Advances in Dual-Three-Phase Permanent Magnet Synchronous Machines and Control Techniques

Abstract

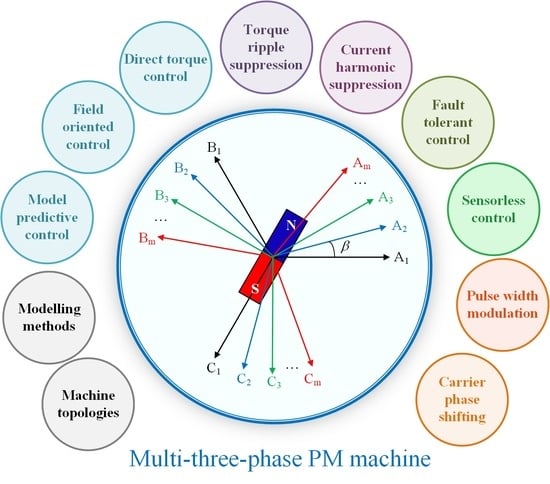

:1. Introduction

2. Various MTP and DTP PMSM Topologies

- Slot/pole number combinations;

- Angle displacement between two sets of three-phase windings;

- Coil pitch of windings.

3. Modelling of MTP PMSMs

3.1. Multiple Individual Three-Phase PMSM Model

3.2. VSD Machine Model

4. Electromagnetic Performance Analysis under Healthy and Open-Circuit Conditions

5. Control Methods

5.1. Field Oriented Control (FOC)

5.2. Direct Torque Control (DTC)

- The look-up table in DTC leads to variable switching frequency, which is not suitable for high-power applications;

- The hysteresis regulator inevitably causes large torque and flux ripples in ST-DTC.

5.3. Model Predictive Control (MPC)

6. PWM Techniques for FOC

6.1. Linear Region

6.2. Overmodulation Region

7. PWM Techniques for ST-DTC

8. Sensorless Control

9. Fault Tolerance Control

10. Conclusions and Future Work

10.1. Conclusions

10.2. Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Singh, G.K. Multi-phase induction machine drive research—A survey. Electr. Power Syst. Res. 2002, 61, 139–147. [Google Scholar] [CrossRef]

- Jones, M.; Levi, E. A literature survey of state-of-the-art in multiphase AC drives. In Proceedings of the International Universities Power Engineering Conference (UPEC), Stafford, UK, 9–11 September 2002; pp. 505–510. [Google Scholar]

- Bojoi, R.; Farina, F.; Profumo, F.; Tenconi, A. Dual-three phase induction machine drives control—A survey. IEEE Trans. Ind. Appl. 2006, 126, 420–429. [Google Scholar] [CrossRef]

- Levi, E.; Bojoi, R.; Profumo, F.; Toloyat, H.A. Multiphase induction motor drives—A technology status review. IET Electr. Power Appl. 2007, 1, 489–516. [Google Scholar] [CrossRef] [Green Version]

- Zhao, W.; Xu, L.; Liu, G. Overview of permanent-magnet fault-tolerant machines: Topology and design. CES Trans. Electr. Mach. Syst. 2018, 2, 51–63. [Google Scholar] [CrossRef]

- Levi, E. Multiphase electric machines for variable-speed applications. IEEE Trans. Ind. Electron. 2008, 55, 1893–1909. [Google Scholar] [CrossRef]

- Levi, E. Advances in converter control and innovative exploitation of additional degrees of freedom for multiphase machines. IEEE Trans. Ind. Electron. 2016, 63, 433–448. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z.; Li, Y.; Zheng, Z. A review of drive techniques for multiphase machines. CES Trans. Electr. Mach. Syst. 2018, 2, 243–251. [Google Scholar] [CrossRef]

- Salem, A.; Narimani, M. A review on multiphase drives for automotive traction applications. IEEE Trans. Transport. Electr. 2019, 5, 1329–1348. [Google Scholar] [CrossRef]

- Parsa, L.; Toliyat, H.A. Five-phase permanent magnet motor drives for ship propulsion applications. In Proceedings of the IEEE Electric Ship Technologies Symposium, Philadelphia, PA, USA, 27–27 July 2005; pp. 371–378. [Google Scholar]

- Zahr, H.; Scuiller, F.; Semail, E. Five-phase SPM machine with electronic pole changing effect for marine propulsion. In Proceedings of the Electrical Systems for Aircraft, Railway, Ship Propulsion and Road Vehicles & International Transportation Electrification Conference (ESARS-ITEC), Toulouse, France, 2–4 November 2016; pp. 1–6. [Google Scholar]

- Qiao, M.; Jiang, C.; Zhu, Y.; Li, G. Research on design method and electromagnetic vibration of six-phase fractional-slot concentrated winding PM motor suitable for ship propulsion. IEEE Access 2016, 4, 8535–8543. [Google Scholar] [CrossRef]

- Terrien, F.; Siala, S.; Noy, P. Multiphase induction motor sensorless control for electric ship propulsion. In Proceedings of the Power Electronics, Machines and Drives Conference (PEMD), Edinburgh, UK, 27–29 March 2004; pp. 556–561. [Google Scholar]

- Pires, V.F.; Cordeiro, A.; Foito, D.; Silva, J.F. A three-phase onboard integrated battery charger for EVs with six-phase machine and nine switch converter. In Proceedings of the IEEE 13th International Conference on Compatibility, Power Electronics and Power Engineering (CPE-POWERENG), Sonderborg, Denmark, 23–25 April 2019; pp. 1–6. [Google Scholar]

- Subotic, I.; Bodo, N.; Levi, E. An EV drive-train with integrated fast charging capability. IEEE Trans. Power Electron. 2016, 31, 1461–1471. [Google Scholar] [CrossRef] [Green Version]

- Sousa, L.D.; Silvestre, B.; Bouchez, B. A combined multiphase electric drive and fast battery charger for electric vehicles. In Proceedings of the IEEE Vehicle Power and Propulsion Conference, Lille, France, 1–3 September 2010; pp. 1–6. [Google Scholar]

- Subotic, I.; Bodo, N.; Levi, E.; Jones, M.; Levi, V. Isolated chargers for EVs incorporating six-phase machines. IEEE Trans. Ind. Electron. 2016, 63, 653–664. [Google Scholar] [CrossRef] [Green Version]

- Bodo, N.; Levi, E.; Subotic, I.; Espina, J.; Empringham, L.; Johnson, C.M. Efficiency evaluation of fully integrated on-board EV battery chargers with nine-phase machines. IEEE Trans. Energy Convers. 2017, 32, 257–566. [Google Scholar] [CrossRef]

- Che, H.S.; Levi, E.; Jones, M.; Duran, M.J.; Hew, W.P.; Rahim, N.A. Operation of a six-phase induction machine using series-connected machine-side converters. IEEE Trans. Ind. Electron. 2014, 61, 164–176. [Google Scholar] [CrossRef] [Green Version]

- Gjerde, S.S.; Olsen, P.K.; Ljokelsoy, K.; Undeland, T.M. Control and fault handling in a modular series-connected converter for a transformerless 100 kV low-weight offshore wind turbine. IEEE Trans. Ind. Appl. 2014, 50, 1094–1105. [Google Scholar] [CrossRef]

- Gonzalez-Prieto, I.; Duran, M.J.; Barrero, F.; Bermudez, M.; Guzman, H. Impact of post-fault flux adaptation on six-phase induction motor drives with parallel converters. IEEE Trans. Power Electron. 2014, 32, 515–528. [Google Scholar] [CrossRef] [Green Version]

- Duran, M.J.; Gonzalez-Prieto, I.; Bermudez, M.; Barrero, F.; Guzman, H.; Arahal, M.R. Optimal fault-tolerant control of six-phase induction motor drives with parallel converters. IEEE Trans. Ind. Electron. 2016, 63, 629–640. [Google Scholar] [CrossRef]

- Gonzalez-Prieto, I.; Duran, M.J.; Che, H.S.; Levi, E.; Barrero, F. Fault-tolerant operation of six-phase energy conversion systems with parallel machine-side converters. IEEE Trans. Power Electron. 2016, 31, 3068–3079. [Google Scholar] [CrossRef] [Green Version]

- De Lillo, L.; Empringham, L.; Wheeler, P.W.; Khwan-On, S.; Grada, C.; Othman, M.N.; Huang, X. Multiphase power converter drive for fault-tolerant machine development in aerospace applications. IEEE Trans. Ind. Electron. 2010, 57, 575–583. [Google Scholar] [CrossRef]

- Bojoi, R.; Cavagnino, A.; Tenconi, A.; Vaschetto, S. Control of shaft-line-embedded multiphase starter/generator for aero-engine. IEEE Trans. Ind. Electron. 2016, 63, 641–652. [Google Scholar] [CrossRef]

- Thomas, A.S.; Zhu, Z.Q.; Owen, R.L.; Jewell, G.W.; Howe, D. Multiphase flux-switching permanent-magnet brushless machine for aerospace application. IEEE Trans. Ind. Appl. 2009, 45, 1971–1981. [Google Scholar] [CrossRef]

- Barcaro, M.; Bianchi, N.; Magnussen, F. Analysis and tests of a dual three-phase 12-slot 10-pole permanent-magnet motor. IEEE Trans. Ind. Appl. 2010, 46, 2355–2362. [Google Scholar] [CrossRef]

- Barcaro, M.; Bianchi, N.; Magnussen, F. Six-phase supply feasibility using a PM fractional-slot dual winding machine. IEEE Trans. Ind. Appl. 2011, 47, 2042–2050. [Google Scholar] [CrossRef]

- Abdel-Khalik, A.S.; Ahmed, S.; Massoud, A.M. Low space harmonics cancelation in double-layer fractional slot winding using dual multiphase winding. IEEE Trans. Magn. 2015, 51, 1–10. [Google Scholar] [CrossRef]

- Abdel-Khalik, A.S.; Ahmed, S.; Massoud, A.M. A six-phase 24-slot/10-pole permanent-magnet machine with low space harmonics for electric vehicle applications. IEEE Trans. Magn. 2016, 52, 1–10. [Google Scholar] [CrossRef]

