1.1. Energy Consumption and Energy Efficiency in WWTP

WWTPs are a significant energy consumer, with electricity representing one of the major operational costs in most WWTPs around the world [

1]. For example, in a study of Austrian WWTPs, the electricity costs represented around 11% and 17% of the total operating costs, the second largest costs, after personnel, in WWTP < 100,000 PE [

2]. Another study in Brazil estimates that the energy represents 11–31% of the total operational costs in WWTP with activated sludge and nutrient removal [

3]. In other countries, where personnel costs are lower and/or electricity prices are higher, the electricity share can be even higher. According to data extracted from a benchmarking study of the IBNET Database of the World Bank, it has been estimated to be as high as 40% in Bangladesh or 55% in Iraq [

4].

It is estimated that WWTPs represent about 1–3% of the overall energy use of a country [

5]; in Europe, the overall electricity use of WWTPs > 2000 PE, is about 0.8% of the total electricity consumption in the EU-28 [

6]. Furthermore, in practice, the energy demand is inversely proportional to the treatment capacity of the plant, for capacities below approximately 38,000 m

3/d or 190,000 PE—for 200 L/(PE·d) [

1]. This is also observed in Europe, where plants smaller than 50,000 PE represent almost 90% of the total number of plants, but process only 31% of the PE and require 42% of the electricity use [

6].

The energy consumption of WWTPs with conventional activated sludge is estimated to be in a range between 0.27 and 1.89 kWh/m

3, depending on the country and for A2/O 0.267 kWh/m

3 [

7]. However, this value is an oversimplification, as diverse factors directly impact the energy consumption, such as the type of treatment processes (with or without primary treatment, type of biological treatment step, type of sludge treatment, etc.), the treatment target (i.e., COD removal, nitrogen and phosphorous removal), the norm to comply (dependant on the local regulations or and/or water bodies to discharge), influent load and the topography of the catchment area, among others.

In recent years, internal energy consumption in WWTPs seems to be on the rise due to the modernisation and adaptation of processes to meet the increasingly stringent effluent discharge standards that apply in a growing number of countries [

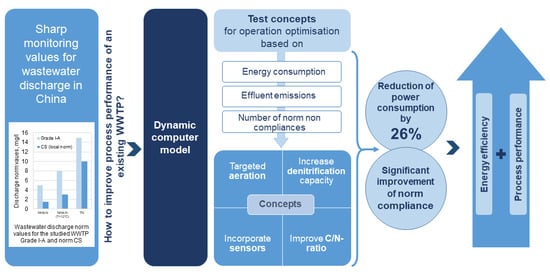

1]. This is has been observed in China, where the effluent discharge standards have been tightened in recent years [

8].

The biological treatment, and more specifically aeration, is usually the main energy consumer in a WWTP, with a share between ca. 50 and 70%, as observed in studies from different countries (see

Figure 1). This consume is commonly followed by pumping and or sludge treatment processes. Therefore, in optimisation studies, these are usually the first consumers to pay attention to.

In the biological stage, the main consumption is usually aeration [

5,

9,

11,

14,

15], but mixing and recirculation [

15] are also significant consumers. In the treatment of sludge, dewatering is commonly identified as one of the largest consumers [

11].

The aeration system in a WWTP generally offers many optimisation opportunities. On one hand, an adequate air distribution in the aeration tank, with a surface-covering aeration that avoids anoxic pockets or dead zones should be assured. On the other hand, excess aeration can have negative consequences for the denitrification (anoxic) stage [

16].

To adjust the current air requirements in the individual tank zones, numerous measuring instruments, fittings and controllers are required [

17]. The incorporation of the adequate instrumentation, control and automation (ICA) strategies, with adequate online measurements and regular maintenance is key, because the air delivery can be tailored to the system requirements at different points in time, while assuring effluent quality. The incorporation of ammonium and or nitrate sensors to the aeration control loop shows significant advantages in the air requirement [

18,

19]. Computer simulation is a useful tool to test different ICA approaches [

20,

21].

Upstream denitrification is one of the preferred configurations for WWTPs with activated sludge systems for nitrogen removal. However, alternative configurations, such as intermittent denitrification or simultaneous nitrification/denitrification, present advantages in WWTP with simultaneous aerobic sludge stabilisation; the higher activated sludge volume and solids retention time (SRT) are advantageous in the case of highly variable influent loads [

17].

The power reduction for mixing in anoxic and anaerobic tanks can offer not only advantages for the energy efficiency, but also to the process efficiency, as reduced surface turbulence minimises the transfer of oxygen to the sludge liquor [

5].

