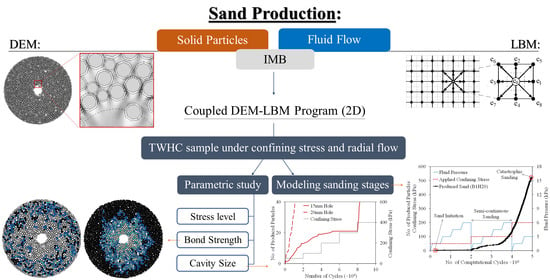

Particulate Modeling of Sand Production Using Coupled DEM-LBM

Abstract

:1. Introduction

2. Methodology

2.1. Bonded Discrete Element Method

2.2. LBM

2.3. DEM-LBM Coupling Scheme

2.3.1. Immersed Moving Boundary (IMB) Method

2.3.2. Subcycling Time Integration

3. Model Validation

3.1. Poisseuile Flow

3.2. Single Particle Sedimentation

3.3. Bonding Effects on Particulate Assembly

- Particle generation: The desired number of polygon particles are randomly placed in a circular assembly. In this step, the particles have no overlap, and the number of generated particles with each specific size follows the given particle-size distribution.

- Initial compaction: A stress-controlled isotropic compaction is applied on boundary particles. The boundary stress is maintained until the desired planar void ratio is achieved. It might be challenging to form loose homogeneous models with high values of void ratio. Relatively loose models can be formed if high values of inter-particle friction coefficient and considerable damping are considered while small boundary stresses are applied during the initial compaction. Conversely, if dense particle assemblies are to be modeled, negligible damping and zero friction coefficient should be considered.

- Bond generation: If cemented particles are to be simulated in the assembly, bonds are created at all existing contacts at the beginning of this step (as explained in Section 2.1).

- Confining stress: In this step, the particle assembly is subjected to given isotropic boundary stress. The intergranular friction coefficient and damping constants should be restored to common values at the beginning of this step.

- Deviatoric stress: When the variation of the planar void ratio with loading cycles becomes negligible during confinement, the last step of the biaxial test can be initiated. In this step, while maintaining the confining boundary stress of the previous loading step, a compressive displacement is applied vertically at a uniform rate, increasing the vertical stress of the assembly. The test continues until the particle assembly reaches high vertical strains.

4. Numerical Simulation and Results

4.1. Modeling Procedure

4.2. Modeling Results and Discussion

4.2.1. Sand Production Stages

- Sand initiation: In this stage, the first particles are eroded from the assembly as they enter the inner cavity. The effect of fluid flow on this stage and the number of produced particles is negligible.

- Transient sand production: In relatively higher stress levels, the number of produced particles occasionally undergoes sudden (but small) increases when fluid pressure changes. This particle production subsequently stops when the fluid pressure is kept constant for a while.

- Semi-continuous production: As the stress level increases, the fluid flow casts more impact on the sanding procedure. In this stage, fluid-induced erosion becomes influential, and there are some increases of produced particles even when fluid pressure is constant.

- Continuous production: At higher stress levels, particles are easily eroded at a relatively constant rate.

- Catastrophic sanding: Further increase in stress level leads to the rapid erosion of many particles known as catastrophic sand production. The most common symptoms of catastrophic sanding reported in the literature are the production of a large amount of sand followed by a reduction in radial stress, a considerable decrease in the cavity dimension or blockage of the inner hole [29].

4.2.2. Parametric Study on the Effect of Stress Level

4.2.3. Parametric Study on the Effect of Bond Strength

4.2.4. Parametric Study on the Effect of Cavity Size

5. Conclusions

- Different stages of sand production reported by experimental studies (sand initiation, transient, semi-continuous, continuous, and catastrophic sanding) are successfully simulated. It means that the growing impact of fluid flow on sand production is appropriately captured as the stress level increases during the sand production process.