- Patel, V.I.; Wang, J.; Wang, W.; Chen, X. Analysis and design of 6-phase fractional slot per pole per phase permanent magnet machines with low space harmonics. In Proceedings of the International Electric Machines & Drives Conference (IEMDC), Chicago, IL, USA, 12–15 May 2013; pp. 386–393. [Google Scholar]

- Patel, V.I.; Wang, J.; Wang, W.; Chen, X. Six-phase fractional-slot-per-pole-per-phase permanent-magnet machines with low space harmonics for electric vehicle application. IEEE Trans. Ind. Appl. 2014, 50, 2554–2563. [Google Scholar] [CrossRef] [Green Version]

- Chen, X.; Wang, J.; Patel, V.I. A generic approach to reduction of magnetomotive force harmonics in permanent-magnet machines with concentrated multiple three-phase windings. IEEE Trans. Magn. 2014, 50, 1–4. [Google Scholar] [CrossRef]

- Chen, X.; Wang, J.; Patel, V.I.; Lazari, P. A nine-phase 18-slot 14-pole interior permanent-magnet machine with low space harmonics for electric vehicle applications. IEEE Trans. Energy Convers. 2016, 31, 860–871. [Google Scholar] [CrossRef] [Green Version]

- Onsal, M.; Demir, Y.; Aydin, M. A new nine-phase permanent magnet synchronous motor with consequent pole rotor for high-power traction applications. IEEE Trans. Magn. 2017, 53, 1–6. [Google Scholar] [CrossRef]

- Shao, L.; Hua, W.; Dai, N.; Tong, M.; Cheng, M. Mathematical modeling of a 12-phase flux-switching permanent-magnet machine for wind power generation. IEEE Trans. Ind. Electron. 2016, 63, 504–516. [Google Scholar] [CrossRef]

- Mecriw, B.C.; Jack, A.G.; Atkinson, D.J.; Green, S.R.; Atkinson, G.J.; King, A.; Green, B. Design and testing of a four-phase fault-tolerant permanent-magnet machine for an engine fuel pump. IEEE Trans. Energy Convers. 2004, 19, 671–678. [Google Scholar] [CrossRef]

- Toliyat, H.A. Analysis and simulation of five-phase variable-speed induction motor drives under asymmetrical connections. IEEE Trans. Power Electron. 1998, 13, 748–756. [Google Scholar] [CrossRef]

- Parsa, L.; Toliyat, H.A. Five-phase permanent-magnet motor drives. IEEE Trans. Ind. Appl. 2005, 41, 30–37. [Google Scholar] [CrossRef]

- Scuiller, F. Design of a 7-phase surface-mounted pm machine with tooth-concentrated winding. In Proceedings of the International Conference on Electrical Machines (ICEM), Alexandroupoli, Greece, 3–6 September 2018; pp. 2458–2464. [Google Scholar]

- Scuiller, F.; Becker, F.; Zahr, H.; Semail, E. Design of a bi-harmonic 7-phase pm machine with tooth-concentrated winding. IEEE Trans. Energy Convers. 2020, 35, 1567–1576. [Google Scholar] [CrossRef] [Green Version]

- Abdelkhalik, A.; Masoud, M.; Williams, B.W. Eleven-phase induction machine: Steady-state analysis and performance evaluation with harmonic injection. IET Elect. Power Appl. 2010, 4, 670–685. [Google Scholar] [CrossRef]

- Cheng, L.; Sui, Y.; Zheng, P.; Yin, Z.; Wang, C. Investigation of low space harmonic six-phase PMSM with FSCWs for electric vehicle applications. In Proceedings of the IEEE Transportation Electrification Conference and Expo, Asia-Pacific (ITEC Asia-Pacific), Harbin, China, 7–10 August 2017; pp. 1–5. [Google Scholar]

- Cheng, L.; Sui, Y.; Zheng, P.; Yin, Z.; Wang, C. Influence of stator MMF harmonics on the utilization of reluctance torque in six-phase PMA-SynRM with FSCW. Energies 2018, 11, 108. [Google Scholar] [CrossRef] [Green Version]

- Zhu, S.; Cox, T.; Xu, Z.; Gerada, C. A novel 24-slots14-poles fractional-slot concentrated winding topology with low space harmonics for electrical machine. In Proceedings of the Power Electronics, Machines and Drives Conference (PEMD), Liverpool, UK, 17–19 April 2018. [Google Scholar]

- Xu, P.L.; Feng, J.; Guo, S.; Feng, S.; Chu, W.Q.; Ren, Y.; Zhu, Z.Q. Analysis of dual three-phase permanent magnet synchronous machines with different angle displacements. IEEE Trans. Ind. Electron. 2018, 65, 1941–1954. [Google Scholar] [CrossRef]

- Xu, P.L.; Zhu, Z.Q.; Shao, B.; Wang, S.S.; Feng, J.H.; Guo, S.Y.; Li, Y.F.; Feng, S.Z. Analysis of dual 3-phase fractional-slot non-overlapping winding pm synchronous machines with different angle displacements. In Proceedings of the IEEE Energy Conversion Congress and Exposition (ECCE 2019), Baltimore, MD, USA, 29 September–3 October 2019; pp. 5616–5623. [Google Scholar]

- Li, Y.X.; Zhu, Z.Q.; Thomas, A.; Wu, Y.; Wu, X.M. Comparison of modular dual 3-phase PM machines with overlapping/non-overlapping windings. IEEE Trans. Ind. Appl. 2019, 55, 3566–3576. [Google Scholar] [CrossRef]

- Li, Y.X.; Zhu, Z.Q.; Thomas, A.S.; Wu, Z.Y.; Wu, X.M. Novel modular fractional slot permanent magnet machines with redundant teeth. IEEE Trans. Magn. 2019, 55, 1–10. [Google Scholar] [CrossRef]

- Li, Y.X.; Zhu, Z.Q.; Thomas, A.S. Generic slot and pole number combinations for novel modular permanent magnet dual 3-phase machines with redundant teeth. IEEE Trans. Energy Convers. 2020, 35, 1676–1687. [Google Scholar] [CrossRef]

- Zheng, P.; Wu, F.; Lei, Y.; Sui, Y.; Yu, B. Investigation of a novel 24-slot/14-pole six-phase fault-tolerant modular permanent-magnet in-wheel motor for electric vehicles. Energies 2013, 6, 4980–5002. [Google Scholar] [CrossRef]

- Abdel-Khalik, A.S.; Masoud, M.I.; Williams, B.W. Improved flux pattern with third harmonic injection for multiphase induction machines. IEEE Trans. Power Electron. 2012, 27, 1563–1578. [Google Scholar] [CrossRef]

- Zhu, Z.Q.; Howe, D. Electrical machines and drives for electric, hybrid and fuel cell vehicles. Proc. IEEE 2007, 95, 746–765. [Google Scholar] [CrossRef]

- Karttunen, J.; Kallio, S.; Peltoniemi, P.; Silventoinen, P.; Pyrhonen, O. Dual three-phase permanent magnet synchronous machine supplied by two independent voltage source inverters. In Proceedings of the International Symposium on Power Electronics, Electrical Drives, Automation and Motion, Sorrento, Italy, 20–22 June 2012; pp. 741–747. [Google Scholar]

- Singh, G.K.; Nam, K.; Lim, S.K. A simple indirect field-oriented control scheme for multiphase induction machine. IEEE Trans. Ind. Electron. 2005, 52, 1177–1184. [Google Scholar] [CrossRef]

- Bojoi, R.; Lazzari, M.; Profumo, F.; Tenconi, A. Digital field-oriented control for dual three-phase induction motor drives. IEEE Trans. Ind. Appl. 2003, 39, 752–760. [Google Scholar] [CrossRef]

- He, Y.; Wang, Y.; Wu, J.; Feng, Y.; Liu, J. A simple current sharing scheme for dual three-phase permanent-magnet synchronous motor drives. In Proceedings of the Annual IEEE Conference on Applied Power Electronics Conference and Exposition (APEC), Palm Springs, CA, USA, 21–25 February 2010; pp. 1093–1096. [Google Scholar]

- Hu, Y.; Zhu, Z.Q.; Odavic, M. Comparison of two-individual current control and vector space decomposition control for dual three-phase PMSM. IEEE Trans. Ind. Appl. 2017, 53, 4483–4492. [Google Scholar] [CrossRef]

- Hu, S.; Liang, Z.; Zhang, W.; He, X. Research on the integration of hybrid energy storage system and dual three-phase PMSM drive in EV. IEEE Trans. Ind. Electron. 2018, 65, 6602–6611. [Google Scholar] [CrossRef]

- Tessarolo, A.; Bortolozzi, M.; Contin, A. Modeling of split-phase machines in Park’s coordinates. Part I: Theoretical foundations. In Proceedings of the IEEE Euro Conference, Zagreb, Croatia, 1–4 July 2013; pp. 1308–1313. [Google Scholar]

- Tessarolo, A.; Bortolozzi, M.; Contin, A. Modeling of split-phase machines in Park’s coordinates. Part II: Equivalent circuit representation. In Proceedings of the IEEE Euro Conference, Zagreb, Croatia, 1–4 July 2013; pp. 1314–1319. [Google Scholar]

- Zhao, Y.; Lipo, T.A. Space vector PWM control of dual three-phase induction machine using vector space decomposition. IEEE Trans. Ind. Appl. 1995, 31, 1100–1109. [Google Scholar] [CrossRef]

- Zabaleta, M.; Levi, E.; Jones, M. Modelling approaches for triple three-phase permanent magnet machines. In Proceedings of the International Conference on Electrical Machines (ICEM), Lausanne, Switzerland, 4–7 September 2016; pp. 466–472. [Google Scholar]

- Zoric., I.; Jones, M.; Levi, E. Vector space decomposition algorithm for asymmetrical multiphase machines. In Proceedings of the International Symposium on Power Electronics, Novi Sad, Serbia, 19–21 October 2017; pp. 1–6. [Google Scholar]

- Tani, A.; Serra, G.; Mengoni, M.; Zarri, L.; Rini, G.; Casadei, D. Dynamic stator current sharing in quadruple three-phase induction motor drives. In Proceedings of the 39th Annual Conference of the IEEE Industrial Electronics Society (IECON), Vienna, Austria, 10–13 November 2013; pp. 5173–5178. [Google Scholar]