1.2. Overview of the Wastewater Situation in China

China is one of the fastest growing economies worldwide and has undergone an unparalleled process of accelerated urbanisation and industrialisation [

22]. However, its rapid economic development and population growth has brought on many challenges, including high inequality and challenges to environmental sustainability [

23]. This rapid industrial expansion has also implied an enormous exploitation of natural resources and a general degradation of environmental quality [

24].

China’s rapid economic growth also surpassed the speed of institutional development, which is why the country is addressing important institutional and reform gaps to move towards more sustainable growth [

23].

The most recent 14th Five-Year Plan (2021‒2025) has a focus on the “new progress of ecological civilisation” and includes several energy and climate indicators, such as a reduction in energy consumption and CO

2 emissions per unit of GDP, an increment in the days with good air quality and an increase in surface water quality and an aim to ensure that 85% of surface water has a quality class III or superior by 2025 [

25].

This is also reflected in the recently enforced stricter norms for treated wastewater quality [

26]. The main parameters of the standard GB 18918-2002, which is currently officially valid, are presented in

Table 1 Moreover, a consultation draft was released in 2015 to update the standard for stricter values, especially for N and P. This gives an insight into the coming years and has already been incorporated into many regional regulations. For example, in some regions discharging in the Tai Hu basin, the city standard (CS) is applied from 2021.

Chinese discharge standards are divided into four stages, which differ depending on not only the treated wastewater volume but also on the regional situation, the purpose of water reuse and the receiving waterbody. China applies the 24-h composite samples, which are mixtures of samples that are taken at least once every 2 h.

Unfortunately, according to Zhang et al. about 50% of wastewater treatment plants in China do not meet the monitoring values for nitrogen and about 90% of wastewater treatment plants have problems with nutrient removal [

8]. A significant fraction of WWTPs experience difficulties in meeting increasingly strict effluent discharge standards, taking into account that the number of WWTPs required to meet Grade I-A and Grade I-B standards increased to 90% in 2018 [

27].

As a result of the update to China’s policies, in the last three decades, the number of WWTPs in China has grown enormously, as observed in

Figure 2. Most plants are concentrated in the largest urban agglomerations. Moreover, as China continues increasing its standards for wastewater treatment, WWTPs must follow this accelerated pace, challenging their adaptation capacity and generating sometimes unsustainable coping mechanisms.

Approximately 75% of the WWTPs in China correspond to medium size plants, treating 1000–10,000 m

3/d [

29]. In China, the most dominant process in the WWTPs is the activated sludge process in different variations. The processes mainly used are the A2/O process (anaerobic–anoxic–aerobic) and oxidation ditch, which accounted for 31% and 21% of the WWTPs in 2013 [

29].

Step-by-step monitoring facilities have been increasingly applied in modern WWTPs, but until now the operation often lacks a reliable strategical process control. Therefore, in many cases, treatment processes can be improved in order to run more stably and to reduce highly fluctuating effluent quality.

In China, a study has shown that the energy consumption of different plant sizes differs greatly, in that it averages 27 kWh/(PE·a) at the treatment plants up to a size of 50,000 PE. For plants with more than 100,000 PE, the specific energy consumption decreases to an average of about 16 kWh/(PE·a) [

30]. Increasing energy demand for wastewater treatment, increasing energy prices and higher standards for the discharge of treated sewage are drivers towards more efficient treatment systems.

1.3. Modelling as a Tool for Operational Optimisation and Energy Efficiency

The modelling of activated sludge processes became a common part of the design and operation of wastewater treatment plants in the early 2000 [

31]. Models and simulation can be used as cost-effective tools to support decision-making processes, sustained with data and analysis, backing up the first steps for implementing change. The dynamic simulation of wastewater treatment plants has been used in many studies worldwide as an instrument to increase the knowledge of the process and system behaviour [

32,

33], for optimisation studies [

34], for training and teaching and for model-based process control [

35,

36]. SIMBA

® is a simulation system that allows the holistic consideration of sewer system, wastewater treatment plant, sludge treatment and rivers. The software can be applied for a large variety of tasks in engineering practice, research and education [

37]. The software has been widely used, especially in the German-speaking community, for water systems modelling, e.g., in [

38,

39,

40] to demonstrate adequate performance, for studies to improve operation (costs, critical situations), as well as for the planning and dimensioning of WWTPs [

41].

In this context, and with the use of modelling as a tool, China has the opportunity to adapt its wastewater treatment for future challenges, reducing its pollutant emissions to water bodies by applying an energy and resource-efficient approach to WWTPs and increasing its treatment standards.