- The stress level has a considerable effect on the sanding mechanism. An increase in the stress level increases the number of produced particles and alters the sanding stage. The stress level is also responsible for the bond breakage and the formation of yield zones around the inner cavity of the models. The higher the stress, the more bonds break. The bond breakage starts from the particles close to the cavity and propagates as the loading continues. Consequently, yield zones extend to the circumference of the model, while the radius of the shear yield zone always exceeds that of the tensile yield zone.

- The strength of inter-particle bonds also affect the sanding results. The increase of bond strength limits the number of produced particles and delays the catastrophic sanding.

- The cavity size (hole diameter) has a significant effect on sand production. A relatively small increase in hole diameter (from 15 to 20 mm) at a given stress level can lead to the erosion of much more particles and catastrophic sanding. Additionally, in models with larger cavities, the stress levels triggering sand initiation and catastrophic sanding are smaller. The effect of hole enlargement on the stress level leading to catastrophic sanding is more pronounced in stronger models (with higher inter-particle bond strength) than weaker ones.

- While expected qualitatively, the predicted sand initiation stress (the stress causing the onset of sand production) in models with large cavities are quantitatively comparable to experimental data. However, sand initiation stress in models with smaller cavities is overestimated in the numerical simulations.

- The catastrophic stress level (the stress causing the catastrophic sand production) does not necessarily correspond to the general failure of the model. In stronger models, catastrophic sanding occurs when the yield zones are not extended to the outer boundaries (outer radius) of the model, and many bonds are still intact.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| DEM | Discrete Element Method |

| LBM | Lattice-Boltzmann Method |

| IMB | Immersed Moving Boundary |

| 2D | Two-Dimensional |

| 3D | Three-Dimensional |

| TWHC | Thick-Walled Hollow Cylinder |

| UCS | Uniaxial Compressive Strength |

| CFD | Computational Fluid Dynamics |

| BGK | Bhatnagar–Gross–Krook |

| IBM | Immersed Boundary Method |

References

- Wang, M. Modelling of sand production using a mesoscopic bonded particle lattice Boltzmann method. Eng. Comput. 2019, 36, 691–706. [Google Scholar] [CrossRef] [Green Version]

- Fattahpour, V.; Moosavi, M.; Mehranpour, M. An experimental investigation on the effect of rock strength and perforation size on sand production. J. Pet. Sci. Eng. 2012, 86, 172–189. [Google Scholar] [CrossRef]

- Fattahpour, V.; Moosavi, M.; Mehranpour, M. An experimental investigation on the effect of grain size on oil-well sand production. Pet. Sci. 2012, 9, 343–353. [Google Scholar] [CrossRef] [Green Version]

- Nouri, A. A comparison of two sanding criteria in physical and numerical modeling of sand production. J. Pet. Sci. Eng. 2006, 50, 55–70. [Google Scholar] [CrossRef]

- Heiland, J.C.; Flor, M.E. Influence of rock failure characteristics on sanding behavior: Analysis of reservoir sandstones from the Norwegian Sea. In Proceedings of the SPE International Symposium and Exhibition on Formation Damage Control, Lafayette, LA, USA, 15–17 February 2006; Society of Petroleum Engineers: Houston, TX, USA, 2006. [Google Scholar] [CrossRef]

- Antheunis, D. Perforation collapse: Failure of perforated friable sandstones. In Proceedings of the SPE European Spring Meeting, Amsterdam, The Netherlands, 8–9 April 1976; Society of Petroleum Engineers: Houston, TX, USA, 1976. [Google Scholar]

- Walton, I.C. Perforating Unconsolidated Sands: An Experimental and Theoretical Investigation. SPE Drill. Completion 2002, 17, 141–150. [Google Scholar] [CrossRef]

- Papamichos, E. Erosion and multiphase flow in porous media: Application to sand production. Eur. J. Environ. Civ. Eng. 2010, 14, 1129–1154. [Google Scholar] [CrossRef]

- Ranjith, P.G. Effective parameters for sand production in unconsolidated formations: An experimental study. J. Pet. Sci. Eng. 2013, 105, 34–42. [Google Scholar] [CrossRef]