- Rockhill, A.; Lipo, T.A. A simplified model of a nine-phase synchronous machine using vector space decomposition. In Proceedings of the IEEE Power Electronics and Machines in Wind Applications (PEMWA), Lincoln, NE, USA, 24–26 June 2009; pp. 1–5. [Google Scholar]

- Moinoddin, S.; Abu-Rub, H.; Iqbal, A.; Alammari, R. Modelling and implementation of SVPWM technique for a fifteen-phase voltage source inverter for sinusoidal output waveform. In Proceedings of the IEEE International Conference on Industrial Technology (ICIT), Seville, Spain, 17–19 March 2015; pp. 1075–1080. [Google Scholar]

- Hu, Y.; Zhu, Z.Q.; Liu, K. Current control for dual three-phase permanent magnet synchronous motors accounting for current unbalance and harmonics. IEEE J. Emerg. Sel. Topics Power Electron. 2014, 2, 272–284. [Google Scholar]

- Karttunen, J.; Kallio, S.; Peltoniemi, P.; Silventoinen, P.; Pyrhönen, O. Decoupled vector control scheme for dual three-phase permanent magnet synchronous machines. IEEE Trans. Ind. Electron. 2014, 61, 2185–2196. [Google Scholar] [CrossRef]

- Karttunen, J.; Kallio, S.; Honkanen, J.; Peltoniemi, P.; Silventoinen, P. Partial current harmonic compensation in dual three-phase PMSMs considering the limited available voltage. IEEE Trans. Ind. Electron. 2017, 64, 1038–1048. [Google Scholar] [CrossRef]

- Jones, M.; Vukosavic, S.N.; Dujic, D.; Levi, E. A synchronous current control scheme for multiphase induction motor drives. IEEE Trans. Energy Convers. 2009, 24, 860–868. [Google Scholar] [CrossRef]

- Bojoi, R.; Levi, E.; Farina, F.; Tenconi, A.; Profumo, F. DTP induction motor drive with digital current control in the stationary reference frame. Power Eng. 2006, 153, 129–139. [Google Scholar]

- Che, H.; Levi, E.; Jones, M.; Hew, W.; Rahim, N. Current control methods for an asymmetrical six-phase induction motor drive. IEEE Trans. Power Electron. 2014, 29, 407–417. [Google Scholar] [CrossRef] [Green Version]

- Yepes, A.; Malvar, J.; Vidal, A.; Lopez, O.; Doval-Gandoy, J. Current harmonic compensation based on multi-resonant control in synchronous frames for symmetrical n-phase machines. IEEE Trans. Ind. Electron. 2014, 29, 407–417. [Google Scholar]

- Ruan, Z.; Song, W.; Yan, Y. Current harmonic suppression for dual three-phase permanent magnet synchronous motor drives. IEEE Access 2019, 7, 143888–143898. [Google Scholar] [CrossRef]

- Karttunen, J.; Kallio, S.; Peltoniemi, P.; Silventoinen, P. Current harmonic compensation in dual three-phase PMSMs using a disturbance observer. IEEE Trans. Ind. Electron. 2016, 63, 583–594. [Google Scholar] [CrossRef]

- Xu, Y.; Zheng, B.; Wang, G.; Yan, H.; Zou, J. Current harmonic suppression in dual three-phase permanent magnet synchronous machine with extended state observer. IEEE Trans. Power Electron. 2020, 35, 12166–12180. [Google Scholar] [CrossRef]

- Yan, L.C.; Zhu, Z.Q.; Qi, J.; Ren, Y.; Gan, C.; Brockway, S.; Hilton, C. Enhancement of disturbance rejection capability in dual three-phase PMSM system by using virtual impedance. IEEE Trans. Ind. Appl. 2021, 57, 4901–4912. [Google Scholar] [CrossRef]

- Xu, J.; Odavic, M.; Zhu, Z.Q.; Wu, Z.Y.; Freire, N.M.A. A generalized decomposition model of dual three-phase permanent magnet synchronous machines considering asymmetric impedances and compensation capability. IEEE Trans. Ind. Appl. 2021, 57, 3763–3775. [Google Scholar] [CrossRef]

- Yan, L.C.; Zhu, Z.Q.; Qi, J.; Ren, Y.; Gan, C.; Brockway, S.; Hilton, C. Multiple synchronous reference frame current harmonic regulation of dual three phase PMSM with enhanced dynamic performance and system stability. IEEE Trans. Ind. Electron. 2021, in press. [Google Scholar] [CrossRef]

- Yan, L.C.; Zhu, Z.Q.; Qi, J.; Ren, Y.; Gan, C.; Brockway, S.; Hilton, C. Suppression of major current harmonics for dual three phase PMSMs by virtual multi three phase systems. IEEE Trans. Ind. Electron. 2021, in press. [Google Scholar] [CrossRef]

- Lyra, R.O.C.; Lipo, T.A. Torque density improvement in a six-phase induction motor with third harmonic current injection. IEEE Trans. Ind. Appl. 2002, 38, 1351–1360. [Google Scholar] [CrossRef]

- Wang, K.; Zhu, Z.Q.; Ren, Y.; Ombach, G. Torque improvement of dual three-phase permanent-magnet machine with third-harmonic current injection. IEEE Trans. Ind. Electron. 2015, 62, 6833–6844. [Google Scholar] [CrossRef]

- Hu, Y.; Zhu, Z.Q.; Odavic, M. Torque capability enhancement of dual three-phase PMSM drive with fifth and seventh current harmonics injection. IEEE Trans. Ind. Appl. 2017, 53, 4526–4535. [Google Scholar] [CrossRef]

- Bojoi, R.; Farina, F.; Griva, G.; Profumo, F.; Tenconi, A. Direct torque control for dual three-phase induction motor drives. IEEE Trans. Ind. Appl. 2005, 41, 1627–1636. [Google Scholar] [CrossRef] [Green Version]

- Hatua, K.; Ranganathan, V. Direct torque control schemes for split-phase induction machine. IEEE Trans. Ind. Appl. 2005, 41, 1243–1254. [Google Scholar] [CrossRef]

- Ren, Y.; Zhu, Z.Q. Enhancement of steady-state performance in direct torque controlled dual-three phase permanent magnet synchronous machine drives with modified switching table. IEEE Trans. Ind. Electron. 2015, 62, 3338–3350. [Google Scholar] [CrossRef]

- Hoang, K.; Ren, Y.; Zhu, Z.Q.; Forster, M. Modified switching-table strategy for reduction of current harmonics in direct torque controlled dual-three-phase permanent magnet synchronous machine drives. IET Elect. Power Appl. 2015, 9, 10–19. [Google Scholar] [CrossRef]

- Pandit, J.K.; Aware, M.V.; Nemade, R.; Tatte, Y. Simplified implementation of synthetic vectors for DTC of asymmetric six-phase induction motor drives. IEEE Trans. Ind. Appl. 2018, 54, 2306–2318. [Google Scholar] [CrossRef]

- Shao, B.; Zhu, Z.Q.; Feng, J.; Guo, S.; Li, Y.; Liao, W. Compensation of selective current harmonics for switching-table-based direct torque control of dual three-phase PMSM drives. IEEE Trans. Ind. Appl. 2021, 57, 2505–2515. [Google Scholar] [CrossRef]

- Shao, B.; Zhu, Z.Q.; Feng, J.; Guo, S.; Li, Y.; Feng, L.; Bo, S. Improved direct torque control method for dual-three-phase permanent-magnet synchronous machines with back-EMF harmonics. IEEE Trans. Ind. Electron. 2021, 68, 9319–9333. [Google Scholar] [CrossRef]

- Ren, Y.; Zhu, Z.Q. Reduction of both harmonic current and torque ripple for dual three-phase permanent-magnet synchronous machine using modified switching-table-based direct torque control. IEEE Trans. Ind. Electron. 2015, 62, 6671–6683. [Google Scholar] [CrossRef]

- Taheri, A.; Rahmati, A.; Kaboli, S. Efficiency improvement in DTC of six-phase induction machine by adaptive gradient descent of flux. IEEE Trans. Power Electron. 2012, 27, 1552–1562. [Google Scholar] [CrossRef]

- Holakooie, M.H.; Ojaghi, M.; Taheri, A. Direct torque control of six-phase induction motor with a novel MRAS-based stator resistance estimator. IEEE Trans. Power Electron. 2012, 27, 1552–1562. [Google Scholar] [CrossRef]

- Holakooie, M.H.; Ojaghi, M.; Taheri, A. Modified DTC of a six-phase induction motor with a second-order sliding-mode MRAS-based speed estimator. IEEE Trans. Power Electron. 2019, 34, 600–611. [Google Scholar] [CrossRef]

- Ren, Y.; Zhu, Z.Q.; Green, J.E.; Li, Y.; Zhu, S.; Li, Z. Duty-ratio-based direct torque control for dual three-phase permanent magnet synchronous machine drives. IEEE Energy Convers. Congr. Expo 2018, 3367–3374. [Google Scholar]

- Ren, Y.; Zhu, Z.Q.; Green, J.E.; Li, Y.; Zhu, S.; Li, Z. Improved duty-ratio-based direct torque control for dual three-phase permanent magnet synchronous machine drives. IEEE Trans. Ind. Appl. 2019, 55, 5843–5853. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Z.; Cheng, M.; Hu, Y. Remedial strategies of T-NPC three-level asymmetric six-phase PMSM drives based on SVM-DTC. IEEE Trans. Ind. Electron. 2017, 64, 6841–6853. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Wang, Z.; Xu, Z. A hybrid direct torque control scheme for dual three-phase PMSM drives with improved operation performance. IEEE Trans. Power Electron. 2019, 34, 1622–1634. [Google Scholar] [CrossRef]

- Xu, J.; Odavic, M.; Zhu, Z.Q.; Wu, Z.Y.; Freire, N. Switching-table-based direct torque control of dual three-phase PMSMs with closed-loop current harmonics compensation. IEEE Trans. Power Electron. 2021, 36, 10645–10659. [Google Scholar] [CrossRef]

- Barrero, F.; Arahal, M.; Gregor, R.; Toral, S.; Duran, M. A proof of concept study of predictive current control for VSI-driven asymmetrical dual three-phase AC machines. IEEE Trans. Ind. Electron. 2009, 56, 1937–1954. [Google Scholar] [CrossRef]

