested devices with soldered thermal pad. Differences in values of this parameter exceed even 50% for MCE diode. Consequently, an excess in junction temperature ΔTj of the tested diode at selected value of current ID caused by self-heating phenomenon is much higher for the diode operating without thermal pad.

Finally, the change in surface power density Δ

Φe at selected value of the current

ID at changing temperature of the cold plate by 80 °C is not big and it does not exceed 5% for both the diodes. Analyzing presented results of measurements, it can be stated that the use of thermal pads makes it possible to reduce visibly the values of thermal resistance and junction temperature of the considered devices, but changes in values of optical and electric parameters are not significant. Consistent with the classic theory of reliability of semiconductor devices [

21] and obtained results of measurements, the lifetime of the power LEDs operating with soldered thermal pad can be three times longer than for the same devices operating without the thermal pad.

5. Conclusions

This paper presented the results of measurements illustrating the influence of the thermal pad on electric, thermal and optical parameters of selected power LEDs. As demonstrated, these parameters influence one another. For example, an increase in thermal resistance causes a decrease in electrical power consumed by the considered diodes. In turn, an increase in junction temperature causes a decrease in the density of emitted light flux.

Based on these results, it is clearly visible that the thermal pad considerably reduces thermal resistance of the considered diodes. This reduction is more visible for the diode situated on the larger MCPCBs. For the MCE diode, its thermal resistance is a decreasing function of forward current and cold plate temperature. It was demonstrated that due to differences in the thermal resistance of power LEDs mounted in a different manner, the differences in the junction temperature of these diodes at the same value of forward current can attain even 30 °C. Owing to the more effective cooling of the LED mounted with the thermal pad soldered, it is possible to attain higher power values of the emitted light. This power could be even by 10% higher than for the XPLAWT diode operating without the thermal pad. The observed difference in the power value is an increasing function of the forward current.

Furthermore, it was shown that using the thermal pad results in the increase in the value of the efficiency of the electrical energy conversion into light, especially for higher values of the diode forward current. It was also shown that the increased temperature over the ambient causes the decrease of the conversion efficiency. It is worth pointing out that the efficiency of the tested XPLAWT diodes for low values of forward current exceeded even 80%. Moreover, it is worth noticing that an increase in temperature of the cold plate causes a visible decrease in the diode forward voltage and in the power density of the emitted light. This decrease is the most visible for high forward current values.

The results of performed investigations could be useful for designers of solid-state light sources or substrates dedicated for their applications. Taking into account presented results it might be possible to significantly improve the efficiency and lifetime of the power LEDs used in light sources.