- Garolera, D.; Carol, I.; Papanastasiou, P. Micromechanical analysis of sand production. Int. J. Numer. Anal. Methods Geomech. 2019, 43, 1207–1229. [Google Scholar] [CrossRef]

- Ong, S.; Ramos, R.; Zheng, Z. Sand Production Prediction in High Rate, Perforated and Open-hole Gas Wells. In Proceedings of the SPE International Symposium on Formation Damage Control, Lafayette, LA, USA, 23–24 February 2000; Society of Petroleum Engineers: Houston, TX, USA, 2000. [Google Scholar] [CrossRef]

- Younessi Sinaki, A.R. Sand Production Simulation under True-Triaxial Stress Conditions. Ph.D. Thesis, Department of Petroleum Engineering, Curtin University, Bentley, Australia, 2012. [Google Scholar]

- Ahad, N.A.; Jami, M.; Tyson, S. A review of experimental studies on sand screen selection for unconsolidated sandstone reservoirs. J. Pet. Explor. Prod. Technol. 2020, 10, 1675–1688. [Google Scholar] [CrossRef] [Green Version]

- Eshiet, K.I.-I.; Yang, D.; Sheng, Y. Computational study of reservoir sand production mechanisms. Geotech. Res. 2019, 6, 177–204. [Google Scholar] [CrossRef] [Green Version]

- Rahmati, H. Review of Sand Production Prediction Models. J. Pet. Eng. 2013, 2013, 1–16. [Google Scholar] [CrossRef] [Green Version]

- Nauroy, J.-F. Geomechanics Applied to the Petroleum Industry; Editions Technip: Paris, France, 2011. [Google Scholar]

- Fjær, E. Petroleum Related Rock Mechanics; Elsevier: Amsterdam, The Netherlands, 2008. [Google Scholar]

- Hall, C., Jr.; Harrisberger, W. Stability of sand arches: A key to sand control. J. Pet. Technol. 1970, 22, 821–829. [Google Scholar] [CrossRef]

- Tippie, D.; Kohlhaas, C. Effect of flow rate on stability of unconsolidated producing sands. In Proceedings of the Fall Meeting of the Society of Petroleum Engineers of AIME, Las Vegas, NV, USA, September 30–3 October 1973; Society of Petroleum Engineers: Houston, TX, USA, 1973. [Google Scholar] [CrossRef]

- Yim, K.; Dusseault, M.; Zhang, L. Experimental study of sand production processes near an orifice. In Proceedings of the Rock Mechanics in Petroleum Engineering, Delft, The Netherlands, 29–31 August 1994; Society of Petroleum Engineers: Houston, TX, USA, 1994. [Google Scholar] [CrossRef]

- Tronvoll, J.; Morita, N.; Santarelli, F. Perforation cavity stability: Comprehensive laboratory experiments and numerical analysis. In Proceedings of the SPE Annual Technical Conference and Exhibition, Washington, DC, USA, 4–7 October 1992; Society of Petroleum Engineers: Houston, TX, USA, 1992. [Google Scholar] [CrossRef]

- Tronvoll, J. Experimental investigation of perforation cavity stability. In The 33rd U.S. Symposium on Rock Mechanics (USRMS); American Rock Mechanics Association: Santa Fe, New Mexico, 1992; p. 10. [Google Scholar]

- Tronvoll, J.; Fjær, E. Experimental study of sand production from perforation cavities. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1994, 31, 393–410. [Google Scholar] [CrossRef]

- Tronvoll, J. Sand production in ultra-weak sandstones: Is sand control absolutely necessary? In Proceedings of the Latin American and Caribbean Petroleum Engineering Conference, Rio de Janeiro, Brazil, August 30–3 September 1997; Society of Petroleum Engineers: Houston, TX, USA, 1997. [Google Scholar] [CrossRef]

- Tronvoll, J.; Skj, A.; Papamichos, E. Sand production: Mechanical failure or hydrodynamic erosion? Int. J. Rock Mech. Min. Sci. 1997, 34, 291. [Google Scholar] [CrossRef]