- Barrero, F.; Arahal, M.; Gregor, R.; Toral, S.; Duran, M. One-step modulation predictive current control method for the asymmetrical dual three-phase induction machine. IEEE Trans. Ind. Electron. 2009, 56, 1974–1983. [Google Scholar] [CrossRef]

- Duran, M.; Prieto, J.; Barrero, F.; Toral, S. Predictive current control of dual three-phase drives using restrained search techniques. IEEE Trans. Ind. Electron. 2011, 58, 3253–3263. [Google Scholar] [CrossRef]

- Barrero, F.; Prieto, J.; Levi, E.; Gregor, R.; Toral, S.; Duran, M.; Jones, M. An enhanced predictive current control method for asymmetrical six-phase motor drives. IEEE Trans. Ind. Electron. 2011, 58, 3242–3252. [Google Scholar] [CrossRef]

- Gonzalez-Prieto, I.; Duran, M.J.; Aciego, J.J.; Martin, C.; Barrero, F. Model predictive control of six-phase induction motor drives using virtual VVs. IEEE Trans. Ind. Electron. 2018, 65, 27–37. [Google Scholar] [CrossRef]

- Luo, Y.; Liu, C. Elimination of harmonic currents using a reference voltage vector based-model predictive control for a six-phase PMSM motor. IEEE Trans. Power Electron. 2019, 34, 6960–6972. [Google Scholar] [CrossRef]

- Aciego, J.J.; González Prieto, I.; Duran, M.J. Model predictive control of six-phase induction motor drives using two virtual VVs. IEEE J. Emerg. Sel. Topics Power Electron. 2019, 7, 321–330. [Google Scholar] [CrossRef]

- Goncalves, P.F.; Cruz, S.M.; Mendes, A.M. Bi-subspace predictive current control of six-phase PMSM drives based on virtual vectors with optimal amplitude. IET Elect. Power Appl. 2019, 13, 1672–1683. [Google Scholar] [CrossRef]

- Gonçalves, P.F.C.; Cruz, S.M.A.; Mendes, A. Multistage predictive current control based on virtual vectors for the reduction of current harmonics in six-phase PMSMs. IEEE Trans. Energy Convers. 2021, in press. [Google Scholar]

- Aciego, J.J.; Gonzalez-Prieto, I.; Duran, M.J.; Bermudez, M.; Salas-Biedma, P. Model predictive control based on dynamic VVs for six-phase induction machines. IEEE J. Emerg. Sel. Topics Power Electron. 2021, in press. [Google Scholar] [CrossRef]

- Bermudez, M.; Arahal, M.R.; Duran, M.J.; Gonzalez-Prieto, I. Model predictive control of six-phase electric drives including ARX disturbance estimator. IEEE Trans. Ind. Electron. 2021, 68, 81–91. [Google Scholar] [CrossRef]

- Gonçalves, P.F.C.; Cruz, S.M.A.; Mendes, A.M.S. Disturbance-observer-based predictive current control of six-phase PMSMs for the mitigation of steady-state errors and current harmonics. IEEE Trans. Ind. Electron. 2021, in press. [Google Scholar]

- Luo, Y.; Liu, C. A simplified model predictive control for a dual three-phase PMSM with reduced harmonic currents. IEEE Trans. Ind. Electron. 2018, 65, 9079–9089. [Google Scholar] [CrossRef]

- Luo, Y.; Liu, C. Multi-vector-based model predictive torque control for a six-phase PMSM motor with fixed switching frequency. IEEE Trans. Energy Convers. 2019, 34, 1369–1379. [Google Scholar] [CrossRef]

- Luo, Y.; Liu, C. Model predictive control for a six-phase PMSM with high robustness against weighting factor variation. IEEE Trans. Ind. Appl. 2019, 55, 2781–2791. [Google Scholar] [CrossRef]

- Luo, Y.; Liu, C. Model predictive control for a six-phase PMSM motor with a reduced-dimension cost function. IEEE Trans. Ind. Electron. 2020, 67, 969–979. [Google Scholar] [CrossRef]

- Luo, Y.; Liu, C. A flux constrained predictive control for a six-phase PMSM motor with lower complexity. IEEE Trans. Ind. Electron. 2019, 66, 5081–5093. [Google Scholar] [CrossRef]

- Karugaba, S.; Ojo, O. A carrier-based PWM modulation technique for balanced and unbalanced reference voltages in multiphase voltage-source inverters. IEEE Trans. Ind. Appl. 2012, 48, 2102–2109. [Google Scholar] [CrossRef]

- Liu, Z.; Zheng, Z.; Sudhoff, S.D.; Gu, C.; Li, Y. Reduction of common-mode voltage in multiphase two-level inverters using SPWM with phase shifted carriers. IEEE Trans. Power Electron. 2016, 31, 6631–6645. [Google Scholar] [CrossRef]

- Liu, Z.; Zheng, Z.; Peng, Z.; Li, Y.; Hao, L. A sawtooth carrier-based PWM for asymmetrical six-phase inverters with improved common mode voltage performance. IEEE Trans. Power Electron. 2017, 8, 9444–9458. [Google Scholar] [CrossRef]

- Rakesh, P.R.; Narayanan, G. Analysis of sine-triangle and zero-sequence injection modulation schemes for split-phase induction motor drive. IET Power Electron. 2016, 9, 344–355. [Google Scholar] [CrossRef]

- Dujic, D.; Levi, E.; Jones, M. DC bus utilization in multiphase VSI supplied drives with a composite stator phase number. In Proceedings of the 2010 IEEE International Conference on Industrial Technology, Via del Mar, Chile, 14–17 March 2010; pp. 1495–1500. [Google Scholar]

- Bojoi, R.; Tenconi, A.; Profumo, F.; Griva, G.; Martinello, D. Complete analysis and comparative study of digital modulation techniques for dual three–phase AC motor drives. Conf. Rec. IEEE Power Electron. Spec. Conf. 2002, 2, 851–857. [Google Scholar]

- Prieto, J.; Levi, E.; Barrero, F.; Toral, S. Output current ripple analysis for asymmetrical six-phase drives using double zero-sequence injection PWM. In Proceedings of the IECON 37th Annual Conference of the IEEE Industrial Electronics Society, Melbourne, VIC, Australia, 7–10 November 2011; pp. 3692–3697. [Google Scholar]

- Glose, D.; Kennel, R. Carrier-based pulse width modulation for symmetrical six-phase drives. IEEE Trans. Power Electron. 2015, 30, 6873–6882. [Google Scholar] [CrossRef]

- Rakesh, P.R.; Narayanan, G. Investigation on zero-sequence signal injection for improved harmonic performance in split-phase induction motor drives. IEEE Trans. Ind. Electron. 2017, 64, 2732–2741. [Google Scholar] [CrossRef]

- Gopakumar, K.; Ranganthan, V.; Bhat, S. Split-phase induction motor operation from PWM voltage source inverter. IEEE Trans. Ind. Appl. 1993, 29, 927–932. [Google Scholar] [CrossRef]

- Prieto, J.; Riveros, J.A.; Bogado, B. Continuous and discontinuous SVPWM 2L+2M for asymmetrical dual three-phase drives. In Proceedings of the 2017 IEEE International Electric Machines and Drives Conference (IEMDC), Miami, FL, USA, 21–24 May 2017; pp. 1–6. [Google Scholar]

- Marouani, K.; Baghli, L.; Hadiouche, D.; Kheloui, A.; Rezzoug, A. A new PWM strategy based on a 24-sector vector space decomposition for a six-phase VSI-fed dual stator induction motor. IEEE Trans. Ind. Electron. 2008, 55, 1910–1920. [Google Scholar] [CrossRef]

- Suhel, S.M.; Maurya, R. Realization of 24-sector SVPWM with new switching pattern for six-phase induction motor drive. IEEE Trans. Power Electron. 2019, 34, 5079–5092. [Google Scholar] [CrossRef]

- Hadiouche, D.; Baghli, L.; Rezzoug, A. Space-vector PWM techniques for dual three-phase AC machine: Analysis, performance evaluation, and DSP implementation. IEEE Trans. Ind. Appl. 2006, 42, 1112–1122. [Google Scholar] [CrossRef]

- Wang, C.; Wang, K.; You, X. Research on synchronized SVPWM strategies under low switching frequency for six-phase VSI-Fed asymmetrical dual stator induction machine. IEEE Trans. Ind. Electron. 2016, 63, 6767–6776. [Google Scholar] [CrossRef]

- Kun, W.; Xiaojie, Y.; Chenchen, W.; Minglei, Z. An equivalent dual three-phase SVPWM realization of the modified 24-sector SVPWM strategy for asymmetrical dual stator induction machine. In Proceedings of the 2016 IEEE Energy Conversion Congress and Exposition (ECCE), Milwaukee, WI, USA, 18–22 September 2016; pp. 1–7. [Google Scholar]

- Xu, J.; Odavic, M.; Zhu, Z.Q.; Wu, Z.Y.; Freire, N.M.A. Modulation restraint analysis of space vector PWM for dual three-phase machines under vector space decomposition. IEEE Trans. Power Electron. 2021, 36, 14491–14507. [Google Scholar] [CrossRef]

- Maheshwari, R.; Busquets-Monge, S.; Nicolas-Apruzzese, J. A novel approach to generate effective carrier-based pulse width modulation strategies for diode-clamped multilevel dc–ac converters. IEEE Trans. Ind. Electron. 2016, 63, 7243–7252. [Google Scholar] [CrossRef] [Green Version]

- López, Ó.; Álvarez, J.; Yepes, A.G.; Baneira, F.; Pérez-Estévez, D.; Freijedo, F.D.; Doval-Gandoy, J. Carrier-based PWM equivalent to multilevel multiphase space vector PWM techniques. IEEE Trans. Ind. Electron. 2020, 67, 5220–5231. [Google Scholar] [CrossRef]

- Zhu, Y.; Gu, W.; Lu, K.; Wu, Z. Vector control of asymmetric dual three-phase PMSM in full modulation range. IEEE Access 2020, 8, 104479–104493. [Google Scholar] [CrossRef]

- Yazdani, D.; Ali Khajehoddin, S.; Bakhshai, A.; Joos, G. Full utilization of the inverter in split-phase drives by means of a dual three-phase space vector classification algorithm. IEEE Trans. Ind. Electron. 2009, 56, 120–129. [Google Scholar] [CrossRef]

- Zhou, C.; Yang, G.; Su, J. PWM strategy with minimum harmonic distortion for dual three-phase permanent-magnet synchronous motor drives operating in the overmodulation region. IEEE Trans. Power Electron. 2016, 31, 1367–1380. [Google Scholar] [CrossRef]

- Paul, S.; Basu, K. Overmodulation techniques of asymmetrical six-phase machine with optimum harmonic voltage injection. IEEE Trans. Ind. Electron. 2021, 68, 4679–4690. [Google Scholar] [CrossRef]

- Paul, S.; Basu, K. A three-phase inverter based overmodulation strategy of asymmetrical six-phase induction machine. IEEE Trans. Power Electron. 2021, 36, 5802–5817. [Google Scholar] [CrossRef]

- Wang, G.; Valla, M.; Solsona, J. Position sensorless permanent magnet synchronous machine drives—A review. IEEE Trans. Ind. Electron. 2020, 67, 5830–5842. [Google Scholar] [CrossRef]

- Matsui, N. Sensorless PM brushless DC motor drives. IEEE Trans. Ind. Electron. 1996, 43, 300–308. [Google Scholar] [CrossRef]

- Chen, Z.; Tomita, M.; Doki, S.; Okuma, S. An extended electromotive force model for sensorless control of interior permanent-magnet synchronous motors. IEEE Trans. Ind. Electron. 2003, 50, 288–295. [Google Scholar] [CrossRef]

- Genduso, F.; Miceli, R.; Rando, C.; Galluzzo, G.R. Back EMF sensorless-control algorithm for high-dynamic performance PMSM. IEEE Trans. Ind. Electron. 2010, 57, 2092–2100. [Google Scholar] [CrossRef]

- Morimoto, S.; Kawamoto, K.; Sanada, M.; Takeda, Y. Sensorless control strategy for salient-pole PMSM based on extended EMF in rotating reference frame. IEEE Trans. Ind. Appl. 2002, 38, 1054–1061. [Google Scholar] [CrossRef]

- Liu, J.M.; Zhu, Z.Q. Improved sensorless control of permanent-magnet synchronous machine based on third-harmonic back EMF. IEEE Trans. Ind. Appl. 2014, 50, 1861–1870. [Google Scholar] [CrossRef]

- Kim, J.; Jeong, I.; Nam, K.; Yang, J.; Hwang, T. Sensorless control of PMSM in a high-speed region considering iron loss. IEEE Trans. Ind. Electron. 2015, 62, 6151–6159. [Google Scholar] [CrossRef]

- Boldea, I.; Paicu, M.C.; Andreescu, G. Active flux concept for motion-sensorless unified AC drives. IEEE Trans. Power Electron. 2008, 23, 2612–2618. [Google Scholar] [CrossRef]

- Boldea, I.; Paicu, M.C.; Andreescu, G.D.; Blaabjerg, F. Active flux DTFC-SVM sensorless control of IPMSM. IEEE Trans. Energy Convers 2009, 24, 314–322. [Google Scholar] [CrossRef]

- Liu, K.; Zhu, Z.Q.; Stone, D.A. Parameter estimation for condition monitoring of PMSM stator winding and rotor permanent magnets. IEEE Trans. Ind. Electron. 2013, 60, 5902–5913. [Google Scholar] [CrossRef] [Green Version]

- Xie, G.; Lu, K.; Dwivedi, S.K.; Riber, R.J.; Wu, W. Permanent magnet flux online estimation based on zero-voltage vector injection method. IEEE Trans. Power Electron. 2015, 30, 6506–6509. [Google Scholar] [CrossRef]

- Yoo, A.; Sul, S.K. Design of flux observer robust to interior permanent-magnet synchronous motor flux variation. IEEE Trans. Ind. Appl. 2009, 45, 1670–1677. [Google Scholar]

- Kim, S.I.; Im, J.H.; Song, E.Y.; Kim, R.Y. A new rotor position estimation method of IPMSM using all-pass filter on high-frequency rotating voltage signal injection. IEEE Trans. Ind. Electron. 2016, 63, 6499–6509. [Google Scholar] [CrossRef]

- Medjmadj, S.; Diallo, D.; Mostefai, M.; Delpha, C.; Arias, A. PMSM drive position estimation: Contribution to the high-frequency injection voltage selection issue. IEEE Trans. Energy Convers 2015, 30, 349–358. [Google Scholar] [CrossRef] [Green Version]

- Basic, D.; Malrait, F.; Rouchon, P. Current controller for low frequency signal injection and rotor flux position tracking at low speeds. IEEE Trans. Ind. Electron. 2011, 58, 4010–4022. [Google Scholar] [CrossRef] [Green Version]

- Bianchi, N.; Bolognani, S.; Jang, J.H.; Sul, S.K. Comparison of PM motor structures and sensorless control techniques for zero-speed rotor position detection. IEEE Trans. Power Electron. 2007, 22, 2466–2475. [Google Scholar] [CrossRef]

- Liu, J.M.; Zhu, Z.Q. Rotor position estimation for single- and dual-three-phase permanent magnet synchronous machines based on third harmonic back-EMF under imbalanced situation. Chin. J. Electr. Eng. 2017, 3, 63–72. [Google Scholar]

- Almarhoon, A.H.; Zhu, Z.Q.; Xu, P.L. Improved pulsating signal injection using zero-sequence carrier voltage for sensorless control of dual three-phase PMSM. IEEE Trans. Energy Convers. 2017, 32, 436–446. [Google Scholar] [CrossRef]

- Almarhoon, A.H.; Zhu, Z.Q.; Xu, P.L. Improved rotor position estimation accuracy by rotating carrier signal injection utilizing zero-sequence carrier voltage for dual three-phase PMSM. IEEE Trans. Ind. Electron. 2017, 64, 4454–4462. [Google Scholar] [CrossRef]

- Liu, T.; Zhu, Z.Q.; Wu, Z.Y.; Stone, D.; Foster, M. A simple sensorless position error correction method for dual three-phase permanent magnet synchronous machines. IEEE Trans. Energy Convers. 2021, in press. [Google Scholar] [CrossRef]

- Barcaro, M.; Bianchi, N.; Magnussen, F. Faulty operations of a PM fractional-slot machine with a dual three-phase winding. IEEE Trans. Ind. Electron. 2011, 58, 3825–3832. [Google Scholar] [CrossRef]

- Alberti, L.; Bianchi, N. Experimental tests of dual three-phase induction motor under faulty operating condition. IEEE Trans. Ind. Electron. 2012, 59, 2041–2048. [Google Scholar] [CrossRef]

- Jiang, X.; Huang, W.; Cao, R.; Hao, Z.; Jiang, W. Electric drive system of dual-winding fault-tolerant permanent-magnet motor for aerospace applications. IEEE Trans. Ind. Electron. 2015, 62, 7322–7330. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, X.; Wang, Y.; Chen, J.; Cheng, M. Fault tolerant control of multiphase multilevel motor drives—Technical review. Chin. J. Electr. Eng. 2017, 3, 76–86. [Google Scholar]

- Feng, G.; Lai, C.; Li, W.; Tjong, J.; Kar, N.C. Open-phase fault modeling and optimized fault-tolerant control of dual three-phase permanent magnet synchronous machines. IEEE Trans. Power Electron. 2019, 34, 11116–11127. [Google Scholar] [CrossRef]

- Cao, W.P.; Mecrow, B.C.; Atkinson, G.J.; Bennett, J.W.; Atkinson, D.J. Overview of electric motor technologies used for more electric aircraft (MEA). IEEE Trans. Ind. Electron. 2012, 59, 3523–3531. [Google Scholar]

- Mantero, S.; De Paola, E.; Marina, G. An optimised control strategy for double star motors configuration in redundancy operation mode. In Proceedings of the European Power Electronics Conference, Lausanne, Switzerland, 7–9 September 1999. [Google Scholar]

- Mantero, S.; Monti, A.; Spreafico, S. DC-bus voltage control for double star asynchronous fed drive under fault conditions. In Proceedings of the IEEE 2000 Power Electronics Specialist Conference, Galway, Ireland, 18–23 June 2000. [Google Scholar]

- Yu, F.; Cheng, M.; Chau, K.T. Controllability and performance of a nine-phase FSPM motor under severe five open-phase fault conditions. IEEE Trans. Energy Convers. 2016, 31, 323–332. [Google Scholar] [CrossRef]

- Locment, F.; Semail, E.; Kestelyn, X. Vectorial approach-based control of a seven-phase axial flux machine designed for fault operation. IEEE Trans. Ind. Electron. 2008, 55, 3682–3691. [Google Scholar] [CrossRef] [Green Version]

- Tani, A.; Mengoni, M.; Zarri, L.; Serra, G.; Casadei, D. Control of multiphase induction motors with an odd number of phases under open-circuit phase faults. IEEE Trans. Power Electron. 2012, 27, 565–577. [Google Scholar] [CrossRef]

- Sui, Y.; Zheng, P.; Yin, Z.; Wang, M.; Wang, C. Open-circuit fault-tolerant control of five-phase PM machine based on reconfiguring maximum round magnetomotive force. IEEE Trans. Ind. Electron. 2019, 66, 48–59. [Google Scholar] [CrossRef]

- Feng, G.; Lai, C.; Li, W.; Han, Y.; Kar, N.C. Computation-efficient solution to open-phase fault tolerant control of dual three-phase interior PMSMs with maximized torque and minimized ripple. IEEE Trans. Power Electron. 2021, 36, 4488–4499. [Google Scholar] [CrossRef]

- Chen, Q.; Gu, L.; Lin, Z.; Liu, G. Extension of space-vector-signal-injection-based MTPA control into SVPWM fault-tolerant operation for five-phase IPMSM. IEEE Trans. Ind. Electron. 2020, 67, 7321–7333. [Google Scholar] [CrossRef]

- Wang, J.B.; Atallah, K.; Howe, D. Optimal torque control of fault-tolerant permanent magnet brushless machines. IEEE Trans. Magn. 2003, 39, 2962–2964. [Google Scholar] [CrossRef]