- Papamichos, E. Volumetric sand production model and experiment. Int. J. Numer. Anal. Methods Geomech. 2001, 25, 789–808. [Google Scholar] [CrossRef]

- Papamichos, E. Sand production: Physical and experimental evidence. Rev. Eur. De Génie Civ. 2006, 10, 803–816. [Google Scholar] [CrossRef]

- Papamichos, E. Hole stability of Red Wildmoor sandstone under anisotropic stresses and sand production criterion. J. Pet. Sci. Eng. 2010, 72, 78–92. [Google Scholar] [CrossRef]

- Younessi, A.; Rasouli, V.; Wu, B. Sand production simulation under true-triaxial stress conditions. Int. J. Rock Mech. Min. Sci. 2013, 61, 130–140. [Google Scholar] [CrossRef] [Green Version]

- Bruno, M.; Bovberg, C.; Meyer, R. Some influences of saturation and fluid flow on sand production: Laboratory and discrete element model investigations. In Proceedings of the SPE Annual Technical Conference and Exhibition, Denver, Colorado, 6–9 October 1996; Society of Petroleum Engineers: Houston, TX, USA, 1996. [Google Scholar] [CrossRef]

- O’Connor, R.I. Discrete element modeling of sand production. Int. J. Rock Mech. Min. Sci. 1997, 34, 231. [Google Scholar] [CrossRef]

- Dorfmann, A.; Rothenburg, L.; Bruno, M. Micromechanical modeling of sand production and arching effects around a cavity. Int. J. Rock Mech. Min. Sci. 1997, 34. [Google Scholar] [CrossRef]

- Jensen, R.P. Preece, D.S. Modeling Sand Production with Darcy-Flow Coupled with Discrete Elements; Sandia National Labs: Albuquerque, NM, USA, 2000.

- Li, L.; Papamichos, E.; Cerasi, P. Investigation of sand production mechanisms using DEM with fluid flow. In Eurock 2006: Multiphysics Coupling and Long Term Behaviour in Rock Mechanics: Proceedings of the Multiphysics Coupling and Long Term Behaviour in Rock Mechanics, Liege, Belgium, 9–12 May 2006; Taylor & Francis: Boca Raton, FL, USA, 2006. [Google Scholar] [CrossRef]

- Boutt, D.F.; Cook, B.K.; Williams, J.R. A coupled fluid-solid model for problems in geomechanics: Application to sand production. Int. J. Numer. Anal. Methods Geomech. 2011, 35, 997–1018. [Google Scholar] [CrossRef]

- Climent, N. Sand production simulation coupling DEM with CFD. Eur. J. Environ. Civ. Eng. 2014, 18, 983–1008. [Google Scholar] [CrossRef]

- Cui, Y. A new approach to DEM simulation of sand production. J. Pet. Sci. Eng. 2016, 147, 56–67. [Google Scholar] [CrossRef]

- Cook, B.K. A Numerical Framework for the Direct Simulation of Solid-Fluid Systems. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2001. [Google Scholar]

- Cook, B.K.; Noble, D.R.; Williams, J.R. A direct simulation method for particle-fluid systems. Eng. Comput. 2004, 21, 151–168. [Google Scholar] [CrossRef]

- Ghassemi, A.; Pak, A. Numerical simulation of sand production experiment using a coupled Lattice Boltzmann-Discrete Element Method. J. Pet. Sci. Eng. 2015, 135, 218–231. [Google Scholar] [CrossRef]

- Han, Y.; Cundall, P. Verification of two-dimensional LBM-DEM coupling approach and its application in modeling episodic sand production in borehole. Petroleum 2016. [Google Scholar] [CrossRef] [Green Version]

- Cundall, P. A computer model for simulating progressive, large-scale movements in blocky rock systems. In Proceedings of the Symposium of the International Society of Rock Mechanics, Nancy, France, 4–6 October 1971. [Google Scholar] [CrossRef]

- Mirghasemi, A.A.; Rothenburg, L.; Matyas, E.L. Numerical Simulations of Assemblies of Two-Dimensional Polygon-Shaped Particles and Effects of Confining Pressure on Shear Strength. Soils Found. 1997, 37, 43–52. [Google Scholar] [CrossRef]