- Guo, H.; Xu, J.; Chen, Y. Robust control of fault-tolerant permanent-magnet synchronous motor for aerospace application with guaranteed fault switch process. IEEE Trans. Ind. Electron. 2015, 62, 7309–7321. [Google Scholar] [CrossRef]

- Shamsi-Nejad, M.; Nahid-Mobarakeh, B.; Pierfederici, S.; Meibody-Tabar, F. Fault tolerant and minimum loss control of double-star synchronous machines under open phase conditions. IEEE Trans. Ind. Electron. 2008, 55, 1956–1965. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, J.; Cheng, M.; Li, S. Fault-tolerant control of dual three-phase permanent-magnet synchronous machine drives under open-phase faults. IEEE. Trans. Power Electron. 2017, 32, 2052–2063. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Z.; He, M.; Zhou, Q.; Liu, X.; Meng, X. Fault-tolerant control of dual three-phase PMSM drives with minimized copper loss. IEEE Trans. Power Electron. 2021, 36, 12938–12953. [Google Scholar] [CrossRef]

- Che, H.S.; Duran, M.J.; Levi, E.; Jones, M.; Hew, W.P.; Rahim, N.A. Postfault operation of an asymmetrical six-phase induction machine with single and two isolated neutral points. IEEE Trans. Power Electron. 2014, 29, 5406–5416. [Google Scholar] [CrossRef] [Green Version]

- Kianinezhad, R.; Nahid-Mobarakeh, B.; Baghli, L.; Betin, F.; Capolino, G.A. Modeling and control of six-phase symmetrical induction machine under fault condition due to open phases. IEEE Trans. Ind. Electron. 2008, 55, 1966–1977. [Google Scholar] [CrossRef]

- Fnaiech, M.A.; Betin, F.; Capolino, G.A.; Fnaiech, F. Fuzzy logic and sliding-mode controls applied to six-phase induction machine with open phases. IEEE Trans. Ind. Electron. 2010, 57, 354–364. [Google Scholar] [CrossRef]

- Hu, Y.; Feng, Y.; Li, X. Fault-tolerant hybrid current control of dual three-phase PMSM with one phase open. IEEE J. Emerg. Sel. Topics Power Electron. 2021, in press. [Google Scholar] [CrossRef]

- Hu, Y.; Zhu, Z.Q.; Wu, Z. Modelling and vector control of dual three-phase PMSM with one-phase open. IET Electr. Power Appl. 2021, 15, 847–860. [Google Scholar] [CrossRef]

- Liu, Z.; Zheng, Z.; Li, Y. Enhancing fault-tolerant ability of a nine-phase induction motor drive system using fuzzy logic current controllers. IEEE Trans. Energy Convers 2017, 32, 759–769. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Z.; Xu, Z.; Cheng, M.; Wang, W.; Hu, Y. Comprehensive diagnosis and tolerance strategies for electrical faults and sensor faults in dual three-phase PMSM drives. IEEE Trans. Power Electron. 2019, 34, 6669–6684. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, X.; Cao, J.; Cheng, M.; Hu, Y. Direct torque control of T-NPC inverters-fed double-stator-winding PMSM drives with SVM. IEEE Trans. Power Electron. 2018, 33, 1541–1553. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Z.; Xu, Z.; He, J.; Zhao, W. Diagnosis and tolerance of common electrical faults in T-type three-level inverters fed dual three-phase PMSM drives. IEEE Trans. Ind. Electron. 2020, 35, 1753–1769. [Google Scholar] [CrossRef]

- Liu, Y.; Zhu, Z.Q. Influence of gear ratio on the performance of fractional slot concentrated winding permanent magnet machines. IEEE Trans. Ind. Electron. 2019, 66, 7593–7602. [Google Scholar] [CrossRef] [Green Version]

- Mao, X.; Jain, A.K.; Ayyanar, R. Hybrid interleaved space vector PWM for ripple reduction in modular converters. IEEE. Trans. Power Electron. 2011, 26, 1954–1967. [Google Scholar] [CrossRef]

- Miyama, Y.; Hazeyama, M.; Hanioka, S.; Watanabe, N.; Daikoku, A.; Inoue, M. PWM carrier harmonic iron loss reduction technique of permanent-magnet motors for electric vehicles. IEEE Trans. Ind. Appl. 2016, 52, 2865–2871. [Google Scholar] [CrossRef]

- Miyama, Y.; Ishizuka, M.; Kometani, H.; Akatsu, K. Vibration reduction by applying carrier phase-shift PWM on dual three-phase winding permanent magnet synchronous motor. IEEE Trans. Ind. Appl. 2018, 54, 5998–6004. [Google Scholar] [CrossRef]

- Han, X.; Jiang, D.; Zou, T.; Qu, R.; Yang, K. Two-segment three-phase PMSM drive with carrier phase-shift PWM for torque ripple and vibration reduction. IEEE. Trans. Power Electron. 2019, 34, 588–599. [Google Scholar] [CrossRef]

- Huang, Y.; Xu, Y.; Zhang, W.; Zou, J. PWM frequency noise cancellation in two-segment three-phase motor using parallel interleaved inverters. IEEE. Trans. Power Electron. 2019, 34, 2515–2525. [Google Scholar] [CrossRef]

- Zhang, W.; Xu, Y.; Huang, H.; Zou, J. Vibration reduction for dual-branch three-phase permanent magnet synchronous motor with carrier phase-shift technique. IEEE. Trans. Power Electron. 2020, 35, 607–618. [Google Scholar] [CrossRef]

- Ji, Z.; Cheng, S.; Lv, Y.; Wang, D.; Sun, W.; Li, X. The mechanism for suppressing high-frequency vibration of multiphase surface permanent magnet motors via PWM carrier phase shifting. IEEE. Trans. Power Electron. 2021, in press. [Google Scholar] [CrossRef]

- Wang, X.; Yan, H.; Sala, G.; Buticchi, G.; Gu, C.; Zhao, W.; Xu, L.; Zhang, H. Selective torque harmonic elimination for dual three-phase PMSMs based on PWM carrier phase shift. IEEE. Trans. Power Electron. 2020, 35, 13255–13269. [Google Scholar] [CrossRef]

- Capella, G.J.; Pou, J.; Ceballos, S.; Konstantinou, G.; Zaragoza, J.; Agelidis, V.G. Enhanced phase-shifted PWM carrier disposition for interleaved voltage-source inverters. IEEE. Trans. Power Electron. 2015, 30, 1121–1125. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Sala, G.; Zhang, H.; Gu, C.; Buticchi, G.; Formentini, A.; Gerada, C.; Wheeler, P. Torque ripple reduction in sectored multi three-phase machines based on PWM carrier phase shift. IEEE Trans. Ind. Electron. 2020, 67, 4315–4325. [Google Scholar] [CrossRef]

- Reddy, B.P.; Keerthipati, S. Torque ripple minimization of PPMIM drives with phase-shifted carrier PWM. In Proceedings of the IECON 44th Annual Conference of the IEEE Industrial Electronics Society, Washington, DC, USA; 2018; pp. 725–730. [Google Scholar]

| Topics | References | Typical Papers |

|---|---|---|

| Design of multi-three-phase PM machine | [27,28,29,30,31,32,33,34,35,36,37,38,39,40,41,42,43,44,45,46,47,48,49,50,51,52,53] | Barcaro, et al., 2010, [27], University of Padova, Italy Abdel-Khalik, et al., 2015, [29], Alexandria University, Egypt Chen, et al., 2014, [33], University of Sheffield, UK Xu, et al., 2018, [46], University of Sheffield, UK Li, et al., 2020, [50], University of Sheffield, UK |

| Modelling of multi-three-phase PM machine | [54,55,56,57,58,59,60,61,62,63,64,65,66,67] | Karttunen, et al., 2012, [54], Lappeenranta University of Technology, Finland Hu, et al., 2017, [58], University of Sheffield, UK Zhao, et al., 1995, [62], University of Wisconsin-Madison, USA Zabaleta, et al., 2017, [63], Liverpool John Moores University, UK |

| Vector control | [54,55,56,57,58,68,69,70,71,72,73,74,75,76,77,78,79,80,81,82,83,84] | Che, et al., 2014, [73], Liverpool John Moores University, UK Karttunen, et al., 2017, [70], Lappeenranta University of Technology, Finland Yan, et al., 2021, [81], University of Sheffield, UK |

| Direct torque control | [85,86,87,88,89,90,91,92,93,94,95,96,97,98,99,100] | Bojoi, et al., 2005, [85], Power Electronics Innovation Center at Politecnico di Torino, Italy Ren, et al., 2015, [87], University of Sheffield, UK Shao, et al., 2021, [91], University of Sheffield, UK |

| Model predictive control | [101,102,103,104,105,106,107,108,109,110,111,112,113,114,115,116,117] | Barrero, et al., 2009, [101], University of Seville, Spain Duran, et al., 2011, [103], University of Malaga, Spain Luo, et al., 2019, [113], City University of Hong Kong, HK, China |

| PWM techniques | [118,119,120,121,122,123,124,125,126,127,128,129,130,131,132,133,134,135,136,137,138,139,140,141] | Marouani, et al., 2008, [129], Ecole Militaire Polytechnique, Algeria Suhel, et al., 2008, [130], Sarvajanik College of Engineering and Technology, India Yazdani, et al., 2009, [138], Fairchild Semiconductor, USA Zhou, et al., 2016, [139], Harbin Institute of Technology, China |

| Sensorless control | [142,143,144,145,146,147,148,149,150,151,152,153,154,155,156,157,158,159,160,161] | Almarhoon, et al., 2017, [159], University of Sheffield, UK Almarhoon, et al., 2017, [160], University of Sheffield, UK Liu, et al., 2021, [161], University of Sheffield, UK |

| Fault tolerant control | [162,163,164,165,166,167,168,169,170,171,172,173,174,175,176,177,178,179,180,181,182,183,184,185,186,187,188,189,190] | Barcaro, et al., 2011, [162], University of Seville, Spain Cheng, et al., 2016, [170], Southeast University, China Wang, et al., 2003, [176], University of Sheffield, UK Hu, et al., 2021, [185], University of Sheffield, UK |