- Seyedi Hosseininia, E.; Mirghasemi, A.A. Numerical simulation of breakage of two-dimensional polygon-shaped particles using discrete element method. Powder Technol. 2006, 166, 100–112. [Google Scholar] [CrossRef]

- Seyedi Hosseininia, E.; Mirghasemi, A.A. Effect of particle breakage on the behavior of simulated angular particle assemblies. China Particuology 2007, 5, 328–336. [Google Scholar] [CrossRef]

- Seyedi Hosseininia, E. Investigating the micromechanical evolutions within inherently anisotropic granular materials using discrete element method. Granul. Matter 2012, 14, 483–503. [Google Scholar] [CrossRef]

- Seyedi Hosseininia, E. Discrete element modeling of inherently anisotropic granular assemblies with polygonal particles. Particuology 2012, 10, 542–552. [Google Scholar] [CrossRef]

- Seyedi Hosseininia, E. Stress-force-fabric relationship for planar granular materials. Géotechnique 2013, 63, 830–841. [Google Scholar] [CrossRef]

- Seyedi Hosseininia, E. A micromechanical study on the stress rotation in granular materials due to fabric evolution. Powder Technol. 2015, 283, 462–474. [Google Scholar] [CrossRef]

- Khabazian, M.; Seyedi Hosseininia, E. Instability of saturated granular materials in biaxial loading with polygonal particles using discrete element Method (DEM). Powder Technol. 2020, 363, 428–441. [Google Scholar] [CrossRef]

- Jiang, M.; Yu, H.-S.; Leroueil, S. A simple and efficient approach to capturing bonding effect in naturally microstructured sands by discrete element method. Int. J. Numer. Methods Eng. 2007, 69, 1158–1193. [Google Scholar] [CrossRef]

- Jiang, M.J. Modeling shear behavior and strain localization in cemented sands by two-dimensional distinct element method analyses. Comput. Geotech. 2011, 38, 14–29. [Google Scholar] [CrossRef]

- Jiang, M.; Zhang, F.; Sun, Y. An evaluation on the degradation evolutions in three constitutive models for bonded geomaterials by DEM analyses. Comput. Geotech. 2014, 57, 1–16. [Google Scholar] [CrossRef]

- Chaussonnet, G. Smoothed Particle Hydrodynamics Simulation of High Velocity Impact Dynamics of Molten Sand Particles. Energies 2020, 13, 5134. [Google Scholar] [CrossRef]

- Wang, M. A coupled 3-dimensional bonded discrete element and lattice Boltzmann method for fluid-solid coupling in cohesive geomaterials. Int. J. Numer. Anal. Methods Geomech. 2018, 42, 1405–1424. [Google Scholar] [CrossRef] [Green Version]

- Sukop, M.C.; Thorne, D.T. Lattice Boltzmann Modeling: An Introduction for Geoscientists and Engineers; Springer: Berlin/Heidelberg, Germany, 2006. [Google Scholar]

- Mohamad, A. Lattice Boltzmann Method: Fundamentals and Engineering Applications with Computer Codes, 2nd ed.; Springer: London, UK, 2011; Volume 70. [Google Scholar]

- Krüger, T. The Lattice Boltzmann Method: Principles and Practice; Springer: Cham, Switzerland, 2017. [Google Scholar]

- Feng, Y.T.; Han, K.; Owen, D.R.J. Coupled lattice Boltzmann method and discrete element modelling of particle transport in turbulent fluid flows: Computational issues. Int. J. Numer. Methods Eng. 2007, 72, 1111–1134. [Google Scholar] [CrossRef]

- Wang, M.; Feng, Y.; Qu, T. On the implicit immersed boundary method in coupled discrete element and lattice Boltzmann method. Int. J. Numer. Anal. Methods Geomech. 2020, 44, 516–532. [Google Scholar] [CrossRef]

- Owen, D.R.J.; Leonardi, C.R.; Feng, Y.T. An efficient framework for fluid–structure interaction using the lattice Boltzmann method and immersed moving boundaries. Int. J. Numer. Methods Eng. 2011, 7, 66–95. [Google Scholar] [CrossRef]

- Peskin, C.S. Numerical analysis of blood flow in the heart. J. Comput. Phys. 1977, 25, 220–252. [Google Scholar] [CrossRef]

- Noble, D.; Torczynski, J. A lattice-Boltzmann method for partially saturated computational cells. Int. J. Mod. Phys. C 1998, 9, 1189–1201. [Google Scholar] [CrossRef]

- Wang, M. Instability and treatments of the coupled discrete element and lattice Boltzmann method by the immersed moving boundary scheme. Int. J. Numer. Methods Eng. 2020, 121, 4901–4919. [Google Scholar] [CrossRef]

- Wang, M.; Feng, Y.; Wang, C. Coupled bonded particle and lattice Boltzmann method for modelling fluid-solid interaction. Int. J. Numer. Anal. Methods Geomech. 2016. [Google Scholar] [CrossRef]

- Wang, M.; Feng, Y.T.; Wang, C.Y. Numerical investigation of initiation and propagation of hydraulic fracture using the coupled Bonded Particle-Lattice Boltzmann Method. Comput. Struct. 2017, 181, 32–40. [Google Scholar] [CrossRef]

- Hu, H.H.; Joseph, D.D.; Crochet, M.J. Direct simulation of fluid particle motions. Theor. Comput. Fluid Dyn. 1992, 3, 285–306. [Google Scholar] [CrossRef]

- Wu, J.; Shu, C. Particulate flow simulation via a boundary condition-enforced immersed boundary-lattice Boltzmann scheme. Commun. Comput. Phys. 2010, 7, 793. [Google Scholar] [CrossRef] [Green Version]

- Wu, J. A Comparative Study of Three Classes of Boundary Treatment Schemes for Coupled LBM/DEM Simulations; Springer: Singapore, 2017. [Google Scholar] [CrossRef]

- Norouzi, H. Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase Flows; John Wiley & Sons: Chichester, UK, 2016. [Google Scholar]

- Schnaid, F.; Prietto, P.D.; Consoli, N.C. Characterization of cemented sand in triaxial compression. J. Geotech. Geoenviron. Eng. 2001, 127, 857–868. [Google Scholar] [CrossRef]

- Wang, Y.H.; Leung, S.C. A particulate-scale investigation of cemented sand behavior. Can. Geotech. J. 2008, 45, 29–44. [Google Scholar] [CrossRef]

- Wang, Y.; Leung, S. Characterization of cemented sand by experimental and numerical investigations. J. Geotech. Geoenviron. Eng. 2008, 134, 992–1004. [Google Scholar] [CrossRef]

- Clough, G.W.; Sitar, N.; Bachus, R.; Shafii-Rad, N. Cemented sands under static loading. J. Geotech. Geoenviron. Eng. 1981, 107, 799–817. [Google Scholar]

- Clough, G.W. Influence of Cementation on Liquefaction of Sands. J. Geotech. Eng. 1989, 115, 1102–1117. [Google Scholar] [CrossRef]

- Das, B.M.; Dass, R.N. Lightly cemented sand in tension and compression. Geotech. Geol. Eng. 1995, 13, 169–177. [Google Scholar] [CrossRef]

- Jiang, M.; Zhang, F.; Thornton, C. A simple three-dimensional distinct element modeling of the mechanical behavior of bonded sands. Int. J. Numer. Anal. Methods Geomech. 2015, 39, 1791–1820. [Google Scholar] [CrossRef]

- Obermayr, M. A bonded-particle model for cemented sand. Comput. Geotech. 2013, 49, 299–313. [Google Scholar] [CrossRef]

- Jiang, M. An investigation on loose cemented granular materials via DEM analyses. Granul. Matter 2013, 15, 65–84. [Google Scholar] [CrossRef]