| Carrier phase-shift techniques | [191,192,193,194,195,196,197,198,199,200,201] | Miyama, et al., 2018, [193], Mitsubishi Electric Corporation, Japan Han, et al., 2019, [194], Huazhong University of Science and Technology, China Zhang, et al., 2020, [196], Harbin Institute of Technology, China |

| 2p | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 26 | 28 | 30 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ns | ||||||||||||||||

| 6 | 0 | 0 | ** | 0 | 0 | ** | 0 | 0 | ** | 0 | 0 | ** | 0 | 0 | ** | |

| 12 | 0/30 | 0 | ** | 0 | 0/30 | ** | 0/30 | 0 | ** | 0 | 0/30 | ** | 0/30 | 0 | ** | |

| 18 | 0/20 | 0/20 | 0 | 0/20 | 0/20 | 0 | 0/20 | 0/20 | ** | 0/20 | 0/20 | 0 | 0/20 | 0/20 | 0 | |

| 24 | 0/15/30 | 0/30 | ** | 0 | 0/15/30 | ** | 0/15/30 | 0 | ** | 0/30 | 0/15/30 | ** | 0/15/30 | 0/30 | ** | |

| 30 | 0/12 | 0/12 | ** | 0/12 | 0 | ** | 0/12 | 0/12 | ** | 0 | 0/12 | ** | 0/12 | 0/12 | ** | |

| 36 | 0/10/30 | 0/20 | 0/30 | 0/20 | 0/10/30 | 0 | 0/10/30 | 0/20 | ** | 0/20 | 0/10/30 | 0 | 0/10/30 | 0/20 | 0/30 | |

| Note |  | |||||||||||||||

| Ns | Angle Displacement, β (°) | Distribution Factor, Kd |

|---|---|---|

| 6 | 0 | 1 |

| 12 | 0 | 0.966 |

| 30 | 1 | |

| 18 | 0/20 | 0.960 |

| 24 | 0 | 0.958 |

| 15 | 0.968 | |

| 30 | 0.991 | |

| 30 | 0/12 | 0.957 |

| 36 | 0 | 0.956 |

| 10 | 0.960 | |

| 30 | 0.990 |

| y = 1 | ||||||||||||||||

| 2p | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 26 | 28 | 30 | |

| Ns | ||||||||||||||||

| 6 | 0.500 | 0.866 | 1.000 | 0.866 | 0.500 | 0.000 | 0.500 | 0.866 | 1.000 | 0.866 | 0.500 | 0.000 | 0.500 | 0.866 | 1.000 | |

| 12 | 0.259 | 0.500 | 0.707 | 0.866 | 0.966 | 1.000 | 0.966 | 0.866 | 0.707 | 0.500 | 0.259 | 0.000 | 0.259 | 0.500 | 0.707 | |

| 18 | 0.174 | 0.342 | 0.500 | 0.643 | 0.766 | 0.866 | 0.940 | 0.985 | 1.000 | 0.985 | 0.940 | 0.866 | 0.766 | 0.643 | 0.500 | |

| 24 | 0.131 | 0.259 | 0.383 | 0.500 | 0.609 | 0.707 | 0.793 | 0.866 | 0.924 | 0.966 | 0.991 | 1.000 | 0.991 | 0.966 | 0.924 | |

| 30 | 0.105 | 0.208 | 0.309 | 0.407 | 0.500 | 0.588 | 0.669 | 0.743 | 0.809 | 0.866 | 0.914 | 0.951 | 0.978 | 0.995 | 1.000 | |

| 36 | 0.087 | 0.174 | 0.259 | 0.342 | 0.423 | 0.500 | 0.574 | 0.643 | 0.707 | 0.766 | 0.819 | 0.866 | 0.906 | 0.940 | 0.966 | |

| y = 2 | ||||||||||||||||

| 2p | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 26 | 28 | 30 | |

| Ns | ||||||||||||||||

| 6 | 0.866 | 0.866 | 0.000 | 0.866 | 0.866 | 0.000 | 0.866 | 0.866 | 0.000 | 0.866 | 0.866 | 0.000 | 0.866 | 0.866 | 0.000 | |

| 12 | 0.500 | 0.866 | 1.000 | 0.866 | 0.500 | 0.000 | 0.500 | 0.866 | 1.000 | 0.866 | 0.500 | 0.000 | 0.500 | 0.866 | 1.000 | |

| 18 | 0.342 | 0.643 | 0.866 | 0.985 | 0.985 | 0.866 | 0.643 | 0.342 | 0.000 | 0.342 | 0.643 | 0.866 | 0.985 | 0.985 | 0.866 | |

| 24 | 0.259 | 0.500 | 0.707 | 0.866 | 0.966 | 1.000 | 0.966 | 0.866 | 0.707 | 0.500 | 0.259 | 0.000 | 0.259 | 0.500 | 0.707 | |

| 30 | 0.208 | 0.407 | 0.588 | 0.743 | 0.866 | 0.951 | 0.995 | 0.995 | 0.951 | 0.866 | 0.743 | 0.588 | 0.407 | 0.208 | 0.000 | |

| 36 | 0.174 | 0.342 | 0.500 | 0.643 | 0.766 | 0.866 | 0.940 | 0.985 | 1.000 | 0.985 | 0.940 | 0.866 | 0.766 | 0.643 | 0.500 | |

| y = 3 | ||||||||||||||||

| 2p | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 26 | 28 | 30 | |

| Ns | ||||||||||||||||

| 6 | 1.000 | 0.000 | 1.000 | 0.000 | 1.000 | 0.000 | 1.000 | 0.000 | 1.000 | 0.000 | 1.000 | 0.000 | 1.000 | 0.000 | 1.000 | |

| 12 | 0.707 | 1.000 | 0.707 | 0.000 | 0.707 | 1.000 | 0.707 | 0.000 | 0.707 | 1.000 | 0.707 | 0.000 | 0.707 | 1.000 | 0.707 | |

| 18 | 0.500 | 0.866 | 1.000 | 0.866 | 0.500 | 0.000 | 0.500 | 0.866 | 1.000 | 0.866 | 0.500 | 0.000 | 0.500 | 0.866 | 1.000 | |

| 24 | 0.383 | 0.707 | 0.924 | 1.000 | 0.924 | 0.707 | 0.383 | 0.000 | 0.383 | 0.707 | 0.924 | 1.000 | 0.924 | 0.707 | 0.383 | |

| 30 | 0.309 | 0.588 | 0.809 | 0.951 | 1.000 | 0.951 | 0.809 | 0.588 | 0.309 | 0.000 | 0.309 | 0.588 | 0.809 | 0.951 | 1.000 | |

| 36 | 0.259 | 0.500 | 0.707 | 0.866 | 0.966 | 1.000 | 0.966 | 0.866 | 0.707 | 0.500 | 0.259 | 0.000 | 0.259 | 0.500 | 0.707 | |

| y = 4 | ||||||||||||||||

| 2p | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 26 | 28 | 30 | |

| Ns | ||||||||||||||||

| 6 | 0.866 | 0.866 | 0.000 | 0.866 | 0.866 | 0.000 | 0.866 | 0.866 | 0.000 | 0.866 | 0.866 | 0.000 | 0.866 | 0.866 | 0.000 | |

| 12 | 0.866 | 0.866 | 0.000 | 0.866 | 0.866 | 0.000 | 0.866 | 0.866 | 0.000 | 0.866 | 0.866 | 0.000 | 0.866 | 0.866 | 0.000 | |

| 18 | 0.643 | 0.985 | 0.866 | 0.342 | 0.342 | 0.866 | 0.985 | 0.643 | 0.000 | 0.643 | 0.985 | 0.866 | 0.342 | 0.342 | 0.866 | |

| 24 | 0.500 | 0.866 | 1.000 | 0.866 | 0.500 | 0.000 | 0.500 | 0.866 | 1.000 | 0.866 | 0.500 | 0.000 | 0.500 | 0.866 | 1.000 | |

| 30 | 0.407 | 0.743 | 0.951 | 0.995 | 0.866 | 0.588 | 0.208 | 0.208 | 0.588 | 0.866 | 0.995 | 0.951 | 0.743 | 0.407 | 0.000 | |

| 36 | 0.342 | 0.643 | 0.866 | 0.985 | 0.985 | 0.866 | 0.643 | 0.342 | 0.000 | 0.342 | 0.643 | 0.866 | 0.985 | 0.985 | 0.866 | |

| Note | 1. | High pitch factors (>0.866) | ||||||||||||||

| 2. | Pitch factor = 0 suggests unfeasible winding configuration. | |||||||||||||||

| 3. | The feasibility of the specific slot/pole and pitch number combination is determined in Table 2 and Table 4. | |||||||||||||||

| 2p | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 26 | 28 | 30 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ns | ||||||||||||||||

| 6 | 1.000 | 0.866 | ** | 0.866 | 1.000 | ** | 1.000 | 0.866 | ** | 0.866 | 1.000 | ** | 1.000 | 0.866 | ** | |

| 12 | 1.000 | 1.000 | ** | 0.866 | 0.966 | ** | 0.966 | 0.866 | ** | 1.000 | 0.866 | ** | 0.866 | 1.000 | ** | |

| 18 | 1.000 | 0.985 | 1.000 | 0.985 | 0.985 | 0.866 | 0.985 | 0.985 | ** | 0.985 | 0.985 | 0.866 | 0.985 | 0.985 | 1.000 | |

| 24 | 1.000 | 1.000 | ** | 1.000 | 0.966 | ** | 0.966 | 0.866 | ** | 0.966 | 0.991 | ** | 0.991 | 0.966 | ** | |

| 30 | 1.000 | 0.995 | ** | 0.995 | 1.000 | ** | 0.995 | 0.995 | ** | 0.866 | 0.995 | ** | 0.978 | 0.995 | ** | |

| 36 | 1.000 | 1.000 | 1.000 | 0.985 | 0.985 | 1.000 | 0.966 | 0.985 | ** | 0.985 | 0.940 | 0.866 | 0.985 | 0.985 | 0.966 | |

| Note |  | |||||||||||||||

| 2p | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 26 | 28 | 30 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ns | ||||||||||||||||

| 6 | 3 | 1 | ** | 1 | 3 | ** | 3 | 1 | ** | 1 | 3 | ** | 3 | 1 | ** | |

| 12 | 6 | 3 | ** | 1 | 1 | ** | 1 | 1 | ** | 3 | 4 | ** | 4 | 3 | ** | |

| 18 | 9 | 4 | 3 | 2 | 2 | 1 | 4 | 1 | ** | 1 | 4 | 1 | 2 | 2 | 3 | |

| 24 | 12 | 6 | ** | 3 | 2 | ** | 2 | 1 | ** | 1 | 1 | ** | 1 | 1 | ** | |

| 30 | 15 | 7 | ** | 4 | 3 | ** | 2 | 2 | ** | 1 | 4 | ** | 8 | 1 | ** | |

| 36 | 18 | 9 | 6 | 4 | 4 | 3 | 3 | 2 | ** | 2 | 2 | 1 | 4 | 4 | 1 | |

| Note |  | |||||||||||||||

| 2p | β (°) | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 26 | 28 | 30 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ns | |||||||||||||||||

| 6 | 0 | 1.000 | 0.866 | ** | 0.866 | 1.000 | ** | 1.000 | 0.866 | ** | 0.866 | 1.000 | ** | 1.000 | 0.866 | ** | |

| 12 | 0 | 0.966 | ++ | ** | ++ | 0.933 | ** | 0.933 | ++ | ** | ++ | 0.837 | ** | 0.837 | ++ | ** | |

| 30 | 1.000 | ++ | ** | ++ | 0.966 | ** | 0.966 | ++ | ** | ++ | 0.866 | ** | 0.866 | ++ | ** | ||

| 18 | 0/20 | 0.960 | 0.945 | 0.945 | 0.945 | ++ | 0.945 | 0.945 | ** | 0.945 | 0.945 | ++ | 0.945 | 0.945 | ++ | ||

| 24 | 0 | 0.958 | ++ | ** | ++ | 0.925 | ** | 0.925 | ++ | ** | ++ | 0.949 | ** | 0.949 | ++ | ** | |

| 15 | 0.966 | ++ | ** | ++ | 0.933 | ** | 0.933 | ++ | ** | ++ | 0.958 | ** | 0.958 | ++ | ** | ||

| 30 | 0.991 | ++ | ** | ++ | 0.958 | ** | 0.958 | ++ | ** | ++ | 0.983 | ** | 0.983 | ++ | ** | ||

| 30 | 0/12 | 0.957 | 0.951 | ** | 0.951 | + | ** | 0.951 | 0.951 | ** | ++ | 0.951 | ** | 0.951 | 0.951 | ** | |

| 36 | 0 | 0.956 | ++ | ++ | ++ | 0.942 | ++ | 0.924 | ++ | ** | ++ | 0.898 | ++ | 0.867 | ++ | ++ | |

| 10 | 0.960 | ++ | ++ | ++ | 0.945 | ++ | 0.927 | ++ | ** | ++ | 0.902 | ++ | 0.870 | ++ | ++ | ||

| 30 | 0.990 | ++ | ++ | ++ | 0.975 | ++ | 0.956 | ++ | ** | ++ | 0.930 | ++ | 0.897 | ++ | ++ | ||

| Note |  | ||||||||||||||||

| 2p | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 26 | 28 | 30 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ns | ||||||||||||||||

| 6 | ** | ** | ** | ** | ** | |||||||||||

| 12 | ** | β = 0°/30°, y = 1, [27] β = 0°/30°, y = 1, [29] | ** | ** | ** | ** | ||||||||||

| 18 | β = 0°/20°, y = 2, [31] | β = 0°/20°, y = 1, [33] | ** | |||||||||||||

| 24 | ** | β = 0°/30°, y = 2, [30] β=0°/15°/30°, y = 2, [46] | ** | β = 0°/30°, y = 2, [43] β = 30°, y = 1, [45] | ** | β = 0°/15°/30°, y = 1, [47] | ** | ** | ||||||||

| 30 | ** | ** | ** | ** | ** | |||||||||||

| 36 | ** | |||||||||||||||

| Note |  | |||||||||||||||

| Modelling Methods | Multiple Individual Three-Phase | VSD |

|---|---|---|

| Advantages | 1. Straightforward. 2. Modular modeling and control of each three-phase set. | 1. Decoupled and simpler models in several subspaces. 2. Simpler controller design. 3. Easier to regulate the harmonics in control strategy. |

| Disadvantages | 1. Additional coupling among sets. 2. Complexity of model and control increases as number of sets increases. | 1. Less capable of dealing with the unbalance issues due to asymmetry among the sets. 2. More complex to achieve active power/torque sharing. |

| Machines | Angle Displacement, β | Coil Connection (A1) | Coil Connection (A2) |

|---|---|---|---|

| 24 slot/10 pole 2 slot-pitch coils | 0° | 1-3′-6-8′ | 13′-15-18′-20 |

| 15° | 1-3′-13′-15 | 6-8′-18′-20 | |

| 30° | 3′-8′-15-20 | 1-6-13′-18′ | |

| 24 slot/22 pole 1 slot-pitch coil | 0° | 14-16-13′-15′ | 1-3-2′-4′ |

| 15° | 14-16-2′-4′ | 1-3-13′-15′ | |

| 30° | 1-14-2′-13′ | 3-16-4′-15′ |

| Angle Displacement, β | 0° | 15° | 30° |

|---|---|---|---|

| 24-slot/10-pole, y = 2 | |||

| Kd | 0.958 | 0.968 | 9.991 |

| Kp | 0.966 | 0.966 | 0.966 |

| Kw | 0.925 | 0.933 | 0.958 |

| 24-slot/22-pole, y = 1 | |||

| Kd | 0.958 | 0.968 | 9.991 |

| Kp | 0.991 | 0.991 | 0.991 |

| Kw | 0.949 | 0.958 | 0.980 |

| ψs | Te | I | II | III | IV | V | VI |

| 1 | 1 | V27, V10 | V26, V19 | V18, V30 | V22, V50 | V54, V20 | V52, V38 |

| 0 | V0, V63 | V0, V63 | V0, V63 | V0, V63 | V0, V63 | V0, V63 | |

| −1 | V37,V44 | V45, V33 | V41, V13 | V9, V43 | V1, V25 | V27, V10 | |

| −1 | 1 | V26, V19 | V18, V30 | V22, V50 | V54, V20 | V52, V38 | V36, V53 |

| 0 | V0, V63 | V0, V63 | V0, V63 | V0, V63 | V0, V63 | V0, V63 | |

| −1 | V36, V53 | V37, V44 | V45, V33 | V41, V13 | V9, V43 | V11, V25 | |

| ψs | Te | VII | VIII | IX | X | XI | XII |

| 1 | 1 | V36, V53 | V37, V44 | V45, V33 | V41, V13 | V9, V43 | V11, V25 |

| 0 | V0, V63 | V0, V63 | V0, V63 | V0, V63 | V0, V63 | V0, V63 | |

| −1 | V26, V19 | V18, V30 | V22, V50 | V54, V20 | V52, V38 | V36, V53 | |

| −1 | 1 | V37, V44 | V45, V33 | V41, V13 | V9, V43 | V11, V25 | V27, V10 |

| 0 | V0, V63 | V0, V63 | V0, V63 | V0, V63 | V0, V63 | V0, V63 | |

| −1 | V27, V10 | V26, V19 | V18, V30 | V22, V50 | V54,V20 | V52, V38 |

| FOC | DTC | MPC | |

|---|---|---|---|

| Steady-state performance | High | Low | Normal |

| Dynamic performance | Slow | Fast | Fast |

| Switching frequency | Fixed | Variable | Variable |

| Implementation complexity | Normal | Simple | Complex |

| Parameter sensitivity | Normal | Normal | High |

| Sensorless | No | Yes | No |

| PWM modulator | Yes | No | No |

| Computation burden | Low | Low | High |

| Robustness | High | High | Low |

| VVs Group | Magnitude | |

|---|---|---|

| αβ Subspace | z1z2 Subspace | |

| L (D1) | ||

| ML (D2) | ||

| M (D3) | ||

| S (D4) | ||

| CPWM(SPWM) | ZIPWM | SVPWM | |

|---|---|---|---|

| Maximum modulation index | 1 | 1.154 | 1.154 |

| Redundant switching states | No | No | Yes |

| Reduction of z1z2 currents | No | No | Yes |

| Implementation complexity | Simple | Simple | Complex |

| L | L + ML | L + ML + M | |

|---|---|---|---|

| Maximum modulation index | 1.12 | 1 | 0.894 |

| Utilization of dc link voltage | 0.644UDC | 0.577UDC | 0.512UDC |

| Reduction of z1−z2 currents | Worse | Normal | Good |

| Implementation complexity | Simple | Normal | Complex |

| Pulsating Injection [159] | Rotating Injection [160] | |

|---|---|---|

| Optimal phase shift angle | ||

| Demodulation | ||

| Test results without phase shift |  |  |

| Test results with optimal phase shift |  |  |

| Isolated Neutral Point Type | Connected Neutral Point Type | ||

|---|---|---|---|

| Fault tolerant control: 1. Simply cut off the entire three-phase set with fault. 2. Extended VSD control with negative sequence current injection. |  | Optimal current control: 1. Maximal average torque 2. Minimal torque ripples 3. Minimal copper loss 4. Uniform distribution of copper loss Robust control: 1. Fuzzy current control 2. Robust speed control |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Z.; Wang, S.; Shao, B.; Yan, L.; Xu, P.; Ren, Y. Advances in Dual-Three-Phase Permanent Magnet Synchronous Machines and Control Techniques. Energies 2021, 14, 7508. https://0-doi-org.brum.beds.ac.uk/10.3390/en14227508

Zhu Z, Wang S, Shao B, Yan L, Xu P, Ren Y. Advances in Dual-Three-Phase Permanent Magnet Synchronous Machines and Control Techniques. Energies. 2021; 14(22):7508. https://0-doi-org.brum.beds.ac.uk/10.3390/en14227508

Chicago/Turabian StyleZhu, Ziqiang, Shensheng Wang, Bo Shao, Luocheng Yan, Peilin Xu, and Yuan Ren. 2021. "Advances in Dual-Three-Phase Permanent Magnet Synchronous Machines and Control Techniques" Energies 14, no. 22: 7508. https://0-doi-org.brum.beds.ac.uk/10.3390/en14227508