- Cerasi, P.; Papamichos, E.; Stenebraten, J.F. Quantitative sand-production prediction: Friction-dominated flow model. In Proceedings of the SPE Latin American and Caribbean Petroleum Engineering Conference, Rio de Janeiro, Brazil, 20–23 June 2005; Society of Petroleum Engineers: Houston, TX, USA, 2005. [Google Scholar] [CrossRef]

- Zhao, B. Comprehensive comparison of pore-scale models for multiphase flow in porous media. Proc. Natl. Acad. Sci. USA 2019, 116, 13799. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Schulz, R. Beyond Kozeny-Carman: Predicting the Permeability in Porous Media. Transp. Porous Media 2019, 130, 487–512. [Google Scholar] [CrossRef]

- Cohen, E.; Klar, A.; Yamamoto, K. Micromechanical Investigation of Stress Relaxation in Gas Hydrate-Bearing Sediments Due to Sand Production. Energies 2019, 12, 2131. [Google Scholar] [CrossRef] [Green Version]

- Perkins, T.K.; Weingarten, J.S. Stability and failure of spherical cavities in unconsolidated sand and weakly consolidated rock. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 2–5 October 1988; Society of Petroleum Engineers: Houston, TX, USA, 1988. [Google Scholar] [CrossRef]

- Papanastasiou, P.C.; Vardoulakis, I.G. Numerical treatment of progressive localization in relation to borehole stability. Int. J. Numer. Anal. Methods Geomech. 1992, 16, 389–424. [Google Scholar] [CrossRef]

- Hashemi, S.S.; Melkoumian, N.; Taheri, A. A borehole stability study by newly designed laboratory tests on thick-walled hollow cylinders. J. Rock Mech. Geotech. Eng. 2015, 7, 519–531. [Google Scholar] [CrossRef]

| Channel Width, a (m) | Channel Length, L (m) | Fluid Density, ρ (kg/m3) | Fluid Kinematic Viscosity, ν (m2/s) | Pressure Difference, ΔP (Pa) |

|---|---|---|---|---|

| 0.1 | 0.1 | 803 |

| Density of Solid Particles (kg/m3) | Inter-Particle Friction Coefficient | Normal/Shear Contact Stiffness (MN/m) | Bond Strength (N) |

|---|---|---|---|

| 3000 | 0.6 | 200 | 0, 50, 500, 5000 |

| Model Name | Inner Cavity Diameter (mm) | Initial Void Ratio | Bond Strength (N) | Uniaxial Compressive Strength, UCS (kPa) |

|---|---|---|---|---|

| UH15 | 15 | 0.20 | - | - |

| UH20 | 20 | |||

| B1H15 | 15 | 50 | 10.65 | |

| B1H20 | 20 | |||

| B2H15 | 15 | 500 | 47.29 | |

| B2H20 | 20 | |||

| B3H15 | 15 | 5000 | 87.79 | |

| B3H20 | 20 |

| Fluid Density, (kg/m3) | Kinematic Viscosity, ν (m2/s) | Lattice Spacing, h (mm) | Inlet/Outlet Pressure Difference, ΔP (kPa) | Relaxation Time Parameter, | Hydraulic Radius Multiplier |

|---|---|---|---|---|---|

| 803 | 3E-5 | 0.20 | 0–6 | 0.521 | 0.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Honari, S.; Seyedi Hosseininia, E. Particulate Modeling of Sand Production Using Coupled DEM-LBM. Energies 2021, 14, 906. https://0-doi-org.brum.beds.ac.uk/10.3390/en14040906

Honari S, Seyedi Hosseininia E. Particulate Modeling of Sand Production Using Coupled DEM-LBM. Energies. 2021; 14(4):906. https://0-doi-org.brum.beds.ac.uk/10.3390/en14040906

Chicago/Turabian StyleHonari, Siavash, and Ehsan Seyedi Hosseininia. 2021. "Particulate Modeling of Sand Production Using Coupled DEM-LBM" Energies 14, no. 4: 906. https://0-doi-org.brum.beds.ac.uk/10.3390/en14040906